Extrusion Of Plastic Define . This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. To understand the process better, it’s important to first understand the extruder and how it works. Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. The process is highly efficient.

from www.xometry.com

Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a The process is highly efficient. plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. To understand the process better, it’s important to first understand the extruder and how it works. It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form.

All About Plastic Extrusion Xometry

Extrusion Of Plastic Define Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. To understand the process better, it’s important to first understand the extruder and how it works. at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. The process is highly efficient.

From www.rainbowbelts.com

What Is The Profile Extrusion Process? Extrusion Of Plastic Define The process is highly efficient. To understand the process better, it’s important to first understand the extruder and how it works. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Extrusion Of Plastic Define.

From www.slideserve.com

PPT Plastic Manufacturing Processes PowerPoint Presentation ID4176129 Extrusion Of Plastic Define This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. plastic extrusion is a process where. Extrusion Of Plastic Define.

From cetamxps.blob.core.windows.net

What Is Plastic Profile Extrusion at Laura ONeill blog Extrusion Of Plastic Define plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a plastics extrusion is a normally high volume manufacturing process where a. Extrusion Of Plastic Define.

From www.fukuvi-usa.com

EXTRUSION 101 Fukuvi USA, manufacturer of highquality extruded Extrusion Of Plastic Define The process is highly efficient. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. To understand the process better, it’s important to first understand the extruder and how it works. Plastic. Extrusion Of Plastic Define.

From mavink.com

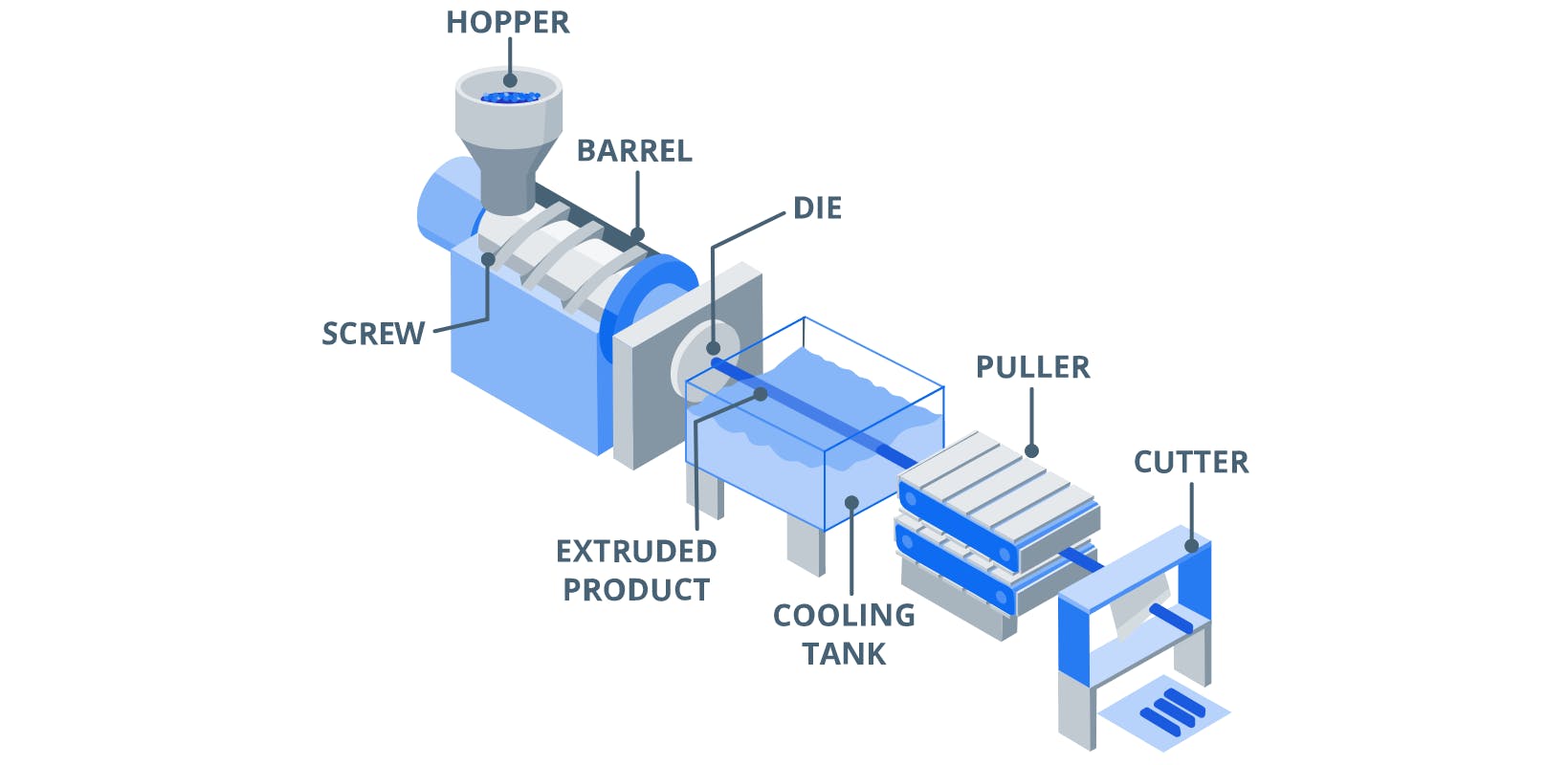

Plastic Extrusion Diagram Extrusion Of Plastic Define This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. To understand the process better,. Extrusion Of Plastic Define.

From rpmindinc.com

Plastic Extrusions Basic Principles and Processes Extrusion Of Plastic Define plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. The process is highly efficient. To understand the process. Extrusion Of Plastic Define.

From www.youtube.com

Basic Of Extrusion Process I Type of extrusion technique YouTube Extrusion Of Plastic Define To understand the process better, it’s important to first understand the extruder and how it works. Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. It’s commonly used to produce items such. Extrusion Of Plastic Define.

From www.researchgate.net

Schematic diagrams of three different extrusion forming of plastic Extrusion Of Plastic Define Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. To understand the process better, it’s important to first understand the extruder and how it works. This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. plastics extrusion is. Extrusion Of Plastic Define.

From ramextrusion.co.uk

Plastic Extrusion Process Explained Thoroughly By RAM Extrusion Extrusion Of Plastic Define This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. plastics extrusion is. Extrusion Of Plastic Define.

From mavink.com

Plastic Extrusion Process Training Extrusion Of Plastic Define To understand the process better, it’s important to first understand the extruder and how it works. It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a The process is highly efficient. Plastic extrusion is a manufacturing process in which. Extrusion Of Plastic Define.

From www.essaii.com

What is a plastic extrusion process in a stepbystep guide? Extrusion Of Plastic Define plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a To understand the process better, it’s important to first understand the extruder and how it works. It’s commonly used to produce items such as pipes, tubing,. Extrusion Of Plastic Define.

From seashorerubber.com

Plastic Extrusion Process Definitive Guide Extrusion Of Plastic Define This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. The process is highly efficient. . Extrusion Of Plastic Define.

From paulmurphyplastics.com

Ultimate Guide to The Plastic Extrusion Process • Paul Murphy Plastics Extrusion Of Plastic Define plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. at its core, plastic extrusion involves forcing molten plastic. Extrusion Of Plastic Define.

From www.ipfinc.net

Plastic Extrusion Integrated Packaging Film Inc. Extrusion Of Plastic Define Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a To understand the process better, it’s important to. Extrusion Of Plastic Define.

From www.iqsdirectory.com

Plastic Trim Types, Extrusion Methods, Applications, and Benefits Extrusion Of Plastic Define plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. at its core, plastic extrusion involves forcing molten plastic. Extrusion Of Plastic Define.

From www.kemalmfg.com

Plastic Extrusion Guide Extrusion Of Plastic Define The process is highly efficient. Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up. Extrusion Of Plastic Define.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Extrusion Of Plastic Define It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. The process is highly efficient. Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in. Extrusion Of Plastic Define.

From www.iqsdirectory.com

Plastic Rods Definition, Types, Applications, and Benefits Extrusion Of Plastic Define It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. To understand the process better, it’s important to first understand the extruder and how it works. The process is highly efficient. Plastic extrusion. Extrusion Of Plastic Define.

From www.youtube.com

EXTRUSION PROCESS EXPLANATION by 3D diagrams and types of extrusion Extrusion Of Plastic Define plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. This process starts with the feeding of plastic material. Extrusion Of Plastic Define.

From www.essaii.com

Plastic Extrusion Manufacturer Custom Plastic Extrusion Molding Extrusion Of Plastic Define at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. The process is highly efficient. This technique is. Extrusion Of Plastic Define.

From industrysurfer.com

Proceso de extrusión cómo funciona, tipos, usos, ventajas y desventajas Extrusion Of Plastic Define plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. Plastic extrusion is a manufacturing process in which raw plastic is melted and. Extrusion Of Plastic Define.

From www.xometry.com

All About Plastic Extrusion Xometry Extrusion Of Plastic Define Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. This process starts with the feeding of plastic material (pellets,. Extrusion Of Plastic Define.

From www.opusplastics.com

What is Plastic Extrusion? Process Guide Opus Plastics Extrusion Of Plastic Define plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. The process is highly efficient. Plastic extrusion is a manufacturing. Extrusion Of Plastic Define.

From protoplastics.com

How Does Plastic Extrusion Work? Extrusion Of Plastic Define plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a This technique is commonly used to produce. Extrusion Of Plastic Define.

From hitechextrusions.com

The Extrusion Process • HiTech Extrusions Extrusion Of Plastic Define plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. To understand the process better, it’s important to first understand the extruder and how it works. It’s commonly used to produce items such as pipes, tubing, window frames,. Extrusion Of Plastic Define.

From www.bausano.com

Plastic Extrusion Process, Materials, Applications & Advantages Bausano Extrusion Of Plastic Define This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. Plastic extrusion is a manufacturing process. Extrusion Of Plastic Define.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Extrusion Of Plastic Define To understand the process better, it’s important to first understand the extruder and how it works. plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a It’s commonly used to produce items such as pipes, tubing,. Extrusion Of Plastic Define.

From www.hardwareinterviews.fyi

Basics of Plastic Extrusion Consumer Hardware Guide Hardware FYI Extrusion Of Plastic Define To understand the process better, it’s important to first understand the extruder and how it works. The process is highly efficient. at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. plastics. Extrusion Of Plastic Define.

From www.slideserve.com

PPT Understanding Plastic Extrusion PowerPoint Presentation, free Extrusion Of Plastic Define Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. To understand the process better, it’s important to first understand the extruder and how it works. It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. at its core, plastic extrusion involves forcing molten plastic through. Extrusion Of Plastic Define.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Extrusion Of Plastic Define To understand the process better, it’s important to first understand the extruder and how it works. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. Plastic extrusion is a manufacturing process in which raw plastic. Extrusion Of Plastic Define.

From www.youtube.com

What is Plastic Extrusion? YouTube Extrusion Of Plastic Define plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. To understand the process better, it’s important to first understand the extruder and how it works. at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. This technique is commonly used to produce. Extrusion Of Plastic Define.

From www.inpvc.com

News Understanding Plastic Extrusion Extrusion Of Plastic Define This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and plastic films. To understand the process better, it’s important to first understand the extruder and how it works. plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired. The process is highly. Extrusion Of Plastic Define.

From seashorerubber.com

Plastic Extrusion Process Definitive Guide Extrusion Of Plastic Define To understand the process better, it’s important to first understand the extruder and how it works. The process is highly efficient. at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. This technique is commonly used to produce items such as piping, tubing, weather stripping, fencing, deck railings, window frames, and. Extrusion Of Plastic Define.

From xometry.eu

Plastic Extrusion Technology Overview Xometry Europe Extrusion Of Plastic Define plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure. Plastic extrusion is a manufacturing process in which raw plastic is melted and formed into a continuous profile. The process is highly efficient. This process starts with the. Extrusion Of Plastic Define.

From mechanicstips.blogspot.com

Plastic Extrusion MechanicsTips Extrusion Of Plastic Define It’s commonly used to produce items such as pipes, tubing, window frames, and plastic sheets. This process starts with the feeding of plastic material (pellets, granules, flakes or powders) from a at its core, plastic extrusion involves forcing molten plastic through a shaped die to create a specific form. plastic extrusion is a process where granular pieces of. Extrusion Of Plastic Define.