Shear Edge Design . Most commonly, shearing is used to cut a sheet. To facilitate the design process, the program provides a set. The design is based on loading combinations specified by the user (section 1.2). The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal.

from mungfali.com

Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. To facilitate the design process, the program provides a set. The design is based on loading combinations specified by the user (section 1.2). Most commonly, shearing is used to cut a sheet. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed.

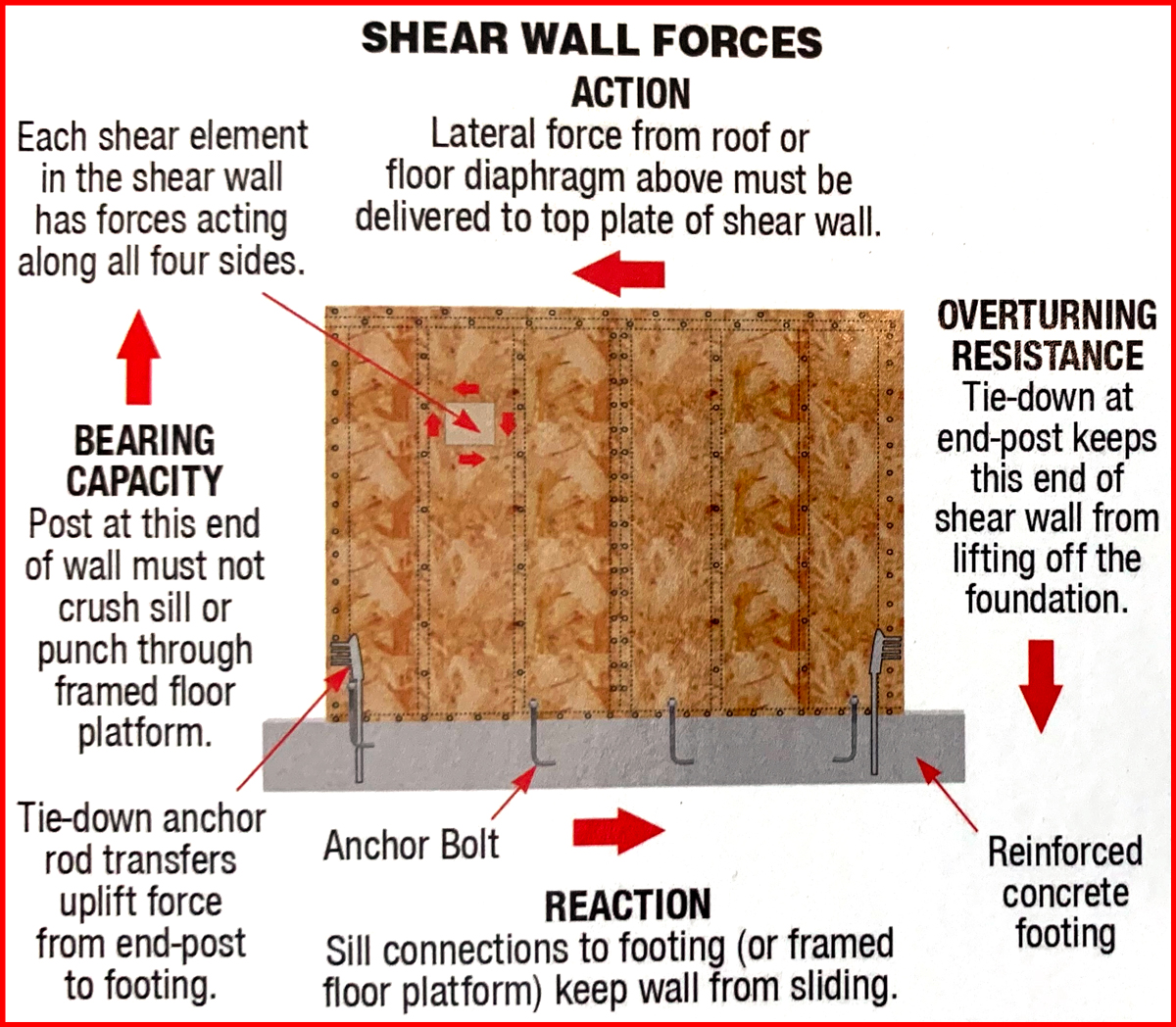

Shear Wall Design

Shear Edge Design The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. To facilitate the design process, the program provides a set. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. The design is based on loading combinations specified by the user (section 1.2). However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. Most commonly, shearing is used to cut a sheet.

From structville.com

Comparison of Shear Design to EC2 and BS 8110 Structville Shear Edge Design Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. Most commonly, shearing is used to cut a sheet. To facilitate the design process, the program provides a set. However, the. Shear Edge Design.

From skyciv.com

Shear, Axial, and Moment Steel Connections SkyCiv Engineering Shear Edge Design The design is based on loading combinations specified by the user (section 1.2). Most commonly, shearing is used to cut a sheet. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a. Shear Edge Design.

From mungfali.com

Shear Wall Design Shear Edge Design To facilitate the design process, the program provides a set. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. Most commonly, shearing is used to cut a sheet. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal.. Shear Edge Design.

From www.youtube.com

Shearing Process Die Cutting Sheet metal Metal Forming PPT Shear Edge Design However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. The objective of this work is to provide an overview of the factors that influence the quality of. Shear Edge Design.

From toolnotes.com

Sheet Metal Shearing ToolNotes Shear Edge Design The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles. Shear Edge Design.

From salondiscover.com

Shear Edge Hair Design Westlake, OH 44145 Services and Reviews Shear Edge Design The design is based on loading combinations specified by the user (section 1.2). Most commonly, shearing is used to cut a sheet. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge,. Shear Edge Design.

From www.youtube.com

Design of Steel Structure Lecture 9 Terms in rivet connections pitch Shear Edge Design The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. Most commonly, shearing is used to cut a sheet. However, the term shearing by itself refers to a specific cutting. Shear Edge Design.

From www.youtube.com

Shear Wall Design in ETABS With Boundary Element and Spandrel YouTube Shear Edge Design The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. To facilitate the design process, the program provides a set. Most commonly, shearing is used to cut a sheet. The design is based on loading combinations specified by the user (section 1.2). However, the term shearing by itself. Shear Edge Design.

From www.chegg.com

Solved Name CIET 215 Structural Steel Design Homework No. 15 Shear Edge Design However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. The objective of this work is to provide an overview of the factors that influence the quality of the. Shear Edge Design.

From www.structuralguide.com

Shear Design of Beam Structural Guide Shear Edge Design The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. The design is based on loading combinations specified by the user (section 1.2). Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. To facilitate the design process, the program. Shear Edge Design.

From www.structuralguide.com

Impressive Stuff about Shear Links Structural Guide Shear Edge Design The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece. Shear Edge Design.

From toolnotes.com

Sheet Metal Shearing ToolNotes Shear Edge Design Most commonly, shearing is used to cut a sheet. To facilitate the design process, the program provides a set. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. The design is based on loading combinations specified by the user (section 1.2). The objective of this work is to provide an overview of. Shear Edge Design.

From www.vrogue.co

Punching Shear Edge Column Concrete Structures Euroco vrogue.co Shear Edge Design Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. To facilitate the design process, the program provides a set. Most commonly, shearing is used to cut a sheet. The design is based on loading combinations specified by the user (section 1.2). However, the term shearing by itself refers to a specific cutting. Shear Edge Design.

From www.hpdconsult.com

What is a Shear Wall? Types of Shear Wall Designs Importance of Shear Shear Edge Design The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. However, the term. Shear Edge Design.

From www.slideshare.net

Shearing Shear Edge Design Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. The design is based on loading combinations specified by the user (section 1.2). However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. Edge quality varies based on parameters. Shear Edge Design.

From www.researchgate.net

(PDF) Design of Shear Tab Connections for Gravity and Seismic Loads Shear Edge Design Most commonly, shearing is used to cut a sheet. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. The design is based on loading combinations specified by the user (section 1.2). The objective of. Shear Edge Design.

From civilrack.com

Shear Wall Types and Design Techniques for Shear Wall Civil Rack Shear Edge Design To facilitate the design process, the program provides a set. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. Most commonly, shearing is used to cut a sheet. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements.. Shear Edge Design.

From www.researchgate.net

Shear edge test with clamped specimen (see online version for colours Shear Edge Design The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. The design is based on loading combinations specified by the user (section 1.2). To facilitate the design process, the program provides a set. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of. Shear Edge Design.

From studylib.net

Perforated Shearwall Design Jeffrey Stone, Ph.D., Philip Line, P.E., Shear Edge Design Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. The design is based on loading combinations specified by the user (section 1.2). To facilitate the design process, the program provides a set. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate. Shear Edge Design.

From toolnotes.com

Sheet Metal Shearing ToolNotes Shear Edge Design Most commonly, shearing is used to cut a sheet. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. To facilitate the design process, the program provides a. Shear Edge Design.

From www.youtube.com

Shear Design Example Reinforced Concrete Beams using ACI 31819 YouTube Shear Edge Design Most commonly, shearing is used to cut a sheet. The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. Shear is the term assigned to forces that act perpendicular to. Shear Edge Design.

From www.jlconline.com

Shear Walls, The Basics JLC Online Shear Edge Design To facilitate the design process, the program provides a set. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. Most commonly, shearing is used to cut a sheet. The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. Edge quality. Shear Edge Design.

From www.structuralguide.com

Impressive Stuff about Shear Links Structural Guide Shear Edge Design However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. To facilitate the design process, the program provides a set. Edge quality varies based. Shear Edge Design.

From steeltubeinstitute.org

Deep Dive into HSS Shear and Moment Connection Examples Steel Tube Shear Edge Design However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. To facilitate the design process, the program provides a set. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. Edge quality varies based on parameters like cutting clearances,. Shear Edge Design.

From www.youtube.com

Design of structural steel shear elements Understanding code Shear Edge Design To facilitate the design process, the program provides a set. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. Most commonly, shearing is used to cut a. Shear Edge Design.

From www.youtube.com

Prokon/Punching shear design in flat slab at edge column YouTube Shear Edge Design Most commonly, shearing is used to cut a sheet. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. The design is based on loading combinations specified by the user (section 1.2). Shear is the term assigned to forces that act perpendicular to the longitudinal axis. Shear Edge Design.

From www.yelp.com

Shear Edge Hair Design Hair Salons 24369 Lorain Rd, North Olmsted Shear Edge Design Most commonly, shearing is used to cut a sheet. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. To facilitate the design process, the program provides a set. The design is based on loading combinations specified by the user (section 1.2). However, the term shearing by itself refers to a specific cutting. Shear Edge Design.

From www.woodsolutions.com.au

Shear walls WoodSolutions Shear Edge Design The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. Most commonly, shearing is used to cut a sheet. The design is based on loading combinations specified by the user (section 1.2). Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural. Shear Edge Design.

From civildigital.com

Punching Shear How to design against Punching Shear Forces Shear Edge Design Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. The. Shear Edge Design.

From dokumen.tips

(PDF) Design Guide Reid NZ Home · urc = design ultimate concrete Shear Edge Design To facilitate the design process, the program provides a set. Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. The design is based on loading combinations specified by the user (section 1.2). The objective of this work is to provide an overview of the factors that influence the quality of the. Shear Edge Design.

From www.pinterest.com

Shear Wall Detail Student portfolios, How to plan, Concept Shear Edge Design Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. To facilitate the design process, the program provides a set. The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. Most commonly, shearing is used to cut a sheet. The. Shear Edge Design.

From www.excelcalcs.com

Simple Shear Connection Design AISC Shear Edge Design However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. Most commonly, shearing is used to cut a sheet. The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. To facilitate the design process,. Shear Edge Design.

From dilandroandrews.com

Understanding Shear Walls Design, Construction, and Importance Shear Edge Design Edge quality varies based on parameters like cutting clearances, shear angles, and rake angles on mechanical shearing operations. The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. To facilitate the design process, the program provides a set. Shear is the term assigned to forces that act perpendicular. Shear Edge Design.

From jsmithmoore.com

Cranked beam design example Shear Edge Design Shear is the term assigned to forces that act perpendicular to the longitudinal axis of structural elements. To facilitate the design process, the program provides a set. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. Most commonly, shearing is used to cut a sheet.. Shear Edge Design.

From www.eng-tips.com

Surface Preparation for LongSlotted Shear Connections Subjected to Shear Edge Design The design is based on loading combinations specified by the user (section 1.2). The objective of this work is to provide an overview of the factors that influence the quality of the sheared edge, speed. However, the term shearing by itself refers to a specific cutting process that produces straight line cuts to separate a piece of sheet metal. To. Shear Edge Design.