Belt Vibration Analysis . Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. When analyzing vibration we look at two. Simply enter both driver and driven pulley diameters. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Models available for analyzing the free and forced vibrations of the belt are discussed. Belt resonant frequency can be checked by placing transducer on bearing. The belt passing frequency is always less than the speed of either pulley/sheave. The effects of initial tension,.

from www.researchgate.net

Models available for analyzing the free and forced vibrations of the belt are discussed. When analyzing vibration we look at two. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. Belt resonant frequency can be checked by placing transducer on bearing. The effects of initial tension,. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. Simply enter both driver and driven pulley diameters. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. The belt passing frequency is always less than the speed of either pulley/sheave.

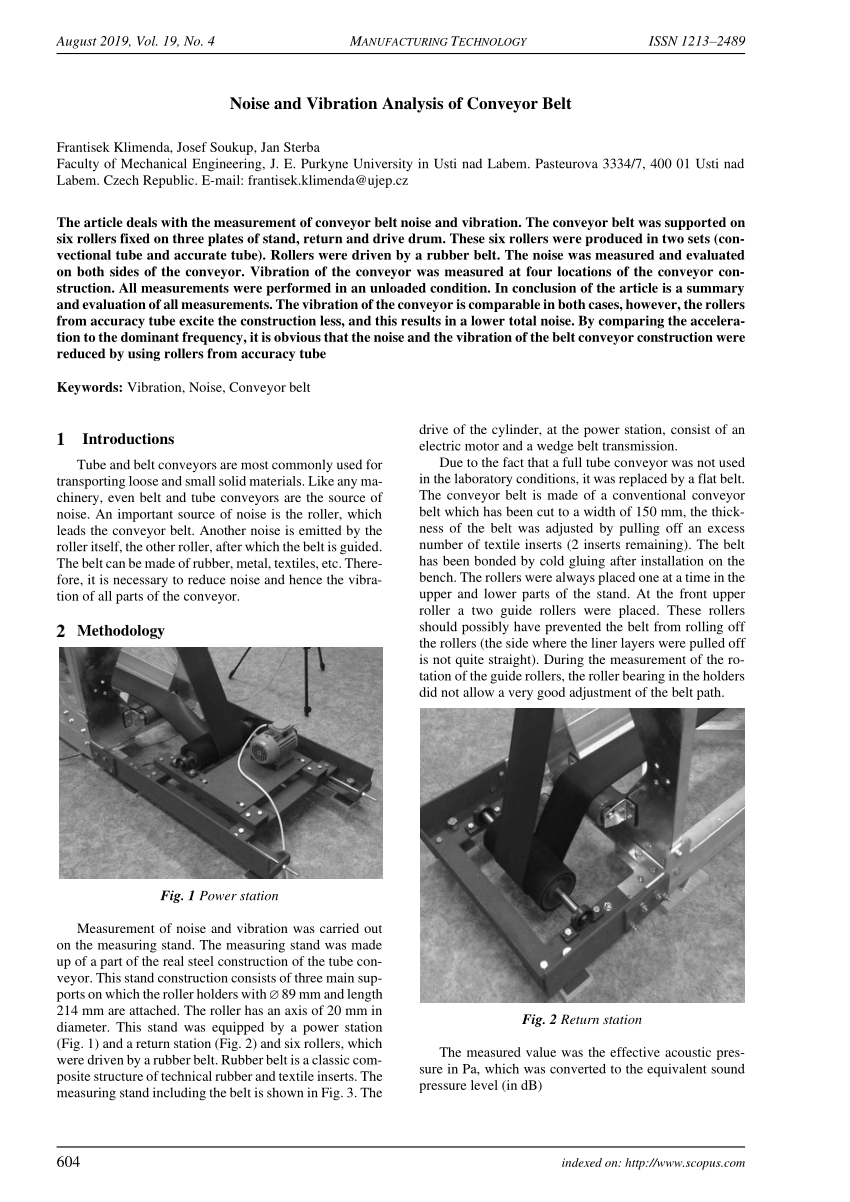

(PDF) Noise and Vibration Analysis of Conveyor Belt

Belt Vibration Analysis The effects of initial tension,. When analyzing vibration we look at two. Simply enter both driver and driven pulley diameters. Belt resonant frequency can be checked by placing transducer on bearing. The belt passing frequency is always less than the speed of either pulley/sheave. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. The effects of initial tension,. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Models available for analyzing the free and forced vibrations of the belt are discussed.

From power-mi.com

Vibration Analysis of Centrifugal Fans PowerMI Belt Vibration Analysis Models available for analyzing the free and forced vibrations of the belt are discussed. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. The effects of initial tension,. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. The belt passing frequency is. Belt Vibration Analysis.

From ritec.us

RITEC Belt Vibration Frequency Calculator Belt Vibration Analysis Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. The effects of initial tension,. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. When analyzing vibration we look at two. Diagnosing an impending failure in rotating machinery by spectrum analysis is the. Belt Vibration Analysis.

From www.slideshare.net

Vibration Monitoring Belt Vibration Analysis Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Belt resonant frequency can be checked by placing transducer on bearing. When analyzing vibration we look at two. The effects of initial tension,. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting. Belt Vibration Analysis.

From power-mi.com

Typical bearing defects and spectral identification PowerMI Belt Vibration Analysis Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. When analyzing vibration we look at two. Belt resonant frequency can be checked by placing transducer on bearing. Models available. Belt Vibration Analysis.

From www.researchgate.net

Vibration trend analysis diagram. (a) xdirection at bearing A. (b Belt Vibration Analysis The effects of initial tension,. Belt resonant frequency can be checked by placing transducer on bearing. Simply enter both driver and driven pulley diameters. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. When analyzing vibration we look at two. Models available for analyzing the free and forced vibrations of the belt are. Belt Vibration Analysis.

From new.abb.com

ABB launches new condition monitoring digital service, tailormade for Belt Vibration Analysis We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. The belt passing frequency is always less than the speed of either pulley/sheave. Models available for analyzing the free and forced vibrations of the belt are discussed. Simply enter both driver and driven pulley diameters. The effects of initial tension,. Belt resonant frequency can. Belt Vibration Analysis.

From www.etssolution-asia.com

Vibration Analysis on a conveyor unit Belt Vibration Analysis Models available for analyzing the free and forced vibrations of the belt are discussed. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. When analyzing vibration we look at two. Simply enter both driver and driven pulley diameters. Vibration analysis can often pinpoint a failing element of a rotating. Belt Vibration Analysis.

From fr.mathworks.com

Vibration Analysis of Rotating Machinery MATLAB & Simulink Belt Vibration Analysis Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Belt resonant frequency can be checked by placing transducer on bearing. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. Models available for analyzing the free and forced vibrations. Belt Vibration Analysis.

From www.machineryanalysis.org

bad belt? Vibration Analysis & Machinery Diagnostics Forum Belt Vibration Analysis Models available for analyzing the free and forced vibrations of the belt are discussed. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. The belt passing frequency is always less than the speed of either pulley/sheave. The effects of initial tension,. Simply enter both driver and driven pulley diameters.. Belt Vibration Analysis.

From tishitu.net

Vibration Analysis of Machine by (MEMS) Micro Electro Mechanical Belt Vibration Analysis Models available for analyzing the free and forced vibrations of the belt are discussed. Simply enter both driver and driven pulley diameters. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. Belt resonant frequency can be checked by placing transducer on bearing. When analyzing vibration we look at two. The effects of initial. Belt Vibration Analysis.

From power-mi.com

Typical bearing defects and spectral identification PowerMI Belt Vibration Analysis Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. When analyzing vibration we look at two. Belt resonant frequency can be checked by placing transducer on bearing. Models available for analyzing the free and forced vibrations of the belt are discussed. The belt passing frequency is always less than. Belt Vibration Analysis.

From www.youtube.com

Vibration Analysis Practical Calculating Belt Fundamental Frequency to Belt Vibration Analysis Models available for analyzing the free and forced vibrations of the belt are discussed. The belt passing frequency is always less than the speed of either pulley/sheave. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Belt resonant frequency can be checked by placing transducer on bearing. Simply enter. Belt Vibration Analysis.

From rms-reliability.com

Vibration Analysis Pocket Guide RMS Ltd Belt Vibration Analysis Models available for analyzing the free and forced vibrations of the belt are discussed. The belt passing frequency is always less than the speed of either pulley/sheave. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. The effects of initial tension,. When analyzing vibration we look at two. Simply. Belt Vibration Analysis.

From www.researchgate.net

Belt vibrations during one revolution of crankshaft (engine revs = 4500 Belt Vibration Analysis We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. The effects of initial tension,. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information. Belt Vibration Analysis.

From www.youtube.com

BELTS & SHEAVES VIBRATION ANALYSIS TRAINING YouTube Belt Vibration Analysis The belt passing frequency is always less than the speed of either pulley/sheave. Models available for analyzing the free and forced vibrations of the belt are discussed. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. Simply enter both driver and driven pulley diameters. The effects of initial tension,.. Belt Vibration Analysis.

From www.slideshare.net

Vibration Monitoring Belt Vibration Analysis We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. The belt passing frequency is always less than the speed of either pulley/sheave. When analyzing vibration we look at two. The effects of initial tension,. Models available for analyzing the free and forced vibrations of the belt are discussed. Diagnosing an impending failure in. Belt Vibration Analysis.

From www.youtube.com

Torsional Vibration Dampers & Belt Analysis Hyperelastics YouTube Belt Vibration Analysis When analyzing vibration we look at two. Simply enter both driver and driven pulley diameters. Models available for analyzing the free and forced vibrations of the belt are discussed. The effects of initial tension,. The belt passing frequency is always less than the speed of either pulley/sheave. Vibration analysis can often pinpoint a failing element of a rotating machine in. Belt Vibration Analysis.

From www.youtube.com

Belt & Pulley Vibration YouTube Belt Vibration Analysis The belt passing frequency is always less than the speed of either pulley/sheave. The effects of initial tension,. When analyzing vibration we look at two. Belt resonant frequency can be checked by placing transducer on bearing. Simply enter both driver and driven pulley diameters. Models available for analyzing the free and forced vibrations of the belt are discussed. Diagnosing an. Belt Vibration Analysis.

From ncd.io

The Purpose of Vibration Analysis Key Concepts and Types of Sensors Belt Vibration Analysis The effects of initial tension,. The belt passing frequency is always less than the speed of either pulley/sheave. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Models available for analyzing the free and forced vibrations of the belt are discussed. Belt resonant frequency can be checked by placing. Belt Vibration Analysis.

From www.mdpi.com

Applied Sciences Free FullText Investigation into the Modulation Belt Vibration Analysis Simply enter both driver and driven pulley diameters. Belt resonant frequency can be checked by placing transducer on bearing. When analyzing vibration we look at two. Models available for analyzing the free and forced vibrations of the belt are discussed. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly.. Belt Vibration Analysis.

From www.researchgate.net

Vibration measurement point [4]. Download Scientific Diagram Belt Vibration Analysis The belt passing frequency is always less than the speed of either pulley/sheave. The effects of initial tension,. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. Belt resonant frequency can be checked by placing transducer on bearing. When analyzing vibration we look at two. Simply enter both driver. Belt Vibration Analysis.

From kienitvc.ac.ke

The Ultimate Guide to Vibration Analysis kienitvc.ac.ke Belt Vibration Analysis Belt resonant frequency can be checked by placing transducer on bearing. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. The effects of initial tension,. Simply enter both driver and driven pulley diameters.. Belt Vibration Analysis.

From www.vibescorp.ca

Learn About Vibration, Volume 1 Basic Understanding of Machinery Belt Vibration Analysis We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. Simply enter both driver and driven pulley diameters. When analyzing vibration we look at two. Belt resonant frequency can be checked by placing transducer on bearing. The effects of initial tension,. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process. Belt Vibration Analysis.

From machinerylubricationindia.com

Oil Analysis or Vibration Analysis? Belt Vibration Analysis We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. When analyzing vibration we look at two. Models available for analyzing the free and forced vibrations of the belt are discussed. Belt resonant frequency. Belt Vibration Analysis.

From www.researchgate.net

(PDF) Dignosis of PulleyBelt System Faults Using Vibration Analysis Belt Vibration Analysis Simply enter both driver and driven pulley diameters. Belt resonant frequency can be checked by placing transducer on bearing. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. The effects of initial tension,.. Belt Vibration Analysis.

From www.academia.edu

(PDF) Vibration analysis applied to conveyor belt IRJET Journal Belt Vibration Analysis We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. When analyzing vibration we look at two. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Models available for analyzing the free and forced vibrations of the belt are discussed. Diagnosing an impending. Belt Vibration Analysis.

From power-mi.com

Misalignment PowerMI Belt Vibration Analysis Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. Simply enter both driver and driven pulley diameters. Models available for analyzing the free and forced vibrations of the belt are discussed. The belt. Belt Vibration Analysis.

From www.variusinc.com

Vibration Analysis — VARIUS INC Belt Vibration Analysis Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Belt resonant frequency can be checked by placing transducer on bearing. The effects of initial tension,. Models available for analyzing the free and forced vibrations of the belt are discussed. The belt passing frequency is always less than the speed. Belt Vibration Analysis.

From www.etssolution-asia.com

Vibration Analysis on a conveyor unit Belt Vibration Analysis We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. The effects of initial tension,. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. When analyzing vibration we look at two. Simply enter both driver and driven pulley diameters. Diagnosing an impending failure. Belt Vibration Analysis.

From www.youtube.com

Motion Amplification Vibration Analysis YouTube Belt Vibration Analysis The belt passing frequency is always less than the speed of either pulley/sheave. Simply enter both driver and driven pulley diameters. Models available for analyzing the free and forced vibrations of the belt are discussed. Belt resonant frequency can be checked by placing transducer on bearing. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of. Belt Vibration Analysis.

From tractian.com

Vibration Analysis The Complete Guide [2022] TRACTIAN Belt Vibration Analysis When analyzing vibration we look at two. Simply enter both driver and driven pulley diameters. Belt resonant frequency can be checked by placing transducer on bearing. Models available for analyzing the free and forced vibrations of the belt are discussed. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from.. Belt Vibration Analysis.

From www.mdpi.com

Energies Free FullText Models of Transverse Vibration in Conveyor Belt Vibration Analysis We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. Models available for analyzing the free and forced vibrations of the belt are discussed. Simply enter both driver and driven pulley diameters. The belt. Belt Vibration Analysis.

From www.mdpi.com

Energies Free FullText Models of Transverse Vibration in Conveyor Belt Vibration Analysis We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. Belt resonant frequency can be checked by placing transducer on bearing. Simply enter both driver and driven pulley diameters. When analyzing vibration we look at two. Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital. Belt Vibration Analysis.

From www.metrixvibration.com

Fundamentals of Vibration Analysis A Comprehensive Overview Belt Vibration Analysis Diagnosing an impending failure in rotating machinery by spectrum analysis is the process of measuring and extracting vital information from. Simply enter both driver and driven pulley diameters. Belt resonant frequency can be checked by placing transducer on bearing. We therefore analyze the “type” of vibration to identify its cause and take appropriate repair action. When analyzing vibration we look. Belt Vibration Analysis.

From www.researchgate.net

(PDF) Noise and Vibration Analysis of Conveyor Belt Belt Vibration Analysis Simply enter both driver and driven pulley diameters. The belt passing frequency is always less than the speed of either pulley/sheave. Vibration analysis can often pinpoint a failing element of a rotating machine in time to avoid catastrophic failure and costly. Models available for analyzing the free and forced vibrations of the belt are discussed. Diagnosing an impending failure in. Belt Vibration Analysis.