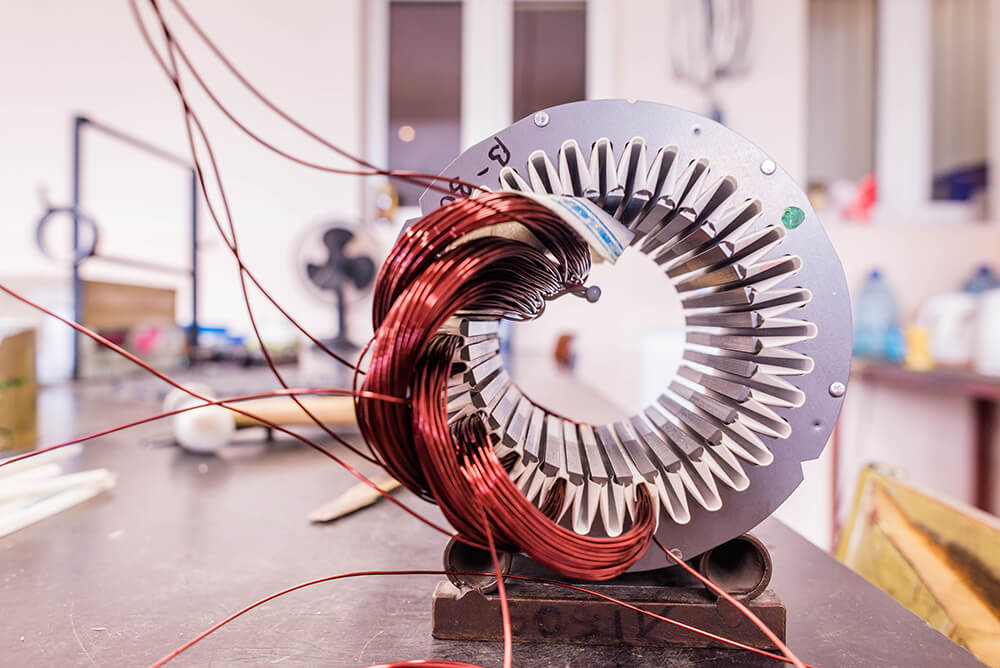

Magnet Wire Process . The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. Enamelling process for magnet wire. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Reduces the cost, increases the reliability and enables new applications. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. All magnet wires are magnet on special enamelling machines which are developed and produced by. Typically, these insulated electrical conductors are made of copper or aluminum.

from mwswire.com

The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Enamelling process for magnet wire. Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. All magnet wires are magnet on special enamelling machines which are developed and produced by. Reduces the cost, increases the reliability and enables new applications. Typically, these insulated electrical conductors are made of copper or aluminum.

Coil Winding Wire MWS Wire

Magnet Wire Process Typically, these insulated electrical conductors are made of copper or aluminum. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Typically, these insulated electrical conductors are made of copper or aluminum. Reduces the cost, increases the reliability and enables new applications. Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Enamelling process for magnet wire. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. All magnet wires are magnet on special enamelling machines which are developed and produced by.

From sciencing.com

How to Increase the Strength of an Sciencing Magnet Wire Process Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. Enamelling process for magnet wire. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Typically, these insulated electrical conductors are made of copper or aluminum. All magnet wires are magnet. Magnet Wire Process.

From physics-12th.blogspot.com

Physics 12 Field and Force Magnet Wire Process Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Enamelling process for magnet wire. Typically, these insulated electrical conductors are made of copper or aluminum. Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. Reduces the cost, increases the reliability and enables new applications. All magnet. Magnet Wire Process.

From www.linstitute.net

AQA A Level Physics复习笔记7.8.6 Required Practical Investigating Magnet Wire Process Reduces the cost, increases the reliability and enables new applications. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. The state of the. Magnet Wire Process.

From www.hsmagnets.com

Manufacturing Process By HSMAG Magnet Wire Process Magnet wire is used to create coils that, when energized, produce an electromagnetic field. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Enamelling process for magnet wire. Magnet wires are broadly. Magnet Wire Process.

From cestriom.com

basics Cestriom GmbH Magnet Wire Process Typically, these insulated electrical conductors are made of copper or aluminum. All magnet wires are magnet on special enamelling machines which are developed and produced by. Reduces the cost, increases the reliability and enables new applications. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Magnet wires are broadly divided into enamelled wire (coating insulation),. Magnet Wire Process.

From www.scienceabc.com

How Can A Be Quickly? » ScienceABC Magnet Wire Process Reduces the cost, increases the reliability and enables new applications. Enamelling process for magnet wire. All magnet wires are magnet on special enamelling machines which are developed and produced by. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Typically, these insulated electrical conductors are made of copper or aluminum. Magnet wires are broadly. Magnet Wire Process.

From www.paramhimalaya.com

field patterns produced by currentcarrying conductors Magnet Wire Process Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. Reduces the cost, increases the reliability and enables new applications. Typically, these insulated electrical conductors are made of copper or aluminum. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Enamelling process for magnet wire. The state. Magnet Wire Process.

From www.windingwire.net

Wire, Wire Stripping Magnet Wire Process The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Reduces the cost, increases the reliability and enables new applications. All magnet wires are magnet on special enamelling machines which are developed and produced by. Typically, these insulated electrical conductors are made of copper or aluminum. Please contact. Magnet Wire Process.

From www.windingwire.net

Broad Range of LP Wire Magnet Wire Process All magnet wires are magnet on special enamelling machines which are developed and produced by. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Reduces the cost, increases the reliability and enables. Magnet Wire Process.

From www.lpmagnetwire.com

Wires Manufacturing wire,aluminum Magnet Wire Process The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. All magnet wires are magnet on special enamelling machines which are developed and produced by. Reduces the cost, increases the reliability and enables new. Magnet Wire Process.

From www.youtube.com

TEMCo Wire Soldering Process YouTube Magnet Wire Process Reduces the cost, increases the reliability and enables new applications. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire. Magnet Wire Process.

From mwswire.com

Coil Winding Wire MWS Wire Magnet Wire Process Reduces the cost, increases the reliability and enables new applications. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. All magnet wires are magnet on special enamelling machines which are developed and produced by. Typically, these insulated electrical conductors are made of copper or aluminum. Magnet wire. Magnet Wire Process.

From www.flinnsci.com

Wire Flinn Scientific Magnet Wire Process Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Enamelling process for magnet wire. Typically, these insulated electrical conductors are made of copper or aluminum. All magnet wires are magnet on special enamelling machines which are developed and produced by. The state of the art of magnet wire manufacturing process is the application of liquid. Magnet Wire Process.

From www.lpmagnetwire.com

Wires Manufacturing wire,aluminum Magnet Wire Process The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. All magnet wires are magnet on special enamelling machines which are developed and produced by. Typically, these insulated electrical conductors are made of copper or aluminum. Enamelling process for magnet wire. Please contact nema for information regarding the. Magnet Wire Process.

From www.youtube.com

Manufacturing PROCESS YouTube Magnet Wire Process Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. All magnet wires are magnet on special enamelling machines which are developed and produced by. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Enamelling process for magnet wire. Please. Magnet Wire Process.

From www.lpenamelwire.com

Production of Enameled Wire Wire Magnet Wire Process Please contact nema for information regarding the specific changes to the nema mw 1000 publication. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. Magnet wire is used to create. Magnet Wire Process.

From www.instructables.com

Wire 5 Steps Instructables Magnet Wire Process All magnet wires are magnet on special enamelling machines which are developed and produced by. Typically, these insulated electrical conductors are made of copper or aluminum. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. The state of. Magnet Wire Process.

From mmerevise.co.uk

Flux Density Questions and Revision MME Magnet Wire Process Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Typically, these insulated electrical conductors are made of copper or aluminum. Reduces the cost, increases the reliability and enables new applications. Enamelling process for magnet wire. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn. Magnet Wire Process.

From www.youtube.com

Physics Understanding induction (EMI) and Magnet Wire Process Typically, these insulated electrical conductors are made of copper or aluminum. Enamelling process for magnet wire. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. Reduces the cost, increases the. Magnet Wire Process.

From www.thesciencehive.co.uk

Induction (GCSE) — the science sauce Magnet Wire Process All magnet wires are magnet on special enamelling machines which are developed and produced by. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Please contact nema for information regarding the specific changes. Magnet Wire Process.

From www.animalia-life.club

Field Of A Wire Magnet Wire Process Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. All magnet wires are magnet on special enamelling machines which are developed and produced by. Typically, these insulated electrical conductors are made of copper or aluminum. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Magnet wire. Magnet Wire Process.

From www.wisegeek.com

What is Wire? (with pictures) Magnet Wire Process Typically, these insulated electrical conductors are made of copper or aluminum. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. All magnet wires are magnet on special enamelling machines which are developed and produced by. Please contact nema for information regarding the specific changes to the nema. Magnet Wire Process.

From www.youtube.com

Field of a Wire YouTube Magnet Wire Process Typically, these insulated electrical conductors are made of copper or aluminum. Enamelling process for magnet wire. All magnet wires are magnet on special enamelling machines which are developed and produced by. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Reduces the cost, increases the reliability and enables new applications. The state of the art. Magnet Wire Process.

From www.science-sparks.com

How to make an Magnet Wire Process Typically, these insulated electrical conductors are made of copper or aluminum. All magnet wires are magnet on special enamelling machines which are developed and produced by. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Enamelling process for magnet wire. Reduces the cost, increases the reliability and. Magnet Wire Process.

From www.igcsephysics.com

IGCSE Physics Unit 4 Electricity and Magnet Wire Process Enamelling process for magnet wire. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Typically, these insulated electrical conductors are made of copper or aluminum. All magnet wires are magnet on special enamelling machines which are developed and produced by. Please contact nema for information regarding the specific changes to the nema mw 1000 publication.. Magnet Wire Process.

From www.livescience.com

What is Facts about fields and force Magnet Wire Process Enamelling process for magnet wire. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. Typically, these. Magnet Wire Process.

From www.slideserve.com

PPT Wire PowerPoint Presentation, free download ID7818460 Magnet Wire Process Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. All magnet wires are magnet on special enamelling machines which are developed and produced by. Reduces the cost, increases the reliability and enables new applications. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on. Magnet Wire Process.

From physics-12th.blogspot.com

Physics 12 Field and Force Magnet Wire Process Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Reduces the cost, increases the reliability and enables new applications. Enamelling process for magnet wire. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. The state of the art of magnet wire manufacturing process is the application of liquid enamel. Magnet Wire Process.

From www.youtube.com

FORCE ON A CURRENT CARRYING WIRE PLACED IN A FIELD YouTube Magnet Wire Process Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially. Reduces the cost, increases the reliability and enables new applications. All magnet wires are magnet on special enamelling machines which are developed and produced by. Typically, these insulated electrical conductors are made of copper or aluminum. The state of the art of magnet. Magnet Wire Process.

From mammothmemory.net

field of a wire between two opposing poles Magnet Wire Process Reduces the cost, increases the reliability and enables new applications. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Typically, these insulated electrical conductors are made of copper or aluminum. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Please contact nema. Magnet Wire Process.

From jtcopper.com

Motor Wire For EV, Wire Supplier JINTIAN COPPER Magnet Wire Process Typically, these insulated electrical conductors are made of copper or aluminum. Enamelling process for magnet wire. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. All magnet wires are magnet on special enamelling machines which are developed and produced by. Reduces the cost, increases the reliability and enables new applications. Magnet wires are broadly. Magnet Wire Process.

From www.sciencebuddies.org

The Strength of an Magnet Wire Process Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Reduces the cost, increases the reliability and enables new applications. Typically, these insulated electrical conductors are made of copper or aluminum. All magnet wires are magnet on special enamelling machines which are developed and produced by. The state of the art of magnet wire manufacturing. Magnet Wire Process.

From philschatz.com

and · Physics Magnet Wire Process Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. The state of the art of magnet wire manufacturing process is the application of liquid enamel (varnish) on a drawn conductive material. Reduces the cost, increases the reliability and enables new. Magnet Wire Process.

From www.youtube.com

How to Get FREE Wire (Enameled Copper Wire) // Microwave Motor Magnet Wire Process Reduces the cost, increases the reliability and enables new applications. Enamelling process for magnet wire. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Typically, these insulated electrical conductors are made of copper or aluminum. Magnet wires are broadly divided. Magnet Wire Process.

From itecnotes.com

How to Make an Valuable Tech Notes Magnet Wire Process Please contact nema for information regarding the specific changes to the nema mw 1000 publication. Magnet wire is used to create coils that, when energized, produce an electromagnetic field. Typically, these insulated electrical conductors are made of copper or aluminum. Enamelling process for magnet wire. All magnet wires are magnet on special enamelling machines which are developed and produced by.. Magnet Wire Process.