Types Of Bead Blasting . Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. Machinists generally use two types of beads for a bead blast surface finish. It uses smoother beads, often made of glass, ceramic or metal that can. Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. They are glass beads and steel beads. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Bead blasting is different from sandblasting because it may be too rough on some materials; Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture.

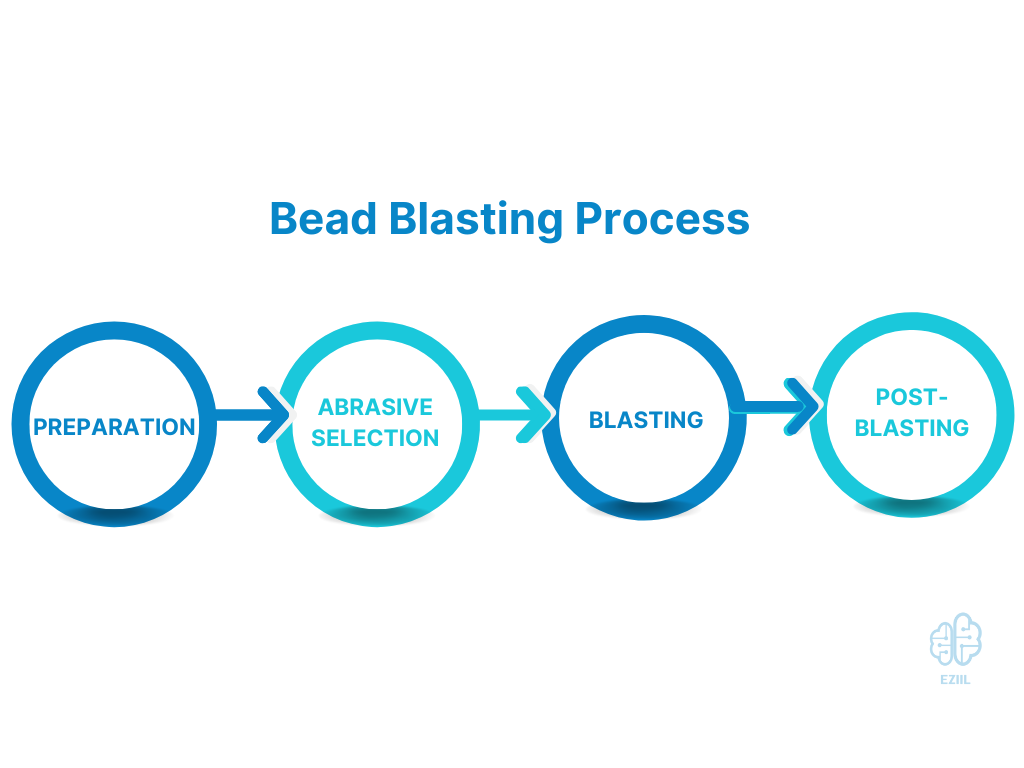

from eziil.com

It uses smoother beads, often made of glass, ceramic or metal that can. Machinists generally use two types of beads for a bead blast surface finish. Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. They are glass beads and steel beads. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Bead blasting is different from sandblasting because it may be too rough on some materials;

Bead Blast Finish How It Works & Sandblasting Comparison

Types Of Bead Blasting Machinists generally use two types of beads for a bead blast surface finish. Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. It uses smoother beads, often made of glass, ceramic or metal that can. Machinists generally use two types of beads for a bead blast surface finish. Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. They are glass beads and steel beads. Bead blasting is different from sandblasting because it may be too rough on some materials; Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to.

From www.youtube.com

How Does Bead Blasting Work? YouTube Types Of Bead Blasting Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Machinists generally use two types of beads for a bead blast surface finish. They are glass beads and steel beads. Bead blasting is different from sandblasting because it may be too rough on some materials; It uses smoother beads, often made. Types Of Bead Blasting.

From www.fictiv.com

Bead Blasting Is it the Right Finish for Your Part? Fictiv Types Of Bead Blasting It uses smoother beads, often made of glass, ceramic or metal that can. Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. Bead blasting is different from sandblasting because it may be too rough on some materials; Bead blasting is a surface preparation technique that uses a stream of small,. Types Of Bead Blasting.

From www.youtube.com

Bead Blasting Tips for Long Bead Life and Best Finish YouTube Types Of Bead Blasting Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. Machinists generally use two types of beads for a bead blast surface finish. It uses smoother beads, often made of glass, ceramic or metal that can. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads. Types Of Bead Blasting.

From www.youtube.com

Everything About Bead Blasting YouTube Types Of Bead Blasting They are glass beads and steel beads. Machinists generally use two types of beads for a bead blast surface finish. Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. Bead blasting is different from sandblasting because it may be too rough on some materials; Bead blasting is a surface finishing. Types Of Bead Blasting.

From www.youtube.com

Bead Blasting Process Overview (Why Bead Blasting Your Metal Parts Types Of Bead Blasting Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. They are glass beads and steel beads. Machinists generally use two types of beads for a bead blast surface finish. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity. Types Of Bead Blasting.

From raysun.ae

Bead Blasting Raysun Types Of Bead Blasting Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Machinists employ a range of bead blasting media types to achieve specific surface finishes,. Types Of Bead Blasting.

From hcsplating.com

Abrasive Blasting Media Guide Which Blasting Media Is Best? Types Of Bead Blasting It uses smoother beads, often made of glass, ceramic or metal that can. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Bead. Types Of Bead Blasting.

From www.iqsdirectory.com

Sandblasting Machinery What Is It? How Does It Work? Types Types Of Bead Blasting Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Bead blasting is different from sandblasting because it may be too rough on some materials; Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. Machinists employ a range of. Types Of Bead Blasting.

From eziil.com

Bead Blast Finish How It Works & Sandblasting Comparison Types Of Bead Blasting Bead blasting is different from sandblasting because it may be too rough on some materials; Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar. Types Of Bead Blasting.

From at-machining.com

Bead Blasting Finish A Complete OverviewAT Machining Ltd Types Of Bead Blasting Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. They are glass beads and steel beads. It uses smoother beads, often. Types Of Bead Blasting.

From at-machining.com

Bead Blasting Finish A Complete OverviewAT Machining Ltd Types Of Bead Blasting Bead blasting is different from sandblasting because it may be too rough on some materials; Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to. Types Of Bead Blasting.

From www.fastradius.com

Is Bead Blasting The Right Finish For Your Part? Fast Radius Types Of Bead Blasting Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. They are glass beads and steel beads. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads. Types Of Bead Blasting.

From enviro-tech-coatings.com

The Difference Between Bead Blasting and Sandblasting EnviroTech Types Of Bead Blasting Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. It uses smoother beads, often made of glass, ceramic or metal that can. Machinists. Types Of Bead Blasting.

From cncmass.com

About Bead Blasting Everything You Need to Know CNC Mass Types Of Bead Blasting They are glass beads and steel beads. Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. Machinists generally use two types of beads for a bead blast surface finish. Bead blasting is different from sandblasting because it may be too rough on some materials; Bead blasting is a. Types Of Bead Blasting.

From proleantech.com

Beadblasting Vs Sandblasting A Detailed Comparision Guide Types Of Bead Blasting Bead blasting is different from sandblasting because it may be too rough on some materials; Machinists generally use two types of beads for a bead blast surface finish. Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. It uses smoother beads, often made of glass, ceramic or metal. Types Of Bead Blasting.

From www.linkedin.com

Bead Blasting What, How and Why? Types Of Bead Blasting It uses smoother beads, often made of glass, ceramic or metal that can. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Machinists generally use two types of beads for a bead blast surface finish. Bead blasting is different from sandblasting because it may be too rough on some materials;. Types Of Bead Blasting.

From exombatdn.blob.core.windows.net

What Is Bead Blasting at Robin Mercer blog Types Of Bead Blasting Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by. Types Of Bead Blasting.

From hlhrapid.com

Sandblasting vs Glass Bead Blasting Which is Better? Types Of Bead Blasting Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. It. Types Of Bead Blasting.

From proleantech.com

Bead Blasting vs. Sandblasting The Differences Between the Two Types Of Bead Blasting Bead blasting is different from sandblasting because it may be too rough on some materials; Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. They are glass beads and steel beads. Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and.. Types Of Bead Blasting.

From hitopindustrial.com

Bead Blasting 101 Everything You Need to Know About Bead Blast Finish Types Of Bead Blasting It uses smoother beads, often made of glass, ceramic or metal that can. Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to. Types Of Bead Blasting.

From cncserviceschina.com

What is Bead Blasting? Is Bead Blasting The Right Finish For Your Part? Types Of Bead Blasting Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. Bead blasting is different from sandblasting because it may be too rough on some materials; Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar. Types Of Bead Blasting.

From www.indiamart.com

Portable Stainless Steel Glass Bead Blasting, Unimech Engineers Private Types Of Bead Blasting Bead blasting is different from sandblasting because it may be too rough on some materials; Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. It uses smoother beads, often made of glass, ceramic or metal that can. They are glass beads and steel beads. Bead blasting is a. Types Of Bead Blasting.

From raysun.ae

Bead Blasting Raysun Types Of Bead Blasting Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. It uses smoother beads, often made of glass, ceramic or metal that can. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Bead blasting is different from sandblasting because it may. Types Of Bead Blasting.

From www.kemalmfg.com

Bead Blasting 101 The Basics of the Bead Blast Finish Kemal Types Of Bead Blasting Bead blasting is different from sandblasting because it may be too rough on some materials; Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. It uses smoother beads, often made of glass, ceramic or metal that can. Bead blasting is a surface finishing technique that provides a clean. Types Of Bead Blasting.

From raysun.ae

Bead Blasting Raysun Types Of Bead Blasting They are glass beads and steel beads. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Bead blasting is different from sandblasting because it may be too rough on some materials; It uses smoother beads, often made of glass, ceramic or metal that can. Bead blasting is a surface preparation. Types Of Bead Blasting.

From raysun.ae

Bead Blasting Raysun Types Of Bead Blasting Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. It uses smoother beads, often made of glass, ceramic or metal that can. Machinists generally use two types of beads for a bead blast surface finish. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads. Types Of Bead Blasting.

From cncserviceschina.com

What is Bead Blasting? Is Bead Blasting The Right Finish For Your Part? Types Of Bead Blasting Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. They are glass beads and steel beads. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. It uses smoother beads, often made of. Types Of Bead Blasting.

From www.kemalmfg.com

Bead Blasting 101 The Basics of the Bead Blast Finish Kemal Types Of Bead Blasting Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. Machinists generally use two types of beads for a bead blast surface finish. It uses smoother beads, often made of. Types Of Bead Blasting.

From www.worthyhardware.com

Mastering Bead Blasting A Comprehensive Guide to Bead Blast Surface Types Of Bead Blasting Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. They are glass beads and steel beads. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Bead blasting is different from sandblasting because. Types Of Bead Blasting.

From chansmachining.com

The guide to the bead blasting ChansMachining Types Of Bead Blasting Bead blasting is different from sandblasting because it may be too rough on some materials; It uses smoother beads, often made of glass, ceramic or metal that can. Machinists generally use two types of beads for a bead blast surface finish. They are glass beads and steel beads. Bead blasting is a surface finishing technique that provides a clean and. Types Of Bead Blasting.

From proleantech.com

Bead Blasting Unlimited Guide A Case Study CNC Machining Service Types Of Bead Blasting They are glass beads and steel beads. Machinists generally use two types of beads for a bead blast surface finish. Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture.. Types Of Bead Blasting.

From proleantech.com

Transforming Surfaces A Comprehensive Guide to Bead Blasting vs Types Of Bead Blasting Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Machinists generally use two types of beads for a bead blast surface finish. They are glass beads and steel beads. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed. Types Of Bead Blasting.

From www.ceramicbeadblasting.com

Stainless Steel Finish B400 Ceramic Beads Blasting Media packed in Types Of Bead Blasting Bead blasting is different from sandblasting because it may be too rough on some materials; They are glass beads and steel beads. It uses smoother beads, often made of glass, ceramic or metal that can. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Common options include glass beads, aluminum. Types Of Bead Blasting.

From www.youtube.com

Vapor Honing Glass Bead Blasting Media Visual Finishes by Grit YouTube Types Of Bead Blasting Machinists generally use two types of beads for a bead blast surface finish. Bead blasting is a surface preparation technique that uses a stream of small, abrasive beads propelled at high velocity by compressed air or centrifugal force to clean,. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Common. Types Of Bead Blasting.

From medium.com

Bead Blast Finish 101 A Comprehensive Guide to Bead Blasting by Types Of Bead Blasting Common options include glass beads, aluminum oxide, silicon carbide, and plastic media, each offering different levels of abrasion and surface texture. Bead blasting is a surface finishing technique that provides a clean and uniform texture to various materials similar to. Machinists employ a range of bead blasting media types to achieve specific surface finishes, each with unique characteristics and. It. Types Of Bead Blasting.