Calculation Of Standard Time . 2.1 calculation of working time. Welcome to our informative video on. standard normal and observed time calculation explained with. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has to produce each part that rolls off the assembly line. Standard time = (observed time * rating factor) + relaxation allowances + other. standard and normal time calculation explained with advanced. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. In process design, it is necessary to consider the working time of all actions in a complete. takt time for this purpose is the time it takes to produce one part. 1.3k views 4 months ago. formula for standard time.

from haipernews.com

standard normal and observed time calculation explained with. Welcome to our informative video on. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. 2.1 calculation of working time. takt time for this purpose is the time it takes to produce one part. 1.3k views 4 months ago. formula for standard time. In process design, it is necessary to consider the working time of all actions in a complete. Standard time = (observed time * rating factor) + relaxation allowances + other. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has to produce each part that rolls off the assembly line.

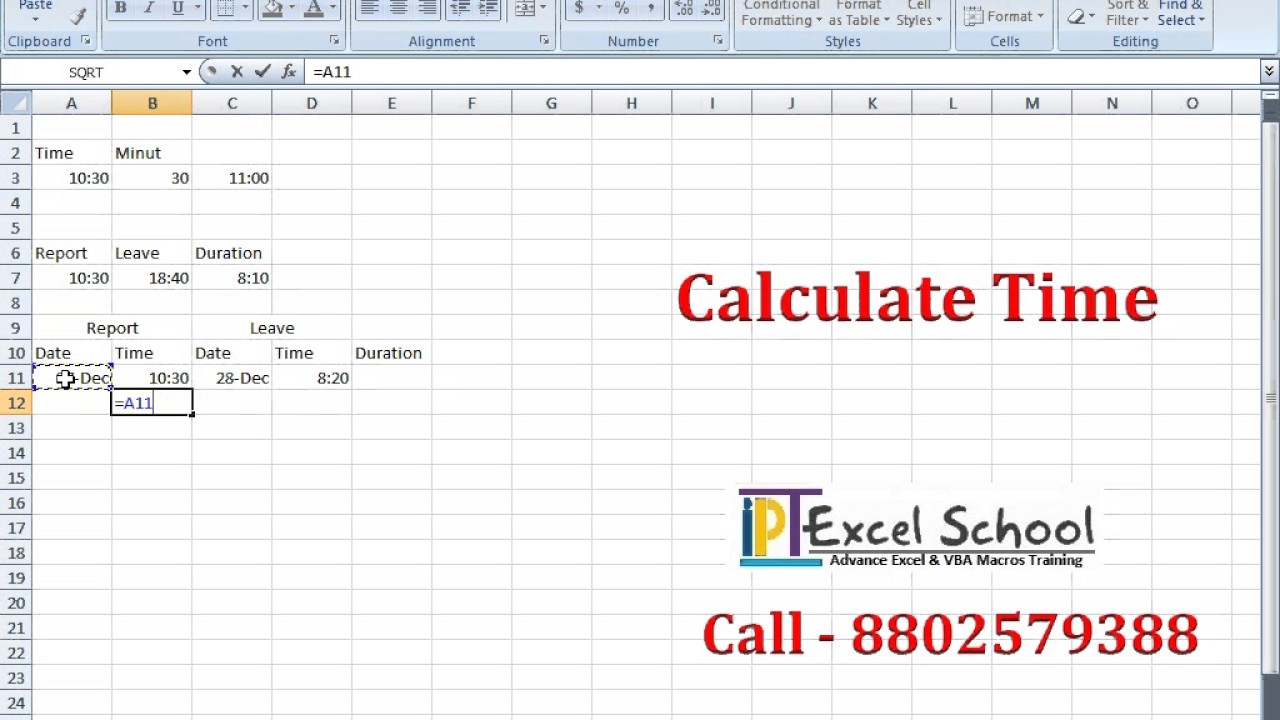

How To Calculate Average Time In Excel Haiper

Calculation Of Standard Time For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has to produce each part that rolls off the assembly line. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has to produce each part that rolls off the assembly line. 2.1 calculation of working time. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. takt time for this purpose is the time it takes to produce one part. Standard time = (observed time * rating factor) + relaxation allowances + other. formula for standard time. Welcome to our informative video on. standard normal and observed time calculation explained with. In process design, it is necessary to consider the working time of all actions in a complete. standard and normal time calculation explained with advanced. 1.3k views 4 months ago.

From stackoverflow.com

How calculate average time in Excel (if sum of hours more, than 24 Calculation Of Standard Time 2.1 calculation of working time. Standard time = (observed time * rating factor) + relaxation allowances + other. standard normal and observed time calculation explained with. takt time for this purpose is the time it takes to produce one part. 1.3k views 4 months ago. standard time can be calculated directly using a stopwatch or indirectly. Calculation Of Standard Time.

From www.youtube.com

Sample Standard Deviation Example YouTube Calculation Of Standard Time standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. formula for standard time. 2.1 calculation of working time. standard normal and observed time calculation explained with. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out. Calculation Of Standard Time.

From www.slideserve.com

PPT Operations Management Work Measurement Supplement 10 PowerPoint Calculation Of Standard Time takt time for this purpose is the time it takes to produce one part. standard normal and observed time calculation explained with. In process design, it is necessary to consider the working time of all actions in a complete. formula for standard time. 2.1 calculation of working time. For example, if you have to produce 25,000. Calculation Of Standard Time.

From my.forms.app

How to find the correct sample size for your research survey (formula Calculation Of Standard Time standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has to produce each part that rolls off. Calculation Of Standard Time.

From www.slideserve.com

PPT Customer Demand PowerPoint Presentation, free download ID144555 Calculation Of Standard Time standard normal and observed time calculation explained with. Standard time = (observed time * rating factor) + relaxation allowances + other. In process design, it is necessary to consider the working time of all actions in a complete. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out. Calculation Of Standard Time.

From sparkypedia.electricianu.com

Dwelling Unit Service Load Calculations Optional Method Sparkypedia Calculation Of Standard Time Welcome to our informative video on. standard normal and observed time calculation explained with. standard and normal time calculation explained with advanced. In process design, it is necessary to consider the working time of all actions in a complete. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or.. Calculation Of Standard Time.

From www.bank2home.com

Standard Time Calculation Of Standard Time standard normal and observed time calculation explained with. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has to produce each part that rolls off the assembly line. standard time can be calculated directly. Calculation Of Standard Time.

From crackct.weebly.com

C Program To Find Mean Variance And Standard Deviation crackct Calculation Of Standard Time formula for standard time. takt time for this purpose is the time it takes to produce one part. 2.1 calculation of working time. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has. Calculation Of Standard Time.

From www.youtube.com

How to Perform Time Period Calculations in Excel YouTube Calculation Of Standard Time Standard time = (observed time * rating factor) + relaxation allowances + other. 1.3k views 4 months ago. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has to produce each part that rolls off the. Calculation Of Standard Time.

From fastloans.ph

What is Standard Deviation? Formula for calculating standard deviation Calculation Of Standard Time standard and normal time calculation explained with advanced. takt time for this purpose is the time it takes to produce one part. formula for standard time. In process design, it is necessary to consider the working time of all actions in a complete. standard time can be calculated directly using a stopwatch or indirectly using standard. Calculation Of Standard Time.

From www.gene-quantification.de

BioInformatics & relative quantification using real time PCR Calculation Of Standard Time formula for standard time. Welcome to our informative video on. 1.3k views 4 months ago. standard and normal time calculation explained with advanced. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. For example, if you have to produce 25,000 parts in 2 weeks, you can do the. Calculation Of Standard Time.

From www.onlineclothingstudy.com

Standard Minute Value (SMV) Definition, Calculation and Use Calculation Of Standard Time standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. takt time for this purpose is the time it takes to produce one part. formula for standard time. standard and normal time calculation explained with advanced. Standard time = (observed time * rating factor) + relaxation allowances +. Calculation Of Standard Time.

From www.wikihow.com

How to Calculate Sample Size 14 Steps (with Pictures) wikiHow Calculation Of Standard Time Welcome to our informative video on. 2.1 calculation of working time. formula for standard time. Standard time = (observed time * rating factor) + relaxation allowances + other. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how. Calculation Of Standard Time.

From www.wikihow.com

How to Calculate Mean, Standard Deviation, and Standard Error (with Calculation Of Standard Time takt time for this purpose is the time it takes to produce one part. Standard time = (observed time * rating factor) + relaxation allowances + other. standard and normal time calculation explained with advanced. In process design, it is necessary to consider the working time of all actions in a complete. 2.1 calculation of working time.. Calculation Of Standard Time.

From getvoip.com

What is Average Handle Time (AHT) & How to Calculate It? Calculation Of Standard Time In process design, it is necessary to consider the working time of all actions in a complete. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. standard normal and observed time calculation explained with. formula for standard time. standard and normal time calculation explained with advanced. . Calculation Of Standard Time.

From www.worldtimezone.com

Standard Time Zone chart of the World in 1927 map presentation Calculation Of Standard Time takt time for this purpose is the time it takes to produce one part. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has to produce each part that rolls off the assembly line. In. Calculation Of Standard Time.

From www.slideserve.com

PPT Introduction to sample size and power calculations PowerPoint Calculation Of Standard Time 2.1 calculation of working time. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. Welcome to our informative video on. takt time for this purpose is the time it takes to produce one part. formula for standard time. standard normal and observed time calculation explained with.. Calculation Of Standard Time.

From www.youtube.com

Standard and Normal Time Calculation Explained with Advanced Examples Calculation Of Standard Time For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has to produce each part that rolls off the assembly line. standard time can be calculated directly using a stopwatch or indirectly using standard time data. Calculation Of Standard Time.

From thaiphotos.net

Example 10 Calculate mean, variance, standard deviation Calculation Of Standard Time standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. formula for standard time. standard and normal time calculation explained with advanced. Welcome to our informative video on. standard normal and observed time calculation explained with. In process design, it is necessary to consider the working time of. Calculation Of Standard Time.

From classfullherzog.z19.web.core.windows.net

Military Time Chart Conversion Minutes Calculation Of Standard Time Standard time = (observed time * rating factor) + relaxation allowances + other. takt time for this purpose is the time it takes to produce one part. Welcome to our informative video on. In process design, it is necessary to consider the working time of all actions in a complete. For example, if you have to produce 25,000 parts. Calculation Of Standard Time.

From www.researchgate.net

Correspondence calculation standard deviation under different Calculation Of Standard Time formula for standard time. Welcome to our informative video on. Standard time = (observed time * rating factor) + relaxation allowances + other. 2.1 calculation of working time. standard normal and observed time calculation explained with. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out. Calculation Of Standard Time.

From discover.hubpages.com

How to Use Standard Deviation Formula For Equations (Statistics Help Calculation Of Standard Time standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. standard and normal time calculation explained with advanced. 2.1 calculation of working time. standard normal and observed time calculation explained with. Standard time = (observed time * rating factor) + relaxation allowances + other. 1.3k views 4 months. Calculation Of Standard Time.

From db-excel.com

Commercial Electrical Load Calculation Spreadsheet Inside Commercial Calculation Of Standard Time standard normal and observed time calculation explained with. Welcome to our informative video on. In process design, it is necessary to consider the working time of all actions in a complete. Standard time = (observed time * rating factor) + relaxation allowances + other. takt time for this purpose is the time it takes to produce one part.. Calculation Of Standard Time.

From haipernews.com

How To Calculate Standard Deviation Formula Haiper Calculation Of Standard Time standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. Standard time = (observed time * rating factor) + relaxation allowances + other. formula for standard time. In process design, it is necessary to consider the working time of all actions in a complete. Welcome to our informative video on.. Calculation Of Standard Time.

From www.youtube.com

Calculating Time YouTube Calculation Of Standard Time formula for standard time. Welcome to our informative video on. Standard time = (observed time * rating factor) + relaxation allowances + other. In process design, it is necessary to consider the working time of all actions in a complete. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to. Calculation Of Standard Time.

From rayb78.github.io

Units Of Time Chart Calculation Of Standard Time takt time for this purpose is the time it takes to produce one part. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many parts each shift must produce and how long a shift has to produce each part that rolls off the assembly line. Standard. Calculation Of Standard Time.

From www.teachoo.com

Example 12 Calculate mean, variance, standard deviation Calculation Of Standard Time Welcome to our informative video on. 2.1 calculation of working time. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. 1.3k views 4 months ago. Standard time = (observed time * rating factor) + relaxation allowances + other. standard and normal time calculation explained with advanced. formula. Calculation Of Standard Time.

From haipernews.com

How To Calculate Standard Deviation Below The Mean Haiper Calculation Of Standard Time In process design, it is necessary to consider the working time of all actions in a complete. 2.1 calculation of working time. Welcome to our informative video on. takt time for this purpose is the time it takes to produce one part. For example, if you have to produce 25,000 parts in 2 weeks, you can do the. Calculation Of Standard Time.

From www.thoughtco.com

How to Calculate Percent Error Calculation Of Standard Time 1.3k views 4 months ago. Welcome to our informative video on. Standard time = (observed time * rating factor) + relaxation allowances + other. standard normal and observed time calculation explained with. standard and normal time calculation explained with advanced. In process design, it is necessary to consider the working time of all actions in a complete. . Calculation Of Standard Time.

From haipernews.com

How To Calculate Average Time In Excel Haiper Calculation Of Standard Time In process design, it is necessary to consider the working time of all actions in a complete. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. 1.3k views 4 months ago. standard and normal time calculation explained with advanced. 2.1 calculation of working time. Standard time = (observed. Calculation Of Standard Time.

From www.youtube.com

GCSE Revision Video 22 Standard Form YouTube Calculation Of Standard Time standard normal and observed time calculation explained with. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. 1.3k views 4 months ago. 2.1 calculation of working time. Standard time = (observed time * rating factor) + relaxation allowances + other. In process design, it is necessary to consider. Calculation Of Standard Time.

From www.youtube.com

Standard Normal and Observed Time Calculation Explained with Examples Calculation Of Standard Time 1.3k views 4 months ago. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. Welcome to our informative video on. takt time for this purpose is the time it takes to produce one part. standard normal and observed time calculation explained with. Standard time = (observed time *. Calculation Of Standard Time.

From www.slideshare.net

Job Design and Work Measurement Calculation Of Standard Time standard normal and observed time calculation explained with. standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. Welcome to our informative video on. standard and normal time calculation explained with advanced. 1.3k views 4 months ago. takt time for this purpose is the time it takes to. Calculation Of Standard Time.

From www.researchgate.net

Fig S12. Limit of detection (LOD) calculation. Download Scientific Calculation Of Standard Time In process design, it is necessary to consider the working time of all actions in a complete. takt time for this purpose is the time it takes to produce one part. formula for standard time. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure out how many. Calculation Of Standard Time.

From www.youtube.com

Activity Variation and Standard Deviation YouTube Calculation Of Standard Time standard time can be calculated directly using a stopwatch or indirectly using standard time data tables, curves or. Welcome to our informative video on. takt time for this purpose is the time it takes to produce one part. For example, if you have to produce 25,000 parts in 2 weeks, you can do the appropriate calculations to figure. Calculation Of Standard Time.