Gear Shaving Disadvantages . Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. the gear shaper is not as quick when it comes to cutting speed. In creating gears with a module greater than 5. the rotary gear sbaving process. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a.

from exomtxqck.blob.core.windows.net

In creating gears with a module greater than 5. the rotary gear sbaving process. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. the gear shaper is not as quick when it comes to cutting speed. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a.

Gear Shaving Tool at John Sales blog

Gear Shaving Disadvantages gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. the gear shaper is not as quick when it comes to cutting speed. quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. the rotary gear sbaving process. In creating gears with a module greater than 5. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the.

From www.modulbey.com

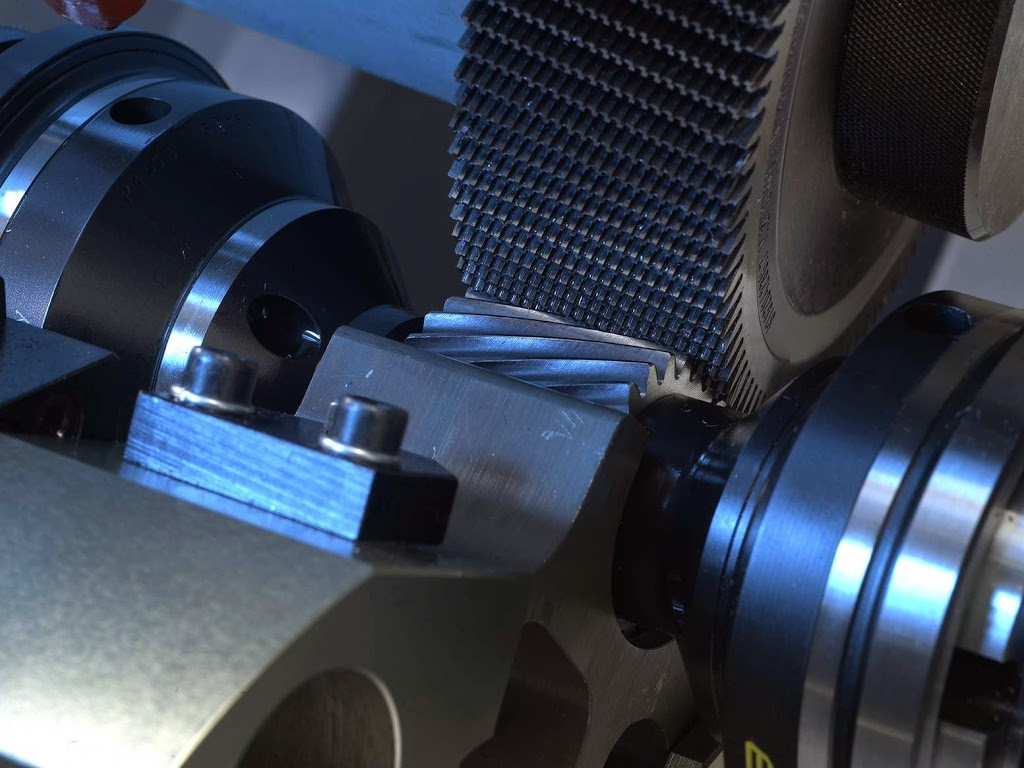

Gear Shaving Tool » Modulbey Gear Cutting Tools Gear Shaving Disadvantages In creating gears with a module greater than 5. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. the rotary gear sbaving process. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears.. Gear Shaving Disadvantages.

From www.hindlegears.com

Gear shaving Hindle Gears Gear Shaving Disadvantages In creating gears with a module greater than 5. quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a.. Gear Shaving Disadvantages.

From www.emag.com

Gear shaving EMAG ensures productive solutions Gear Shaving Disadvantages gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. the gear shaper is not as quick when it comes to cutting speed. the rotary gear sbaving process. quality of the shaved gear is dependent to a large degree upon having good hobbed or. Gear Shaving Disadvantages.

From www.yashtools.com

Gear Shaving Cutter Yash International Tools Gear Shaving Disadvantages shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. quality of the shaved gear is dependent to a large. Gear Shaving Disadvantages.

From mechanicaltalks.in

Gear Hobbing Parts, Working, Diagram, Advantages, Disadvantages Gear Shaving Disadvantages quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. In creating gears with a module greater than 5. the rotary gear sbaving process. the gear shaper is not as quick when it comes to cutting speed. shaping is a subtractive process where. Gear Shaving Disadvantages.

From www.jiangxinggongju.com

PA20° Preshaving Gear Hob with Module m3 Chongqing Jiangxing Tools Gear Shaving Disadvantages the gear shaper is not as quick when it comes to cutting speed. the rotary gear sbaving process. quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. gear hobbing is more versatile in producing various gear types, while gear shaping is more. Gear Shaving Disadvantages.

From www.yashtools.com

Gear Shaving Cutter Yash International Tools Gear Shaving Disadvantages gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. quality of the shaved gear is dependent to a large degree upon having good. Gear Shaving Disadvantages.

From www.youtube.com

Gear Shaping Process (हिन्दी ) YouTube Gear Shaving Disadvantages the gear shaper is not as quick when it comes to cutting speed. In creating gears with a module greater than 5. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. Shaving is a kind of generating manufacturing or machining method. Gear Shaving Disadvantages.

From www.studocu.com

Gears Advantages and Disadvantages of Gear Drive The following are Gear Shaving Disadvantages Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. the rotary gear sbaving process. quality of the shaved. Gear Shaving Disadvantages.

From www.geartechnology.com

Gear Finishing by Shaving, Rolling and Honing, Part I Gear Technology Gear Shaving Disadvantages Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. In creating gears with a module greater than 5. quality of the shaved gear. Gear Shaving Disadvantages.

From www.samputensili.com

What is a gear shaving machine ? Samputensili Machine Tools Gear Shaving Disadvantages the rotary gear sbaving process. the gear shaper is not as quick when it comes to cutting speed. quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. In creating gears with a module greater than 5. gear hobbing is more versatile in. Gear Shaving Disadvantages.

From exomtxqck.blob.core.windows.net

Gear Shaving Tool at John Sales blog Gear Shaving Disadvantages quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. the gear shaper is not as quick when it comes to cutting. Gear Shaving Disadvantages.

From www.youtube.com

Gear shaving process,ITI and Diploma most important topic YouTube Gear Shaving Disadvantages gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. the gear shaper is not as quick when it comes to cutting speed. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool,. Gear Shaving Disadvantages.

From geartechnologyindia.com

Key Basic Conditions in the Gear Shaving Process to Achieve Finish Gear Gear Shaving Disadvantages shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. the gear shaper is not as quick when it comes to cutting speed. the rotary gear sbaving process. Shaving is a kind of generating manufacturing or machining method commonly used to. Gear Shaving Disadvantages.

From www.docsity.com

Gear Shaving Manufacturing Technology Exam Docsity Gear Shaving Disadvantages the rotary gear sbaving process. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. In creating gears with a module greater than 5.. Gear Shaving Disadvantages.

From geartechnologyindia.com

Key Basic Conditions in the Gear Shaving Process to Achieve Finish Gear Gear Shaving Disadvantages quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. the gear shaper is not as quick when it comes to cutting speed. In creating gears with a module greater than 5. the rotary gear sbaving process. Shaving is a kind of generating manufacturing. Gear Shaving Disadvantages.

From dokumen.tips

(PDF) Gear Shaving Basics, Part I · Gear Shaving Basics Part I John P Gear Shaving Disadvantages quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. gear hobbing is more versatile in producing various. Gear Shaving Disadvantages.

From slidetodoc.com

Milling Gear Cutting Presented By Bidve M A Gear Shaving Disadvantages the rotary gear sbaving process. the gear shaper is not as quick when it comes to cutting speed. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. quality of the shaved gear is dependent to a large degree upon. Gear Shaving Disadvantages.

From www.youtube.com

Gear Shaping and Hobbing YouTube Gear Shaving Disadvantages shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. In creating gears with a module greater than 5. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. the. Gear Shaving Disadvantages.

From www.samputensili.com

GearshavingRASO200001WP Samputensili Gear Shaving Disadvantages the gear shaper is not as quick when it comes to cutting speed. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. In creating gears with a module greater than 5. Shaving is a kind of generating manufacturing or machining method. Gear Shaving Disadvantages.

From fdocuments.in

Introduction to Universal Gear Shaving [DOCX Document] Gear Shaving Disadvantages quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. In creating gears with a module greater than 5. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. the rotary gear. Gear Shaving Disadvantages.

From www.geartechnology.com

Gear Finishing by Shaving, Rolling and Honing, Part II Gear Gear Shaving Disadvantages the gear shaper is not as quick when it comes to cutting speed. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. In creating gears with a module greater than 5. the rotary gear sbaving process. shaping is a subtractive process where the gear. Gear Shaving Disadvantages.

From www.scribd.com

The Process of Gear Shaving An InDepth Look at Gear Finishing Gear Shaving Disadvantages shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. gear hobbing is more versatile in producing various. Gear Shaving Disadvantages.

From www.youtube.com

Gear drive Advantages of Gear Drive Disadvantages of Gear Drive Gear Shaving Disadvantages the gear shaper is not as quick when it comes to cutting speed. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. In creating gears with a module greater than 5. shaping is a subtractive process where the gear is cut into a blank. Gear Shaving Disadvantages.

From www.scribd.com

Gear Hobbing, Shaping and Shaving A Guide to Cycle Time Estimating Gear Shaving Disadvantages the gear shaper is not as quick when it comes to cutting speed. quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. In creating gears with a module greater than 5. gear hobbing is more versatile in producing various gear types, while gear. Gear Shaving Disadvantages.

From www.artofit.org

How to control impulsive shaving gear buys Artofit Gear Shaving Disadvantages shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. quality of the shaved gear is dependent to a large. Gear Shaving Disadvantages.

From seibushoko.com

ギアシェービングカッター|切削工具|取扱製品|西部商工株式会社 Gear Shaving Disadvantages quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. In creating gears with a module greater than 5. Shaving is a kind. Gear Shaving Disadvantages.

From www.theengineerspost.com

What is Gear Cutting? Types, Advantages, Disadvantages [PDF] Gear Shaving Disadvantages the rotary gear sbaving process. In creating gears with a module greater than 5. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears.. Gear Shaving Disadvantages.

From kawoodgear.com

Gear Shaving Machines KAWood Gear & Machine Company Precision Gear Gear Shaving Disadvantages quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. the rotary gear sbaving process. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. shaping is a subtractive process where the. Gear Shaving Disadvantages.

From en.wikipedia.org

Gear shaping Wikipedia Gear Shaving Disadvantages the gear shaper is not as quick when it comes to cutting speed. In creating gears with a module greater than 5. the rotary gear sbaving process. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. Shaving is a kind. Gear Shaving Disadvantages.

From dir.indiamart.com

Gear Shaving Cutter in Delhi, गियर शेविंग कटर, दिल्ली, Delhi Gear Gear Shaving Disadvantages the gear shaper is not as quick when it comes to cutting speed. gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. Shaving is a kind of generating manufacturing or machining method commonly used to improve the accuracy of tooth profile and reduce the. . Gear Shaving Disadvantages.

From www.slideserve.com

PPT CHGEAR CUTTING OPERATIONS PowerPoint Presentation, free download Gear Shaving Disadvantages In creating gears with a module greater than 5. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is.. Gear Shaving Disadvantages.

From www.stcgeartools.com

Gear Shaving Cutter Re Sharpening STC Gear Tool Gear Shaving Disadvantages gear hobbing is more versatile in producing various gear types, while gear shaping is more suitable for spur gears and internal gears. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. the gear shaper is not as quick when it. Gear Shaving Disadvantages.

From www.youtube.com

Gear Shaving Process (हिन्दी ) YouTube Gear Shaving Disadvantages shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting tool, which is usually a. In creating gears with a module greater than 5. quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is.. Gear Shaving Disadvantages.

From sstools.net

Know about Gear Shaving Cutters for Precise Gear Shaping Process Gear Shaving Disadvantages quality of the shaved gear is dependent to a large degree upon having good hobbed or shaped gear teeth, excellent surface finish is. the gear shaper is not as quick when it comes to cutting speed. shaping is a subtractive process where the gear is cut into a blank or a partially formed gear using a cutting. Gear Shaving Disadvantages.