Lobe Compressor Diagram . The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. Lobe blowers consist of two rotors spinning in opposite directions. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. The mechanical device used to compress air is called an ‘air compressor’. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. Air compression is the process of increasing the air pressure above the atmospheric pressure. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. The blower sucks in air, and the lobes spin the air around before pushing the air out.

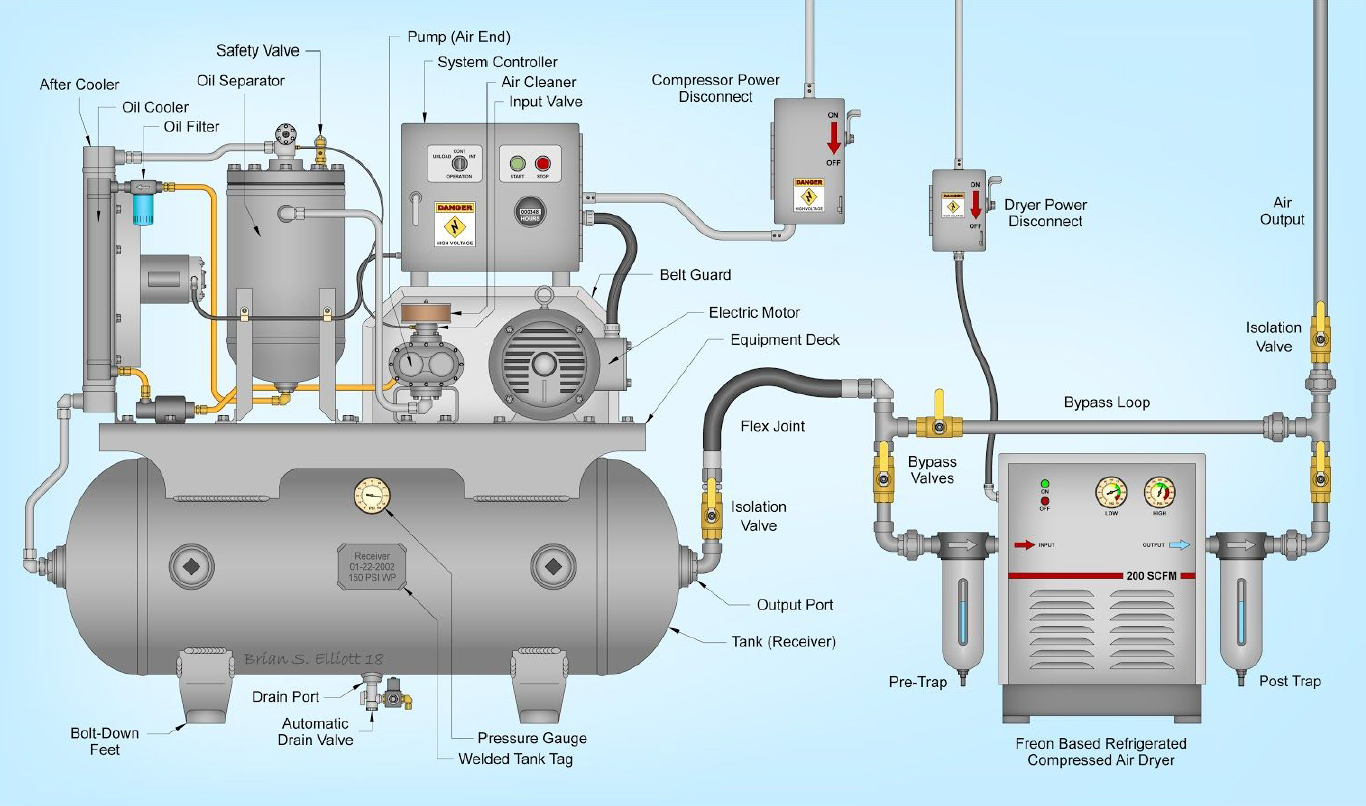

from www.rasmech.com

The mechanical device used to compress air is called an ‘air compressor’. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. Lobe blowers consist of two rotors spinning in opposite directions. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. The blower sucks in air, and the lobes spin the air around before pushing the air out. Air compression is the process of increasing the air pressure above the atmospheric pressure.

Rotary Screw Air Compressor Basics Rasmussen Mechanical

Lobe Compressor Diagram Lobe blowers consist of two rotors spinning in opposite directions. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. Lobe blowers consist of two rotors spinning in opposite directions. The mechanical device used to compress air is called an ‘air compressor’. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. The blower sucks in air, and the lobes spin the air around before pushing the air out. Air compression is the process of increasing the air pressure above the atmospheric pressure.

From www.bigrentz.com

How Air Compressors Work An Animated Guide BigRentz Lobe Compressor Diagram When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. The mechanical device used to compress air is called an. Lobe Compressor Diagram.

From instrumentationtools.com

Rotary Compressors Inst Tools Lobe Compressor Diagram The mechanical device used to compress air is called an ‘air compressor’. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. The blower sucks in air, and the lobes spin the air around before pushing the. Lobe Compressor Diagram.

From chempedia.info

Compressors HelicalLobe Big Chemical Encyclopedia Lobe Compressor Diagram The blower sucks in air, and the lobes spin the air around before pushing the air out. Air compression is the process of increasing the air pressure above the atmospheric pressure. The mechanical device used to compress air is called an ‘air compressor’. When the compression chamber comes into contact with the outlet port, compressed air flows back into the. Lobe Compressor Diagram.

From www.researchgate.net

14 Lobe Compressor (Courtesy of Delta Hybrid) Download Scientific Lobe Compressor Diagram Air compression is the process of increasing the air pressure above the atmospheric pressure. The mechanical device used to compress air is called an ‘air compressor’. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. The pumping capacity of a lobe. Lobe Compressor Diagram.

From www.theengineerspost.com

5 Types of Air Compressors Working principle, Application (PDF) Lobe Compressor Diagram The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. Lobe blowers consist of two. Lobe Compressor Diagram.

From instrumentationtools.com

Rotary Compressors Inst Tools Lobe Compressor Diagram The mechanical device used to compress air is called an ‘air compressor’. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. The blower sucks in air, and the lobes spin the air around before pushing the air out. Lobe blowers consist of two rotors spinning in opposite. Lobe Compressor Diagram.

From www.brighthubengineering.com

Types of Air Compressors Reciprocating, Rotary, Screw, Vane, Lobe Lobe Compressor Diagram The mechanical device used to compress air is called an ‘air compressor’. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. When the compression chamber comes into contact with the outlet port, compressed air flows back. Lobe Compressor Diagram.

From fity.club

Lobe Pump Diagram Lobe Compressor Diagram If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. Lobe blowers consist of two rotors spinning in opposite directions. The blower sucks in air, and the lobes. Lobe Compressor Diagram.

From www.youtube.com

Roots Blower Five Lobe YouTube Lobe Compressor Diagram Air compression is the process of increasing the air pressure above the atmospheric pressure. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. Lobe blowers consist of two rotors spinning in opposite directions. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side.. Lobe Compressor Diagram.

From www.air-equipment.co.uk

rotary lobe pump operating Air Equipment Lobe Compressor Diagram The mechanical device used to compress air is called an ‘air compressor’. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. Lobe blowers consist of two rotors spinning in opposite directions. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. If you have an application. Lobe Compressor Diagram.

From www.rasmech.com

Rotary Screw Air Compressor Basics Rasmussen Mechanical Lobe Compressor Diagram The mechanical device used to compress air is called an ‘air compressor’. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. When the compression chamber comes into contact with the outlet port, compressed air flows back. Lobe Compressor Diagram.

From www.evomart.co.uk

Vol 7 Fundamentals Part 7 Compressors (Continued) Evomart Lobe Compressor Diagram Lobe blowers consist of two rotors spinning in opposite directions. The mechanical device used to compress air is called an ‘air compressor’. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. When the compression chamber comes into contact with the outlet. Lobe Compressor Diagram.

From www.sunrise-metal.com

Oilfree Compressor Parts Construction of Different Oilfree Compressors Lobe Compressor Diagram The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. The mechanical device used to compress air is called an ‘air compressor’. Lobe blowers consist of two rotors spinning in opposite directions. If you have an application. Lobe Compressor Diagram.

From www.pneumofore.com

Rotary Vane Technology Pneumofore Lobe Compressor Diagram The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. Air compression is the process of increasing the air pressure above the atmospheric pressure. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. The blower sucks in. Lobe Compressor Diagram.

From www.bigrentz.com

How Air Compressors Work An Animated Guide BigRentz Lobe Compressor Diagram The blower sucks in air, and the lobes spin the air around before pushing the air out. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. The mechanical device used to compress air is called an ‘air compressor’. When the compression chamber comes into contact with the outlet port, compressed. Lobe Compressor Diagram.

From www.linquip.com

4 Types of Air Compressors & Application) Linquip Lobe Compressor Diagram The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. Air compression is the process of increasing the air pressure above the atmospheric pressure. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. The mechanical device used to compress air is called an. Lobe Compressor Diagram.

From www.youtube.com

NASH Twin Lobe Liquid Ring Compressor How It Works YouTube Lobe Compressor Diagram The mechanical device used to compress air is called an ‘air compressor’. Air compression is the process of increasing the air pressure above the atmospheric pressure. Lobe blowers consist of two rotors spinning in opposite directions. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. The value of atmospheric pressure. Lobe Compressor Diagram.

From www.youtube.com

Rotary Lobe Pump What Is It? How Does It Work? YouTube Lobe Compressor Diagram If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. Lobe blowers consist of two rotors spinning in opposite directions. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. The value of. Lobe Compressor Diagram.

From www.researchgate.net

Figure3 Oilinjected Twin Screw Compressor [6] Download Scientific Lobe Compressor Diagram Lobe blowers consist of two rotors spinning in opposite directions. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. The blower sucks in air, and the lobes spin the air around before pushing the air out. The mechanical device used to compress air is called an ‘air compressor’. Air compression. Lobe Compressor Diagram.

From www.youtube.com

Root Blower Rotor Lobe Compressor Lobe Compressor Rotor Root Blower Lobe Compressor Diagram Lobe blowers consist of two rotors spinning in opposite directions. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. The mechanical device used to compress air is called an ‘air compressor’. The blower sucks in air,. Lobe Compressor Diagram.

From amechieneer.com

Screw Compressor Working Principle The Mechanical Engineer Lobe Compressor Diagram Lobe blowers consist of two rotors spinning in opposite directions. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. Air compression is the process of increasing the air. Lobe Compressor Diagram.

From maritime.org

Figure 51. Vapor compressor, two lobe (exploded view). Lobe Compressor Diagram When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. Lobe blowers consist of two rotors spinning in opposite directions.. Lobe Compressor Diagram.

From www.youtube.com

Lobe type Compressor YouTube Lobe Compressor Diagram Air compression is the process of increasing the air pressure above the atmospheric pressure. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. Lobe blowers consist of two rotors spinning in opposite directions.. Lobe Compressor Diagram.

From navalfacilities.tpub.com

Figure 29. Rotary TwinLobe Compressor Lobe Compressor Diagram The mechanical device used to compress air is called an ‘air compressor’. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. Air compression is the process of increasing the air pressure above the atmospheric pressure. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. When. Lobe Compressor Diagram.

From www.google.com

Patent US20140010698 Multiple Segment Lobe Pump Google Patents Lobe Compressor Diagram Lobe blowers consist of two rotors spinning in opposite directions. Air compression is the process of increasing the air pressure above the atmospheric pressure. The blower sucks in air, and the lobes spin the air around before pushing the air out. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. The pumping capacity of a. Lobe Compressor Diagram.

From intidayads.com

Apa itu Root Blower, Fungsi, Cara Kerja dan Penggunaannya Blog Intidaya Lobe Compressor Diagram The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. Air compression is the process of increasing the air pressure above the atmospheric pressure. The mechanical device used to compress air is called an ‘air compressor’. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. The. Lobe Compressor Diagram.

From www.sundyne.com

How Do Centrifugal Compressors Work? Sundyne Lobe Compressor Diagram The blower sucks in air, and the lobes spin the air around before pushing the air out. The mechanical device used to compress air is called an ‘air compressor’. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. When the compression. Lobe Compressor Diagram.

From amechieneer.com

Screw Compressor Working Principle The Mechanical Engineer Lobe Compressor Diagram The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty. Lobe Compressor Diagram.

From learnmech.com

Reciprocating Compressor Diagram , Parts , Working, Advantages Lobe Compressor Diagram The mechanical device used to compress air is called an ‘air compressor’. When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. Lobe blowers consist of two rotors spinning in opposite directions. The blower sucks in air, and the lobes spin the air around before pushing the air. Lobe Compressor Diagram.

From www.about-air-compressors.com

Parts of An Air Compressor Diagram Guide Air Compressor Parts List Lobe Compressor Diagram The mechanical device used to compress air is called an ‘air compressor’. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. Air compression is the process of. Lobe Compressor Diagram.

From www.tec-science.com

What is a roots type blower and how does it work? tecscience Lobe Compressor Diagram When the compression chamber comes into contact with the outlet port, compressed air flows back into the housing from the pressure side. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. Air compression is the process of increasing the air pressure. Lobe Compressor Diagram.

From chaprabazaar.blogspot.com

Lobe compressor Lobe Compressor Diagram Lobe blowers consist of two rotors spinning in opposite directions. The mechanical device used to compress air is called an ‘air compressor’. The value of atmospheric pressure is given as ‘1 atm’ or ‘101,325 pa (pascals)’. The blower sucks in air, and the lobes spin the air around before pushing the air out. The pumping capacity of a lobe compressor,. Lobe Compressor Diagram.

From www.zillionsbuyer.com

What is Lobe type Rotary Air Compressor Zillions Buyer Lobe Compressor Diagram If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty environment, a rotary lobe. The blower sucks in air, and the lobes spin the air around before pushing the air out. Air compression is the process of increasing the air pressure above the atmospheric pressure. The. Lobe Compressor Diagram.

From amechieneer.com

Screw Compressor Working Principle The Mechanical Engineer Lobe Compressor Diagram The mechanical device used to compress air is called an ‘air compressor’. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. The blower sucks in air, and the lobes spin the air around before pushing the air out. When the compression chamber comes into contact with the outlet port, compressed. Lobe Compressor Diagram.

From engineeringlearn.com

7 Types of Air Compressor Definition, Uses & Working Principle Lobe Compressor Diagram The blower sucks in air, and the lobes spin the air around before pushing the air out. The pumping capacity of a lobe compressor, operating at constant speed remains relatively independent of inlet and discharge pressure. If you have an application that needs below 15 psi of air, a large volume of air, and you have a dirty or dusty. Lobe Compressor Diagram.