Electrodeposited Copper Foil . the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. in this blog article, we will see the ed copper foil manufacturing key processes. Starting with the most important part, the. When you get into the. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium.

from resources.altium.com

the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. Starting with the most important part, the. When you get into the. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. in this blog article, we will see the ed copper foil manufacturing key processes. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium.

Types of PCB Copper Foil for HighFrequency Design Zach Peterson Blog PCB Design

Electrodeposited Copper Foil the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. in this blog article, we will see the ed copper foil manufacturing key processes. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. Starting with the most important part, the. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. When you get into the.

From www.rf-shielded.com

Pure Electrodeposited Copper Foil Customizable In Roll For Mri Rf Cage Electrodeposited Copper Foil When you get into the. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design.. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

Electrodeposited Copper Foil 12um , C1100 Rolled Copper Foil For Graphene Electrodeposited Copper Foil with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. in this blog article, we will see the ed copper foil manufacturing key processes. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. Starting with the most important part, the. When. Electrodeposited Copper Foil.

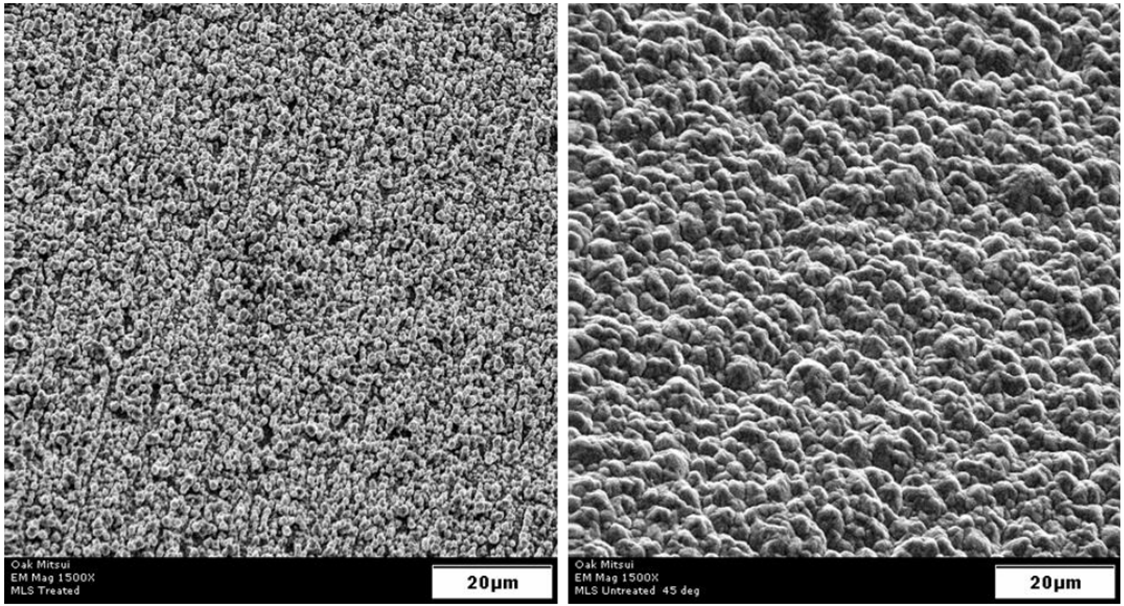

From www.semanticscholar.org

Figure 1 from Mechanical properties of electrodeposited copper foils for PCB applications Electrodeposited Copper Foil When you get into the. in this blog article, we will see the ed copper foil manufacturing key processes. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. in this paper,. Electrodeposited Copper Foil.

From www.ecvv.com

Electrodeposited Copper foil For PCB from China Manufacturer, Manufactory, Factory and Supplier Electrodeposited Copper Foil Starting with the most important part, the. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. When you get into the. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. the many different classes. Electrodeposited Copper Foil.

From www.copperfoilrolls.com

Width 1295mm ED Pure Electrodeposited Copper Foil Electrodeposited Copper Foil the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. in this blog article, we will see the ed copper foil manufacturing key processes. with nearly a century of experience, de nora can. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

Low Coarsening Reverse Treated Electrodeposited Copper Foil Roll 35um 70um 105um Electrodeposited Copper Foil explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. When you get into the. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. the many different classes of copper foils used in the pcb. Electrodeposited Copper Foil.

From ec21.com

RA Electrodeposited Copper Foil Thick Copper Plate for Fpc(id10672588). Buy China copper foil Electrodeposited Copper Foil the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. When you get into the. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. in this blog article, we will see the ed copper foil manufacturing. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

RoHS 18um Copper Foil Pcb , Low Profile CCL Electrodeposited Copper Foil Electrodeposited Copper Foil the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. in this blog article, we will see the ed copper foil manufacturing key processes. When you get into the. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

35um Electrodeposited Copper Foil , Flexible Printed Circuit ED Copper Electrodeposited Copper Foil Starting with the most important part, the. in this blog article, we will see the ed copper foil manufacturing key processes. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. When you get into the. explore the increasing demand for copper foil in electronic products and the manufacturing processes. Electrodeposited Copper Foil.

From www.assignmenthelp.net

Electrodeposited and rolled copper foil Electrodeposited Copper Foil explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium.. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

Electrodeposited Copper Shielding Foil High Peel Strength 2 Oz Thickness Electrodeposited Copper Foil When you get into the. in this blog article, we will see the ed copper foil manufacturing key processes. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. explore the increasing. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

ED Electrodeposited Copper Foil For Mylar Tape None Pinholes 99.8 Purity Electrodeposited Copper Foil Starting with the most important part, the. When you get into the. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. in this blog article, we will. Electrodeposited Copper Foil.

From www.linkedin.com

Skyrocketing Growth in Electrodeposited Copper Foils Market Electrodeposited Copper Foil in this blog article, we will see the ed copper foil manufacturing key processes. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. Starting with the most important. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

Electrolytic Electrodeposited Copper Foil , 3 / 6 Inch ID Sheet Metal Copper Electrodeposited Copper Foil the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. When you get into the. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. in this blog article, we will see the ed copper foil manufacturing key processes. explore the. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

One Side Shiny Electrodeposited Copper Foil 12 Micron EDCU For Samsung Mobile Phone Electrodeposited Copper Foil the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. Starting with the most important part, the. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. in this blog article, we will see the ed copper foil manufacturing key processes. . Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

RoHS 18um Copper Foil Pcb , Low Profile CCL Electrodeposited Copper Foil Electrodeposited Copper Foil with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. When you get into the. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. the many different classes of copper foils used in the pcb industry have their own capabilities. Electrodeposited Copper Foil.

From www.timonic.com.cn

A StepbyStep Guide to Electrodeposited Copper Foil Production Electrodeposited Copper Foil Starting with the most important part, the. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper. Electrodeposited Copper Foil.

From www.pcbaaa.com

What is electrodeposited copper foil ? IBE Electronics Electrodeposited Copper Foil the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. When you get into. Electrodeposited Copper Foil.

From www.civen-inc.com

Best Cheap PriceList for Beryllium Copper Foil HTE Electrodeposited Copper Foils for PCB Electrodeposited Copper Foil When you get into the. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. the many different classes of copper foils used in the pcb industry have their own capabilities. Electrodeposited Copper Foil.

From japan.denora.com

Electrodeposited (ED) copper foil manufacturing De Nora Japan Electrodeposited Copper Foil the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. When you get into the. Starting with the most important part, the. in this paper, we reported a novel composite additive, consisting. Electrodeposited Copper Foil.

From www.indiamart.com

Electrodeposited Copper Foil at best price in Pune by D. D. Enterprises ID 12662054548 Electrodeposited Copper Foil the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. in this blog article, we will see the ed copper foil manufacturing key processes. Starting with the most important. Electrodeposited Copper Foil.

From www.pcbaaa.com

Top 15 Electrodeposited copper foil manufacturers in the world IBE Electronics Electrodeposited Copper Foil the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. Starting with the most important part, the. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. When you get into the. the many different classes of copper foils. Electrodeposited Copper Foil.

From www.rf-shielded.com

2oz 0.07mm Electrodeposited Copper Foil Shielding Strip 1290mm Electrodeposited Copper Foil in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. Starting with the most important part, the. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. in this blog article, we will see the ed copper foil manufacturing key processes. . Electrodeposited Copper Foil.

From huazhusteel.en.made-in-china.com

9 Micron Red PCB Copper Coil Width 1295mm ED Pure Electrodeposited Copper Foil Coil China Electrodeposited Copper Foil Starting with the most important part, the. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. in this blog article, we will see the ed copper foil manufacturing key processes. . Electrodeposited Copper Foil.

From resources.altium.com

Types of PCB Copper Foil for HighFrequency Design Zach Peterson Blog PCB Design Electrodeposited Copper Foil Starting with the most important part, the. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. the copper foil was electrodeposited from a plating solution containing. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

RoHS Certificated FPC Copper Foil Sheet,6um Electrodeposited Copper Sheet Metal Electrodeposited Copper Foil with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. Starting with the most important part, the. in this blog article, we will see the ed copper foil manufacturing key processes. When. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

35um Electrodeposited Copper Foil , Flexible Printed Circuit ED Copper Electrodeposited Copper Foil with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in. Electrodeposited Copper Foil.

From www.rf-shielded.com

Pure Customizable Electrodeposited Copper Foil In Roll For Mri Rf Cage Electrodeposited Copper Foil explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. in this blog article, we will see the ed copper foil manufacturing key processes. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. with nearly. Electrodeposited Copper Foil.

From www.ecvv.com

Electrodeposited Copper foil For PCB from China Manufacturer, Manufactory, Factory and Supplier Electrodeposited Copper Foil the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. Starting with the most important part, the. in this blog article, we will see the ed copper foil manufacturing key processes. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. explore the. Electrodeposited Copper Foil.

From www.pcbaaa.com

Top 15 Electrodeposited copper foil manufacturers in the world IBE Electronics Electrodeposited Copper Foil the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

1290mm Width HTE CU Electrodeposited Copper Foil 70 / 35um Thickness For PCB Laminate Electrodeposited Copper Foil with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. When you get into the. Starting with the most important part, the. in this blog article, we will see the ed copper foil manufacturing key processes. in this paper, we reported a novel composite additive, consisting of collagen,. Electrodeposited Copper Foil.

From www.rolledcopperfoil.com

Lithium Battery Electrodeposited Copper Foil 6 / 7 / 8 Micron Thickness Electrodeposited Copper Foil the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. in this blog article, we will see the ed copper foil manufacturing key processes. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used in its production. in this. Electrodeposited Copper Foil.

From www.pcbaaa.com

What is electrodeposited copper foil ? IBE Electronics Electrodeposited Copper Foil When you get into the. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. explore the increasing demand for copper foil in electronic products and the manufacturing processes of electrodeposition and rolling used. Electrodeposited Copper Foil.

From hindi.rolledcopperfoil.com

Electrodeposited Copper Shielding Foil High Peel Strength 2 Oz Thickness Electrodeposited Copper Foil with nearly a century of experience, de nora can support the copper foil manufacturing industry with electrodeposition cell design. in this paper, we reported a novel composite additive, consisting of collagen, glycerol, hydroxyethyl cellulose, and sodium. the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. the copper. Electrodeposited Copper Foil.

From www.rf-shielded.com

8 Micron Electrodeposited Copper Foil Shielding For Rf Cage Mri Room Electrodeposited Copper Foil the many different classes of copper foils used in the pcb industry have their own capabilities and limitations. the copper foil was electrodeposited from a plating solution containing 312.5 g/l copper sulfate (cuso 4. in this blog article, we will see the ed copper foil manufacturing key processes. with nearly a century of experience, de nora. Electrodeposited Copper Foil.