Spinning Production . Within this period of time, all types of regularly scheduled production work happen. Spinning is the most important and the. Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. First stage of spinning involves converting. The spinning process is the process in which cotton fibers are consolidated into yarn. The process of converting fiber into yarn is called as spinning. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. These steps of processing are carried out in the blow room of a spinning mill. Yarn production in spinning mill: Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. The most commonly used spinning systems are. Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn.

from www.alamy.com

These steps of processing are carried out in the blow room of a spinning mill. The process of converting fiber into yarn is called as spinning. Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. Spinning is the most important and the. First stage of spinning involves converting. The spinning process is the process in which cotton fibers are consolidated into yarn. Yarn production in spinning mill: Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. The most commonly used spinning systems are. Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers.

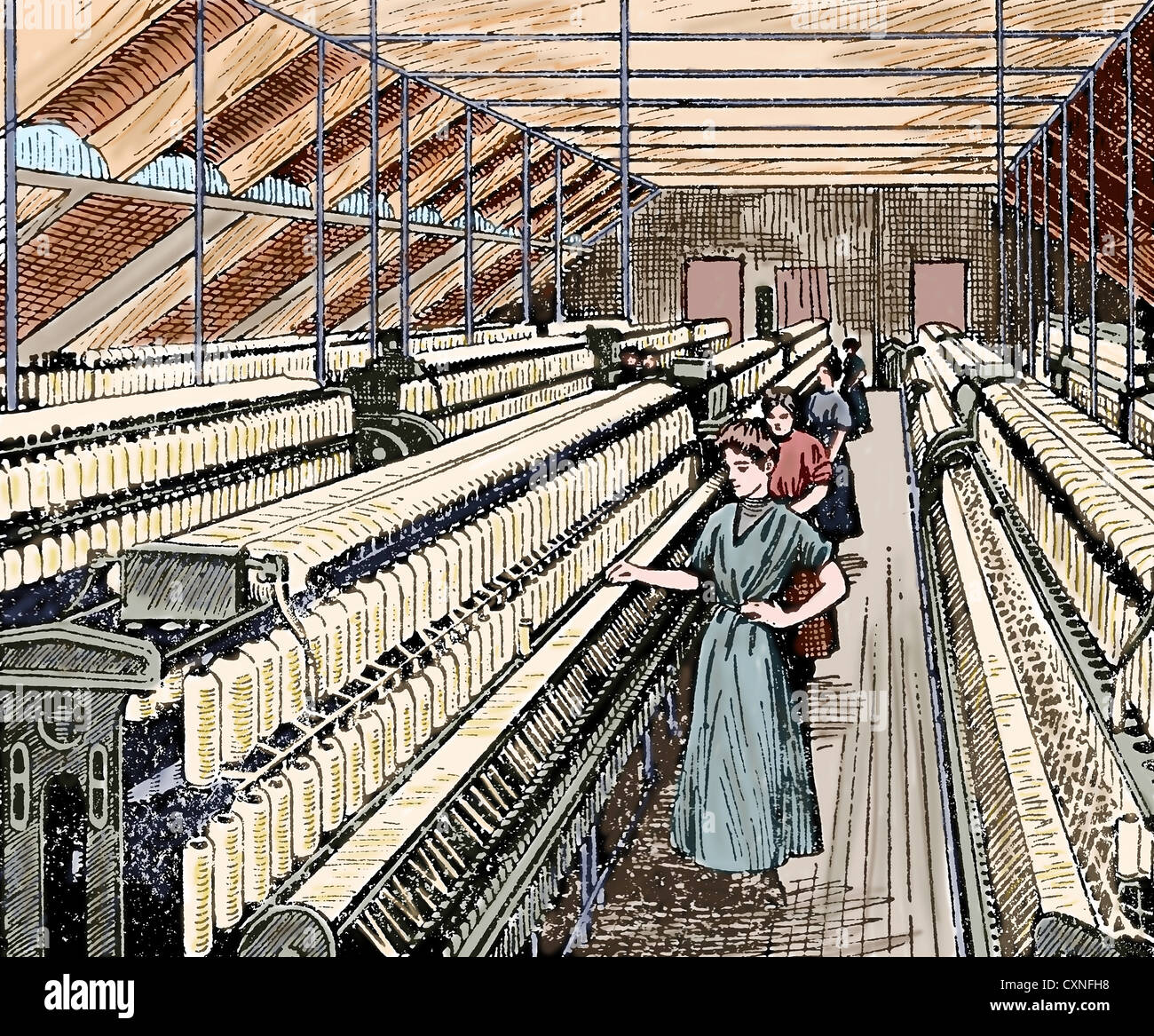

Textile Industry. Ring Spinning. Manufacturing process of cotton yarn

Spinning Production Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. The process of converting fiber into yarn is called as spinning. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. The spinning process is the process in which cotton fibers are consolidated into yarn. Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. First stage of spinning involves converting. Spinning is the most important and the. Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. These steps of processing are carried out in the blow room of a spinning mill. Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. The most commonly used spinning systems are. Within this period of time, all types of regularly scheduled production work happen. Yarn production in spinning mill:

From www.textilesphere.com

Introduction to textile spinning process Flowchart Objectives Spinning Production Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. These steps of processing are carried out in the blow room of a spinning mill. The most commonly used spinning systems are. Yarn spinning. Spinning Production.

From indiantextilejournal.com

Can Spinning Sustain Growth? Indian Textile Journal Spinning Production First stage of spinning involves converting. Spinning is the most important and the. Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. Textile spinning is a crucial process in the manufacturing of textiles,. Spinning Production.

From textalks.com

The crisis in spinning industries is not confined to Pakistan Spinning Production Spinning is the most important and the. There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. The spinning process is the process in which cotton fibers are consolidated into yarn. First stage of spinning involves converting. The most commonly used spinning systems are. Yarn production in spinning mill: Within this period of time, all. Spinning Production.

From www.alamy.com

Spinning production line Stock Photo Alamy Spinning Production Yarn production in spinning mill: These steps of processing are carried out in the blow room of a spinning mill. Within this period of time, all types of regularly scheduled production work happen. Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. Spinning is the most important and. Spinning Production.

From www.shutterstock.com

Machinery Equipment Spinning Production Company Stock Photo (Edit Now Spinning Production Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. These steps of processing are carried out in the blow room of a spinning mill. Yarn production in spinning mill: Within this period of time, all types of regularly scheduled production work happen. There are three different methods for. Spinning Production.

From www.dreamstime.com

Spinning Production. Textile Factory. Yarn Making Processes. Threads Spinning Production First stage of spinning involves converting. Yarn production in spinning mill: Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. These steps of processing are carried out. Spinning Production.

From www.indiamart.com

Spinning Production Monitoring System at best price in Mumbai Spinning Production Within this period of time, all types of regularly scheduled production work happen. Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. Yarn production in spinning mill: Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. Spinning is the. Spinning Production.

From www.shutterstock.com

Cotton Group In Spinning Production Line Factory Stock Photo 303485150 Spinning Production Within this period of time, all types of regularly scheduled production work happen. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. The process of converting fiber into yarn is called as spinning. Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn.. Spinning Production.

From www.dreamstime.com

Automatic Equipment in a Spinning Production Plant Stock Image Image Spinning Production Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn.. Spinning Production.

From www.textileschool.com

Setting up a Spinning Mill Textile School Spinning Production These steps of processing are carried out in the blow room of a spinning mill. Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. The spinning process is the process in which cotton fibers are consolidated into yarn. There are three different methods for spinning,. Spinning Production.

From www.dreamstime.com

Spinning Production Line. Spinning Machinery with Spindles and Wool Spinning Production There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. First stage of spinning involves converting. Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. Within this period. Spinning Production.

From www.rieter.com

Advantageous AirCovering Process for Spinning Corespun Yarns with a Spinning Production Spinning is the most important and the. There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. The spinning process is the process in which cotton fibers are consolidated into yarn. Yarn production in spinning mill: The most commonly used spinning systems are. Generally, without overtime, the production hour is 8 hours, from 9.00 am. Spinning Production.

From www.dreamstime.com

Cotton Group in Spinning Production Line Factory Stock Image Image of Spinning Production Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. The spinning process is the process in which cotton fibers are consolidated into yarn. These steps of processing are carried out in the blow room of a spinning mill. Within this period of time, all types. Spinning Production.

From qdtongda.en.made-in-china.com

Textile Machinery Drawing Frame Spinning Machine for Cotton Yarn Spinning Production The process of converting fiber into yarn is called as spinning. The spinning process is the process in which cotton fibers are consolidated into yarn. Yarn production in spinning mill: First stage of spinning involves converting. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. Textile spinning is a crucial process in the manufacturing. Spinning Production.

From www.dreamstime.com

Cotton Group in Spinning Production Line Factory Stock Image Image of Spinning Production First stage of spinning involves converting. Yarn production in spinning mill: Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. These steps of processing are carried out in the blow room of a. Spinning Production.

From www.dreamstime.com

Spinning Production Line. Spinning Machinery with Spindles and Wool Spinning Production Within this period of time, all types of regularly scheduled production work happen. Spinning is the most important and the. First stage of spinning involves converting. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. These steps of processing. Spinning Production.

From www.dreamstime.com

Cotton Group in Spinning Production Line Factory Stock Photo Image of Spinning Production Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. These steps of processing are carried out in the blow room of a spinning mill. Spinning is the most important and the. Yarn spinning. Spinning Production.

From www.textileschool.com

Standard Staple Yarn Spinning Procedures Textile School Spinning Production The process of converting fiber into yarn is called as spinning. Spinning is the most important and the. These steps of processing are carried out in the blow room of a spinning mill. The most commonly used spinning systems are. First stage of spinning involves converting. The spinning process is the process in which cotton fibers are consolidated into yarn.. Spinning Production.

From ihsancotton.com

Process Ihsan Cotton Spinning Production Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. First stage of spinning involves converting. There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. Yarn production in spinning mill: Within this period of time, all types of regularly scheduled production work happen.. Spinning Production.

From www.youtube.com

Textile Spinning Process Overview Explained TexConnect YouTube Spinning Production The spinning process is the process in which cotton fibers are consolidated into yarn. Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. Within this period of time, all types of regularly scheduled production work happen. These steps of processing are carried out in the blow room of. Spinning Production.

From www.dreamstime.com

Spinning Production. Yarn Making Processes. Textile Factory Equipment Spinning Production Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. These steps of processing are carried out in the blow room of a spinning mill. First stage of spinning involves converting. The spinning process is the process in which cotton fibers are consolidated into yarn. There are three different. Spinning Production.

From www.dreamstime.com

Cotton Group in Spinning Production Line Factory Stock Image Image of Spinning Production Yarn production in spinning mill: Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. The most commonly used spinning systems are. Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. Within this period of time, all types of regularly. Spinning Production.

From jingtianchina.en.made-in-china.com

1008 Spindles Spinning Production Line Ring Frame Machine China Spinning Production There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. Spinning is the most important and the. Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. The spinning. Spinning Production.

From www.jmfibermachine.com

POY PET Polyester multifilament yarn spinning machine, polyester yarn Spinning Production Spinning is the most important and the. Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. Within this period of time, all types of regularly scheduled production work happen. Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely. Spinning Production.

From www.alamy.com

Textile Industry. Ring Spinning. Manufacturing process of cotton yarn Spinning Production Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. First stage of spinning involves converting. These steps of processing are carried out in the blow room of a spinning mill. Yarn production in spinning mill: Textile spinning is a crucial process in the manufacturing of textiles, involving the. Spinning Production.

From schoolhistory.co.uk

Spinning Jenny Facts, Invention, Industrial Revolution & How It Works Spinning Production Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. Yarn production in spinning mill: The process of converting fiber into yarn is called as spinning. First stage of spinning involves converting. The spinning process is the process in which cotton fibers are consolidated into yarn. The most commonly used spinning systems are. Spinning is. Spinning Production.

From www.textileschool.com

Optimum Yarn Spinning conditions Textile School Spinning Production Yarn production in spinning mill: Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. There are three different methods for spinning, or twisting, the prepared cotton fiber into yarn. Within this period of. Spinning Production.

From www.dreamstime.com

Cotton Group in Spinning Production Line Factory Stock Photo Image of Spinning Production These steps of processing are carried out in the blow room of a spinning mill. The spinning process is the process in which cotton fibers are consolidated into yarn. Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. Spinning is the act of taking animal. Spinning Production.

From www.textilesphere.com

Introduction to textile spinning process Flowchart Objectives Spinning Production Yarn production in spinning mill: These steps of processing are carried out in the blow room of a spinning mill. Within this period of time, all types of regularly scheduled production work happen. The process of converting fiber into yarn is called as spinning. The spinning process is the process in which cotton fibers are consolidated into yarn. Textile spinning. Spinning Production.

From qdtongda.en.made-in-china.com

Mini Mill Spinning Production Line Ring Spinning Machine China Ring Spinning Production The process of converting fiber into yarn is called as spinning. Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion of fibers into yarns to create various. Yarn spinning is the process of manufacturing yarn from different types of fibres. Spinning Production.

From www.indiantextilemagazine.in

Operating margins for cotton spinning industry to improve to 11.512.0 Spinning Production Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. The spinning process is the process in which cotton fibers are consolidated into yarn. Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. Generally,. Spinning Production.

From depositphotos.com

Cotton spinning machine Stock Editorial Photo © antoniotruzzi 78529716 Spinning Production Generally, without overtime, the production hour is 8 hours, from 9.00 am to 5.00 pm. Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. The process of converting fiber into yarn is called as spinning. Spinning is the most important and the. These steps of. Spinning Production.

From www.dreamstime.com

Cotton Group in Spinning Production Line Factory Stock Image Image of Spinning Production The spinning process is the process in which cotton fibers are consolidated into yarn. The process of converting fiber into yarn is called as spinning. These steps of processing are carried out in the blow room of a spinning mill. First stage of spinning involves converting. Textile spinning is a crucial process in the manufacturing of textiles, involving the conversion. Spinning Production.

From www.thehindubusinessline.com

Spinning mills in Coimbatore to stop production and sale of yarn from Spinning Production The spinning process is the process in which cotton fibers are consolidated into yarn. These steps of processing are carried out in the blow room of a spinning mill. Spinning is the act of taking animal fibers or vegetable fibres and twisting them to form a continuous, infinitely stretching yarn. Within this period of time, all types of regularly scheduled. Spinning Production.

From www.dreamstime.com

Spinning Production. Textile Factory. Yarn Making Processes. Threads Spinning Production Spinning is the most important and the. Within this period of time, all types of regularly scheduled production work happen. The most commonly used spinning systems are. Yarn spinning is the process of manufacturing yarn from different types of fibres into a continuous length from one or more type of fibers. Textile spinning is a crucial process in the manufacturing. Spinning Production.