Heat Sink Fin Configurations . The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. In this study, we compare and analyze the configurations and thermal performance of fin structures with different.

from www.mdpi.com

In this study, we compare and analyze the configurations and thermal performance of fin structures with different. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure.

Engineering Proceedings Free FullText Numerical Investigation of Different Configurations

Heat Sink Fin Configurations The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. In this study, we compare and analyze the configurations and thermal performance of fin structures with different. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches.

From www.researchgate.net

(PDF) An Active Heat Sink System With Piezoelectric Translational Agitators and Micro Pin Fin Arrays Heat Sink Fin Configurations In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous. Heat Sink Fin Configurations.

From www.simscale.com

6 Tips for Heat Sink Design & Heat Sink Efficiency SimScale Heat Sink Fin Configurations The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. In this study, we compare and analyze the configurations and thermal performance. Heat Sink Fin Configurations.

From www.researchgate.net

(PDF) An Implementation Study on Heat Sink with Different Fin Configurations Under Natural Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Based. Heat Sink Fin Configurations.

From www.researchgate.net

Typical configurations and designations of various heat sink models. Download Table Heat Sink Fin Configurations In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. In this study, we compare and analyze the configurations and thermal performance of fin structures with different. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Different design approaches. Heat Sink Fin Configurations.

From www.mdpi.com

Engineering Proceedings Free FullText Numerical Investigation of Different Configurations Heat Sink Fin Configurations Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. In this study, we compare and analyze the configurations and thermal performance of fin structures with. Heat Sink Fin Configurations.

From www.researchgate.net

Configuration of heat sink with aluminum porous fins on test section⁴⁴... Download Scientific Heat Sink Fin Configurations Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. In this study, we compare and analyze the configurations and thermal performance of fin structures with different. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous. Heat Sink Fin Configurations.

From www.researchgate.net

a Fin configuration with 8mmbased perforated heat sink. b Fin... Download Scientific Diagram Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. Based. Heat Sink Fin Configurations.

From www.researchgate.net

The configurations of finned round and flat tube heat exchanger.... Download Scientific Diagram Heat Sink Fin Configurations The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. In this study, we compare and analyze the configurations and thermal performance. Heat Sink Fin Configurations.

From www.qats.com

What are the benefits of using Pin Fin Heat Sinks in thermal management of electronics Heat Sink Fin Configurations Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. In this study, we compare and analyze the configurations and thermal performance of fin structures with different. The. Heat Sink Fin Configurations.

From www.researchgate.net

Configurations and dimensions of heat sinks (Unit mm) Download Scientific Diagram Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast. Heat Sink Fin Configurations.

From www.mdpi.com

Processes Free FullText Heat Transfer Performance of Plate Fin and Pin Fin Heat Sinks Using Heat Sink Fin Configurations The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to. Heat Sink Fin Configurations.

From www.researchgate.net

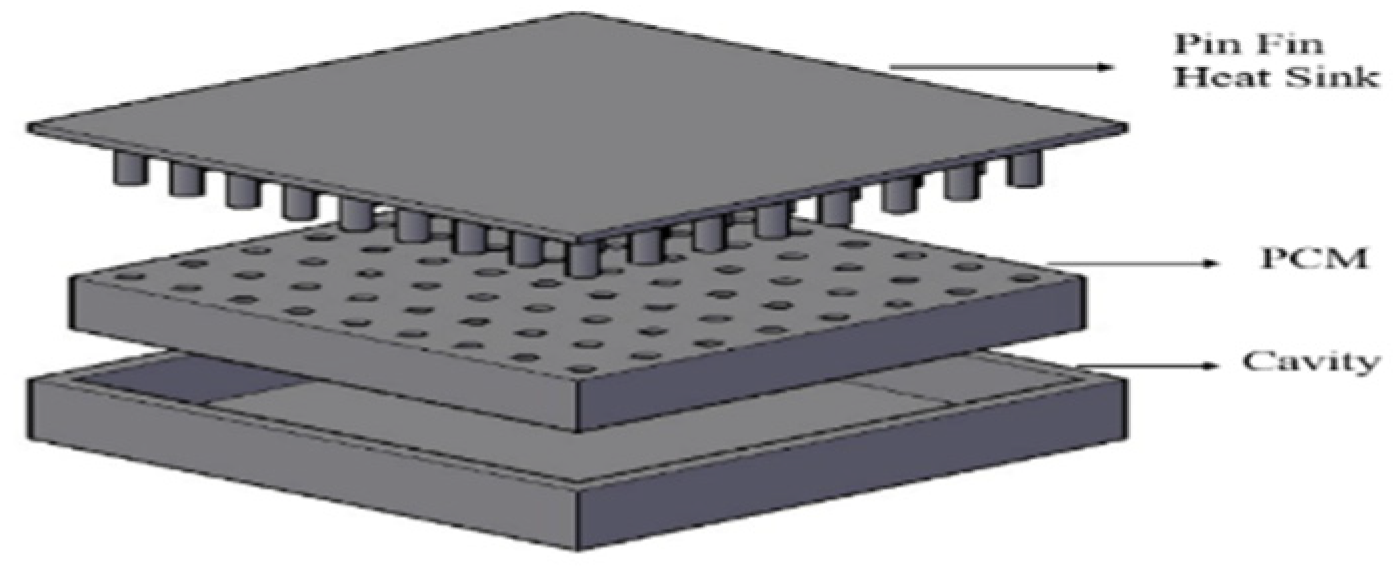

Summary of some possible PCMsbased heat sinks configurations for... Download Scientific Diagram Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous. Heat Sink Fin Configurations.

From www.researchgate.net

Platefin heat sinks with partial heating. Download Scientific Diagram Heat Sink Fin Configurations The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). In this study, we compare and analyze the configurations and thermal performance of fin structures with different. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Based on this. Heat Sink Fin Configurations.

From www.researchgate.net

(a) Porous heat sink. (b) Plain view of a vertical fins heat sink. (c)... Download Scientific Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux. Heat Sink Fin Configurations.

From www2.mdpi.com

Applied Sciences Free FullText A Modification of Offset Strip Fin Heatsink with High Heat Sink Fin Configurations Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. In this study, we compare and analyze the configurations and thermal performance of fin structures with. Heat Sink Fin Configurations.

From www.electricity-magnetism.org

Bonded fin heatsink How it works, Application & Advantages Heat Sink Fin Configurations Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous. Heat Sink Fin Configurations.

From www.mdpi.com

Materials Free FullText Evaluation of Active Heat Sinks Design under Forced Convection Heat Sink Fin Configurations In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter. Heat Sink Fin Configurations.

From www.researchgate.net

Configuration of heat sink with aluminum porous fins on test section⁴⁴... Download Scientific Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux. Heat Sink Fin Configurations.

From www.diabatix.com

Pin Fin Heat Sink Applications Enhancing Thermal Management for Optimal Performance Diabatix Heat Sink Fin Configurations Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter. Heat Sink Fin Configurations.

From www.youtube.com

ATS Straight Fin Heat Sinks YouTube Heat Sink Fin Configurations Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and. Heat Sink Fin Configurations.

From celsiainc.com

Different Heat Pipe Heat Sink Configurations Celsia Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. The. Heat Sink Fin Configurations.

From heatsinkchina.com

kind of bonded fin heat sink type swaged heatsink Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. The heat sink fins are perforated with. Heat Sink Fin Configurations.

From www.slideserve.com

PPT Analytical Modeling of Forced Convection in Slotted Plate Fin Heat Sinks PowerPoint Heat Sink Fin Configurations Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. In this study, we compare and analyze the configurations and thermal performance of fin structures with. Heat Sink Fin Configurations.

From thermocoolcorp.com

Thermo Cool Folded Fins Heat Sink Fin Configurations In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous. Heat Sink Fin Configurations.

From www.researchgate.net

Pictorial view of heat sink configurations under study Download Scientific Diagram Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. Different design approaches have been made in. Heat Sink Fin Configurations.

From www.slideserve.com

PPT Analytical Modeling of Forced Convection in Slotted Plate Fin Heat Sinks PowerPoint Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. Different design approaches have been made in. Heat Sink Fin Configurations.

From www.semanticscholar.org

Figure 2 from Improved thermal design of fin heat sink for highpower LED lamp cooling Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast. Heat Sink Fin Configurations.

From www.researchgate.net

Pictorial view of heat sink configurations under study Download Scientific Diagram Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. The. Heat Sink Fin Configurations.

From www.rapiddirect.com

Optimize Your Heat Sink Design Principles and Practical Tips RapidDirect Heat Sink Fin Configurations The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). In this study, we compare and analyze the configurations and thermal performance of fin structures with different. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. In. Heat Sink Fin Configurations.

From www.semanticscholar.org

Figure 1 from Cooling performance in a minichannel heat sink with different triangular pinfins Heat Sink Fin Configurations In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux. Heat Sink Fin Configurations.

From www.researchgate.net

Designed geometry and dimensions of pinfin heat sink Download Scientific Diagram Heat Sink Fin Configurations In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Different design approaches have been made in micro pin fin heat sinks to enhance heat transfer due to the fast rise in heat flux in. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous. Heat Sink Fin Configurations.

From www.researchgate.net

Perspective view of the heat sink and a single perforated pinfin... Download Scientific Diagram Heat Sink Fin Configurations In this study, we compare and analyze the configurations and thermal performance of fin structures with different. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. In. Heat Sink Fin Configurations.

From www.mdpi.com

Engineering Proceedings Free FullText Numerical Investigation of Different Configurations Heat Sink Fin Configurations The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. Different. Heat Sink Fin Configurations.

From www.researchgate.net

(PDF) Improving Heat Transfer of PlateFin Heat Sinks Using Through Rod Configurations Heat Sink Fin Configurations In the present work, we explore finned heat sinks that combine the advantages of both finning approaches. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Different. Heat Sink Fin Configurations.

From www.researchgate.net

(PDF) Improving Heat Transfer of PlateFin Heat Sinks Using Through Rod Configurations Heat Sink Fin Configurations The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). In this study, we compare and analyze the configurations and thermal performance of fin structures with different. Based on this procedure, a new fin geometry parameter configuration was proposed that was superior to the previous structure. In. Heat Sink Fin Configurations.