Wire Edm Diagram . Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. Extremely fine finishes of 12 rms can be produced with wire edm. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. 9 may 2022 by electrical workbook. While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. Process, diagram, construction & applications. #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part.

from www.absolutewireedm.com

While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. 9 may 2022 by electrical workbook. #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. Extremely fine finishes of 12 rms can be produced with wire edm. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. Process, diagram, construction & applications. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with.

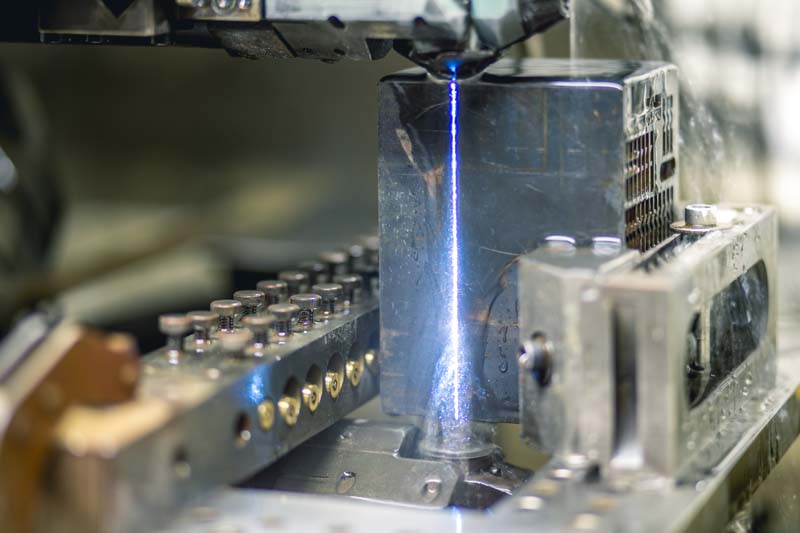

How Wire EDM Works Missouri's Wire EDM machine shop

Wire Edm Diagram The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. 9 may 2022 by electrical workbook. Extremely fine finishes of 12 rms can be produced with wire edm. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. Process, diagram, construction & applications.

From wiringdiagramrods.z19.web.core.windows.net

Working Principle Of Wire Edm Wire Edm Diagram Process, diagram, construction & applications. #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or. Wire Edm Diagram.

From www.absolutewireedm.com

How Wire EDM Works Missouri's Wire EDM machine shop Wire Edm Diagram The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. Extremely fine finishes of 12 rms can be produced with wire edm. Process, diagram, construction & applications. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part.. Wire Edm Diagram.

From www.researchgate.net

Block diagram of wire EDM machine [Source Technological Manual of... Download Scientific Diagram Wire Edm Diagram 9 may 2022 by electrical workbook. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. Wire electrical discharge machining (edm) is one of the greatest innovations. Wire Edm Diagram.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Wire Edm Diagram While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. Process, diagram, construction & applications. Extremely fine. Wire Edm Diagram.

From www.researchgate.net

Detail diagram of the wirecut EDM method and its responses Download Scientific Diagram Wire Edm Diagram No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. Extremely fine finishes of 12 rms can be produced with wire edm. Process, diagram, construction & applications. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. #1 wire edm. Wire Edm Diagram.

From alenaoden.blogspot.com

wire edm machine working principle Alena Oden Wire Edm Diagram #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. Extremely fine finishes of 12 rms can be produced with wire edm. Process, diagram, construction & applications. Machining a. Wire Edm Diagram.

From chanayala.blogspot.com

wire edm machine working principle Chan Ayala Wire Edm Diagram 9 may 2022 by electrical workbook. #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. The working principle of wire edm is same as that of conventional edm except that it uses a small. Wire Edm Diagram.

From www.researchgate.net

Schematic diagram of Wire EDM system [4]. Download Scientific Diagram Wire Edm Diagram #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. 9 may 2022 by electrical workbook. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it. Wire Edm Diagram.

From www.researchgate.net

Principle of multiplepass rotary wire EDM. (a) The general and (b)... Download Scientific Diagram Wire Edm Diagram #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. Process, diagram, construction & applications. 9. Wire Edm Diagram.

From www.madearia.com

Wire EDM Cutting Process, Advantages and Applications Wire Edm Diagram Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. Process, diagram, construction & applications. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. #1 wire edm (wedm) in wire edm. Wire Edm Diagram.

From prototype-shortrun.com

How Wire EDM Services Are Used to Create Intricate Parts Wire Edm Diagram No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. Extremely fine finishes of. Wire Edm Diagram.

From www.iqsdirectory.com

EDM Machining Components, Types, Applications, and Advantages Wire Edm Diagram #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. 9 may 2022 by electrical workbook. Extremely fine finishes of 12 rms can be produced with wire edm. Process,. Wire Edm Diagram.

From www.researchgate.net

Schematic working principle of wire EDM Download Scientific Diagram Wire Edm Diagram The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. #1 wire edm (wedm) in wire edm. Wire Edm Diagram.

From tylercasteel.blogspot.com

wire edm machine working principle Tyler Casteel Wire Edm Diagram While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. Process, diagram, construction & applications. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. The working principle of wire edm is same as that of conventional edm except that it uses. Wire Edm Diagram.

From www.iqsdirectory.com

EDM Machining Components, Types, Applications, and Advantages Wire Edm Diagram Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. 9 may 2022 by electrical workbook. #1 wire. Wire Edm Diagram.

From www.unionfab.com

Wire EDM Explained Everything You Need to Know Wire Edm Diagram #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Extremely fine finishes of 12 rms can be produced with wire edm. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. Process, diagram, construction & applications. 9 may 2022 by electrical workbook. While the workpiece. Wire Edm Diagram.

From www.researchgate.net

WIREEDM processing in the XY plane Rradius of the electrode tool... Download Scientific Diagram Wire Edm Diagram Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. Extremely fine finishes of 12 rms can be produced with wire edm. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. Machining a part using the process involves submerging the. Wire Edm Diagram.

From lynnapinckney.blogspot.com

wire edm machine working principle Lynna Pinckney Wire Edm Diagram Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. The working principle of. Wire Edm Diagram.

From www.researchgate.net

Schematic of the EDM process showing (1) melting of both workpiece and... Download Scientific Wire Edm Diagram Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. 9 may 2022 by electrical workbook. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. Process,. Wire Edm Diagram.

From www.researchgate.net

Schema of Wire EDM principle Download Scientific Diagram Wire Edm Diagram 9 may 2022 by electrical workbook. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. The working principle of wire edm is same as that of conventional edm except. Wire Edm Diagram.

From www.iqsdirectory.com

Sinker EDM Components, Types, Applications, and Advantages Wire Edm Diagram Process, diagram, construction & applications. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. Wire electrical discharge. Wire Edm Diagram.

From www.canadianmetalworking.com

Understanding the power of wire EDM Wire Edm Diagram Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. Process, diagram, construction & applications. Extremely fine finishes of 12 rms can be produced with wire edm. 9 may 2022 by electrical workbook. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. #1 wire edm (wedm). Wire Edm Diagram.

From finemetalworking.com

Sinker EDM (Ram EDM). How DieSinker Woks & Its Uses Wire Edm Diagram While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. Extremely fine finishes of 12 rms can be produced with wire edm. No actual contact is made between the wire and the material, which prevents distorting the path. Wire Edm Diagram.

From alenaoden.blogspot.com

wire edm machine working principle Alena Oden Wire Edm Diagram Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. Extremely fine finishes of 12 rms. Wire Edm Diagram.

From truffe2100momon.blogspot.com

wire edm machine is an electro process Heidy Leblanc Wire Edm Diagram While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. Extremely fine. Wire Edm Diagram.

From blogginhopoetico.blogspot.com

wire edm machine working principle Kaci Osorio Wire Edm Diagram The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with.. Wire Edm Diagram.

From alenaoden.blogspot.com

wire edm machine working principle Alena Oden Wire Edm Diagram No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. 9 may 2022 by electrical workbook. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. Process, diagram, construction & applications. Machining a part using the process involves submerging the workpiece. Wire Edm Diagram.

From finemetalworking.com

Wire EDM. Guide to EDM Wirecut Machine, Process & Uses Fine MetalWorking Wire Edm Diagram No actual contact is made between the wire and the material, which prevents distorting the path of the wire or damaging the part. #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. Wire electrical. Wire Edm Diagram.

From www.electricaldischargemachining.com

EDM Machining Companies EDM Machining Services Wire Edm Diagram 9 may 2022 by electrical workbook. #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Process, diagram, construction & applications. Machining a part using the process involves submerging the workpiece into a dielectric fluid, securing it with. No actual contact is made between the wire and the material, which prevents distorting. Wire Edm Diagram.

From www.ultrasonic-resonators.org

Electrical discharge machining (EDM) Ultrasonic Resonators Wire Edm Diagram Extremely fine finishes of 12 rms can be produced with wire edm. #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. 9 may 2022 by electrical workbook. Machining a part using the process involves submerging. Wire Edm Diagram.

From wiringdiagramrods.z19.web.core.windows.net

Working Principle Of Wire Edm Wire Edm Diagram Process, diagram, construction & applications. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. 9 may 2022 by. Wire Edm Diagram.

From tylercasteel.blogspot.com

wire edm machine working principle Tyler Casteel Wire Edm Diagram #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Extremely fine finishes of 12 rms can be produced with wire edm. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. 9 may 2022 by electrical workbook. Process, diagram, construction &. Wire Edm Diagram.

From finemetalworking.com

Wire EDM. Guide to EDM Wirecut Machine, Process & Uses Fine MetalWorking Wire Edm Diagram #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. The working principle of wire edm is same as that of conventional edm except that it uses a small diameter. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. Extremely fine finishes of 12 rms. Wire Edm Diagram.

From www.researchgate.net

(PDF) Experimental Study of Process Parameters through Dissimilar Form of Electrodes in EDM Wire Edm Diagram #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. Process, diagram, construction & applications. Extremely fine finishes of 12 rms can be produced with wire edm. 9 may 2022 by electrical workbook. No actual contact is made between the wire and the material, which prevents distorting the path of the wire. Wire Edm Diagram.

From huldakelso.blogspot.com

wire edm machine how it works Hulda Kelso Wire Edm Diagram #1 wire edm (wedm) in wire edm (wedm), a thin, electrically conductive wire is used as the electrode. While the workpiece is immersed in dielectric fluid, the wire is continuously fed through it. Wire electrical discharge machining (edm) is one of the greatest innovations affecting the tooling and machining. The working principle of wire edm is same as that of. Wire Edm Diagram.