How To Design A Rack And Pinion . Design, calculation, simulation of rack and pinion mechanismthe rack and. The fastest speeds reach 20 feet per minute. Module = 25.4 / diametral. The rack length defaults to the diameter of gear 2. In mechanical design, rotational and linear movement between components are often required. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. Maintain a controlled gap between the rack and pinion. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. For a rack and pinion, set n=0. The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius.

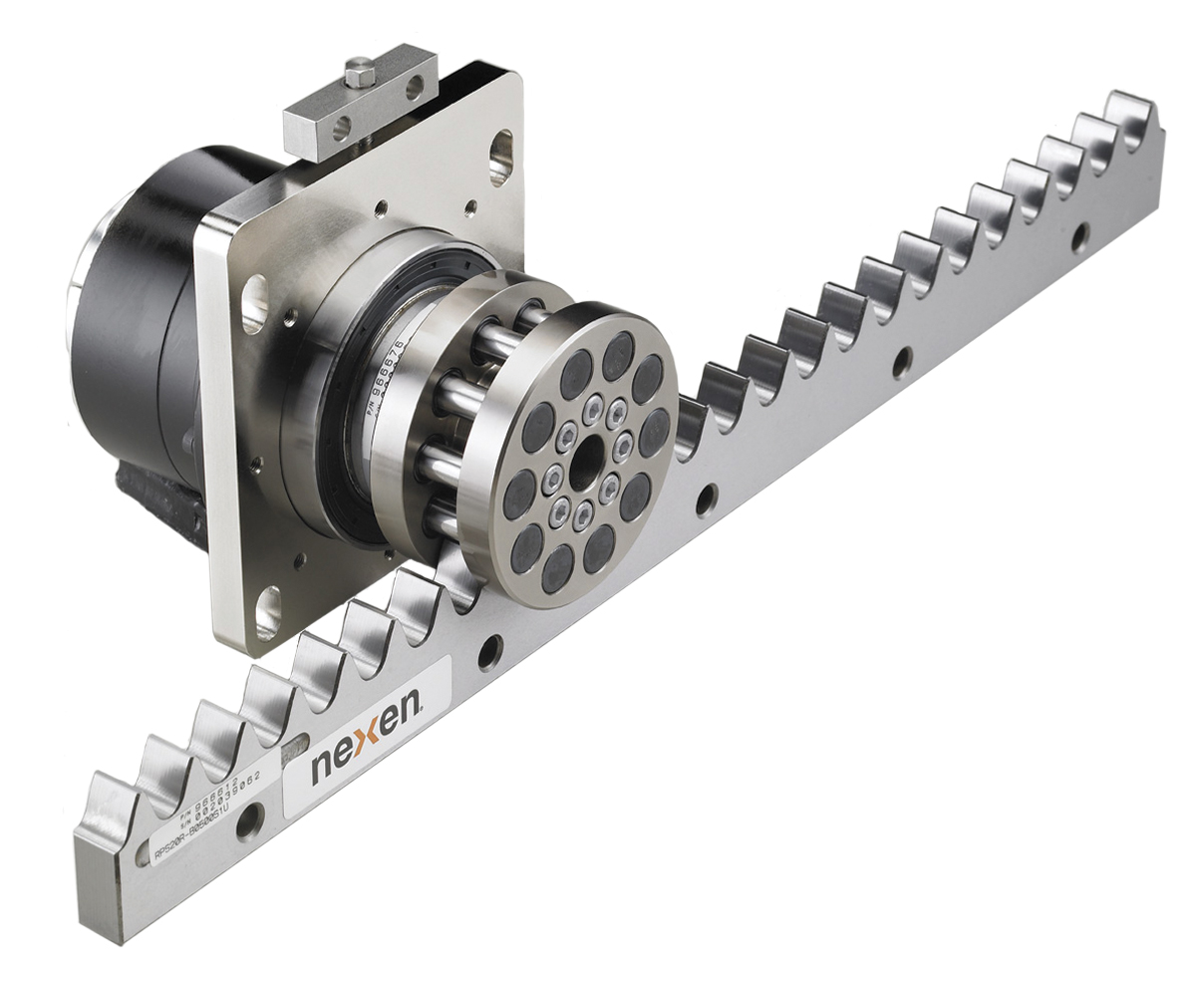

from www.designworldonline.com

One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. The rack length defaults to the diameter of gear 2. Design, calculation, simulation of rack and pinion mechanismthe rack and. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. Maintain a controlled gap between the rack and pinion. The fastest speeds reach 20 feet per minute. The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. Module = 25.4 / diametral. In mechanical design, rotational and linear movement between components are often required.

What are rackandpinion sets? Technical summary

How To Design A Rack And Pinion The rack length defaults to the diameter of gear 2. Design, calculation, simulation of rack and pinion mechanismthe rack and. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. The rack length defaults to the diameter of gear 2. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. Module = 25.4 / diametral. For a rack and pinion, set n=0. The fastest speeds reach 20 feet per minute. Maintain a controlled gap between the rack and pinion. In mechanical design, rotational and linear movement between components are often required. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation.

From www.youtube.com

Design Rack and Pinion Mechanism in Solidworks Solidworks Rack and How To Design A Rack And Pinion Maintain a controlled gap between the rack and pinion. In mechanical design, rotational and linear movement between components are often required. Design, calculation, simulation of rack and pinion mechanismthe rack and. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. One of the disadvantages to using circular pitch rack and pinion is that the mounting. How To Design A Rack And Pinion.

From www.youtube.com

⚡ SOLIDWORKS TUTORIAL 12 Design a rack and pinion mechanism with How To Design A Rack And Pinion The fastest speeds reach 20 feet per minute. Module = 25.4 / diametral. In mechanical design, rotational and linear movement between components are often required. Maintain a controlled gap between the rack and pinion. Design, calculation, simulation of rack and pinion mechanismthe rack and. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance. How To Design A Rack And Pinion.

From www.engineeringchoice.com

What is Rack and Pinion? Definition and Application Engineering Choice How To Design A Rack And Pinion In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. The fastest speeds reach 20 feet per minute. In mechanical design, rotational and linear movement between components are often required. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. For a rack and pinion, set n=0. Design, calculation, simulation. How To Design A Rack And Pinion.

From www.designworldonline.com

What are rackandpinion sets? Technical summary How To Design A Rack And Pinion In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. The rack length defaults to the diameter of gear 2. The fastest speeds reach 20 feet per minute. Module = 25.4 / diametral. The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. For a rack and. How To Design A Rack And Pinion.

From www.youtube.com

design and assembly of rack and pinion gear in SOLIDWORKS using toolbox How To Design A Rack And Pinion In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. The rack length defaults to the diameter of gear 2. For a rack and pinion, set n=0. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. Module = 25.4 / diametral.. How To Design A Rack And Pinion.

From www.youtube.com

SOLIDWORKS Rack and Pinion YouTube How To Design A Rack And Pinion Design, calculation, simulation of rack and pinion mechanismthe rack and. The rack length defaults to the diameter of gear 2. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. The fastest speeds reach 20 feet per minute. The torque on the pinion is simply the tangential force (force on the rack) multiplied by. How To Design A Rack And Pinion.

From by-digital-designs.netlify.app

Rack And Pinion Design Calculations Pdf at Design How To Design A Rack And Pinion In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. Maintain a controlled gap between the rack and pinion. Design, calculation, simulation of rack and pinion mechanismthe rack and. The rack length defaults to the diameter of gear 2. For. How To Design A Rack And Pinion.

From www.youtube.com

ME05 rack & pinion gears YouTube How To Design A Rack And Pinion In mechanical design, rotational and linear movement between components are often required. Module = 25.4 / diametral. The fastest speeds reach 20 feet per minute. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. Maintain a controlled gap between the rack and pinion. For a. How To Design A Rack And Pinion.

From www.onallcylinders.com

Rack and Pinion Revisited A Basic Guide to Rack and Pinion Steering How To Design A Rack And Pinion In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. Design, calculation, simulation of rack and pinion mechanismthe rack and. Maintain a controlled gap between the rack and pinion. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. The torque on. How To Design A Rack And Pinion.

From userdataparalogize.z21.web.core.windows.net

Rack And Pinion Schematic Diagram How To Design A Rack And Pinion The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. Design,. How To Design A Rack And Pinion.

From www.youtube.com

Rack & Pinion Building Instructions No. 1 YouTube How To Design A Rack And Pinion Module = 25.4 / diametral. The rack length defaults to the diameter of gear 2. The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. Maintain a controlled gap between the rack and pinion. Design, calculation, simulation of rack and pinion mechanismthe rack and. The fastest speeds reach 20 feet per. How To Design A Rack And Pinion.

From grabcad.com

How to create Rack & Pinion using Inventor 2016 GrabCAD Tutorials How To Design A Rack And Pinion In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. Maintain a controlled gap between the rack and pinion. Module = 25.4 / diametral. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. The fastest speeds reach 20 feet per minute. For a rack and pinion, set n=0. In. How To Design A Rack And Pinion.

From www.norship.com.au

Rack and Pinion 2 Norship Marine How To Design A Rack And Pinion In mechanical design, rotational and linear movement between components are often required. For a rack and pinion, set n=0. Design, calculation, simulation of rack and pinion mechanismthe rack and. The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. The fastest speeds reach 20 feet per minute. In the assembly below,. How To Design A Rack And Pinion.

From www.slideserve.com

PPT RackandPinion Steering PowerPoint Presentation ID2815041 How To Design A Rack And Pinion Design, calculation, simulation of rack and pinion mechanismthe rack and. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in. How To Design A Rack And Pinion.

From ar.inspiredpencil.com

Rack And Pinion Gear Design How To Design A Rack And Pinion In mechanical design, rotational and linear movement between components are often required. The rack length defaults to the diameter of gear 2. Maintain a controlled gap between the rack and pinion. For a rack and pinion, set n=0. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to. How To Design A Rack And Pinion.

From www.youtube.com

SolidWorks tutorial Rack And Pinion YouTube How To Design A Rack And Pinion In mechanical design, rotational and linear movement between components are often required. The fastest speeds reach 20 feet per minute. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. The torque on the pinion is simply the tangential force (force on the rack) multiplied by. How To Design A Rack And Pinion.

From www.racingjunk.com

How to Diagnose and Repair Rack and Pinion Bushings RacingJunk News How To Design A Rack And Pinion One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. Maintain a controlled gap between the rack and pinion. The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. The fastest speeds reach 20 feet per minute.. How To Design A Rack And Pinion.

From www.autozone.com

Repair Guides Steering Manual Steering/rack And Pinion How To Design A Rack And Pinion The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. Design, calculation, simulation of rack and pinion mechanismthe rack and. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. The rack length defaults to the diameter of gear 2. For a rack and pinion, set n=0.. How To Design A Rack And Pinion.

From design.udlvirtual.edu.pe

How Does Rack And Pinion Steering Work On A Boat Design Talk How To Design A Rack And Pinion In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. In mechanical design, rotational and linear movement between components are often required. For a rack and pinion, set n=0. Design, calculation, simulation of rack and pinion mechanismthe rack and. Module = 25.4 / diametral. One of the disadvantages to using circular pitch rack and pinion is. How To Design A Rack And Pinion.

From www.linearmotiontips.com

How to account for rack and pinion inertia during system design How To Design A Rack And Pinion The fastest speeds reach 20 feet per minute. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. The rack length defaults to the diameter of gear 2. In mechanical design, rotational and linear movement between components are often required. One of the disadvantages to using circular pitch rack and pinion is that the. How To Design A Rack And Pinion.

From www.thomasnet.com

All About Rack and Pinion Gears What They Are and How They Work How To Design A Rack And Pinion Module = 25.4 / diametral. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. In mechanical design, rotational and linear movement between components are often required. Maintain a controlled gap between the rack and. How To Design A Rack And Pinion.

From www.youtube.com

⚡ Solidworks Mechanical Mate Rack and pinion Screw YouTube How To Design A Rack And Pinion In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. Module = 25.4 / diametral. The rack length defaults to the diameter of gear 2. In mechanical design, rotational and. How To Design A Rack And Pinion.

From www.youtube.com

Creo Parametric Mechanisms Rack and Pinion Gear Connection YouTube How To Design A Rack And Pinion Module = 25.4 / diametral. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. Maintain a controlled gap between the rack and pinion. The fastest speeds reach 20 feet per minute. For a rack and pinion, set n=0. In mechanical design, rotational and linear movement between components are often required. Design, calculation, simulation of rack. How To Design A Rack And Pinion.

From www.obdadvisor.com

Steering Systems and Suspension Systems (SAS) A Close Look OBD Advisor How To Design A Rack And Pinion One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. Module = 25.4 / diametral. The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. In rack and pinion gear design, ensuring appropriate clearances is crucial for. How To Design A Rack And Pinion.

From www.researchgate.net

display working principle of rack and pinion mechanism and internal How To Design A Rack And Pinion In mechanical design, rotational and linear movement between components are often required. The fastest speeds reach 20 feet per minute. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. Design, calculation, simulation of rack and pinion mechanismthe rack and. Module = 25.4 / diametral. For a rack and pinion, set n=0. One of. How To Design A Rack And Pinion.

From grabcad.com

How to create Rack & Pinion using Inventor 2016 GrabCAD Tutorials How To Design A Rack And Pinion The rack length defaults to the diameter of gear 2. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. The fastest speeds reach 20 feet per minute. Module = 25.4 / diametral. In mechanical design, rotational and linear movement between components are often required. The. How To Design A Rack And Pinion.

From www.youtube.com

Rack and Pinion Steering System YouTube How To Design A Rack And Pinion In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. Maintain a controlled gap between the rack and pinion. Design, calculation, simulation of rack and pinion mechanismthe rack and. In mechanical design, rotational and linear movement between components are often required. The fastest speeds reach 20 feet per minute. For a rack and pinion, set n=0.. How To Design A Rack And Pinion.

From www.youtube.com

Design Rack and pinion gear drive Autodesk Inventor YouTube How To Design A Rack And Pinion In mechanical design, rotational and linear movement between components are often required. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. The rack length defaults to the diameter of. How To Design A Rack And Pinion.

From www.youtube.com

Making The Reciprocating Rack & Pinion YouTube How To Design A Rack And Pinion Maintain a controlled gap between the rack and pinion. The fastest speeds reach 20 feet per minute. The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. Design, calculation, simulation of rack and pinion mechanismthe rack and. The rack length defaults to the diameter of gear 2. In the assembly below,. How To Design A Rack And Pinion.

From www.youtube.com

Rack & Pinion Installation Tips YouTube How To Design A Rack And Pinion Maintain a controlled gap between the rack and pinion. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. In mechanical design, rotational and linear movement between components are often required. Design, calculation, simulation of rack and pinion mechanismthe rack and. The torque on the pinion is simply the tangential force (force on the. How To Design A Rack And Pinion.

From www.designworldonline.com

What are rackandpinion sets? Technical summary How To Design A Rack And Pinion In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. The fastest speeds reach 20 feet per minute. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. The rack length defaults to the diameter of gear 2. The torque on the pinion is simply the tangential force (force on. How To Design A Rack And Pinion.

From www.youtube.com

ME 340 Modeling of a RackandPinion System YouTube How To Design A Rack And Pinion The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. Module = 25.4 / diametral. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in. How To Design A Rack And Pinion.

From grabcad.com

How to create Rack & Pinion using Inventor 2016 GrabCAD Tutorials How To Design A Rack And Pinion Module = 25.4 / diametral. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. The fastest speeds reach 20 feet per minute. The rack length defaults to the diameter of gear 2. In the assembly below, a motor attached to a gearbox drives a rack and pinion setup. Design, calculation, simulation of rack and pinion. How To Design A Rack And Pinion.

From climate-controls.com

rack and pinions rack&pinions Climate Controls How To Design A Rack And Pinion One of the disadvantages to using circular pitch rack and pinion is that the mounting distance of the pinion in relation to the pitch. The fastest speeds reach 20 feet per minute. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. The rack length defaults to the diameter of gear 2. The torque on the. How To Design A Rack And Pinion.

From www.researchgate.net

Sideways motion of the rack and pinion gear Download Scientific Diagram How To Design A Rack And Pinion The torque on the pinion is simply the tangential force (force on the rack) multiplied by the pinion radius. The rack length defaults to the diameter of gear 2. Module = 25.4 / diametral. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. In mechanical design, rotational and linear movement between components are often required.. How To Design A Rack And Pinion.