Motor Grounding Brush . Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Compare different types of rings and how to install them for optimal performance. A shaft grounding system provides the electrical current a more ideal path to reach the ground. Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Anglocarbon manufacture and supply a range of grounding brushes for use in axle earthing, electric motors, wind turbines. Shaft groundings stop the energy from causing harm to vulnerable motor parts. These devices redirect electrical current away from sensitive. Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. The carbon brush leads the current away from the motor bearings and allows the electricity to leave the motor in a controlled fashion. Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. Electric motors run by variable. Extend the service life of your equipment with schunk's innovative shaft grounding solutions:

from www.emersonbearing.com

Shaft groundings stop the energy from causing harm to vulnerable motor parts. A shaft grounding system provides the electrical current a more ideal path to reach the ground. These devices redirect electrical current away from sensitive. Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. Compare different types of rings and how to install them for optimal performance. Anglocarbon manufacture and supply a range of grounding brushes for use in axle earthing, electric motors, wind turbines. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components.

Shaft Grounding Devices Emerson Bearing

Motor Grounding Brush Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. Anglocarbon manufacture and supply a range of grounding brushes for use in axle earthing, electric motors, wind turbines. Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. A shaft grounding system provides the electrical current a more ideal path to reach the ground. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. Electric motors run by variable. Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Shaft groundings stop the energy from causing harm to vulnerable motor parts. Compare different types of rings and how to install them for optimal performance. Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. These devices redirect electrical current away from sensitive. The carbon brush leads the current away from the motor bearings and allows the electricity to leave the motor in a controlled fashion.

From nems.com.au

40x20x40 GAMESA Grounding Brush National Electric Motor Services Motor Grounding Brush These devices redirect electrical current away from sensitive. Anglocarbon manufacture and supply a range of grounding brushes for use in axle earthing, electric motors, wind turbines. The carbon brush leads the current away from the motor bearings and allows the electricity to leave the motor in a controlled fashion. Thus the current gets diverted from the motor’s internal parts and. Motor Grounding Brush.

From nems.com.au

1690 CO Grounding Brush National Electric Motor Services Australia Motor Grounding Brush Anglocarbon manufacture and supply a range of grounding brushes for use in axle earthing, electric motors, wind turbines. Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Electric motors run by variable. A shaft grounding system provides the. Motor Grounding Brush.

From www.broadcarbon.com

AG20/EG5U Shaft Grounding Carbon Brush Motor Grounding Brush Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. Electric motors run by variable. Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. Emerson bearing offers various shaft. Motor Grounding Brush.

From www.hpac.com

Baldor Introduces ShaftGrounding Brush HPAC Engineering Motor Grounding Brush Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. Compare different types of rings and how to install them for optimal performance. These devices redirect electrical current away from sensitive. Anglocarbon manufacture and supply a range of grounding brushes for use in axle earthing, electric motors, wind turbines. Emerson bearing offers. Motor Grounding Brush.

From nems.com.au

25x12.5x64 Multibrand Grounding Brush NEMS Motor Grounding Brush Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. These devices redirect electrical current away from sensitive. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Anglocarbon manufacture and supply a range of grounding brushes for use in axle earthing, electric motors, wind turbines. Electro static technology’s aegis® shaft grounding. Motor Grounding Brush.

From www.schunk-group.com

Brush Holder for Shaft Grounding (Power Plants) Schunk Carbon Technology Motor Grounding Brush Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Shaft groundings stop the energy from causing harm to vulnerable motor parts. Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Compare different types of rings. Motor Grounding Brush.

From atechcs.com

baldor SuperE motor with BaldorReliance shaft grounding brush A Motor Grounding Brush Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. These devices redirect electrical current away from sensitive. Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Emerson bearing offers various shaft grounding products for different motor sizes and. Motor Grounding Brush.

From www.ecogate.com

Should Shaft Grounding be Used When a Motor is Used with a Variable Motor Grounding Brush Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Shaft groundings stop the energy from causing harm to vulnerable. Motor Grounding Brush.

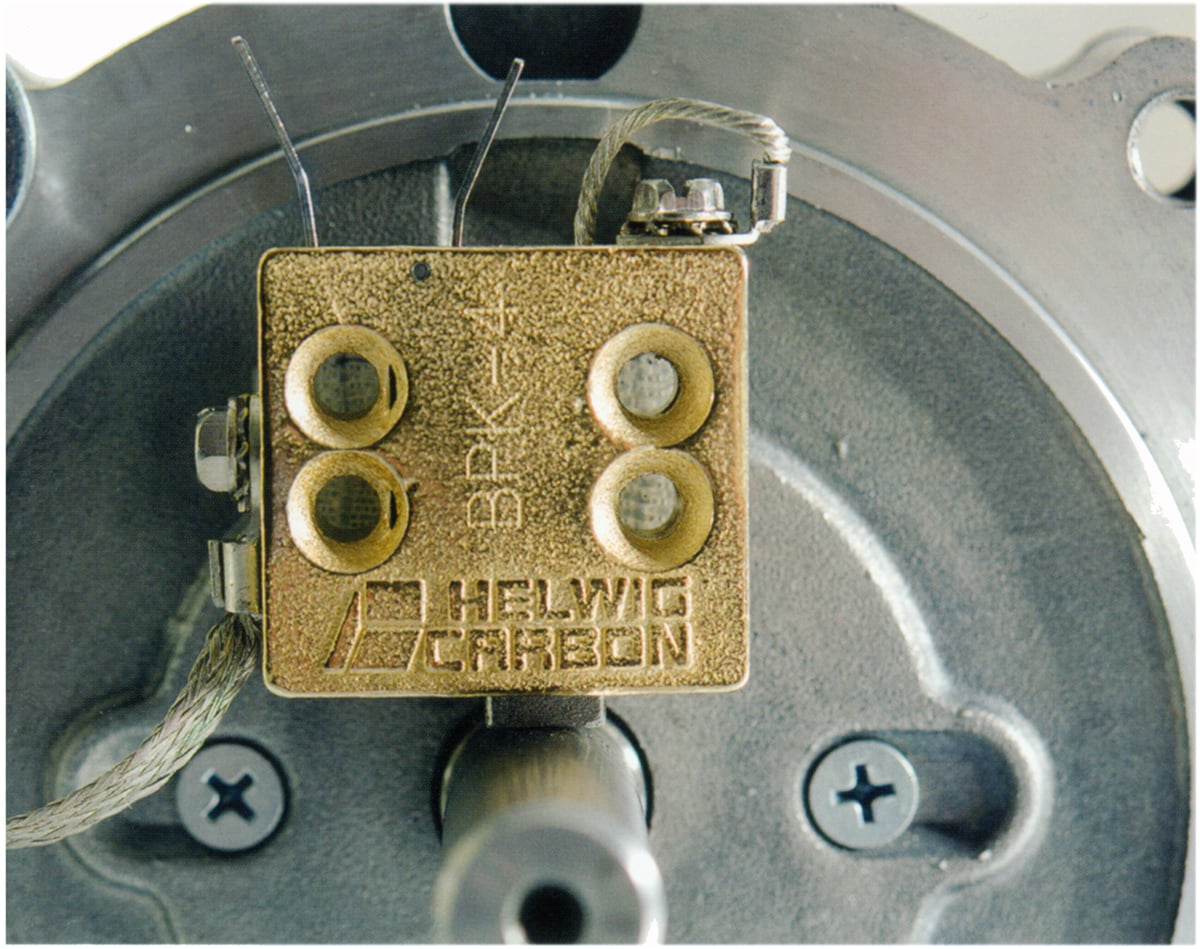

From www.helwigcarbon.com

Shaft Grounding The Industry's Best Shaft Grouding Solution Motor Grounding Brush Compare different types of rings and how to install them for optimal performance. Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. Electric motors run by variable. The carbon brush leads the. Motor Grounding Brush.

From new.abb.com

Baldor shaft grounding brushes come standard on all EC Titanium Motor Grounding Brush The carbon brush leads the current away from the motor bearings and allows the electricity to leave the motor in a controlled fashion. A shaft grounding system provides the electrical current a more ideal path to reach the ground. Anglocarbon manufacture and supply a range of grounding brushes for use in axle earthing, electric motors, wind turbines. Electric motors run. Motor Grounding Brush.

From www.sohreturbo.com

Brush Types Sohre Turbomachinery Motor Grounding Brush Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. Electric motors run by variable. Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. A shaft grounding system provides. Motor Grounding Brush.

From emotorpro.com

Baldor EM3313TBG Three Phase SuperE Motor w/Shaft Grounding Brush Motor Grounding Brush A shaft grounding system provides the electrical current a more ideal path to reach the ground. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts. Motor Grounding Brush.

From www.indiamart.com

Shaft Grounding Brush at Rs 995 Carbon Brush in Mumbai ID Motor Grounding Brush Compare different types of rings and how to install them for optimal performance. Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Shaft groundings stop the energy from causing harm to vulnerable motor parts. Anglocarbon manufacture and supply a range of grounding brushes for use in axle earthing,. Motor Grounding Brush.

From www.helwigcarbon.com

Shaft Grounding The Industry's Best Shaft Grouding Solution Motor Grounding Brush Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Thus the current gets diverted from the motor’s internal parts. Motor Grounding Brush.

From www.indiamart.com

motor grounding brush at Rs 1250/piece in Mumbai ID 2852114277055 Motor Grounding Brush These devices redirect electrical current away from sensitive. Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. A shaft grounding system provides the electrical current a more ideal path to reach the ground. Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility. Motor Grounding Brush.

From www.alibaba.com

T825 Electric Grounding Carbon Brush Buy Mc79p Carbon Motor Grounding Brush Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. Shaft groundings stop the energy from causing harm to vulnerable motor parts. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Compare different types of rings and. Motor Grounding Brush.

From www.helwigcarbon.com

WEG Motors with BPKs™ Shaft Grounding System Motor Grounding Brush Electric motors run by variable. Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. These devices redirect electrical current away from sensitive. Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. Anglocarbon manufacture and supply a range. Motor Grounding Brush.

From www.machinedesign.com

Electric Motors with ShaftGrounding Brush Machine Design Motor Grounding Brush The carbon brush leads the current away from the motor bearings and allows the electricity to leave the motor in a controlled fashion. Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Shaft groundings stop the energy from causing harm to vulnerable motor parts. Learn why shaft grounding. Motor Grounding Brush.

From blog.est-aegis.com

How Do Shaft Grounding Brushes Compare with AEGIS Rings? Motor Grounding Brush These devices redirect electrical current away from sensitive. Anglocarbon manufacture and supply a range of grounding brushes for use in axle earthing, electric motors, wind turbines. Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and. Motor Grounding Brush.

From emotorpro.com

Baldor EM3615T5G Three Phase SuperE Motor w/Shaft Grounding Brush Motor Grounding Brush Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Compare different types of rings and how to install them. Motor Grounding Brush.

From www.emersonbearing.com

Shaft Grounding Devices Emerson Bearing Motor Grounding Brush Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Compare different types of rings and how to install them for optimal performance. Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Learn why shaft grounding. Motor Grounding Brush.

From www.anglocarbon.com

Grounding Brushes Anglo Carbon & Contacts Ltd Motor Grounding Brush Shaft groundings stop the energy from causing harm to vulnerable motor parts. Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and. Motor Grounding Brush.

From www.schunk-group.com

Grounding Brushes Schunk Carbon Technology Motor Grounding Brush Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. These devices redirect electrical current away from sensitive. The carbon brush leads the current away from the motor bearings and allows. Motor Grounding Brush.

From www.helwigcarbon.com

Why Motor OEMs Choose Our Shaft Grounding Solutions Helwig Carbon Motor Grounding Brush The carbon brush leads the current away from the motor bearings and allows the electricity to leave the motor in a controlled fashion. Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Electric motors run by variable. Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. Compare different types of. Motor Grounding Brush.

From www.ebay.com

Air Compressor Drive Motor Grounding Brushes (20 per Lot) p/n T155541 Motor Grounding Brush These devices redirect electrical current away from sensitive. Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Shaft groundings stop the energy from causing harm to vulnerable motor parts. Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. Carbon fiber grounding brushes and grounding systems reliably dissipate. Motor Grounding Brush.

From www.emersonbearing.com

Shaft Grounding Devices Emerson Bearing Motor Grounding Brush These devices redirect electrical current away from sensitive. Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. Shaft groundings. Motor Grounding Brush.

From www.helwigcarbon.com

Shaft Grounding The Industry's Best Shaft Grouding Solution Motor Grounding Brush Carbon fiber grounding brushes and grounding systems reliably dissipate shaft. Compare different types of rings and how to install them for optimal performance. Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe. Motor Grounding Brush.

From blog.est-aegis.com

How Do Shaft Grounding Brushes Compare with AEGIS Rings? Motor Grounding Brush Compare different types of rings and how to install them for optimal performance. Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. A shaft grounding system provides the electrical current a more ideal path to reach the ground. Electric motors run by variable. Thus the current gets diverted from the. Motor Grounding Brush.

From www.manufacturing.net

SuperE Motors With Baldor Shaft Grounding Brush Motor Grounding Brush Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. Anglocarbon manufacture and supply a range of grounding. Motor Grounding Brush.

From nems.com.au

E1716 Grounding Brush National Electric Motor Services Australia Motor Grounding Brush Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Emerson bearing offers various shaft grounding products for different motor sizes and applications, protecting bearings and electronics from damage and failure. Electric motors run by variable. A shaft grounding system provides the electrical current a more ideal path to reach the ground. Thus the current gets diverted. Motor Grounding Brush.

From new.abb.com

Baldor shaft grounding brushes come standard on all EC Titanium Motor Grounding Brush Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. Shaft groundings stop the energy from causing harm to vulnerable motor parts. Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from. Motor Grounding Brush.

From www.indiamart.com

motor shaft grounding brush at Rs 995/piece in Mumbai ID 2852114266155 Motor Grounding Brush Shaft grounding devices redirect extraneous electrical current that accumulates on motor shafts away from more sensitive motor components. The carbon brush leads the current away from the motor bearings and allows the electricity to leave the motor in a controlled fashion. A shaft grounding system provides the electrical current a more ideal path to reach the ground. Anglocarbon manufacture and. Motor Grounding Brush.

From www.alibaba.com

T825 Electric Grounding Carbon Brush Buy Mc79p Carbon Motor Grounding Brush Shaft groundings stop the energy from causing harm to vulnerable motor parts. Electro static technology’s aegis® shaft grounding rings are used in millions of motors across the globe to prevent bearing damage and failure. Extend the service life of your equipment with schunk's innovative shaft grounding solutions: Emerson bearing offers various shaft grounding products for different motor sizes and applications,. Motor Grounding Brush.

From www.machinedesign.com

Electric Motors with ShaftGrounding Brush Machine Design Motor Grounding Brush Learn why shaft grounding rings are necessary to protect motors operated by variable frequency drives (vfd) from bearing failure. A shaft grounding system provides the electrical current a more ideal path to reach the ground. Shaft groundings stop the energy from causing harm to vulnerable motor parts. The carbon brush leads the current away from the motor bearings and allows. Motor Grounding Brush.

From www.tecnoseal-online-catalogue.it

07155 Silver shaft grounding silver bathed ring and brushers Ø 155 Motor Grounding Brush Compare different types of rings and how to install them for optimal performance. The carbon brush leads the current away from the motor bearings and allows the electricity to leave the motor in a controlled fashion. Thus the current gets diverted from the motor’s internal parts and it eliminates the possibility of bearings damage. Learn why shaft grounding rings are. Motor Grounding Brush.