Mold Assembly Unit . Inserts can be plastic mold components or metallic if strength is necessary. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. The mold then closes over it, and the injection process begins. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. It is very common to carry. An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape.

from www.chegg.com

An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. It is very common to carry. The mold then closes over it, and the injection process begins. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. Inserts can be plastic mold components or metallic if strength is necessary.

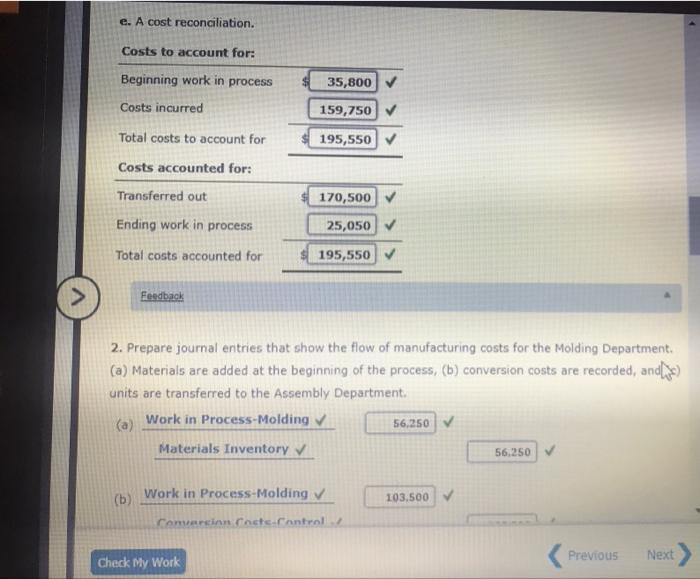

Solved Molding Assembly Beginning inventories Physical

Mold Assembly Unit However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. It is very common to carry. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. Inserts can be plastic mold components or metallic if strength is necessary. An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. The mold then closes over it, and the injection process begins.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Mold Assembly Unit However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. Inserts can be plastic mold components or metallic if strength is necessary. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring. Mold Assembly Unit.

From www.chinamoldmaker.org

injection mold slider design Mold Assembly Unit However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. It is very common to carry. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. An injection mold. Mold Assembly Unit.

From www.chegg.com

Solved Molding Assembly Beginning inventories Physical Mold Assembly Unit It is very common to carry. Inserts can be plastic mold components or metallic if strength is necessary. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. Dive into the art of injection molding as we unravel key components and. Mold Assembly Unit.

From princetontool.com

Business Units Princeton Tool Mold Assembly Unit The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. It is very common to carry. An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape.. Mold Assembly Unit.

From www.kaysun.com

Injection Molding Step by Step How Are Plastic Parts Made? Mold Assembly Unit Inserts can be plastic mold components or metallic if strength is necessary. It is very common to carry. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. An injection mold is a tool comprised of a series of parts that. Mold Assembly Unit.

From www.levic.com

Outlining the Steps of Injection Molding Assembly in Kansas City Mold Assembly Unit Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. The mold then closes over it,. Mold Assembly Unit.

From www.dme.net

Mold Bases DME Mold Assembly Unit The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. The mold then closes over it,. Mold Assembly Unit.

From www.jtspune.com

Cement & Panel Jagruti Technical Services Pvt. Ltd. Pune, MH, India Mold Assembly Unit The mold then closes over it, and the injection process begins. An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. Inserts can be plastic mold components or metallic if strength is necessary. The work of assembling a. Mold Assembly Unit.

From www.chiefmoldusa.com

Chief Mold USA Mold Assembly Unit The mold then closes over it, and the injection process begins. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the. Mold Assembly Unit.

From prototool.com

InMold Assembly Revolutionizing Modern Manufacturing Mold Assembly Unit Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. Inserts can be plastic mold components or metallic if strength is necessary. An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as. Mold Assembly Unit.

From www.karolwarner.com

1.875in TwoPart Compaction Mold Assembly KarolWarner Mold Assembly Unit Inserts can be plastic mold components or metallic if strength is necessary. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. The mold then closes over it, and the injection process begins. It is very common to carry. The work of assembling a plastic injection mold is. Mold Assembly Unit.

From www.matrixplastic.com

Matrix Plastic Products Injection Molding and Moldmaking with Mold Assembly Unit The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. Inserts can be plastic mold components or metallic if strength is necessary. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of. Mold Assembly Unit.

From www.slideserve.com

PPT CHANG WAH TECHNOLOGY CO., LTD (6548 TT) PowerPoint Presentation Mold Assembly Unit An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. Inserts can be plastic mold components or metallic if strength is necessary. It is very common to carry. The work of assembling a plastic injection mold is a. Mold Assembly Unit.

From www.chegg.com

Solved Molding Assembly Beginning inventories Physical Mold Assembly Unit The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. It is very common to carry. Dive into the. Mold Assembly Unit.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Mold Assembly Unit The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. The mold then closes over it, and the injection process begins. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the. Mold Assembly Unit.

From www.chegg.com

Solved Molding Assembly Beginning inventories Physical Mold Assembly Unit Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. The mold then closes over it, and the injection process begins. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. Inserts can be plastic mold. Mold Assembly Unit.

From www.indiamart.com

Mold Assembly Table, For Standard at Rs 39900 in Pune ID 2851967176588 Mold Assembly Unit The mold then closes over it, and the injection process begins. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the. Mold Assembly Unit.

From www.iqsdirectory.com

Thermoplastic Molding Process, Types, Materials, and Applications Mold Assembly Unit An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. Inserts can be plastic mold components or metallic if strength is necessary. The mold then closes over it, and the injection process begins. The work of assembling a. Mold Assembly Unit.

From www.sunrise-metal.com

Die Cast Aluminum Mold Sunrise Metal Aluminium Die Casting Expert Mold Assembly Unit However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. Inserts can be plastic mold components or metallic if. Mold Assembly Unit.

From www.winstonheinrichs.com

Injection Mold Assembly WINSTON HEINRICHS Mold Assembly Unit An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. The mold then closes over it,. Mold Assembly Unit.

From rdplast.com

Engineering R&D Plastics Mold Assembly Unit The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. Inserts can be plastic mold components or metallic if strength is necessary. The mold then closes over it, and the injection process begins. It is very common to carry. An injection mold is a tool comprised of a. Mold Assembly Unit.

From www.iqsdirectory.com

Thermoplastic Molding Process, Types, Materials, and Applications Mold Assembly Unit It is very common to carry. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. The mold then closes over it, and the injection process begins. An injection mold is a tool comprised of a series of parts that allows. Mold Assembly Unit.

From alleycho.com

Main Unit and Equipment of Toshiba Injection Molding Machines Mold Assembly Unit An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process. Mold Assembly Unit.

From www.ameraproducts.com

Brocar by Foundations Plastic Assembly Replacement for Full Stainless Mold Assembly Unit Inserts can be plastic mold components or metallic if strength is necessary. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. An injection mold is. Mold Assembly Unit.

From www.plasticmoulds.net

How much plastic mold & injection molding,china tooling cost analysis blog Mold Assembly Unit Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. The mold then closes over it, and the injection process begins. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the. Mold Assembly Unit.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Mold Assembly Unit Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. Inserts can be plastic mold components or metallic if strength is necessary. It is very common. Mold Assembly Unit.

From hanoimould.com

Mold assembly line Mold Assembly Unit Inserts can be plastic mold components or metallic if strength is necessary. An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold. Mold Assembly Unit.

From www.milacron.com

MoldMasters Hot Runners Milacron Mold Assembly Unit It is very common to carry. Inserts can be plastic mold components or metallic if strength is necessary. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold. Mold Assembly Unit.

From exyvgstfg.blob.core.windows.net

Plastic Injection Molding Automotive Parts at Christine Van blog Mold Assembly Unit Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. Inserts can be plastic mold components or metallic if strength is necessary. It is very common to carry. The mold then closes over it, and the injection process begins. The work of assembling a plastic injection mold is. Mold Assembly Unit.

From blogs.sw.siemens.com

Deliver Top Quality Injection Molds 40 Faster with EndtoEnd Mold Assembly Unit The mold then closes over it, and the injection process begins. An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly,. Mold Assembly Unit.

From exoiisphe.blob.core.windows.net

How Many Types Of Nozzle In Injection Moulding Machine at Larry Wicker blog Mold Assembly Unit The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold. Mold Assembly Unit.

From www.iqsdirectory.com

Plastic Injection Molding What Is It? How Does It Work? Mold Assembly Unit It is very common to carry. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. An injection mold. Mold Assembly Unit.

From www.karolwarner.com

1.4in TwoPart Compaction Mold Assembly KarolWarner Mold Assembly Unit The mold then closes over it, and the injection process begins. Dive into the art of injection molding as we unravel key components and parts of an injection mold, exploring innovation in manufacturing. It is very common to carry. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is. Mold Assembly Unit.

From hanoimould.com

Mold assembly line Mold Assembly Unit An injection mold is a tool comprised of a series of parts that allows molten plastic to be formed and cooled in such a way as to create a discrete part shape. The work of assembling a plastic injection mold is a process step that is always necessary whenever a new mold is prepared. The mold then closes over it,. Mold Assembly Unit.

From en.wikipedia.org

Injection moulding Wikipedia Mold Assembly Unit It is very common to carry. However, regardless of their design, all injection molding machines utilize a power source, injection unit, mold assembly, and clamping unit to perform the four stages of the process cycle. Inserts can be plastic mold components or metallic if strength is necessary. Dive into the art of injection molding as we unravel key components and. Mold Assembly Unit.