Tapping Aluminum Extrusion . So easy to tap 80/20 or other extruded aluminum. In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat and chip creation/disposal. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. You can use aluminum tap magic as it's inexpensive and readily available. Thank you so much if you get your bits here: Holes are already to size and will be at the end of. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. Keys to drilling and tapping aluminum. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. I uses to use the hex shank drill bit type of taps.

from www.machineryoffers.com

Keys to drilling and tapping aluminum. Thank you so much if you get your bits here: Holes are already to size and will be at the end of. You can use aluminum tap magic as it's inexpensive and readily available. If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. I uses to use the hex shank drill bit type of taps. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat and chip creation/disposal. So easy to tap 80/20 or other extruded aluminum.

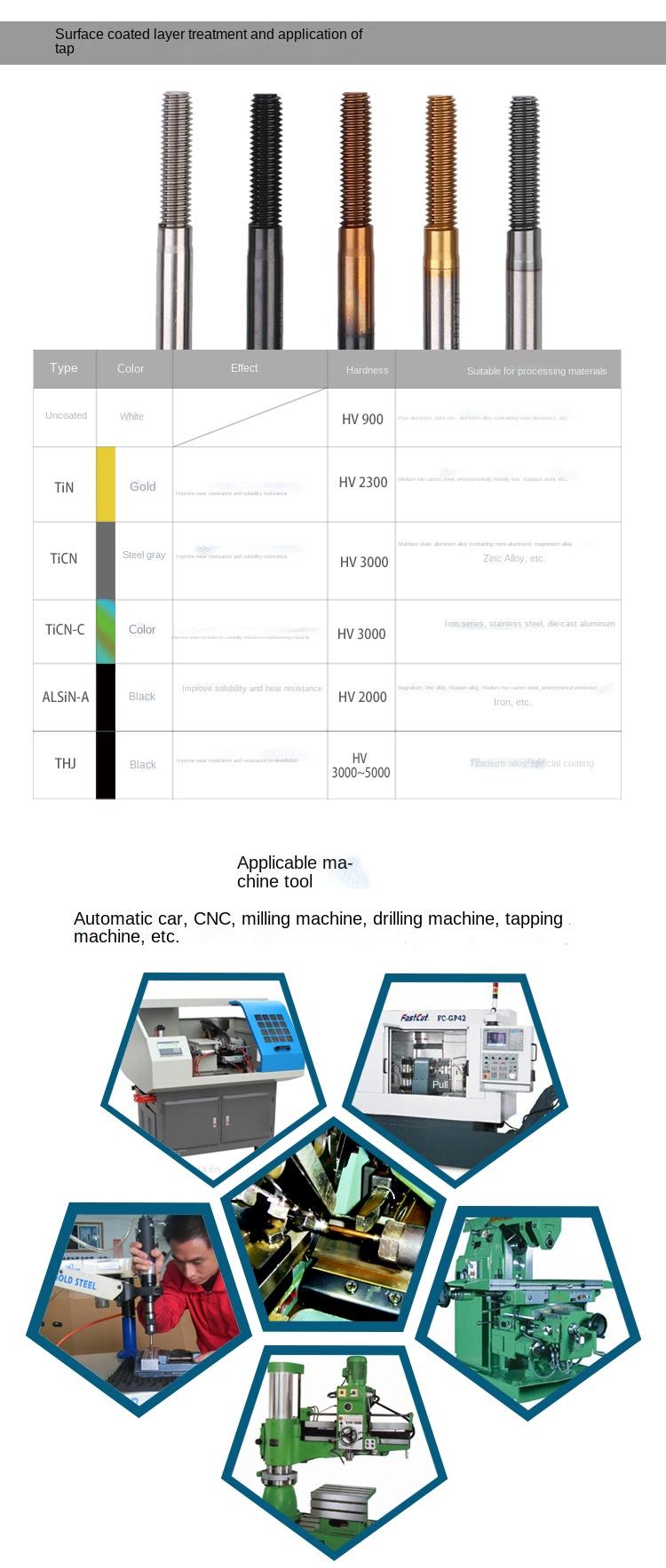

Tap XYC Extrusion Tap M2M3M4M5 Uncoated Machine Tapping Aluminum Powder

Tapping Aluminum Extrusion In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. I uses to use the hex shank drill bit type of taps. If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. Holes are already to size and will be at the end of. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. You can use aluminum tap magic as it's inexpensive and readily available. In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat and chip creation/disposal. Keys to drilling and tapping aluminum. So easy to tap 80/20 or other extruded aluminum. Thank you so much if you get your bits here:

From www.3dprintronics.com

2060 Black V Slot Aluminium Extrusion Profile Tapping Aluminum Extrusion We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. So easy to. Tapping Aluminum Extrusion.

From www.machineryoffers.com

Tap XYC Extrusion Tap M2M3M4M5 Uncoated Machine Tapping Aluminum Powder Tapping Aluminum Extrusion We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. Holes are already. Tapping Aluminum Extrusion.

From www.machineryoffers.com

Tap XYC Extrusion Tap M2M3M4M5 Uncoated Machine Tapping Aluminum Powder Tapping Aluminum Extrusion If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. Thank you so much if you get your bits here: Keys to drilling and tapping aluminum. Holes are already to size and will be at the end of. I uses to use the hex shank drill bit type. Tapping Aluminum Extrusion.

From www.metalplustech.com

Aluminum Extrusion Customized Anodized Enclosure Profile Drilling Tapping Aluminum Extrusion In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. I uses to use the hex shank drill bit type of taps. Holes are already to size and will be at the end of. You can use aluminum tap magic as it's inexpensive and readily available. Thread tapping the bore hole. Tapping Aluminum Extrusion.

From www.printables.com

Tapping Jig for 3030 and 3060 Aluminium Extrusion by TypQxQ Download Tapping Aluminum Extrusion If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding.. Tapping Aluminum Extrusion.

From beyer.app

Tom Beyer VORON 1.5 Tapping aluminium extrusions Tapping Aluminum Extrusion In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat and chip creation/disposal. If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions.. Tapping Aluminum Extrusion.

From www.jonshobbies.com

Part 5 First DIY CNC Project Drilling and Tapping Aluminum Extrusion Tapping Aluminum Extrusion I uses to use the hex shank drill bit type of taps. Keys to drilling and tapping aluminum. Thank you so much if you get your bits here: Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. In either case, you receive the power to craft tailored structures, apparatuses, and. Tapping Aluminum Extrusion.

From beyer.app

Tom Beyer VORON 1.5 Tapping aluminium extrusions Tapping Aluminum Extrusion Keys to drilling and tapping aluminum. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. So easy to tap 80/20 or other extruded aluminum. You can use aluminum tap magic as it's inexpensive and readily available. Holes are already to size and will be at the end of. I uses. Tapping Aluminum Extrusion.

From www.machineryoffers.com

Tap XYC Extrusion Tap M2M3M4M5 Uncoated Machine Tapping Aluminum Powder Tapping Aluminum Extrusion You can use aluminum tap magic as it's inexpensive and readily available. So easy to tap 80/20 or other extruded aluminum. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. Thank you so much if you get your bits here: If you're building a 3d printer or project that uses aluminum extrusion, chances. Tapping Aluminum Extrusion.

From b182eb44507bd860.en.made-in-china.com

Aluminum Profile Opening Custom Aluminum Alloy Power Supply Shell Tapping Aluminum Extrusion In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. You can use aluminum tap magic as it's inexpensive and readily available. So easy to tap 80/20 or other extruded aluminum. Holes are already to size and will be at the end of. In addition to tool geometry and coolant additives,. Tapping Aluminum Extrusion.

From welons09.en.made-in-china.com

High Quality Aluminum Extrusion Profile Customized Drilling and Tapping Tapping Aluminum Extrusion You can use aluminum tap magic as it's inexpensive and readily available. If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat and chip creation/disposal. I uses to use. Tapping Aluminum Extrusion.

From 3bd72f817db094ca.en.made-in-china.com

Aluminum Heat Sink CNC Tapping Machinery Aluminum Extrusion Profile Tapping Aluminum Extrusion We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. Keys to drilling and tapping aluminum. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat. Tapping Aluminum Extrusion.

From www.tslot.com.au

Supplier of Aluminium TSlot extrusions and accessories throughout Tapping Aluminum Extrusion In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. Keys to drilling and tapping aluminum. Holes are already to size and will be at the end of. In. Tapping Aluminum Extrusion.

From www.jonshobbies.com

Part 5 First DIY CNC Project Drilling and Tapping Aluminum Extrusion Tapping Aluminum Extrusion In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. Thank you so much if you get your bits here: Keys to drilling and tapping aluminum. So easy to tap 80/20 or other extruded aluminum. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions.. Tapping Aluminum Extrusion.

From www.youtube.com

KJN INSERTING SELF TAPPING SCREWS FOR ALUMINIUM PROFILE / EXTRUSION Tapping Aluminum Extrusion We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. Thank you so much if you get your bits here: Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using. Tapping Aluminum Extrusion.

From blog.airlinehyd.com

How to Build Anything with Aluminum Extrusion in Three Steps Tapping Aluminum Extrusion I uses to use the hex shank drill bit type of taps. Keys to drilling and tapping aluminum. In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat and chip creation/disposal. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. Holes. Tapping Aluminum Extrusion.

From www.aluminiumextrusionprofile.com

Alloy 6063 T5 Mill Finished Aluminium Extrusion Profiles , With Cutting Tapping Aluminum Extrusion If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. I uses to. Tapping Aluminum Extrusion.

From www.printables.com

Tapping Jig for 3030 and 3060 Aluminium Extrusion by TypQxQ Download Tapping Aluminum Extrusion So easy to tap 80/20 or other extruded aluminum. If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. Holes are already to size and will be at the end of. Thank. Tapping Aluminum Extrusion.

From www.amazon.com

BLCCLOY 4Pcs 2020 Series Aluminum Extrusion Profile Tapping Aluminum Extrusion Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. Thank you so much if you get your bits here: I uses to use the hex shank drill bit type of taps. Holes are already. Tapping Aluminum Extrusion.

From vention.io

Tapping Vention Extrusions How to guide Tapping Aluminum Extrusion If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. Keys to drilling and tapping aluminum. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. I uses to use the hex shank drill bit type of taps. Thank. Tapping Aluminum Extrusion.

From www.youtube.com

Horizontal Tapping Jig for Aluminum Extrusion Profiles 2020, 2040 V Tapping Aluminum Extrusion We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. I uses to use the hex shank drill bit type of taps. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. Thank you so much if you get your bits here: In either case,. Tapping Aluminum Extrusion.

From www.gapengineering.com.au

Why do we use an extrusion tap to form threads? GAP Engineering Tapping Aluminum Extrusion So easy to tap 80/20 or other extruded aluminum. I uses to use the hex shank drill bit type of taps. You can use aluminum tap magic as it's inexpensive and readily available. If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. In either case, you receive. Tapping Aluminum Extrusion.

From beyer-tom.de

Tom Beyer VORON 1.5 Tapping aluminium extrusions Tapping Aluminum Extrusion Holes are already to size and will be at the end of. In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat and chip creation/disposal. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. You can use aluminum tap magic as. Tapping Aluminum Extrusion.

From www.printables.com

20x20 aluminium extrusion Tapping Helper by MP3D Download free STL Tapping Aluminum Extrusion Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. Thank you so much if you get your bits here: If you're building a 3d printer or project that uses aluminum extrusion, chances are it will require tapping holes in the ends. We are undertaking a project that will involve tapping. Tapping Aluminum Extrusion.

From 3bd72f817db094ca.en.made-in-china.com

6061 T5 Aluminum Extrusion Heatsink Profile with CNC Drilling Tapping Tapping Aluminum Extrusion In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. Holes are already to size and will be at the end of. So easy to tap 80/20 or other extruded aluminum. In addition to tool. Tapping Aluminum Extrusion.

From gapengineering.com.au

How to create a strong join in aluminium tslot extrusion GAP Engineering Tapping Aluminum Extrusion In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. I uses to use the hex shank drill bit type of taps. Thank you so much if you get your bits here: So easy to tap 80/20 or other extruded aluminum. Thread tapping the bore hole in a series 8 light. Tapping Aluminum Extrusion.

From www.canton-aluminum.com

CNC Tapping Aluminum Extrusion Service Tapping Aluminum Extrusion Thank you so much if you get your bits here: So easy to tap 80/20 or other extruded aluminum. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat and chip creation/disposal. You can use. Tapping Aluminum Extrusion.

From www.rocheindustry.com

Handbook The Ultimate Guide To Aluminum Extrusion Tapping Aluminum Extrusion We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. Keys to drilling and tapping aluminum. So easy to tap 80/20 or other extruded aluminum. Thank you so much if you get your bits here:. Tapping Aluminum Extrusion.

From pevlabs.com

PEV Labs We Make Things for People and Business DIY CO2 Laser Tapping Aluminum Extrusion You can use aluminum tap magic as it's inexpensive and readily available. I uses to use the hex shank drill bit type of taps. In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat and chip creation/disposal. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion. Tapping Aluminum Extrusion.

From www.machineryoffers.com

Tap XYC Extrusion Tap M2M3M4M5 Uncoated Machine Tapping Aluminum Powder Tapping Aluminum Extrusion Holes are already to size and will be at the end of. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. Thank you so much if you get your bits here: I uses to use the hex shank drill bit type of taps. If you're building a 3d printer or. Tapping Aluminum Extrusion.

From beyer-tom.de

Tom Beyer VORON 1.5 Tapping aluminium extrusions Tapping Aluminum Extrusion In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. Thank you so much if you get your bits here: Holes are already to size and will be at the end of. Keys to drilling and tapping aluminum. If you're building a 3d printer or project that uses aluminum extrusion, chances. Tapping Aluminum Extrusion.

From www.youtube.com

Tapping Aluminum Extrusion with A32 Tapping Arm YouTube Tapping Aluminum Extrusion I uses to use the hex shank drill bit type of taps. You can use aluminum tap magic as it's inexpensive and readily available. So easy to tap 80/20 or other extruded aluminum. We are undertaking a project that will involve tapping thousands of 5/16 holes in aluminum extrusions. Thank you so much if you get your bits here: Thread. Tapping Aluminum Extrusion.

From www.aluminumextrusionsprofiles.com

Pink Anodized Standard Aluminum Extrusion Profiles With Cnc Drilling Tapping Aluminum Extrusion Thank you so much if you get your bits here: You can use aluminum tap magic as it's inexpensive and readily available. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. Keys to drilling and tapping aluminum. If you're building a 3d printer or project that uses aluminum extrusion, chances. Tapping Aluminum Extrusion.

From www.youtube.com

Cut and Form Tapping Aluminum Extrusions Horizontal and Vertical Tapping Aluminum Extrusion In either case, you receive the power to craft tailored structures, apparatuses, and machinery without intricate machining or welding. In addition to tool geometry and coolant additives, proper aluminum tapping and drilling operations can mitigate the extreme heat and chip creation/disposal. So easy to tap 80/20 or other extruded aluminum. If you're building a 3d printer or project that uses. Tapping Aluminum Extrusion.

From robu.in

Buy EasyMech 20X20 T Slot Aluminium Extrusion Profile 750mm Tapping Aluminum Extrusion You can use aluminum tap magic as it's inexpensive and readily available. I uses to use the hex shank drill bit type of taps. Keys to drilling and tapping aluminum. Thread tapping the bore hole in a series 8 light 40x40 aluminium profile extrusion using an m8 x 1.25. In addition to tool geometry and coolant additives, proper aluminum tapping. Tapping Aluminum Extrusion.