Carbide Insert File Guide . Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Selecting the right insert grade for your specific. By kennametal metal cutting pros. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Step 1 for all grooving operations. Insert nose radius and the feed rate. When it comes to cutting tool selection, machinists have three basic choices: Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Determine the basic shape of the cutting insert. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Detailed information on turning inserts identification.

from www.icarbide.com

In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Insert nose radius and the feed rate. Selecting the right insert grade for your specific. When it comes to cutting tool selection, machinists have three basic choices: Detailed information on turning inserts identification. Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. By kennametal metal cutting pros. Step 1 for all grooving operations. From a strictly theoretical perspective, surface roughness can be calculated from the following formula:

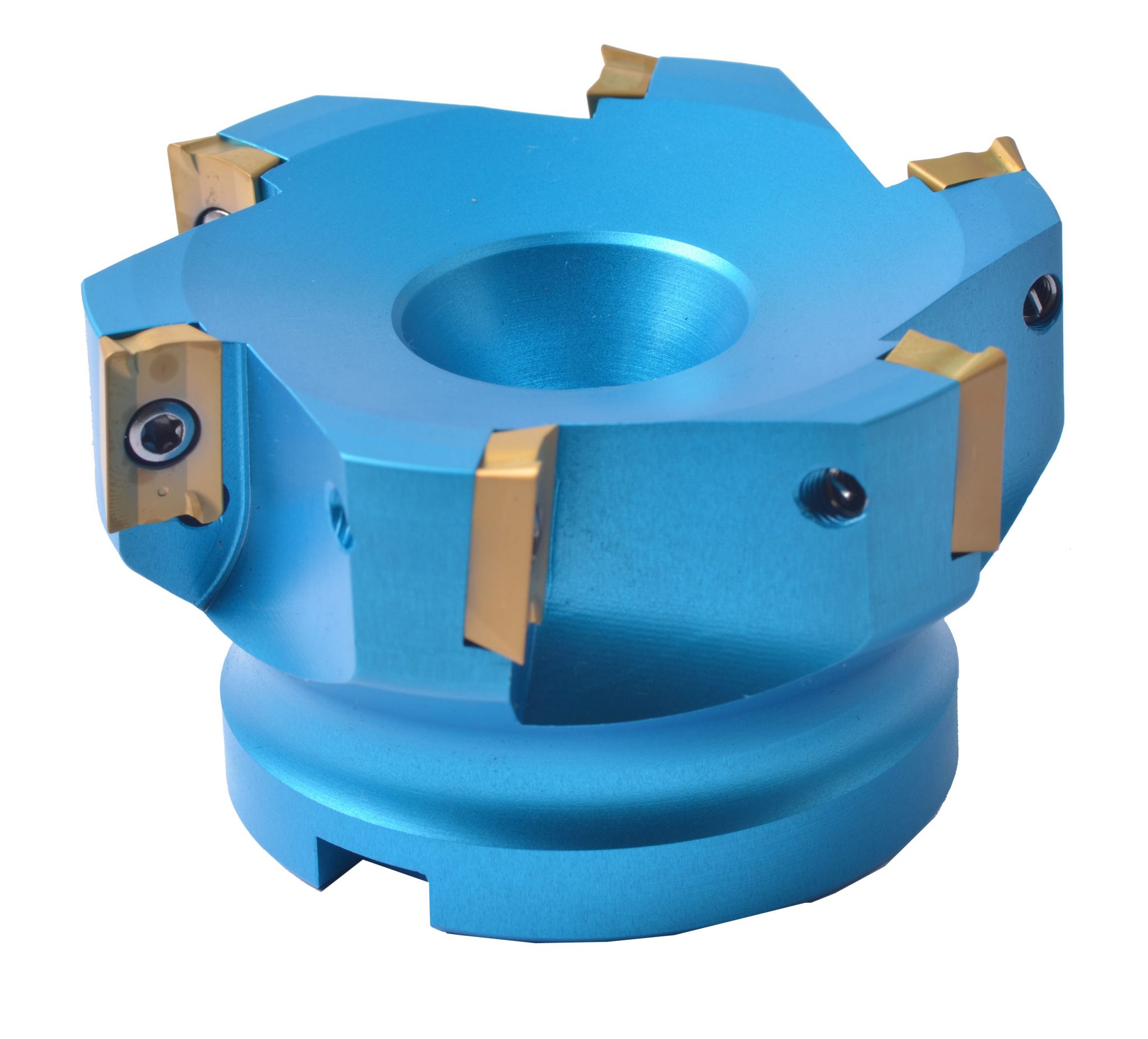

how to understand milling carbide inserts icarbide

Carbide Insert File Guide Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Detailed information on turning inserts identification. Insert nose radius and the feed rate. Selecting the right insert grade for your specific. Determine the basic shape of the cutting insert. When it comes to cutting tool selection, machinists have three basic choices: From a strictly theoretical perspective, surface roughness can be calculated from the following formula: In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. By kennametal metal cutting pros. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Step 1 for all grooving operations.

From www.findbuytool.com

Spiral Flush Trim Router Bit with Carbide Insert, Double Bearing Carbide Insert File Guide Determine the basic shape of the cutting insert. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Insert nose radius and the feed rate. Detailed information on turning inserts identification. By kennametal metal cutting pros. Selecting the right insert grade for your specific. Step 1 for all grooving operations. Regardless of component size, material or. Carbide Insert File Guide.

From www.artisansupplies.com.au

Artisan Supplies Tiny Large Carbide File Guide Artisan Supplies Carbide Insert File Guide Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Step 1 for all grooving operations. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Determine the basic shape of the cutting insert. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Carbide Insert File Guide.

From www.indiamart.com

SCMT 09T304 Carbide Insert at best price in Mumbai by M/s. AMS Traders Carbide Insert File Guide From a strictly theoretical perspective, surface roughness can be calculated from the following formula: By kennametal metal cutting pros. Detailed information on turning inserts identification. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Selecting the. Carbide Insert File Guide.

From www.etsy.com

Knife Makers File Guide Carbide Faced in Stainless Steel Etsy Carbide Insert File Guide Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. When it comes to cutting tool selection, machinists have three basic choices: Step 1 for all grooving operations. Selecting the right insert grade for your specific. Detailed information on turning inserts identification. Regardless of component size, material or design, the carbide insert grade you use can make all the. Carbide Insert File Guide.

From www.indiamart.com

Apmt 1135 Carbide Insert Deskar, For Industrial at Rs 60 in Mohali Carbide Insert File Guide Determine the basic shape of the cutting insert. By kennametal metal cutting pros. Step 1 for all grooving operations. Selecting the right insert grade for your specific. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Detailed information on turning inserts identification. When it comes to cutting tool selection, machinists have. Carbide Insert File Guide.

From www.alibaba.com

Gw Carbide Carbide Insert Ankx1705 Cutting Carbide Turning Insert Carbide Insert File Guide By kennametal metal cutting pros. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: When it comes to cutting tool selection, machinists have three basic choices: Selecting the right insert grade for your specific. Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Determine the basic shape of the cutting insert. Insert nose. Carbide Insert File Guide.

From www.shop-apt.co.uk

VCMT 110304 FM M250 Carbide Inserts for Turning PVD Coated for Finshing Carbide Insert File Guide By kennametal metal cutting pros. Selecting the right insert grade for your specific. Insert nose radius and the feed rate. Step 1 for all grooving operations. Determine the basic shape of the cutting insert. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Regardless of component size, material or design, the. Carbide Insert File Guide.

From www.icarbide.com

SAME AS SUMITOMO TPGT110304 IG701 CARBIDE INSERT BORING INSERTS PACK OF Carbide Insert File Guide Determine the basic shape of the cutting insert. By kennametal metal cutting pros. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. In addition to an overview of cutting tools, safety and precautions,. Carbide Insert File Guide.

From www.findbuytool.com

Flush Trim Router Bit with Carbide Insert FindBuyTool Carbide Insert File Guide Step 1 for all grooving operations. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Determine the basic shape of the cutting insert. Detailed information on turning inserts identification. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: By kennametal metal cutting. Carbide Insert File Guide.

From wbcarbidetool.com

MGMN Carbide insert Carbide Insert File Guide From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Step 1 for all grooving operations. Insert nose radius and the feed rate. By kennametal metal cutting. Carbide Insert File Guide.

From www.betoptools.com

Changeable Carbide Insert Tooling Multi Profile Router Bits Carbide Insert File Guide Insert nose radius and the feed rate. Step 1 for all grooving operations. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Regardless of component size, material or design, the carbide insert grade you use can make all the difference. Carbide Insert File Guide.

From www.ebay.com.au

10pc TCMT 110202 110204 110208 Turning Boring Indexable Lathe Carbide Carbide Insert File Guide Detailed information on turning inserts identification. By kennametal metal cutting pros. Determine the basic shape of the cutting insert. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Insert nose radius and the feed rate. When it. Carbide Insert File Guide.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco Carbide Insert File Guide Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Insert nose radius and the feed rate. Determine the basic shape of the cutting insert. When it comes to cutting tool selection, machinists have three basic choices: From a strictly theoretical perspective, surface roughness can be calculated from. Carbide Insert File Guide.

From www.indiamart.com

Threading Carbide Insert at Rs 4500 Shapar Chokdi Rajkot ID Carbide Insert File Guide Selecting the right insert grade for your specific. Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Step 1 for all grooving operations. Determine the basic shape of the cutting insert. Detailed information on turning inserts identification. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Carbide Insert File Guide.

From www.icarbide.com

how to understand milling carbide inserts icarbide Carbide Insert File Guide In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Determine the basic shape of the cutting insert. Step 1 for all grooving operations. Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. When it comes to cutting tool selection, machinists have three basic choices: Insert nose radius and the. Carbide Insert File Guide.

From www.shop-apt.co.uk

VCGT 160404 AK101 Carbide Inserts for Turning Ground and Polished for Carbide Insert File Guide By kennametal metal cutting pros. Selecting the right insert grade for your specific. When it comes to cutting tool selection, machinists have three basic choices: Insert nose radius and the feed rate. Step 1 for all grooving operations. Determine the basic shape of the cutting insert. From a strictly theoretical perspective, surface roughness can be calculated from the following formula:. Carbide Insert File Guide.

From www.indiamart.com

VBMT 160408 5080 CARBIDE INSERT TAEGUTEC, For Industrial at Rs 225 in Carbide Insert File Guide Selecting the right insert grade for your specific. Determine the basic shape of the cutting insert. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Step 1 for all grooving operations. When it. Carbide Insert File Guide.

From www.betoptools.com

Changeable Carbide Insert Tooling Multi Profile Router Bits Carbide Insert File Guide Step 1 for all grooving operations. Selecting the right insert grade for your specific. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Detailed information on turning inserts identification.. Carbide Insert File Guide.

From chinagrindingwheel.en.made-in-china.com

Tungsten Carbide Insert Turning/Milling/Threading/Grooving CNC Insert Carbide Insert File Guide When it comes to cutting tool selection, machinists have three basic choices: In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Insert nose radius and the feed rate. Brazed carbide tool bits, indexable tooling with carbide inserts,. Carbide Insert File Guide.

From www.betoptools.com

Extended Roundover Router Bit Carbide Insert Tooling IB20301 IB20303 Carbide Insert File Guide In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Detailed information on turning inserts identification. Selecting the right insert grade for your specific. When it comes to cutting tool selection, machinists have three basic choices: Insert nose radius and the feed rate. By kennametal metal cutting pros. From a strictly theoretical. Carbide Insert File Guide.

From www.aliexpress.com

10pcs Mayitr 11ir A60 Carbide Insert Golden External Threading Inserts Carbide Insert File Guide From a strictly theoretical perspective, surface roughness can be calculated from the following formula: In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Detailed information on turning inserts identification. Step 1 for all grooving operations. Selecting the right insert grade for your specific. Determine the basic shape of the cutting insert.. Carbide Insert File Guide.

From tungstencarbide.en.made-in-china.com

Carbide insert with advanced technology and coating China scarfing Carbide Insert File Guide Insert nose radius and the feed rate. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Detailed information on turning inserts identification. By kennametal metal cutting pros. Determine the basic shape of the cutting insert. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Step 1. Carbide Insert File Guide.

From www.shop-apt.co.uk

DNMG 150604 MMN M250 Carbide Inserts for Turning PVD Coated for Carbide Insert File Guide Determine the basic shape of the cutting insert. Step 1 for all grooving operations. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Detailed information on turning inserts identification. Insert nose radius and the feed rate. In addition to an overview of cutting tools,. Carbide Insert File Guide.

From easterncarbide.en.made-in-china.com

Cemented Carbide Insert Carbide Coating Seen1203aftn China Carbide Insert File Guide When it comes to cutting tool selection, machinists have three basic choices: Determine the basic shape of the cutting insert. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Insert nose radius and the feed rate. Regardless of component size, material or design, the carbide insert grade you use can make. Carbide Insert File Guide.

From www.aliexpress.com

ORIGINAL 10PCS CARBIDE INSERT N123J20600RO H13A Carbide Insert File Guide Selecting the right insert grade for your specific. By kennametal metal cutting pros. Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Step 1 for all grooving operations. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. From a strictly theoretical perspective, surface roughness can. Carbide Insert File Guide.

From www.youtube.com

DIY Carbide File Guide Knife Making YouTube Carbide Insert File Guide From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Selecting the right insert grade for your specific. When it comes to cutting. Carbide Insert File Guide.

From www.aliexpress.com

10PCS CARBIDE INSERT EDPT10T308PDERHD KC725M Carbide Insert File Guide Insert nose radius and the feed rate. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Detailed information on turning inserts identification. Determine the basic shape of the cutting insert. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing. Carbide Insert File Guide.

From www.manufacturinget.org

Carbide Insert Model Carbide Insert File Guide Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Determine the basic shape of the cutting insert. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Detailed information on turning inserts identification. Insert nose radius. Carbide Insert File Guide.

From www.indiamart.com

TCMT 110204 MT 7310 Carbide Insert at best price in Mumbai by National Carbide Insert File Guide Determine the basic shape of the cutting insert. Insert nose radius and the feed rate. Step 1 for all grooving operations. When it comes to cutting tool selection, machinists have three basic choices: By kennametal metal cutting pros. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Brazed carbide tool bits, indexable tooling with carbide. Carbide Insert File Guide.

From www.betoptools.com

Changeable Carbide Insert Tooling Multi Profile Router Bits Carbide Insert File Guide By kennametal metal cutting pros. Selecting the right insert grade for your specific. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. When it comes to cutting tool selection,. Carbide Insert File Guide.

From www.icarbide.com

APMT1135 M2 CARBIDE INSERT MILL INSERTS icarbide Carbide Insert File Guide When it comes to cutting tool selection, machinists have three basic choices: By kennametal metal cutting pros. From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Detailed information on turning inserts identification. Brazed. Carbide Insert File Guide.

From www.aliexpress.com

ORIGINAL 1PCS CARBIDE INSERT 880D2200L2503 Carbide Insert File Guide From a strictly theoretical perspective, surface roughness can be calculated from the following formula: In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Determine the basic shape of the. Carbide Insert File Guide.

From www.artisansupplies.com.au

Integral Behnke Carbide File Guide Artisan Supplies Carbide Insert File Guide In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product guides,. Determine the basic shape of the cutting insert. By kennametal metal cutting pros. Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Brazed carbide tool bits, indexable tooling with. Carbide Insert File Guide.

From rdbarrett.co.uk

How to Identify Carbide Inserts R.D. Barrett Carbide Insert File Guide When it comes to cutting tool selection, machinists have three basic choices: From a strictly theoretical perspective, surface roughness can be calculated from the following formula: Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. Step 1 for all grooving operations. Determine the basic shape of the cutting insert. By kennametal metal cutting pros. Insert nose radius and. Carbide Insert File Guide.

From www.aliexpress.com

ORIGINAL 10PCS CARBIDE INSERT SNGX1205ZNNF27 WKP25S Carbide Insert File Guide Brazed carbide tool bits, indexable tooling with carbide inserts, and solid. When it comes to cutting tool selection, machinists have three basic choices: Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity. Determine the basic shape of the cutting insert. Insert nose radius and the feed rate.. Carbide Insert File Guide.