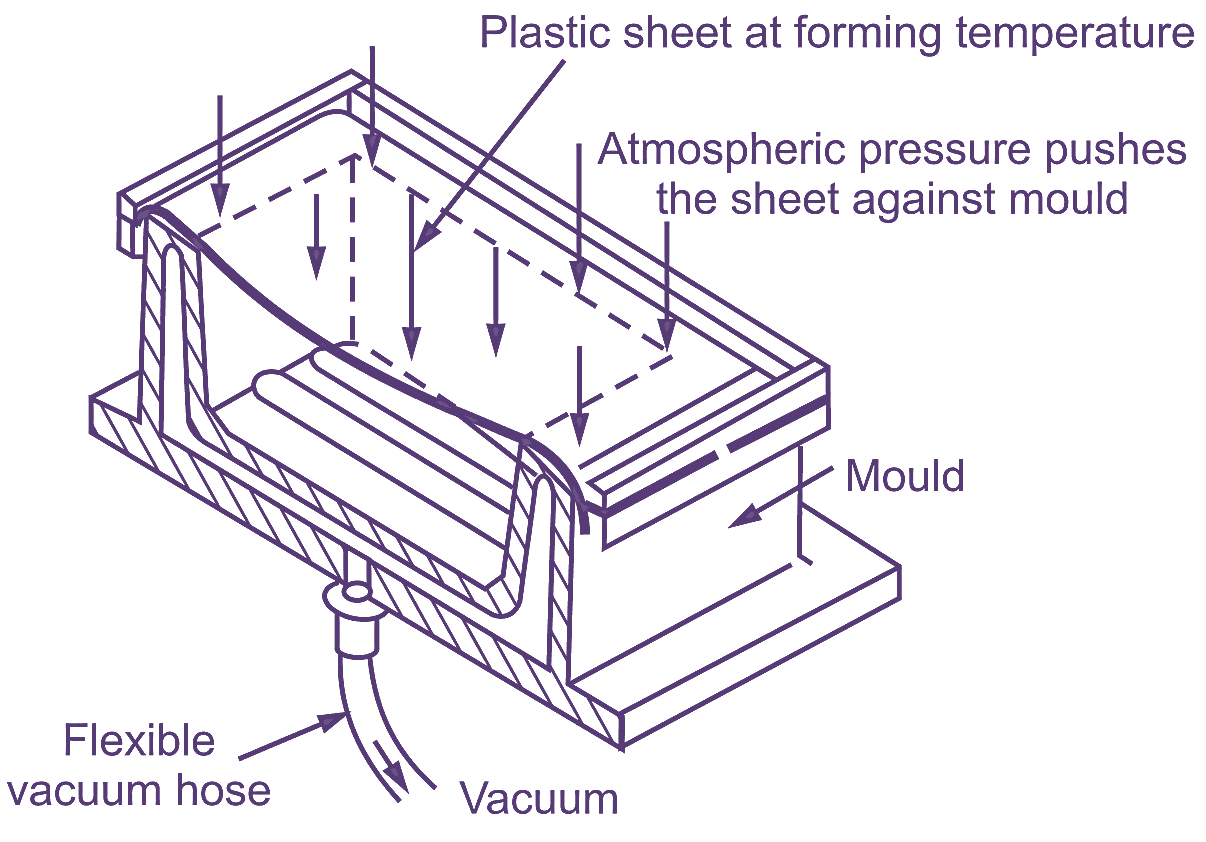

Vacuum Thermoforming Process . Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. It is ideal for parts that only need to be precisely. Thermoforming involves two primary techniques: Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. (2) the softened sheet is placed over a concave mold cavity; The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. (1) a flat plastic sheet is softened by heating; Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. Both methods stretch heated thermoplastic over a. Vacuum forming and pressure forming.

from electricalworkbook.com

(1) a flat plastic sheet is softened by heating; The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. Both methods stretch heated thermoplastic over a. Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Thermoforming involves two primary techniques: (2) the softened sheet is placed over a concave mold cavity; Vacuum forming and pressure forming. It is ideal for parts that only need to be precisely.

What is Vacuum Forming? Process, Applications, Products & Advantages

Vacuum Thermoforming Process Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. Vacuum forming and pressure forming. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. Thermoforming involves two primary techniques: The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Both methods stretch heated thermoplastic over a. It is ideal for parts that only need to be precisely. (1) a flat plastic sheet is softened by heating; (2) the softened sheet is placed over a concave mold cavity;

From www.petervaldivia.com

Fabrication of Plastics. Tecnología ESO en Ingles Vacuum Thermoforming Process Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming and pressure forming. Both methods stretch heated thermoplastic over a. (1) a flat plastic sheet is softened by heating; Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer. Vacuum Thermoforming Process.

From foammolders.com

Vacuum Forming The Processes Foam Molders Uses To Create HighQuality Vacuum Thermoforming Process Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Vacuum forming and pressure forming. Thermoforming involves two primary techniques: (2) the softened sheet is placed over a concave mold cavity; Vacuum forming is a simplified version of thermoforming wherein a sheet of. Vacuum Thermoforming Process.

From www.hardwareinterviews.fyi

Basics of Thermoforming Consumer Hardware Guide Hardware FYI Vacuum Thermoforming Process Thermoforming involves two primary techniques: (2) the softened sheet is placed over a concave mold cavity; Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Both methods stretch heated thermoplastic over a. The vacuum forming process involves preparing a mold, heating the plastic, forming it over the.. Vacuum Thermoforming Process.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Vacuum Thermoforming Process Vacuum forming and pressure forming. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. Both methods stretch heated thermoplastic over a. (1) a flat plastic sheet is softened by heating; (2) the softened sheet is placed over. Vacuum Thermoforming Process.

From scandivac.com

Thermoforming Scandivac Vacuum Thermoforming Process Vacuum forming and pressure forming. Both methods stretch heated thermoplastic over a. The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. (1) a flat plastic sheet is softened by heating; Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold. Vacuum Thermoforming Process.

From www.substech.com

Thermoforming [SubsTech] Vacuum Thermoforming Process Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Vacuum forming and pressure forming. Both methods stretch heated thermoplastic over a. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part. Vacuum Thermoforming Process.

From www.researchgate.net

Schematic illustration of basic thermoforming process (Yanagi Vacuum Thermoforming Process Thermoforming involves two primary techniques: (2) the softened sheet is placed over a concave mold cavity; Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. It is ideal for parts that only need to be precisely. Vacuum forming is a simplified version. Vacuum Thermoforming Process.

From www.vrogue.co

Thermoforming Process vrogue.co Vacuum Thermoforming Process The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Thermoforming involves two primary techniques: Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable. Vacuum Thermoforming Process.

From dienamics.com.au

What is Thermoforming? Dienamics Vacuum Thermoforming Process It is ideal for parts that only need to be precisely. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to. Vacuum Thermoforming Process.

From www.rayplastics.com

A Brief Overview of Thermoforming Blog Ray Products Vacuum Thermoforming Process Thermoforming involves two primary techniques: Vacuum forming and pressure forming. Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Both methods stretch heated thermoplastic over a. The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. (2). Vacuum Thermoforming Process.

From dmd-2000.co.uk

Thermoforming DMD 2000 Ltd Vacuum Thermoforming Process Vacuum forming and pressure forming. (1) a flat plastic sheet is softened by heating; Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. (2) the softened sheet is placed over a concave mold cavity; Both methods stretch. Vacuum Thermoforming Process.

From gregstrom.com

Plastic Thermoforming Vacuum vs. Pressure vs. Twin Sheet Gregstrom Vacuum Thermoforming Process Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. (1) a flat plastic sheet is softened by heating; Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the. Vacuum Thermoforming Process.

From www.vrogue.co

Thermoforming Process vrogue.co Vacuum Thermoforming Process Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. (1). Vacuum Thermoforming Process.

From dir.indiamart.com

Thermoformed Tray thermoformed plastic trays Latest Price Vacuum Thermoforming Process Both methods stretch heated thermoplastic over a. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. (1) a flat plastic sheet is softened by heating; It is ideal for parts that only need to be precisely. Vacuum. Vacuum Thermoforming Process.

From www.youtube.com

Vacuum Forming Process Working Applications ENGINEERING STUDY Vacuum Thermoforming Process Both methods stretch heated thermoplastic over a. Thermoforming involves two primary techniques: It is ideal for parts that only need to be precisely. (1) a flat plastic sheet is softened by heating; The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. Vacuum forming and pressure forming. Vacuum forming is a plastic manufacturing process that. Vacuum Thermoforming Process.

From warringah-plastics.com.au

Industry Leaders in Vacuum Forming in Sydney Warringah Plastics Vacuum Thermoforming Process (2) the softened sheet is placed over a concave mold cavity; It is ideal for parts that only need to be precisely. Thermoforming involves two primary techniques: (1) a flat plastic sheet is softened by heating; The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. Vacuum forming is the simplest type of plastic thermoforming,. Vacuum Thermoforming Process.

From plastifaboftexas.com

Vacuum Forming / Thermoforming Plastic Sheet Fabrication Manufacturing Vacuum Thermoforming Process (1) a flat plastic sheet is softened by heating; Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and. Vacuum Thermoforming Process.

From howtoposeforpicturesbeach.blogspot.com

thermoforming mold design pdf howtoposeforpicturesbeach Vacuum Thermoforming Process Both methods stretch heated thermoplastic over a. (1) a flat plastic sheet is softened by heating; Thermoforming involves two primary techniques: It is ideal for parts that only need to be precisely. Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Vacuum. Vacuum Thermoforming Process.

From www.mdpi.com

JMMP Free FullText Development of a Computationally Efficient Vacuum Thermoforming Process Both methods stretch heated thermoplastic over a. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. (2) the softened sheet is placed over a concave mold cavity; It is ideal for parts that only need to be. Vacuum Thermoforming Process.

From www.mdpi.com

Materials Free FullText 3D Printed Sand Tools for Thermoforming Vacuum Thermoforming Process Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Both methods stretch heated thermoplastic over a. Thermoforming involves two primary techniques: It is ideal for parts that only need to be precisely. Vacuum forming is the simplest type of plastic thermoforming, that. Vacuum Thermoforming Process.

From www.globalspec.com

Thermoforming and Vacuum Forming Equipment Selection Guide Types Vacuum Thermoforming Process It is ideal for parts that only need to be precisely. The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Thermoforming involves two primary techniques: Vacuum forming is a plastic manufacturing process. Vacuum Thermoforming Process.

From www.hongzu.com

8 Things You Need to Know About Thermoforming Molds Part 1 Hong Zu Vacuum Thermoforming Process Both methods stretch heated thermoplastic over a. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. (1) a flat plastic sheet is softened by heating; The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. Thermoforming involves two primary techniques: Vacuum forming. Vacuum Thermoforming Process.

From www.la-plastic.com

What Causes bing in Vacuum Forming? Vacuum Thermoforming Process Thermoforming involves two primary techniques: Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. Vacuum. Vacuum Thermoforming Process.

From www.manufacturingguide.com

Vacuum forming Find suppliers, processes & material Vacuum Thermoforming Process Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. (1) a flat plastic sheet is softened by heating; It is ideal for parts that only need to be precisely. Vacuum forming and pressure forming. The vacuum forming process involves preparing a mold,. Vacuum Thermoforming Process.

From truyenhinhcapsongthu.net

Vacuum Forming Types, Uses, Features And Benefits IQS Directory Vacuum Thermoforming Process It is ideal for parts that only need to be precisely. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer. Vacuum Thermoforming Process.

From www.vrogue.co

Thermoforming Process vrogue.co Vacuum Thermoforming Process Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. (1) a flat plastic sheet is softened by heating; Thermoforming involves two primary techniques: Both methods stretch heated. Vacuum Thermoforming Process.

From dfmpro.com

DFMPro for Thermoforming Process DFMPro Blog Vacuum Thermoforming Process Vacuum forming and pressure forming. Both methods stretch heated thermoplastic over a. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to create. It is ideal for parts that only need to be precisely. Vacuum forming is the simplest. Vacuum Thermoforming Process.

From blog.thepipingmart.com

Vacuum Forming vs Thermoforming What's the Difference Vacuum Thermoforming Process Vacuum forming and pressure forming. Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum,. Vacuum Thermoforming Process.

From www.weetect.com

Plastic Fabrication The Complete Guide In 2018 Wee Tect Vacuum Thermoforming Process It is ideal for parts that only need to be precisely. Vacuum forming and pressure forming. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. (1) a flat plastic sheet is softened by heating; Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic. Vacuum Thermoforming Process.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Vacuum Thermoforming Process Vacuum forming and pressure forming. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. (1) a flat plastic sheet is softened by heating; (2) the softened sheet is placed over a concave mold cavity; It is ideal for parts that only need to be precisely. Both methods. Vacuum Thermoforming Process.

From www.substech.com

Thermoforming [SubsTech] Vacuum Thermoforming Process Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming and pressure forming. The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. (2) the softened sheet is placed over a concave mold cavity; It is ideal for parts that only. Vacuum Thermoforming Process.

From ar.inspiredpencil.com

Forming Process Vacuum Thermoforming Process (2) the softened sheet is placed over a concave mold cavity; It is ideal for parts that only need to be precisely. The vacuum forming process involves preparing a mold, heating the plastic, forming it over the. Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Both. Vacuum Thermoforming Process.

From www.rtprototype.com

Thermoforming Vacuum Blister Molding Process Vacuum Thermoforming Process Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. It is ideal for parts that only need to be precisely. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a. Vacuum Thermoforming Process.

From www.youtube.com

How the THERMOFORMING PROCESS works? Factories YouTube Vacuum Thermoforming Process Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Both methods stretch heated thermoplastic over a. Vacuum forming is a simplified version of thermoforming wherein a sheet of plastic is heated to a pliable forming temperature, shaped over a mold by applying a vacuum, and trimmed to. Vacuum Thermoforming Process.

From www.vrogue.co

Thermoforming Process vrogue.co Vacuum Thermoforming Process Thermoforming involves two primary techniques: Vacuum forming is the simplest type of plastic thermoforming, that uses one mold and vacuum pressure to obtain the desired part geometry. Vacuum forming is a plastic manufacturing process that involves using a machine to heat a plastic polymer till it is pliable before pulling it over a mold. Vacuum forming and pressure forming. The. Vacuum Thermoforming Process.