Brazing Process Vs Tig Welding . Both welding and brazing utilize heat to join materials, but the essential difference is the temperature. While brazing and welding are both methods used to join metals, their processes and applications have distinct differences. Welding, on the other hand, involves melting the base metals to create a fusion between them. Welding typically provides stronger joints, whereas brazing is suited for delicate or dissimilar materials and complex assemblies, with lower heat and distortion risks. Chief among them is this: Understanding these differences is key in choosing the right technique for a particular project. Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Temperature and process are crucial when deciding between brazing and welding. Welding melts the base metals and filler material at. Welding involves the melting of two metals to join them, while the metals are not melted during the brazing process. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. While there are similarities of brazing vs tig welding, there are key differences that differentiate the processes. Brazing utilizes the heat of 840°f, which is enough for the brazing filler metal to melt, yet not enough to reach the melting point of base metals. Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base metal.

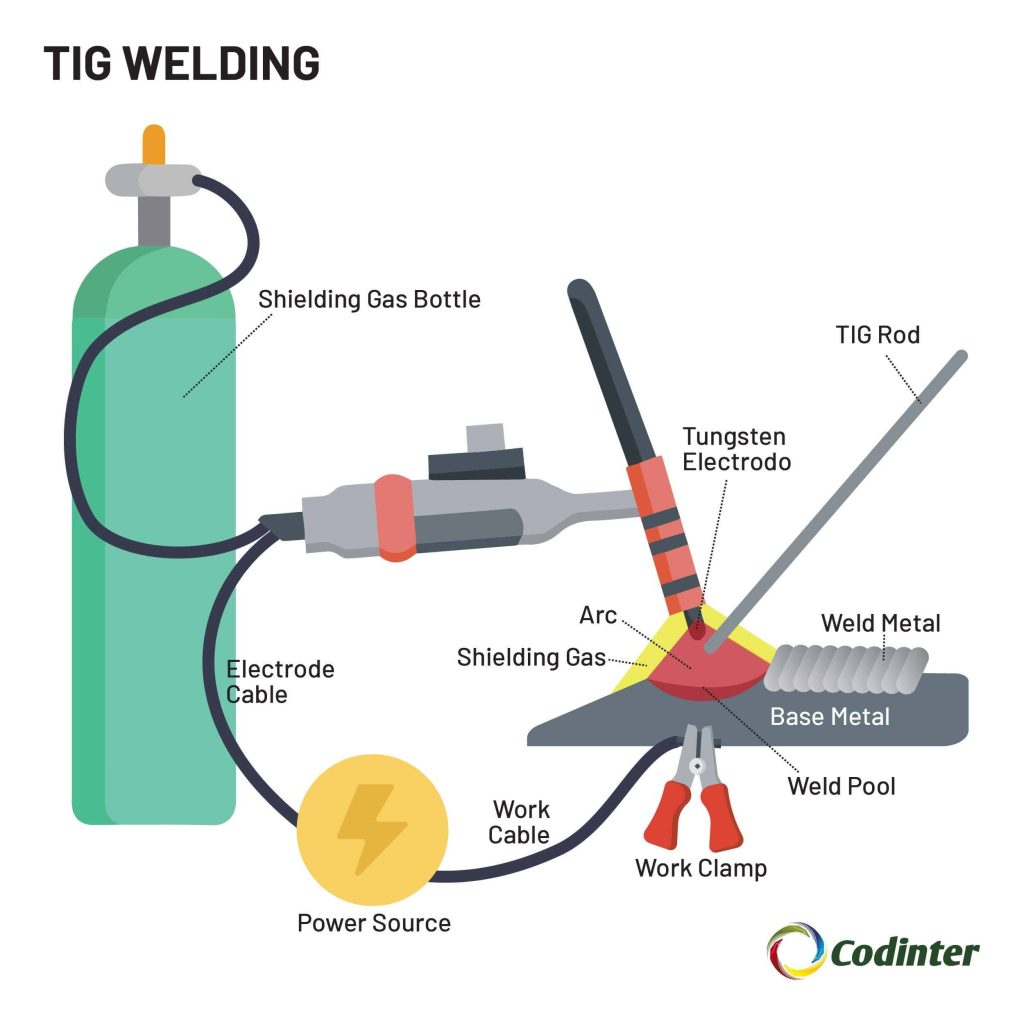

from www.codinter.com

While brazing and welding are both methods used to join metals, their processes and applications have distinct differences. Welding melts the base metals and filler material at. Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base metal. Welding, on the other hand, involves melting the base metals to create a fusion between them. Welding typically provides stronger joints, whereas brazing is suited for delicate or dissimilar materials and complex assemblies, with lower heat and distortion risks. Chief among them is this: Both welding and brazing utilize heat to join materials, but the essential difference is the temperature. While there are similarities of brazing vs tig welding, there are key differences that differentiate the processes. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when.

TIG vs. MIG Welding Which one to use in every case Codinter Americas

Brazing Process Vs Tig Welding Welding, on the other hand, involves melting the base metals to create a fusion between them. Both welding and brazing utilize heat to join materials, but the essential difference is the temperature. While brazing and welding are both methods used to join metals, their processes and applications have distinct differences. Welding typically provides stronger joints, whereas brazing is suited for delicate or dissimilar materials and complex assemblies, with lower heat and distortion risks. Brazing utilizes the heat of 840°f, which is enough for the brazing filler metal to melt, yet not enough to reach the melting point of base metals. Understanding these differences is key in choosing the right technique for a particular project. Temperature and process are crucial when deciding between brazing and welding. Welding, on the other hand, involves melting the base metals to create a fusion between them. Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base metal. Welding melts the base metals and filler material at. Chief among them is this: Welding involves the melting of two metals to join them, while the metals are not melted during the brazing process. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. While there are similarities of brazing vs tig welding, there are key differences that differentiate the processes.

From goo.gl

TIg Brazing vs Tig Welding Brazing Process Vs Tig Welding Welding melts the base metals and filler material at. Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base metal. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that. Brazing Process Vs Tig Welding.

From weldingofwelders.com

MIG vs TIG Which One to Choose? Welding of Welders Brazing Process Vs Tig Welding Understanding these differences is key in choosing the right technique for a particular project. Welding involves the melting of two metals to join them, while the metals are not melted during the brazing process. Welding melts the base metals and filler material at. Brazing utilizes the heat of 840°f, which is enough for the brazing filler metal to melt, yet. Brazing Process Vs Tig Welding.

From www.researchgate.net

MIG/MAG braze welding [4] Download Scientific Diagram Brazing Process Vs Tig Welding While brazing and welding are both methods used to join metals, their processes and applications have distinct differences. Welding, on the other hand, involves melting the base metals to create a fusion between them. Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Unlike welding, brazing. Brazing Process Vs Tig Welding.

From blog.thepipingmart.com

Fusion Welding vs Brazing What's the Difference Brazing Process Vs Tig Welding While brazing and welding are both methods used to join metals, their processes and applications have distinct differences. Chief among them is this: While there are similarities of brazing vs tig welding, there are key differences that differentiate the processes. Welding typically provides stronger joints, whereas brazing is suited for delicate or dissimilar materials and complex assemblies, with lower heat. Brazing Process Vs Tig Welding.

From blog.thepipingmart.com

Exothermic Welding vs Brazing What's the Difference Brazing Process Vs Tig Welding Both welding and brazing utilize heat to join materials, but the essential difference is the temperature. Temperature and process are crucial when deciding between brazing and welding. Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. While brazing and welding are both methods used to join. Brazing Process Vs Tig Welding.

From www.pinterest.ca

Tig Brazing vs Tig Welding YouTube Tig welding, Brazing, Welding Brazing Process Vs Tig Welding Understanding these differences is key in choosing the right technique for a particular project. Brazing utilizes the heat of 840°f, which is enough for the brazing filler metal to melt, yet not enough to reach the melting point of base metals. Chief among them is this: Welding melts the base metals and filler material at. Both welding and brazing utilize. Brazing Process Vs Tig Welding.

From www.welderscave.com

What is the Difference between Welding And Brazing Welders Cave Brazing Process Vs Tig Welding Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Chief among them is this: Welding involves the melting of two metals to join them, while the metals are not melted during the brazing process. Brazing utilizes the heat of 840°f, which is enough for the brazing. Brazing Process Vs Tig Welding.

From www.brilliantdiy.com

[Video] Ultimate Comparison Showing The Differences Between Tig Brazing Brazing Process Vs Tig Welding Temperature and process are crucial when deciding between brazing and welding. Welding melts the base metals and filler material at. Welding typically provides stronger joints, whereas brazing is suited for delicate or dissimilar materials and complex assemblies, with lower heat and distortion risks. Chief among them is this: Brazing involves joining two or more metal parts by heating them to. Brazing Process Vs Tig Welding.

From axenics.com

Brazing Vs. TIG Welding Differences and Advantages of Each Axenics Brazing Process Vs Tig Welding Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base metal. While brazing and welding are both methods used to join metals, their processes and applications have distinct differences. Unlike welding, brazing only melts the filler metal. Brazing Process Vs Tig Welding.

From www.researchgate.net

Welding schematic diagram of Tig arc brazing. Download Scientific Diagram Brazing Process Vs Tig Welding While brazing and welding are both methods used to join metals, their processes and applications have distinct differences. Welding, on the other hand, involves melting the base metals to create a fusion between them. Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Both welding and. Brazing Process Vs Tig Welding.

From www.youtube.com

Welding, brazing and soldering differences. Braze vs. Weld. Beginner Brazing Process Vs Tig Welding Welding involves the melting of two metals to join them, while the metals are not melted during the brazing process. Understanding these differences is key in choosing the right technique for a particular project. Welding typically provides stronger joints, whereas brazing is suited for delicate or dissimilar materials and complex assemblies, with lower heat and distortion risks. Brazing utilizes the. Brazing Process Vs Tig Welding.

From musclehorsepower.com

Tig Brazing Process Vs. Tig Welding! Which One Is Stronger!? Muscle Brazing Process Vs Tig Welding Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base metal. Chief among them is this: Welding typically provides stronger joints, whereas brazing is suited for delicate or dissimilar materials and complex assemblies, with lower heat and. Brazing Process Vs Tig Welding.

From www.smetals.co.uk

Brazing vs. Welding Understanding the Differences and Applications Brazing Process Vs Tig Welding Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base metal. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when.. Brazing Process Vs Tig Welding.

From blog.thepipingmart.com

Brazing vs TIG Welding What's the Difference Brazing Process Vs Tig Welding Welding typically provides stronger joints, whereas brazing is suited for delicate or dissimilar materials and complex assemblies, with lower heat and distortion risks. Welding involves the melting of two metals to join them, while the metals are not melted during the brazing process. Welding, on the other hand, involves melting the base metals to create a fusion between them. While. Brazing Process Vs Tig Welding.

From www.perfectpowerwelders.com

TIG Welding Vs MIG Welding About Difference & Which is Better? Mig Brazing Process Vs Tig Welding While there are similarities of brazing vs tig welding, there are key differences that differentiate the processes. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Brazing utilizes the heat of 840°f, which is enough for the brazing filler metal to melt, yet. Brazing Process Vs Tig Welding.

From www.youtube.com

Difference between brazing and braze welding II Brazing & Braze Welding Brazing Process Vs Tig Welding Welding melts the base metals and filler material at. Welding involves the melting of two metals to join them, while the metals are not melted during the brazing process. While brazing and welding are both methods used to join metals, their processes and applications have distinct differences. While there are similarities of brazing vs tig welding, there are key differences. Brazing Process Vs Tig Welding.

From www.codinter.com

TIG vs. MIG Welding Which one to use in every case Codinter Americas Brazing Process Vs Tig Welding Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Welding, on the other hand, involves melting the base metals to create a fusion between them. While there are similarities of brazing vs tig welding, there are key differences that differentiate the processes. Understanding. Brazing Process Vs Tig Welding.

From www.weldingtipsandtricks.com

TIg Brazing vs Tig Welding Brazing Process Vs Tig Welding Welding, on the other hand, involves melting the base metals to create a fusion between them. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Brazing involves joining two or more metal parts by heating them to a temperature above their melting point. Brazing Process Vs Tig Welding.

From www.youtube.com

TIG Welding & TIG Brazing YouTube Brazing Process Vs Tig Welding Chief among them is this: Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Both welding and brazing utilize heat to join materials, but the essential difference is the temperature. Welding melts the base metals and filler material at. While brazing and welding are both methods. Brazing Process Vs Tig Welding.

From makemoneywelding.com

MIG vs. TIG Welding Differences Which Is Better? Brazing Process Vs Tig Welding Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base metal. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when.. Brazing Process Vs Tig Welding.

From workshopinsider.com

Welding VS Brazing What Is The Difference? Insider Brazing Process Vs Tig Welding Welding, on the other hand, involves melting the base metals to create a fusion between them. Understanding these differences is key in choosing the right technique for a particular project. While there are similarities of brazing vs tig welding, there are key differences that differentiate the processes. Brazing joins metals using a filler metal above 840°f (450°c) without melting the. Brazing Process Vs Tig Welding.

From www.hollyfab.com

Common Welding Methods Brazing Process Vs Tig Welding Temperature and process are crucial when deciding between brazing and welding. Welding, on the other hand, involves melting the base metals to create a fusion between them. Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base. Brazing Process Vs Tig Welding.

From askanydifference.com

Welding vs Brazing Difference and Comparison Brazing Process Vs Tig Welding Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Brazing utilizes the heat of 840°f, which is enough for the brazing filler metal to melt, yet not enough to reach the melting point of base metals. Both welding and brazing utilize heat to join materials, but. Brazing Process Vs Tig Welding.

From www.masseyenergyco.com

Brazing VS Welding VS Soldering In Depth Research Massey Energy Co Brazing Process Vs Tig Welding Welding typically provides stronger joints, whereas brazing is suited for delicate or dissimilar materials and complex assemblies, with lower heat and distortion risks. Welding melts the base metals and filler material at. While there are similarities of brazing vs tig welding, there are key differences that differentiate the processes. Both welding and brazing utilize heat to join materials, but the. Brazing Process Vs Tig Welding.

From www.youtube.com

Tig Brazing vs Tig Welding YouTube Brazing Process Vs Tig Welding Welding involves the melting of two metals to join them, while the metals are not melted during the brazing process. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. Brazing joins metals using a filler metal above 840°f (450°c) without melting the base. Brazing Process Vs Tig Welding.

From www.researchgate.net

Schematic Diagram of TIG welding process Download Scientific Diagram Brazing Process Vs Tig Welding Brazing utilizes the heat of 840°f, which is enough for the brazing filler metal to melt, yet not enough to reach the melting point of base metals. Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base. Brazing Process Vs Tig Welding.

From saferef.in

Welding vs. Brazing Understanding the Crucial Differences Saferef Brazing Process Vs Tig Welding Welding melts the base metals and filler material at. Chief among them is this: Both welding and brazing utilize heat to join materials, but the essential difference is the temperature. While brazing and welding are both methods used to join metals, their processes and applications have distinct differences. Welding involves the melting of two metals to join them, while the. Brazing Process Vs Tig Welding.

From www.senlisweld.com

Mig Vs Tig Welding SENLISWELD Brazing Process Vs Tig Welding Temperature and process are crucial when deciding between brazing and welding. Welding melts the base metals and filler material at. While there are similarities of brazing vs tig welding, there are key differences that differentiate the processes. Welding involves the melting of two metals to join them, while the metals are not melted during the brazing process. Chief among them. Brazing Process Vs Tig Welding.

From workshopinsider.com

Welding VS Brazing What Is The Difference? Insider Brazing Process Vs Tig Welding Understanding these differences is key in choosing the right technique for a particular project. Welding involves the melting of two metals to join them, while the metals are not melted during the brazing process. Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Chief among them. Brazing Process Vs Tig Welding.

From www.youtube.com

Adventures in TIG Brazing YouTube Brazing Process Vs Tig Welding Both welding and brazing utilize heat to join materials, but the essential difference is the temperature. While brazing and welding are both methods used to join metals, their processes and applications have distinct differences. Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Chief among them. Brazing Process Vs Tig Welding.

From migtigstickweld.com

Welding vs Brazing What Are the Essential Differences? Brazing Process Vs Tig Welding Welding typically provides stronger joints, whereas brazing is suited for delicate or dissimilar materials and complex assemblies, with lower heat and distortion risks. Brazing utilizes the heat of 840°f, which is enough for the brazing filler metal to melt, yet not enough to reach the melting point of base metals. Understanding these differences is key in choosing the right technique. Brazing Process Vs Tig Welding.

From askanydifference.com

Welding vs Brazing Difference and Comparison Brazing Process Vs Tig Welding Brazing involves joining two or more metal parts by heating them to a temperature above their melting point and then adding a filler metal that melts at a lower temperature than the base metal. Welding melts the base metals and filler material at. Chief among them is this: Both welding and brazing utilize heat to join materials, but the essential. Brazing Process Vs Tig Welding.

From blog.thepipingmart.com

Brazing vs Gas Welding What's the Difference Brazing Process Vs Tig Welding Brazing joins metals using a filler metal above 840°f (450°c) without melting the base metals, while welding fuses base metals by melting them. Temperature and process are crucial when deciding between brazing and welding. Both welding and brazing utilize heat to join materials, but the essential difference is the temperature. Welding involves the melting of two metals to join them,. Brazing Process Vs Tig Welding.

From weldingpros.net

Brazing Vs Soldering Vs Welding Crucial Differences 2024 Brazing Process Vs Tig Welding Welding, on the other hand, involves melting the base metals to create a fusion between them. Welding melts the base metals and filler material at. Understanding these differences is key in choosing the right technique for a particular project. While there are similarities of brazing vs tig welding, there are key differences that differentiate the processes. Temperature and process are. Brazing Process Vs Tig Welding.

From weldguru.com

MIG vs TIG Welding The Main Differences Weld Guru Brazing Process Vs Tig Welding Brazing utilizes the heat of 840°f, which is enough for the brazing filler metal to melt, yet not enough to reach the melting point of base metals. Unlike welding, brazing only melts the filler metal and uses it as a sort of adhesive that holds the base metals in a solid grip when. While brazing and welding are both methods. Brazing Process Vs Tig Welding.