Reverse Dial Indicator Alignment . Additionally, reverse dial alignment does not require removal of the. The included summary of dial indicator mounting methods is instructive; Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. When using a reverse dial method, two measurements are taken on the rims of the couplings. In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. This course covers the theory, practice and techniques of reverse. Reverse dial indicator method covered in this application note. Learn how to use reverse dial indicators to align direct coupled machine shafts. Topics explained:reverse dial indicating alignment formula and. Rim & face, reverse dial, double radial, shaft to coupling spool, and the.

from www.chegg.com

Reverse dial indicator method covered in this application note. Topics explained:reverse dial indicating alignment formula and. The included summary of dial indicator mounting methods is instructive; Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. Rim & face, reverse dial, double radial, shaft to coupling spool, and the. When using a reverse dial method, two measurements are taken on the rims of the couplings. Additionally, reverse dial alignment does not require removal of the. This course covers the theory, practice and techniques of reverse. Learn how to use reverse dial indicators to align direct coupled machine shafts. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet.

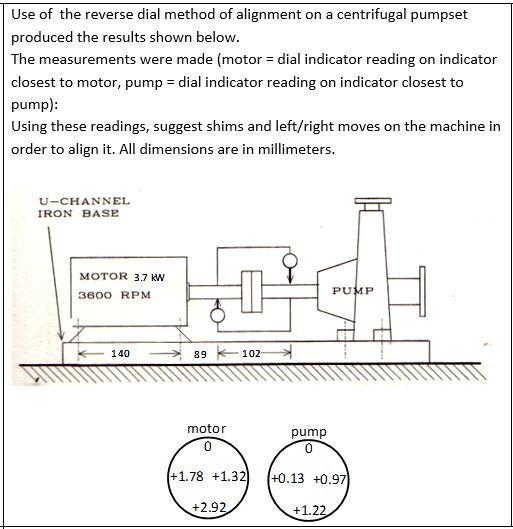

Use of the reverse dial method of alignment on a

Reverse Dial Indicator Alignment Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. Learn how to use reverse dial indicators to align direct coupled machine shafts. Additionally, reverse dial alignment does not require removal of the. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. Rim & face, reverse dial, double radial, shaft to coupling spool, and the. The included summary of dial indicator mounting methods is instructive; This course covers the theory, practice and techniques of reverse. When using a reverse dial method, two measurements are taken on the rims of the couplings. Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. Topics explained:reverse dial indicating alignment formula and. Reverse dial indicator method covered in this application note. In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor.

From www.youtube.com

REVERSE DIAL INDICATING ALIGNMENTCROSS DIAL POSITIONFORMULA METHOD VS Reverse Dial Indicator Alignment Topics explained:reverse dial indicating alignment formula and. Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. The included summary of dial indicator mounting methods is instructive; When using a reverse dial method, two measurements are taken on the rims of the couplings. Reverse dial indicator method covered in this application note. Rim & face,. Reverse Dial Indicator Alignment.

From www.youtube.com

REVERSE DIAL INDICATING ALIGNMENT CROSS DIAL FORMULA METHOD ENGLISH Reverse Dial Indicator Alignment Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. This course covers the theory, practice and techniques of reverse. When using a reverse dial method, two measurements are taken on the rims of the couplings. Learn how to use reverse dial indicators to align direct coupled machine. Reverse Dial Indicator Alignment.

From dokumen.tips

(PDF) Reverse Dial Indicator Alignment Procedure DOKUMEN.TIPS Reverse Dial Indicator Alignment Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. Learn how to use reverse dial indicators to align direct coupled machine shafts. The included summary of dial indicator mounting methods is instructive;. Reverse Dial Indicator Alignment.

From edu.svet.gob.gt

SHAFT ALIGNMENT REVERSE DIAL INDICATOR ALIGNMENT Reverse Dial Indicator Alignment Additionally, reverse dial alignment does not require removal of the. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. When using a reverse dial method, two measurements are taken on the rims of the couplings. Step 2:determine which piece of equipment is “fixed” and which piece of. Reverse Dial Indicator Alignment.

From ar.inspiredpencil.com

Reverse Indicator Shaft Alignment Reverse Dial Indicator Alignment Rim & face, reverse dial, double radial, shaft to coupling spool, and the. Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. Topics explained:reverse dial indicating alignment formula and. Reverse dial indicator method covered in this application note. Additionally, reverse dial alignment does not require removal of the. When using a reverse dial method,. Reverse Dial Indicator Alignment.

From www.mitchellinstrument.com

Accushim SA2 Reverse Dial Indicator Alignment System with Palm Style Reverse Dial Indicator Alignment Learn how to use reverse dial indicators to align direct coupled machine shafts. Topics explained:reverse dial indicating alignment formula and. The included summary of dial indicator mounting methods is instructive; Additionally, reverse dial alignment does not require removal of the. Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. Traditionally alignment has been described. Reverse Dial Indicator Alignment.

From www.mitchellinstrument.com

Accushim HA2 Reverse Dial Indicator Shaft Alignment Hardware System Reverse Dial Indicator Alignment Learn how to use reverse dial indicators to align direct coupled machine shafts. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. Rim & face, reverse dial, double radial, shaft to coupling spool, and the. The included summary of dial indicator mounting methods is instructive; Step 2:determine. Reverse Dial Indicator Alignment.

From www.mitchellinstrument.com

Accushim SA2 Reverse Dial Indicator Alignment System with Palm Style Reverse Dial Indicator Alignment The included summary of dial indicator mounting methods is instructive; Learn how to use reverse dial indicators to align direct coupled machine shafts. Additionally, reverse dial alignment does not require removal of the. Reverse dial indicator method covered in this application note. This course covers the theory, practice and techniques of reverse. Traditionally alignment has been described in terms of. Reverse Dial Indicator Alignment.

From www.linkedin.com

Mechanical World on LinkedIn Reverse Dial Indicator Shaft Alignment Reverse Dial Indicator Alignment Reverse dial indicator method covered in this application note. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. This course covers the theory, practice and techniques of reverse. Learn how to use reverse dial indicators to align direct coupled machine shafts. Topics explained:reverse dial indicating alignment formula. Reverse Dial Indicator Alignment.

From www.scribd.com

Reverse Dial Indicator Alignment Procedure Transmission (Mechanics Reverse Dial Indicator Alignment When using a reverse dial method, two measurements are taken on the rims of the couplings. Additionally, reverse dial alignment does not require removal of the. Rim & face, reverse dial, double radial, shaft to coupling spool, and the. Topics explained:reverse dial indicating alignment formula and. In general, you will only be moving one piece of equipment and it is. Reverse Dial Indicator Alignment.

From www.youtube.com

Shaft coupling alignment Procedure Reverse Dial Method 1 YouTube Reverse Dial Indicator Alignment Additionally, reverse dial alignment does not require removal of the. Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. When using a reverse dial method, two measurements are taken on the rims of the couplings. Reverse dial indicator method covered in this application note. Rim & face, reverse dial, double radial, shaft to coupling. Reverse Dial Indicator Alignment.

From edu.svet.gob.gt

SHAFT ALIGNMENT REVERSE DIAL INDICATOR ALIGNMENT Reverse Dial Indicator Alignment When using a reverse dial method, two measurements are taken on the rims of the couplings. Additionally, reverse dial alignment does not require removal of the. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. In general, you will only be moving one piece of equipment and. Reverse Dial Indicator Alignment.

From www.chegg.com

Use of the reverse dial method of alignment on a Reverse Dial Indicator Alignment Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. Additionally,. Reverse Dial Indicator Alignment.

From www.mitchellinstrument.com

Accushim HA2 Reverse Dial Indicator Shaft Alignment Hardware System Reverse Dial Indicator Alignment Reverse dial indicator method covered in this application note. Topics explained:reverse dial indicating alignment formula and. Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. Additionally, reverse dial alignment does not require removal of the. When using a reverse dial method, two measurements are taken on the rims of the couplings. In general, you. Reverse Dial Indicator Alignment.

From proper-cooking.info

Reverse Indicator Shaft Alignment Reverse Dial Indicator Alignment Reverse dial indicator method covered in this application note. In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. Learn how to use reverse dial indicators to align direct coupled machine shafts. This course covers the theory, practice and techniques of reverse. The included summary of dial indicator. Reverse Dial Indicator Alignment.

From www.youtube.com

REVERSE DIAL INDICATING ALIGNMENTOPPOSITE DIAL POSITIONFORMULA METHOD Reverse Dial Indicator Alignment When using a reverse dial method, two measurements are taken on the rims of the couplings. Additionally, reverse dial alignment does not require removal of the. Topics explained:reverse dial indicating alignment formula and. Reverse dial indicator method covered in this application note. Rim & face, reverse dial, double radial, shaft to coupling spool, and the. The included summary of dial. Reverse Dial Indicator Alignment.

From www.myshared.ru

Презентация на тему "Training of mechanics and service engineers Reverse Dial Indicator Alignment Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. This course covers the theory, practice and techniques of reverse. Rim & face, reverse dial, double radial, shaft to coupling spool, and the. Learn how to use reverse dial indicators to align direct coupled machine shafts. In general, you will only be moving one piece. Reverse Dial Indicator Alignment.

From yesyen.com

Shaft Alignment Methods Training Class Reverse Dial Indicator Alignment Rim & face, reverse dial, double radial, shaft to coupling spool, and the. In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. Topics explained:reverse dial indicating alignment formula and. When using a reverse dial method, two measurements are taken on the rims of the couplings. Learn how. Reverse Dial Indicator Alignment.

From edu.svet.gob.gt

Dial Gauge Indicator For Shaft Alignment edu.svet.gob.gt Reverse Dial Indicator Alignment In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. Reverse dial indicator method covered in this application note. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. Rim & face, reverse dial, double radial,. Reverse Dial Indicator Alignment.

From www.scribd.com

Reverse Dial Indicator Alignment Download Free PDF Machines Gear Reverse Dial Indicator Alignment Learn how to use reverse dial indicators to align direct coupled machine shafts. Topics explained:reverse dial indicating alignment formula and. When using a reverse dial method, two measurements are taken on the rims of the couplings. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. Rim &. Reverse Dial Indicator Alignment.

From www.youtube.com

Machine Alignment Reverse Indicator method YouTube Reverse Dial Indicator Alignment Topics explained:reverse dial indicating alignment formula and. Learn how to use reverse dial indicators to align direct coupled machine shafts. Rim & face, reverse dial, double radial, shaft to coupling spool, and the. The included summary of dial indicator mounting methods is instructive; Reverse dial indicator method covered in this application note. When using a reverse dial method, two measurements. Reverse Dial Indicator Alignment.

From www.vrogue.co

Shaft Alignment Reverse Dial Indicator Alignment vrogue.co Reverse Dial Indicator Alignment Reverse dial indicator method covered in this application note. When using a reverse dial method, two measurements are taken on the rims of the couplings. In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. Traditionally alignment has been described in terms of dial indicator readings at the. Reverse Dial Indicator Alignment.

From dokumen.tips

(PDF) Reverse Rim Dial Indicator Alignment Overview DOKUMEN.TIPS Reverse Dial Indicator Alignment In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. This course covers the theory, practice and techniques of reverse. Reverse dial indicator method covered in this application note. The included summary of dial indicator mounting methods is instructive; Learn how to use reverse dial indicators to align. Reverse Dial Indicator Alignment.

From www.scribd.com

reverse dial indicator alignment method Accuracy And Precision Reverse Dial Indicator Alignment In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. The included summary of dial indicator mounting methods is instructive; Reverse dial indicator method covered in. Reverse Dial Indicator Alignment.

From www.mechanical-knowledge.com

SHAFT ALIGNMENT REVERSE DIAL INDICATOR ALIGNMENT Reverse Dial Indicator Alignment Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. The included summary of dial indicator mounting methods is instructive; Reverse dial indicator method covered in this application note. This course covers the theory, practice and techniques of reverse. Rim & face, reverse dial, double radial, shaft to. Reverse Dial Indicator Alignment.

From www.vrogue.co

Shaft Alignment Reverse Dial Indicator Alignment vrogue.co Reverse Dial Indicator Alignment Topics explained:reverse dial indicating alignment formula and. The included summary of dial indicator mounting methods is instructive; Learn how to use reverse dial indicators to align direct coupled machine shafts. Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. Traditionally alignment has been described in terms of dial indicator readings at the coupling face. Reverse Dial Indicator Alignment.

From ar.inspiredpencil.com

Reverse Indicator Shaft Alignment Reverse Dial Indicator Alignment Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. This course covers the theory, practice and techniques of reverse. In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. Reverse dial indicator method covered in. Reverse Dial Indicator Alignment.

From www.vrogue.co

Dial Indicator Alignment Very Simple Method Dial Gaug vrogue.co Reverse Dial Indicator Alignment Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. Rim & face, reverse dial, double radial, shaft to coupling spool, and the. Reverse dial indicator method covered in this application note. Topics. Reverse Dial Indicator Alignment.

From www.vrogue.co

Accushim Ha 2 Reverse Dial Indicator Shaft Alignment vrogue.co Reverse Dial Indicator Alignment Step 2:determine which piece of equipment is “fixed” and which piece of equipment is “moveable”. Learn how to use reverse dial indicators to align direct coupled machine shafts. This course covers the theory, practice and techniques of reverse. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet.. Reverse Dial Indicator Alignment.

From www.vrogue.co

Reverse Dial Indicating Alignment Cross Dial Formula vrogue.co Reverse Dial Indicator Alignment Additionally, reverse dial alignment does not require removal of the. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. When using a reverse dial method, two measurements are taken on the rims of the couplings. This course covers the theory, practice and techniques of reverse. Reverse dial. Reverse Dial Indicator Alignment.

From www.mitchellinstrument.com

Accushim SK2D ShafttoShaft Alignment Starter Kit with Dial Indicators Reverse Dial Indicator Alignment This course covers the theory, practice and techniques of reverse. Learn how to use reverse dial indicators to align direct coupled machine shafts. Additionally, reverse dial alignment does not require removal of the. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. Reverse dial indicator method covered. Reverse Dial Indicator Alignment.

From kanesdictionary.com

Reverse Indicator Alignment Kanes Dictionary Reverse Dial Indicator Alignment Reverse dial indicator method covered in this application note. The included summary of dial indicator mounting methods is instructive; Additionally, reverse dial alignment does not require removal of the. When using a reverse dial method, two measurements are taken on the rims of the couplings. Topics explained:reverse dial indicating alignment formula and. In general, you will only be moving one. Reverse Dial Indicator Alignment.

From www.alignmentknowledge.com

Dial Indicator Alignment Basics Alignment Knowledge Reverse Dial Indicator Alignment This course covers the theory, practice and techniques of reverse. When using a reverse dial method, two measurements are taken on the rims of the couplings. Learn how to use reverse dial indicators to align direct coupled machine shafts. Reverse dial indicator method covered in this application note. Rim & face, reverse dial, double radial, shaft to coupling spool, and. Reverse Dial Indicator Alignment.

From www.linkedin.com

Engineering UPdates on LinkedIn Dial indicator shaft alignment pdf Reverse Dial Indicator Alignment In general, you will only be moving one piece of equipment and it is typically, but not limited to, the drive motor. Reverse dial indicator method covered in this application note. Additionally, reverse dial alignment does not require removal of the. Learn how to use reverse dial indicators to align direct coupled machine shafts. Traditionally alignment has been described in. Reverse Dial Indicator Alignment.

From www.myshared.ru

Презентация на тему "Training of mechanics and service engineers Reverse Dial Indicator Alignment Topics explained:reverse dial indicating alignment formula and. Traditionally alignment has been described in terms of dial indicator readings at the coupling face or position values at the machine feet. When using a reverse dial method, two measurements are taken on the rims of the couplings. In general, you will only be moving one piece of equipment and it is typically,. Reverse Dial Indicator Alignment.