Gearbox Overhauling Procedure . On the other hand, removal of the gearbox for a full inspection. Evaluate the gearbox condition and repairs needed. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Identify the gearbox make and model and disassemble the unit. Make regular visual inspections of gearboxes. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Understanding gearbox failures is critical for preventing costly downtimes. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed. To prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency.

from www.vizator.ru

Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Identify the gearbox make and model and disassemble the unit. On the other hand, removal of the gearbox for a full inspection. To prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. Evaluate the gearbox condition and repairs needed. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. Understanding gearbox failures is critical for preventing costly downtimes. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed.

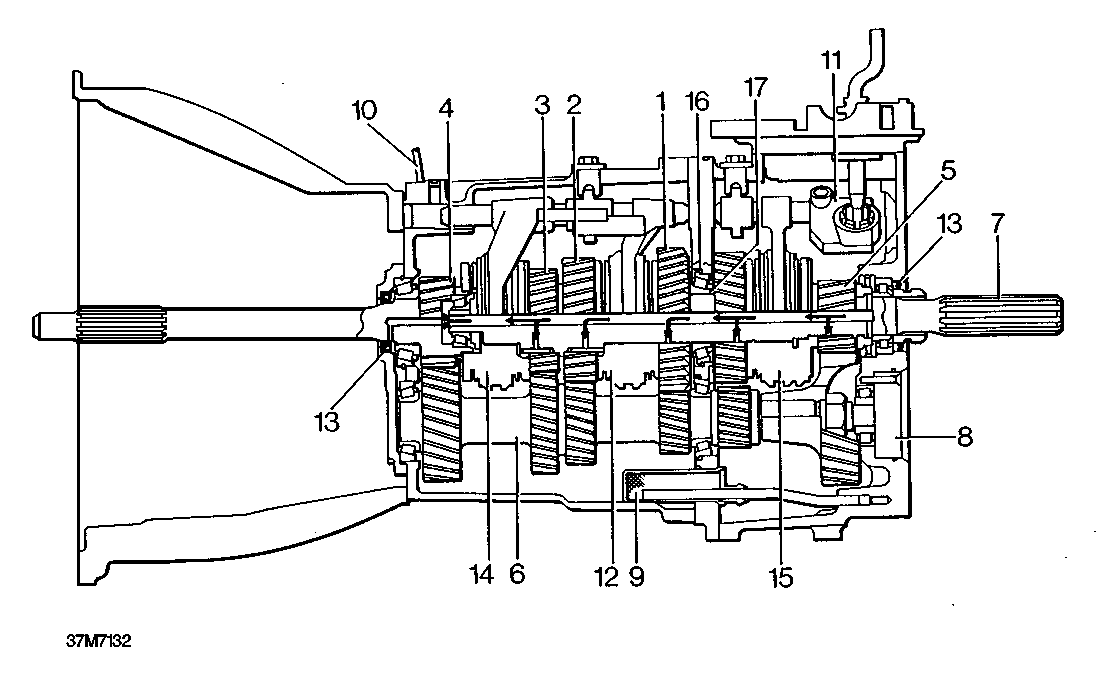

R380 Gearbox Overhaul English Manual

Gearbox Overhauling Procedure To prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Understanding gearbox failures is critical for preventing costly downtimes. Identify the gearbox make and model and disassemble the unit. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed. Evaluate the gearbox condition and repairs needed. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. On the other hand, removal of the gearbox for a full inspection. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Make regular visual inspections of gearboxes. To prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential.

From www.pinterest.com

Flender KBH 400/S/So Gearbox overhauling Repair, All pictures, Gearbox Overhauling Procedure Understanding gearbox failures is critical for preventing costly downtimes. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Make regular visual inspections of gearboxes. Overheating can be caused by insufficient lubrication, damaged. Gearbox Overhauling Procedure.

From ahgears.com

Gearbox Overhaul and Maintenance Ah Gears Gearbox Overhauling Procedure On the other hand, removal of the gearbox for a full inspection. Evaluate the gearbox condition and repairs needed. Identify the gearbox make and model and disassemble the unit. Understanding gearbox failures is critical for preventing costly downtimes. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Make regular visual inspections. Gearbox Overhauling Procedure.

From lles.com.au

Gearbox Overhaul, Assembly & Changeout 4 » LES Engineering Gearbox Overhauling Procedure To prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. Evaluate the gearbox condition and repairs needed. Make regular visual inspections of gearboxes. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. Understanding gearbox failures is critical for preventing costly downtimes. Look for. Gearbox Overhauling Procedure.

From theworkshop.com.my

Gearbox Overhaul The Malaysia Auto Service Specialist Gearbox Overhauling Procedure Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Identify the gearbox make and model and disassemble the unit. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Make regular visual inspections of gearboxes. On the other hand, removal of the gearbox for a full inspection.. Gearbox Overhauling Procedure.

From 4mechtech.blogspot.com

Mechanical Technology Manual Steering Gearbox Overhaul Gearbox Overhauling Procedure Identify the gearbox make and model and disassemble the unit. Make regular visual inspections of gearboxes. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed.. Gearbox Overhauling Procedure.

From www.studypool.com

SOLUTION Engine General Overhauling Procedure Lecture Studypool Gearbox Overhauling Procedure Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. On the other hand, removal of the gearbox for a full inspection. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. Common culprits include wear and tear from continuous use,. Gearbox Overhauling Procedure.

From littlelioness.net

The 6 Steps In The Gearbox Repair Process Simplified littlelioness Gearbox Overhauling Procedure This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed. Evaluate the gearbox condition and repairs needed. Understanding gearbox failures is critical for preventing costly downtimes. Make regular visual inspections of gearboxes. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime.. Gearbox Overhauling Procedure.

From www.youtube.com

DQ 250 gearbox overhauling YouTube Gearbox Overhauling Procedure Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. Evaluate the gearbox condition and repairs needed. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and,. Gearbox Overhauling Procedure.

From www.youtube.com

GB 1150 gearbox full overhauling YouTube Gearbox Overhauling Procedure Identify the gearbox make and model and disassemble the unit. On the other hand, removal of the gearbox for a full inspection. Understanding gearbox failures is critical for preventing costly downtimes. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. This manual contains procedures for overhaul of the r380 gearbox on the bench with. Gearbox Overhauling Procedure.

From www.aeu86.org

gearbox overhauling Gearbox Overhauling Procedure Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Understanding gearbox failures is critical for preventing costly downtimes. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable,. Gearbox Overhauling Procedure.

From www.austin7.org

Gearbox Overhaul Part 1 Gearbox Overhauling Procedure To prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. On the other hand, removal of the gearbox for a full inspection. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Identify the gearbox make and model and disassemble the unit. Overheating can be caused by insufficient lubrication, damaged. Gearbox Overhauling Procedure.

From culturaverde.org

The Ultimate Guide to Manual Transmission Rebuilds Culturaverde Gearbox Overhauling Procedure Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Identify the gearbox make and model and disassemble the unit. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed. Look for oil leaks on the input and output shafts, and discolouration of. Gearbox Overhauling Procedure.

From www.youtube.com

Gear Box Overhauling Hansen Make maintenance gear chemical Gearbox Overhauling Procedure Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. To prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Evaluate the gearbox condition and repairs needed. On the other hand, removal of. Gearbox Overhauling Procedure.

From www.gearbox.ie

Gearbox.ie Gearbox Repairs and Overhauls Gearbox Overhauling Procedure Evaluate the gearbox condition and repairs needed. Make regular visual inspections of gearboxes. To prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Understanding gearbox failures is critical for preventing costly downtimes. On the other hand, removal of the gearbox. Gearbox Overhauling Procedure.

From www.youtube.com

Overhaul gearbox manual model F5M21 YouTube Gearbox Overhauling Procedure Identify the gearbox make and model and disassemble the unit. Understanding gearbox failures is critical for preventing costly downtimes. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. On the other hand, removal of the gearbox for a full inspection. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead. Gearbox Overhauling Procedure.

From www.studocu.com

SMP MEC H 0021 NTM Gearbox Rev1 STANDARD MAINTENANCE PRACTICES Gearbox Overhauling Procedure Identify the gearbox make and model and disassemble the unit. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed. Evaluate the gearbox condition and repairs needed. Make regular visual inspections of gearboxes.. Gearbox Overhauling Procedure.

From www.youtube.com

GB 40 Gearbox Full Overhauling YouTube Gearbox Overhauling Procedure Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Evaluate the gearbox condition and repairs needed. Make regular visual inspections of gearboxes. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can. Gearbox Overhauling Procedure.

From www.rubbercowmotors.de

Gearbox overhaul Gearbox Overhauling Procedure Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Identify the gearbox make and model and disassemble the unit. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Make regular visual. Gearbox Overhauling Procedure.

From www.vizator.ru

R380 Gearbox Overhaul English Manual Gearbox Overhauling Procedure Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Make regular visual inspections of gearboxes. Identify the gearbox make and model and disassemble the unit. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. Look for oil leaks on the input and. Gearbox Overhauling Procedure.

From www.youtube.com

Complete Overhauling of Premium Gearbox (Geared motor) MSB 303 with Gearbox Overhauling Procedure Identify the gearbox make and model and disassemble the unit. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Make regular visual inspections of gearboxes. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. On the other hand, removal of the gearbox for a full inspection.. Gearbox Overhauling Procedure.

From www.youtube.com

How to overhaul manual gearbox YouTube Gearbox Overhauling Procedure On the other hand, removal of the gearbox for a full inspection. To prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. Evaluate the gearbox condition and repairs needed. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed. Identify the gearbox. Gearbox Overhauling Procedure.

From www.thefabricator.com

Stepbystep process for rebuilding a mechanical stamping press gearbox Gearbox Overhauling Procedure On the other hand, removal of the gearbox for a full inspection. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead. Gearbox Overhauling Procedure.

From www.youtube.com

overhaul gearbox manualmenukar bearing gearbox manualcara pasang Gearbox Overhauling Procedure Evaluate the gearbox condition and repairs needed. Identify the gearbox make and model and disassemble the unit. Make regular visual inspections of gearboxes. Understanding gearbox failures is critical for preventing costly downtimes. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction. Gearbox Overhauling Procedure.

From www.daganghalal.com

Gearbox Overhaul Gearbox Overhauling Procedure Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. Identify the gearbox make and model and disassemble the unit. Make regular visual inspections of gearboxes. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Misaligned gears can cause excessive. Gearbox Overhauling Procedure.

From www.coperion.com

Overhaul of Extruder Gearboxes for Maximum System Availability Coperion Gearbox Overhauling Procedure Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Understanding gearbox failures is critical for preventing costly downtimes. Identify the gearbox make and model and disassemble the unit. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. Make regular visual inspections of gearboxes.. Gearbox Overhauling Procedure.

From www.scribd.com

Gearbox Overhaul and Repair Procedure PDF Pipe (Fluid Conveyance Gearbox Overhauling Procedure On the other hand, removal of the gearbox for a full inspection. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Evaluate the gearbox condition and repairs needed. Understanding gearbox failures is critical for preventing costly downtimes. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if. Gearbox Overhauling Procedure.

From www.alatas.com

Gear box overhauling Alatas Gearbox Overhauling Procedure Make regular visual inspections of gearboxes. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Evaluate the gearbox condition and repairs needed. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. Misaligned gears can cause excessive wear and vibration,. Gearbox Overhauling Procedure.

From www.youtube.com

Full Overhauling of Gearbox with Bearings & gear replacement.How to Gearbox Overhauling Procedure Evaluate the gearbox condition and repairs needed. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Identify the gearbox make and model. Gearbox Overhauling Procedure.

From www.youtube.com

overhauling procedure of centrifugal pump YouTube Gearbox Overhauling Procedure Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. Evaluate the gearbox condition and repairs needed. Make regular visual inspections of gearboxes. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. To prolong the operational life of your industrial. Gearbox Overhauling Procedure.

From dcleng.com.au

Gearbox Repair & Overhaul DCL Engineering Group Gearbox Overhauling Procedure Identify the gearbox make and model and disassemble the unit. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed. Evaluate the gearbox condition and repairs needed. Understanding gearbox failures is critical for preventing costly downtimes. Misaligned gears can cause excessive wear and vibration, leading to reduced. Gearbox Overhauling Procedure.

From www.youtube.com

ABB Cooling Tower Gear Motor Overhauling Work II Complete step by step Gearbox Overhauling Procedure Identify the gearbox make and model and disassemble the unit. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. To prolong the. Gearbox Overhauling Procedure.

From www.youtube.com

Gearbox Overhauling Rolling Mill Gearbox Mechanical Technology Gearbox Overhauling Procedure This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed. To prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. On the other hand, removal of the gearbox for a full inspection. Misaligned gears can cause excessive wear and vibration, leading to. Gearbox Overhauling Procedure.

From www.youtube.com

Gearbox Gearbox Part 2 Gearbox Overhauling Gearbox Repair Gearbox Overhauling Procedure Identify the gearbox make and model and disassemble the unit. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. This manual contains procedures for overhaul of the r380 gearbox on the bench with the clutch and, if applicable, the transfer box removed. Misaligned gears can cause excessive wear. Gearbox Overhauling Procedure.

From www.youtube.com

Gearbox Gearbox Part 5 Gearbox Overhauling Gearbox Working Gearbox Overhauling Procedure Evaluate the gearbox condition and repairs needed. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Overheating can be caused by insufficient lubrication, damaged bearings, or other factors, and can lead to increased wear and reduced efficiency. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and.. Gearbox Overhauling Procedure.

From www.elphisengineering.co.uk

Industrial Gearbox Repair, Process Pump Repair, Overhaul Service Gearbox Overhauling Procedure Evaluate the gearbox condition and repairs needed. Look for oil leaks on the input and output shafts, and discolouration of the paint that might indicate. Common culprits include wear and tear from continuous use, insufficient lubrication causing friction and. Misaligned gears can cause excessive wear and vibration, leading to reduced efficiency and increased downtime. This manual contains procedures for overhaul. Gearbox Overhauling Procedure.