What Is Proof Machining Of Casting . Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. These defects are normal in the casting process. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. Specialist computers are programmed to guide the machining tools and shape the component accordingly. Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. Machining is carried out by computer numerical control (cnc).

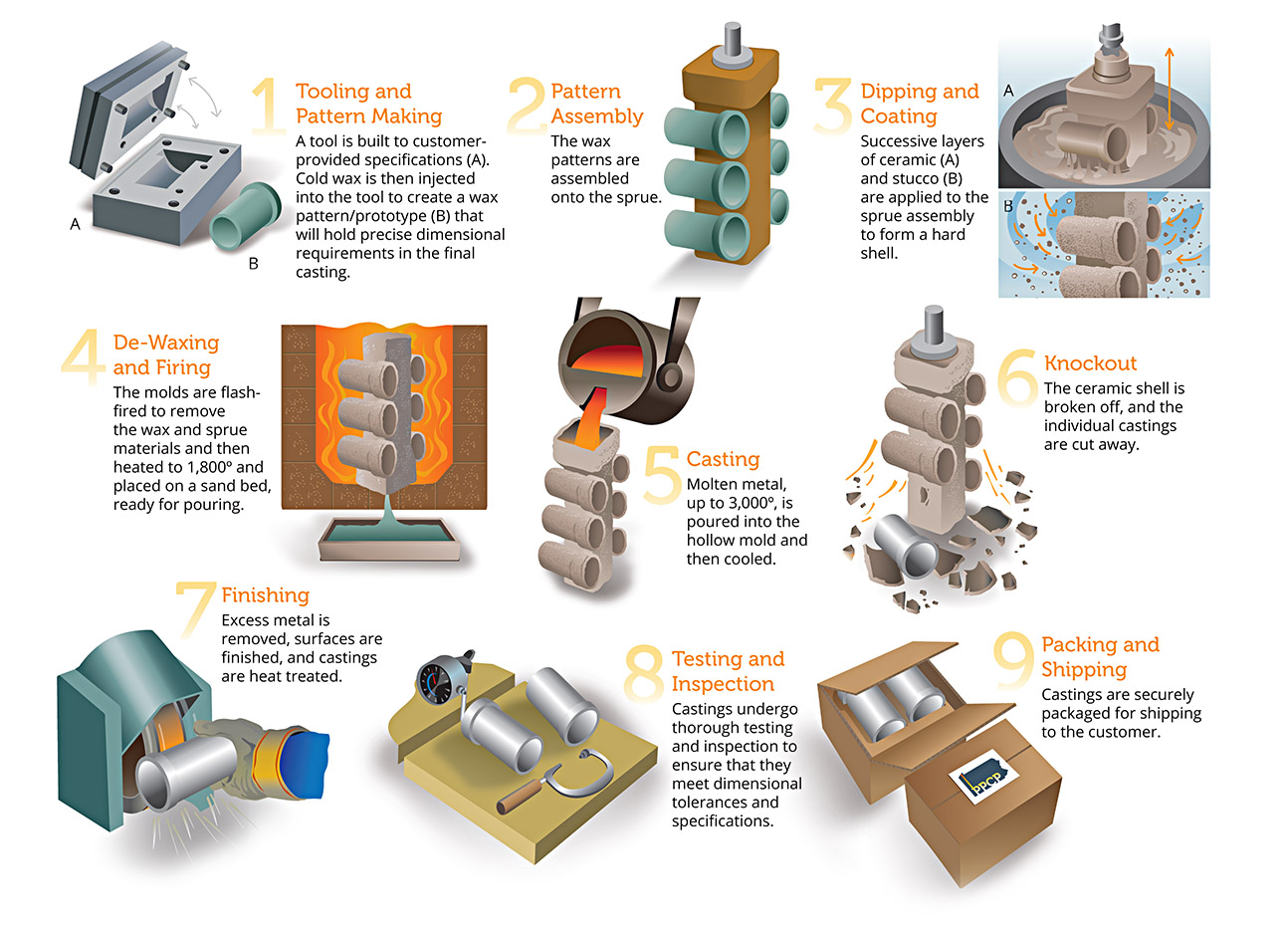

from ppcpinc.com

Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. Specialist computers are programmed to guide the machining tools and shape the component accordingly. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Machining is carried out by computer numerical control (cnc). These defects are normal in the casting process.

» PPCP Process

What Is Proof Machining Of Casting Machining is carried out by computer numerical control (cnc). Machining is carried out by computer numerical control (cnc). These defects are normal in the casting process. Specialist computers are programmed to guide the machining tools and shape the component accordingly. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting.

From www.roucka-slevarna.cz

Machining of castings Roučka slévárna, a.s. What Is Proof Machining Of Casting Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Machining is used because it helps create very fine and detailed objects that would have been impossible. What Is Proof Machining Of Casting.

From www.ctemag.com

Choosing the right tool for machining titanium Cutting Tool Engineering What Is Proof Machining Of Casting These defects are normal in the casting process. Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. Machining is carried out by computer numerical control (cnc). Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Specialist computers. What Is Proof Machining Of Casting.

From blog.thepipingmart.com

Machining vs Casting What's the Difference What Is Proof Machining Of Casting These defects are normal in the casting process. Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Specialist computers are programmed to guide the machining tools and. What Is Proof Machining Of Casting.

From www.omicroncasting.com

5 Different Methods Used in Casting What Is Proof Machining Of Casting Machining is carried out by computer numerical control (cnc). Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. These defects are normal in the casting process. Machining. What Is Proof Machining Of Casting.

From shearxl.co.uk

Castings Machining Precision Machining Of Raw Castings What Is Proof Machining Of Casting Specialist computers are programmed to guide the machining tools and shape the component accordingly. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Cutting, drilling, milling, and. What Is Proof Machining Of Casting.

From kerone.com

Different Types of Casting Process and Uses What Is Proof Machining Of Casting Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. These defects are normal in the casting process. Machining is used because it helps create very. What Is Proof Machining Of Casting.

From ppcpinc.com

» PPCP Process What Is Proof Machining Of Casting Specialist computers are programmed to guide the machining tools and shape the component accordingly. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. These defects are. What Is Proof Machining Of Casting.

From www.deancast.com

Casting & Machining Gallery What Is Proof Machining Of Casting The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. These defects are normal in the casting process. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Aside from the fact that machining can seal surfaces and. What Is Proof Machining Of Casting.

From www.exportersindia.com

Casting with Proof Machining by Sunaina Engineering Industries What Is Proof Machining Of Casting Specialist computers are programmed to guide the machining tools and shape the component accordingly. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. Aside from the fact. What Is Proof Machining Of Casting.

From www.xmzldjx.com

About Die Casting Process(I) What Is Proof Machining Of Casting These defects are normal in the casting process. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Machining is carried out by computer numerical control (cnc). Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Cutting,. What Is Proof Machining Of Casting.

From www.youtube.com

Casting3 programming, fixturing and machining of opperation one. YouTube What Is Proof Machining Of Casting Specialist computers are programmed to guide the machining tools and shape the component accordingly. Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Machining is carried out by. What Is Proof Machining Of Casting.

From www.youtube.com

Casting Machining Sinertecnic YouTube What Is Proof Machining Of Casting These defects are normal in the casting process. Machining is carried out by computer numerical control (cnc). Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Specialist computers are programmed to guide the machining tools and shape the component accordingly. Machining takes place once any fettling or heat. What Is Proof Machining Of Casting.

From cirexfoundry.com

Machining of castings CIREX What Is Proof Machining Of Casting These defects are normal in the casting process. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Machining is carried out by computer numerical control (cnc). Machining is. What Is Proof Machining Of Casting.

From medium.com

Casting vs. Understanding the Differences by microcare Medium What Is Proof Machining Of Casting The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Machining is carried out by computer numerical control (cnc). Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Cutting, drilling, milling, and grinding tools can be used in. What Is Proof Machining Of Casting.

From deancast.com

Aluminium Gravity Die Casting & Machining Deancast What Is Proof Machining Of Casting Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes,. What Is Proof Machining Of Casting.

From edebmachine.com

Edeb Engineering Advanced 3D Modelling Software, Precision Machining What Is Proof Machining Of Casting Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. These defects are normal in the casting process. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Machining is carried out by computer numerical control (cnc). Machining is. What Is Proof Machining Of Casting.

From www.hscast.com

Machining Harrison Steel Castings Company What Is Proof Machining Of Casting These defects are normal in the casting process. Machining is carried out by computer numerical control (cnc). The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Machining. What Is Proof Machining Of Casting.

From www.china-machining.com

Casting vs. Machining What are the Pros and Cons of Each? What Is Proof Machining Of Casting Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. These defects are normal in the casting process. Machining is used because it helps create very. What Is Proof Machining Of Casting.

From spbgroup.in

Spb Metal Casters SPB Castings What Is Proof Machining Of Casting Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. The investment casting process became one of those alternatives and this process became inevitable to fill an. What Is Proof Machining Of Casting.

From www.roucka-slevarna.cz

Machining of castings Roučka slévárna, a.s. What Is Proof Machining Of Casting Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. Specialist computers are programmed to guide the machining tools and shape the component accordingly. The investment. What Is Proof Machining Of Casting.

From www.youtube.com

CNC Machining of Castings & Components Machined Castings UK YouTube What Is Proof Machining Of Casting Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. These defects are normal in the casting process. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Aside from the fact that machining can seal. What Is Proof Machining Of Casting.

From www.haworthcastings.co.uk

Turning a machining process for metal casting Haworth Castings What Is Proof Machining Of Casting Specialist computers are programmed to guide the machining tools and shape the component accordingly. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. These defects are normal in the casting process. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you. What Is Proof Machining Of Casting.

From www.rapiddirect.com

Types of Machining Process Classifications and Differences What Is Proof Machining Of Casting Machining is carried out by computer numerical control (cnc). Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. Specialist computers are programmed to guide the machining tools. What Is Proof Machining Of Casting.

From www.steckermachine.com

Casting, Machining, and the Importance of Tolerances What Is Proof Machining Of Casting Specialist computers are programmed to guide the machining tools and shape the component accordingly. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Cutting, drilling, milling, and grinding. What Is Proof Machining Of Casting.

From www.ferralloy.com

What Is Proof Machined What Is Proof Machining Of Casting These defects are normal in the casting process. Specialist computers are programmed to guide the machining tools and shape the component accordingly. Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent. What Is Proof Machining Of Casting.

From www.fastradius.com

FYI CNC Machining vs. Die Casting Fast Radius What Is Proof Machining Of Casting Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex. What Is Proof Machining Of Casting.

From shearxl.co.uk

Castings Machining Precision Machining Of Raw Castings What Is Proof Machining Of Casting Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined. What Is Proof Machining Of Casting.

From www.market-prospects.com

Five Type Stamping Process To Introduce You Milling, Machining, Die What Is Proof Machining Of Casting Machining is carried out by computer numerical control (cnc). Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Cutting, drilling, milling, and grinding tools can be. What Is Proof Machining Of Casting.

From www.roucka-slevarna.cz

Machining of castings Roučka slévárna, a.s. What Is Proof Machining Of Casting Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings. What Is Proof Machining Of Casting.

From www.mech4study.com

Types of Casting in Manufacturing Mech4study What Is Proof Machining Of Casting Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. Aside from the fact that machining can seal surfaces and threaded holes, it also allows you to produce fine and detailed. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes,. What Is Proof Machining Of Casting.

From www.youtube.com

Difference between Conventional and Non Conventional Machining Process What Is Proof Machining Of Casting Specialist computers are programmed to guide the machining tools and shape the component accordingly. These defects are normal in the casting process. Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce. What Is Proof Machining Of Casting.

From www.3erp.com

What is Machining Definition, Types & Tools What Is Proof Machining Of Casting Specialist computers are programmed to guide the machining tools and shape the component accordingly. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. These defects are normal in the casting process. The investment casting process became one of those alternatives and this process became inevitable to fill. What Is Proof Machining Of Casting.

From www.indiamart.com

Casting Proof Machined Steel Castings at Rs 170/kg in Kuhi ID What Is Proof Machining Of Casting Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. Specialist computers are programmed to guide the machining tools and shape the component accordingly. Machining is carried out. What Is Proof Machining Of Casting.

From www.castingstechnology.com

Proof and Finish Machining Castings Technology What Is Proof Machining Of Casting Specialist computers are programmed to guide the machining tools and shape the component accordingly. The investment casting process became one of those alternatives and this process became inevitable to fill an urgent demand for. These defects are normal in the casting process. Machining is used because it helps create very fine and detailed objects that would have been impossible to. What Is Proof Machining Of Casting.

From mavink.com

Machining Surface Finish Symbols Chart What Is Proof Machining Of Casting These defects are normal in the casting process. Machining is used because it helps create very fine and detailed objects that would have been impossible to manufacture through. Cutting, drilling, milling, and grinding tools can be used in a variety of ways to produce complex machined forgings and machined castings. Machining takes place once any fettling or heat treatment has. What Is Proof Machining Of Casting.