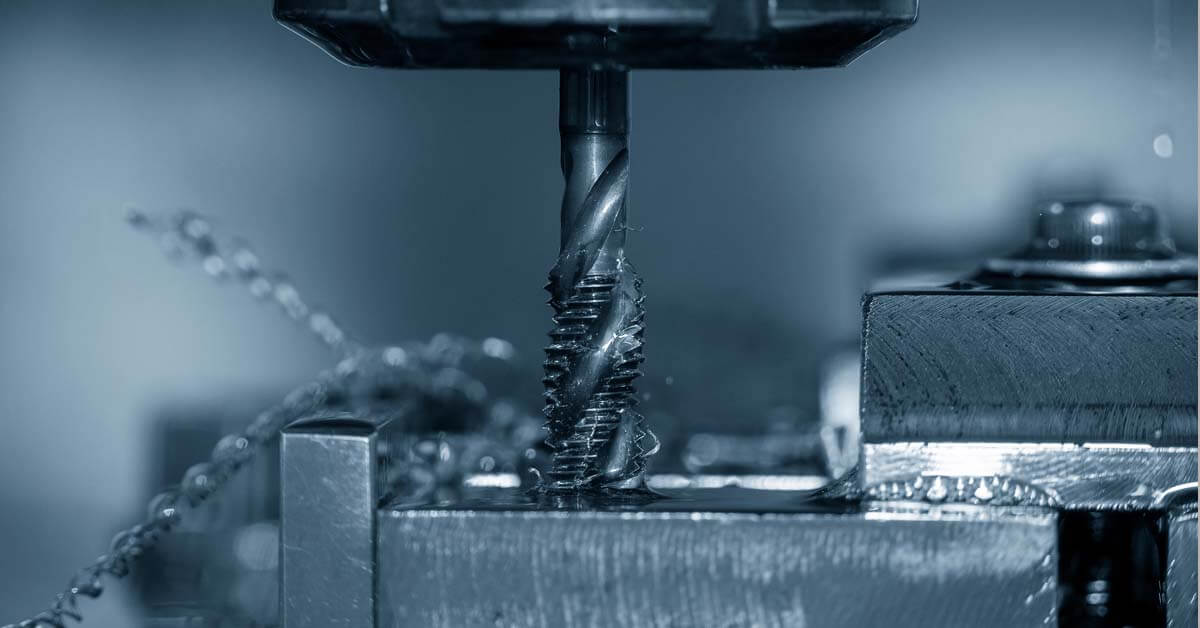

Thread Milling Vs Thread Tapping . Those spiral grooves inside or outside of a hole that screws are meant to fit into. Thread milling and tapping are two methods of making threads in metal; If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. The primary distinction between tapping and thread milling lies in their approach to creating threads. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. Tapping and thread milling each have distinct pros and cons, and the choice of one over the other comes down to production quantity, material hardness or toughness, available machine tool power, accuracy requirements, and personal preference. Thread milling is more versatile and. Thread milling and threading (tapping) differ in terms of process, flexibility, and material suitability. If speed is your requirement,. The primary distinction between tapping and thread milling lies in their approach to creating threads. Here are some things to consider as you weigh the two options: Consequently, tapping is exclusively used to cut threads on the inner surface. For mass production of standard threads, tapping is often more efficient due to its faster cycle times.

from ecoreprap.com

Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. Thread milling and tapping are two methods of making threads in metal; If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. For mass production of standard threads, tapping is often more efficient due to its faster cycle times. The primary distinction between tapping and thread milling lies in their approach to creating threads. Consequently, tapping is exclusively used to cut threads on the inner surface. Tapping and thread milling each have distinct pros and cons, and the choice of one over the other comes down to production quantity, material hardness or toughness, available machine tool power, accuracy requirements, and personal preference. Those spiral grooves inside or outside of a hole that screws are meant to fit into. The primary distinction between tapping and thread milling lies in their approach to creating threads. If speed is your requirement,.

What is Thread Milling in CNC Machining?

Thread Milling Vs Thread Tapping Thread milling is more versatile and. If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. Those spiral grooves inside or outside of a hole that screws are meant to fit into. If speed is your requirement,. For mass production of standard threads, tapping is often more efficient due to its faster cycle times. The primary distinction between tapping and thread milling lies in their approach to creating threads. Thread milling and tapping are two methods of making threads in metal; The primary distinction between tapping and thread milling lies in their approach to creating threads. Thread milling is more versatile and. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. Consequently, tapping is exclusively used to cut threads on the inner surface. Tapping and thread milling each have distinct pros and cons, and the choice of one over the other comes down to production quantity, material hardness or toughness, available machine tool power, accuracy requirements, and personal preference. Thread milling and threading (tapping) differ in terms of process, flexibility, and material suitability. Here are some things to consider as you weigh the two options:

From blog.thepipingmart.com

Self Tapping vs Thread Cutting Screws What's the Difference Thread Milling Vs Thread Tapping Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. Here are some things to consider as you weigh the two options: Thread milling and tapping are two methods of making threads in metal; The primary distinction between tapping and thread milling lies in. Thread Milling Vs Thread Tapping.

From huanatools.com

Which is the best?Thread Milling VS Tapping? Huana Tools Thread Milling Vs Thread Tapping Thread milling is more versatile and. Thread milling and threading (tapping) differ in terms of process, flexibility, and material suitability. Those spiral grooves inside or outside of a hole that screws are meant to fit into. If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is. Thread Milling Vs Thread Tapping.

From rosenet.co.uk

Tapping v thread milling the differences, advantages and disadvantages Thread Milling Vs Thread Tapping Here are some things to consider as you weigh the two options: If speed is your requirement,. For mass production of standard threads, tapping is often more efficient due to its faster cycle times. Thread milling is more versatile and. The primary distinction between tapping and thread milling lies in their approach to creating threads. Tapping employs a tap specifically. Thread Milling Vs Thread Tapping.

From www.datron.com

Thread Milling vs. Tapping DATRON Dynamics Thread Milling Vs Thread Tapping Those spiral grooves inside or outside of a hole that screws are meant to fit into. The primary distinction between tapping and thread milling lies in their approach to creating threads. Here are some things to consider as you weigh the two options: Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the. Thread Milling Vs Thread Tapping.

From be-cu.com

Exploring Thread Milling Types, Principles, and Advantages Thread Milling Vs Thread Tapping Tapping and thread milling each have distinct pros and cons, and the choice of one over the other comes down to production quantity, material hardness or toughness, available machine tool power, accuracy requirements, and personal preference. Here are some things to consider as you weigh the two options: Thread milling and threading (tapping) differ in terms of process, flexibility, and. Thread Milling Vs Thread Tapping.

From www.cutwel.co.uk

Thread Milling vs Tapping An Expert Guide Cutwel Ltd Thread Milling Vs Thread Tapping Thread milling and tapping are two methods of making threads in metal; Here are some things to consider as you weigh the two options: For mass production of standard threads, tapping is often more efficient due to its faster cycle times. Tapping and thread milling each have distinct pros and cons, and the choice of one over the other comes. Thread Milling Vs Thread Tapping.

From tnnengineering.com

Thread Milling vs. Tapping CNC Thread Milling CNC Thread Tapping Thread Milling Vs Thread Tapping For mass production of standard threads, tapping is often more efficient due to its faster cycle times. If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. Consequently, tapping is exclusively used to cut threads on the inner surface. Tapping employs a tap. Thread Milling Vs Thread Tapping.

From ecoreprap.com

What is Thread Milling in CNC Machining? Thread Milling Vs Thread Tapping Here are some things to consider as you weigh the two options: If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. Thread milling is more versatile and. Consequently, tapping is exclusively used to cut threads on the inner surface. Those spiral grooves. Thread Milling Vs Thread Tapping.

From cuttingedgeconversation.blogspot.com

Cutting Edge Conversation Six Reasons Thread Milling is Better Than Thread Milling Vs Thread Tapping Consequently, tapping is exclusively used to cut threads on the inner surface. Thread milling is more versatile and. Tapping and thread milling each have distinct pros and cons, and the choice of one over the other comes down to production quantity, material hardness or toughness, available machine tool power, accuracy requirements, and personal preference. Here are some things to consider. Thread Milling Vs Thread Tapping.

From www.kennametal.com

Machining Guide Thread Milling vs. Tapping Thread Milling Vs Thread Tapping Consequently, tapping is exclusively used to cut threads on the inner surface. If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the. Thread Milling Vs Thread Tapping.

From blog.tormach.com

The Basics of Making Threads Thread Milling Vs Thread Tapping If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. If speed is your requirement,. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. Thread milling. Thread Milling Vs Thread Tapping.

From www.rapiddirect.com

The Ultimate Guide to Machining Thread RapidDirect Blog Thread Milling Vs Thread Tapping Thread milling is more versatile and. Here are some things to consider as you weigh the two options: For mass production of standard threads, tapping is often more efficient due to its faster cycle times. Thread milling and tapping are two methods of making threads in metal; Consequently, tapping is exclusively used to cut threads on the inner surface. Thread. Thread Milling Vs Thread Tapping.

From www.mscdirect.com

Thread Milling vs. Tapping What Are the Pros and Cons? Better MRO Thread Milling Vs Thread Tapping Thread milling is more versatile and. Thread milling and threading (tapping) differ in terms of process, flexibility, and material suitability. If speed is your requirement,. Those spiral grooves inside or outside of a hole that screws are meant to fit into. The primary distinction between tapping and thread milling lies in their approach to creating threads. If you need more. Thread Milling Vs Thread Tapping.

From blog.tormach.com

The Basics of Making Threads Thread Milling Vs Thread Tapping Here are some things to consider as you weigh the two options: Consequently, tapping is exclusively used to cut threads on the inner surface. Those spiral grooves inside or outside of a hole that screws are meant to fit into. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of. Thread Milling Vs Thread Tapping.

From www.cutwel.co.uk

Thread Milling vs Tapping An Expert Guide Cutwel Ltd Thread Milling Vs Thread Tapping Tapping and thread milling each have distinct pros and cons, and the choice of one over the other comes down to production quantity, material hardness or toughness, available machine tool power, accuracy requirements, and personal preference. Consequently, tapping is exclusively used to cut threads on the inner surface. Thread milling is more versatile and. Thread milling and tapping are two. Thread Milling Vs Thread Tapping.

From be-cu.com

Thread Milling vs Tapping Thread Milling Vs Thread Tapping The primary distinction between tapping and thread milling lies in their approach to creating threads. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. Thread milling is more versatile and. Consequently, tapping is exclusively used to cut threads on the inner surface. Tapping. Thread Milling Vs Thread Tapping.

From www.cutwel.co.uk

Thread Milling vs Tapping An Expert Guide Cutwel Ltd Thread Milling Vs Thread Tapping Those spiral grooves inside or outside of a hole that screws are meant to fit into. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. If you need more flexibility, have a range of thread sizes and types and require the ability to. Thread Milling Vs Thread Tapping.

From prochain-cnc.com

4 common thread processing methods you must know PROCHAIN PRECISION Thread Milling Vs Thread Tapping Thread milling is more versatile and. Consequently, tapping is exclusively used to cut threads on the inner surface. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. Tapping and thread milling each have distinct pros and cons, and the choice of one over. Thread Milling Vs Thread Tapping.

From www.sandvik.coromant.com

How to choose the right type of tap Thread Milling Vs Thread Tapping If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. Thread milling and tapping are two methods of making threads in metal; If speed is your requirement,. The primary distinction between tapping and thread milling lies in their approach to creating threads. Thread. Thread Milling Vs Thread Tapping.

From www.sundicuttingtools.com

Thread Milling vs. Tapping Achieving Precision Threads with Mills and Thread Milling Vs Thread Tapping The primary distinction between tapping and thread milling lies in their approach to creating threads. Consequently, tapping is exclusively used to cut threads on the inner surface. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. Tapping and thread milling each have distinct. Thread Milling Vs Thread Tapping.

From smicut.com

Why choose Thread Milling instead of Tapping? SmiCut The Master of Thread Milling Vs Thread Tapping If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. Here are some things to consider as you weigh the two options: If speed is your requirement,. The primary distinction between tapping and thread milling lies in their approach to creating threads. Thread. Thread Milling Vs Thread Tapping.

From www.mfgproto.com

Thread Milling vs. Tapping What Are the Differences? Proto MFG Thread Milling Vs Thread Tapping If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. Thread milling is more versatile and. The primary distinction between tapping and thread milling lies in their approach to creating threads. Here are some things to consider as you weigh the two options:. Thread Milling Vs Thread Tapping.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Milling Vs Thread Tapping Here are some things to consider as you weigh the two options: Thread milling is more versatile and. Consequently, tapping is exclusively used to cut threads on the inner surface. Thread milling and threading (tapping) differ in terms of process, flexibility, and material suitability. For mass production of standard threads, tapping is often more efficient due to its faster cycle. Thread Milling Vs Thread Tapping.

From www.slideserve.com

PPT Module 7 Tapping and Threading PowerPoint Presentation ID2206779 Thread Milling Vs Thread Tapping If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. The primary distinction between tapping and thread milling lies in their approach to creating threads. Tapping and thread milling each have distinct pros and cons, and the choice of one over the other. Thread Milling Vs Thread Tapping.

From www.sandvik.coromant.com

Tapping threads what is tapping? Thread Milling Vs Thread Tapping Thread milling is more versatile and. If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. If speed is your requirement,. Here are some things to consider as you weigh the two options: Consequently, tapping is exclusively used to cut threads on the. Thread Milling Vs Thread Tapping.

From www.nextgentooling.com

Thread Milling Techniques NEXT GENERATION TOOLING Thread Milling Vs Thread Tapping The primary distinction between tapping and thread milling lies in their approach to creating threads. Tapping and thread milling each have distinct pros and cons, and the choice of one over the other comes down to production quantity, material hardness or toughness, available machine tool power, accuracy requirements, and personal preference. The primary distinction between tapping and thread milling lies. Thread Milling Vs Thread Tapping.

From huanatools.com

Which is the best?Thread Milling VS Tapping? Huana Tools Thread Milling Vs Thread Tapping The primary distinction between tapping and thread milling lies in their approach to creating threads. Tapping employs a tap specifically designed to cut a predetermined thread, while thread milling relies on the controlled movement of the tool to define the thread. Those spiral grooves inside or outside of a hole that screws are meant to fit into. If speed is. Thread Milling Vs Thread Tapping.

From www.longshengmfg.com

Thread Milling vs. Tapping Which one is suitable for you Thread Milling Vs Thread Tapping For mass production of standard threads, tapping is often more efficient due to its faster cycle times. If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. Consequently, tapping is exclusively used to cut threads on the inner surface. Here are some things. Thread Milling Vs Thread Tapping.

From www.sundicuttingtools.com

Thread Milling vs. Tapping Achieving Precision Threads with Mills and Thread Milling Vs Thread Tapping Thread milling and threading (tapping) differ in terms of process, flexibility, and material suitability. Thread milling is more versatile and. Those spiral grooves inside or outside of a hole that screws are meant to fit into. For mass production of standard threads, tapping is often more efficient due to its faster cycle times. The primary distinction between tapping and thread. Thread Milling Vs Thread Tapping.

From www.mscdirect.com

Thread Milling vs. Tapping What Are the Pros and Cons? Better MRO Thread Milling Vs Thread Tapping Thread milling and threading (tapping) differ in terms of process, flexibility, and material suitability. For mass production of standard threads, tapping is often more efficient due to its faster cycle times. If you need more flexibility, have a range of thread sizes and types and require the ability to adjust thread fits, thread milling is the best choice. The primary. Thread Milling Vs Thread Tapping.

From huanatools.com

Which is the best?Thread Milling VS Tapping? Huana Tools Thread Milling Vs Thread Tapping Tapping and thread milling each have distinct pros and cons, and the choice of one over the other comes down to production quantity, material hardness or toughness, available machine tool power, accuracy requirements, and personal preference. The primary distinction between tapping and thread milling lies in their approach to creating threads. Thread milling and tapping are two methods of making. Thread Milling Vs Thread Tapping.

From www.machinery.co.uk

Machinery Thread tapping whirling cutting forming milling Thread Milling Vs Thread Tapping Consequently, tapping is exclusively used to cut threads on the inner surface. Thread milling and tapping are two methods of making threads in metal; Thread milling is more versatile and. The primary distinction between tapping and thread milling lies in their approach to creating threads. Thread milling and threading (tapping) differ in terms of process, flexibility, and material suitability. The. Thread Milling Vs Thread Tapping.

From mtdcnc.com

Thread milling vs Tapping Which is best? MTDCNC The home of CNC Thread Milling Vs Thread Tapping For mass production of standard threads, tapping is often more efficient due to its faster cycle times. Tapping and thread milling each have distinct pros and cons, and the choice of one over the other comes down to production quantity, material hardness or toughness, available machine tool power, accuracy requirements, and personal preference. The primary distinction between tapping and thread. Thread Milling Vs Thread Tapping.

From www.kennametal.com

Metal Cutting Blog Kennametal Thread Milling Vs Thread Tapping For mass production of standard threads, tapping is often more efficient due to its faster cycle times. Those spiral grooves inside or outside of a hole that screws are meant to fit into. Thread milling is more versatile and. Thread milling and threading (tapping) differ in terms of process, flexibility, and material suitability. Tapping and thread milling each have distinct. Thread Milling Vs Thread Tapping.

From www.sandvik.coromant.com

Thread milling Thread Milling Vs Thread Tapping Consequently, tapping is exclusively used to cut threads on the inner surface. Here are some things to consider as you weigh the two options: For mass production of standard threads, tapping is often more efficient due to its faster cycle times. The primary distinction between tapping and thread milling lies in their approach to creating threads. Thread milling is more. Thread Milling Vs Thread Tapping.