Function Of Tap In Workshop . Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt. The plug, second, and taper. When the tap is screwed into a hole it removes metal and. The purpose of tapping in machining. Tapping is the operation of cutting internal threads in a hole using a cutting tool called tap. A die is used to cut the male portion of the mating pair (e.g., a screw). Though this tool is most commonly used by machinists and engineers, automotive. A tap is used for cutting of the female segment of. A tap is used to cut the female portion of the mating pair (e.g., a nut). A tap has cutting edges in the shape of threads. Dies and taps are the most common threading tools. In this article you will learn the. There are three main types of taps. A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. 6 features of internal taps at a glance.

from www.wonkeedonkeetools.co.uk

Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt. Though this tool is most commonly used by machinists and engineers, automotive. A tap is used for cutting of the female segment of. In this article you will learn the. The plug, second, and taper. The process of cutting threads using a tap is called. A tap is used to cut the female portion of the mating pair (e.g., a nut). A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. The purpose of tapping in machining. There are three main types of taps.

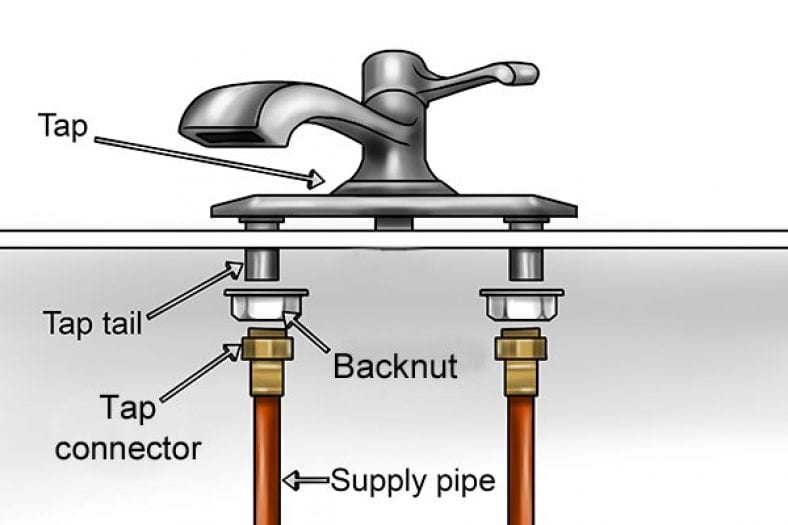

What are the parts of a tap fitting? Wonkee Donkee Tools

Function Of Tap In Workshop There are three main types of taps. 6 features of internal taps at a glance. Tapping is the operation of cutting internal threads in a hole using a cutting tool called tap. Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt. Dies and taps are the most common threading tools. A die is used to cut the male portion of the mating pair (e.g., a screw). A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. The process of cutting threads using a tap is called. The plug, second, and taper. Though this tool is most commonly used by machinists and engineers, automotive. A tap has cutting edges in the shape of threads. In this article you will learn the. A tap is used for cutting of the female segment of. There are three main types of taps. To cut an internal thread, the appropriate tap must be selected. A tap is used to cut the female portion of the mating pair (e.g., a nut).

From www.pinterest.com.au

Metal working tools, Tools, Tap chart Function Of Tap In Workshop A tap has cutting edges in the shape of threads. A die is used to cut the male portion of the mating pair (e.g., a screw). The plug, second, and taper. A tap is used to cut the female portion of the mating pair (e.g., a nut). When the tap is screwed into a hole it removes metal and. Dies. Function Of Tap In Workshop.

From www.slideshare.net

Tap changer Function Of Tap In Workshop In this article you will learn the. A tap is used for cutting of the female segment of. The process of cutting threads using a tap is called. Though this tool is most commonly used by machinists and engineers, automotive. To cut an internal thread, the appropriate tap must be selected. When the tap is screwed into a hole it. Function Of Tap In Workshop.

From www.practicalmachinist.com

A Guide to Tapping and Threading Practical Machinist Practical Function Of Tap In Workshop There are three main types of taps. Though this tool is most commonly used by machinists and engineers, automotive. To cut an internal thread, the appropriate tap must be selected. Tapping is the operation of cutting internal threads in a hole using a cutting tool called tap. Dies and taps are the most common threading tools. A tap is used. Function Of Tap In Workshop.

From www.diynetwork.com

How To Use a Tap and Die Set howtos DIY Function Of Tap In Workshop The plug, second, and taper. A tap is used for cutting of the female segment of. A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. The process of cutting threads using a tap is called. Taps thread the inside surface of a hole to create components like nuts or holes. Function Of Tap In Workshop.

From threadingtoolsguide.com

Hand tap What is a hand tap? Function Of Tap In Workshop The plug, second, and taper. There are three main types of taps. When the tap is screwed into a hole it removes metal and. A tap is used for cutting of the female segment of. The purpose of tapping in machining. Dies and taps are the most common threading tools. To cut an internal thread, the appropriate tap must be. Function Of Tap In Workshop.

From www.youtube.com

M2548+Tap Function YouTube Function Of Tap In Workshop The purpose of tapping in machining. Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt. A tap is used to cut the female portion of the mating pair (e.g., a nut). A tap has cutting edges in the shape of threads. The plug, second,. Function Of Tap In Workshop.

From solutions.travers.com

Tap and Drill Chart Printable PDF Function Of Tap In Workshop A tapping machine, tapping press, or tapping center is a specialized machine that facilitates accurate. Tapping is the operation of cutting internal threads in a hole using a cutting tool called tap. The purpose of tapping in machining. The plug, second, and taper. Though this tool is most commonly used by machinists and engineers, automotive. Dies and taps are the. Function Of Tap In Workshop.

From www.youtube.com

Drill Press Tapping Function YouTube Function Of Tap In Workshop A tap has cutting edges in the shape of threads. A die is used to cut the male portion of the mating pair (e.g., a screw). There are three main types of taps. A tap is used for cutting of the female segment of. Tapping is the operation of cutting internal threads in a hole using a cutting tool called. Function Of Tap In Workshop.

From www.maddoxtransformer.com

Transformer Tap Changers & Voltage Adjustment Taps Function Of Tap In Workshop A tapping machine, tapping press, or tapping center is a specialized machine that facilitates accurate. Though this tool is most commonly used by machinists and engineers, automotive. To cut an internal thread, the appropriate tap must be selected. There are three main types of taps. 6 features of internal taps at a glance. A tap has cutting edges in the. Function Of Tap In Workshop.

From www.youtube.com

Tap Recovery with Retract Function in the SINUMERIK CNC YouTube Function Of Tap In Workshop There are three main types of taps. When the tap is screwed into a hole it removes metal and. The process of cutting threads using a tap is called. 6 features of internal taps at a glance. Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw. Function Of Tap In Workshop.

From www.dreamstime.com

Metalwork Tools on the Table. Threading Dies and Taps I Stock Function Of Tap In Workshop To cut an internal thread, the appropriate tap must be selected. Though this tool is most commonly used by machinists and engineers, automotive. There are three main types of taps. A die is used to cut the male portion of the mating pair (e.g., a screw). A tap is used to make (cut) new threads or clean out (chase) existing. Function Of Tap In Workshop.

From www.pntools.com.au

Carbon Tap Set P&N Tools Function Of Tap In Workshop To cut an internal thread, the appropriate tap must be selected. Tapping is the operation of cutting internal threads in a hole using a cutting tool called tap. In this article you will learn the. The plug, second, and taper. Dies and taps are the most common threading tools. A tap is used to cut the female portion of the. Function Of Tap In Workshop.

From www.theatrealberta.com

(Calgary) Tap Basics for Beginners StoryBook Theatre Function Of Tap In Workshop Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt. The plug, second, and taper. The purpose of tapping in machining. Dies and taps are the most common threading tools. In this article you will learn the. There are three main types of taps. A. Function Of Tap In Workshop.

From starindustrys.com

10 Different Types of Thread Taps Guide] PDF Function Of Tap In Workshop A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. A tap is used to cut the female portion of the mating pair (e.g., a nut). Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt.. Function Of Tap In Workshop.

From www.dreamstime.com

A Tapping Tap Lies in a in a Warehouse Stock Image Image of Function Of Tap In Workshop A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. To cut an internal thread, the appropriate tap must be selected. Though this tool is most commonly used by machinists and engineers, automotive. 6 features of internal taps at a glance. A tap is used to cut the female portion of. Function Of Tap In Workshop.

From www.wonkeedonkeetools.co.uk

What are the parts of a tap fitting? Wonkee Donkee Tools Function Of Tap In Workshop The plug, second, and taper. There are three main types of taps. A tap is used to cut the female portion of the mating pair (e.g., a nut). Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt. Dies and taps are the most common. Function Of Tap In Workshop.

From www.mydance101.com

Tap Skills Dance 101 Function Of Tap In Workshop Tapping is the operation of cutting internal threads in a hole using a cutting tool called tap. When the tap is screwed into a hole it removes metal and. A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. A tap is used for cutting of the female segment of. Though. Function Of Tap In Workshop.

From www.dreamstime.com

A Plumber Connects Brass Fittings To a Water Tap. Closeup of a Master Function Of Tap In Workshop A die is used to cut the male portion of the mating pair (e.g., a screw). 6 features of internal taps at a glance. In this article you will learn the. Though this tool is most commonly used by machinists and engineers, automotive. A tapping machine, tapping press, or tapping center is a specialized machine that facilitates accurate. The process. Function Of Tap In Workshop.

From gadgetbuilder.com

A Tapping Guide Function Of Tap In Workshop In this article you will learn the. Dies and taps are the most common threading tools. A tapping machine, tapping press, or tapping center is a specialized machine that facilitates accurate. Tapping is the operation of cutting internal threads in a hole using a cutting tool called tap. A tap has cutting edges in the shape of threads. To cut. Function Of Tap In Workshop.

From shop.unigreenscheme.co.uk

Job Lot of Taps & Dies Engineering Function Of Tap In Workshop The plug, second, and taper. Dies and taps are the most common threading tools. The purpose of tapping in machining. A tapping machine, tapping press, or tapping center is a specialized machine that facilitates accurate. A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. Though this tool is most commonly. Function Of Tap In Workshop.

From www.dreamstime.com

A Tapping Tap Lies in a in a Warehouse Stock Image Image of Function Of Tap In Workshop A tap has cutting edges in the shape of threads. Tapping is the operation of cutting internal threads in a hole using a cutting tool called tap. A die is used to cut the male portion of the mating pair (e.g., a screw). The purpose of tapping in machining. A tap is used for cutting of the female segment of.. Function Of Tap In Workshop.

From www.dreamstime.com

A Tapping Tap Lies in a in a Warehouse Stock Photo Image of Function Of Tap In Workshop A die is used to cut the male portion of the mating pair (e.g., a screw). The purpose of tapping in machining. There are three main types of taps. The plug, second, and taper. To cut an internal thread, the appropriate tap must be selected. Tapping is the operation of cutting internal threads in a hole using a cutting tool. Function Of Tap In Workshop.

From www.youtube.com

Tapping Operation Explained Practical Demonstration Aravind. N YouTube Function Of Tap In Workshop A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. A die is used to cut the male portion of the mating pair (e.g., a screw). The plug, second, and taper. Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw. Function Of Tap In Workshop.

From www.jadelearning.com

Feeder1_Taps_10FT Jade Learning Function Of Tap In Workshop Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt. The process of cutting threads using a tap is called. A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. A die is used to cut. Function Of Tap In Workshop.

From www.youtube.com

Working of Tap Changer in Transformer Function of Tap Changer in Function Of Tap In Workshop The purpose of tapping in machining. A tap is used for cutting of the female segment of. A tapping machine, tapping press, or tapping center is a specialized machine that facilitates accurate. A tap has cutting edges in the shape of threads. When the tap is screwed into a hole it removes metal and. Tapping is the operation of cutting. Function Of Tap In Workshop.

From www.youtube.com

65xxiv) Function of Tap Changer in Transformer, it's types and Reason Function Of Tap In Workshop The plug, second, and taper. A die is used to cut the male portion of the mating pair (e.g., a screw). The purpose of tapping in machining. A tapping machine, tapping press, or tapping center is a specialized machine that facilitates accurate. A tap is used for cutting of the female segment of. 6 features of internal taps at a. Function Of Tap In Workshop.

From parts-badger.com

Drill and Tap Reference Guide by PartsBadger Function Of Tap In Workshop In this article you will learn the. A tap has cutting edges in the shape of threads. Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt. To cut an internal thread, the appropriate tap must be selected. A tapping machine, tapping press, or tapping. Function Of Tap In Workshop.

From genkiinstrumentshelp.zendesk.com

Tap Genki Instruments Function Of Tap In Workshop Though this tool is most commonly used by machinists and engineers, automotive. To cut an internal thread, the appropriate tap must be selected. 6 features of internal taps at a glance. The plug, second, and taper. A die is used to cut the male portion of the mating pair (e.g., a screw). A tap is used for cutting of the. Function Of Tap In Workshop.

From tapshowcompany.com

Tap (Maintenance) > September 15th 2022 ( + 9 more dates Function Of Tap In Workshop Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt. To cut an internal thread, the appropriate tap must be selected. Though this tool is most commonly used by machinists and engineers, automotive. The process of cutting threads using a tap is called. There are. Function Of Tap In Workshop.

From mechutopia.com

Hand Tapping How To Guide 2023 Mechutopia Function Of Tap In Workshop The process of cutting threads using a tap is called. A die is used to cut the male portion of the mating pair (e.g., a screw). When the tap is screwed into a hole it removes metal and. A tap is used to cut the female portion of the mating pair (e.g., a nut). 6 features of internal taps at. Function Of Tap In Workshop.

From www.youtube.com

How a work transformer tap changer in animation Video YouTube Function Of Tap In Workshop A tapping machine, tapping press, or tapping center is a specialized machine that facilitates accurate. A tap is used to cut the female portion of the mating pair (e.g., a nut). A tap is used to make (cut) new threads or clean out (chase) existing threads in a screw mechanism. 6 features of internal taps at a glance. A tap. Function Of Tap In Workshop.

From www.slideshare.net

Fitting(2) Function Of Tap In Workshop The plug, second, and taper. The purpose of tapping in machining. Though this tool is most commonly used by machinists and engineers, automotive. A die is used to cut the male portion of the mating pair (e.g., a screw). In this article you will learn the. A tap is used to make (cut) new threads or clean out (chase) existing. Function Of Tap In Workshop.

From www.promaxxtool.com

Different Types of Taps and When to Use Them ProMAXX Tool Function Of Tap In Workshop A tapping machine, tapping press, or tapping center is a specialized machine that facilitates accurate. Though this tool is most commonly used by machinists and engineers, automotive. In this article you will learn the. A tap is used for cutting of the female segment of. A tap is used to cut the female portion of the mating pair (e.g., a. Function Of Tap In Workshop.

From www.youtube.com

Taps and Dies Drill America Tool School YouTube Function Of Tap In Workshop A die is used to cut the male portion of the mating pair (e.g., a screw). A tap is used to cut the female portion of the mating pair (e.g., a nut). There are three main types of taps. A tap has cutting edges in the shape of threads. When the tap is screwed into a hole it removes metal. Function Of Tap In Workshop.

From www.researchgate.net

Function model diagram for water dispenser tap assembly Download Function Of Tap In Workshop To cut an internal thread, the appropriate tap must be selected. A die is used to cut the male portion of the mating pair (e.g., a screw). Taps thread the inside surface of a hole to create components like nuts or holes (blind or through) to screw in a screw or bolt. A tap has cutting edges in the shape. Function Of Tap In Workshop.