Material Requirements Planning Sap . Are you wondering how material requirements planning works? The system calculates net requirements for all the requirement quantities that are to be planned. You can plan material requirements at plant level or for different mrp areas. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). The system thereby compares available warehouse. With mrp at plant level, the system adds together stocks from all. Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. Let’s get some deeper insights into the process. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in.

from www.erp-information.com

The system thereby compares available warehouse. With mrp at plant level, the system adds together stocks from all. Let’s get some deeper insights into the process. You can plan material requirements at plant level or for different mrp areas. Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. The system calculates net requirements for all the requirement quantities that are to be planned. Are you wondering how material requirements planning works? The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. You can create purchase requisitions for stock material automatically using material requirements planning (mrp).

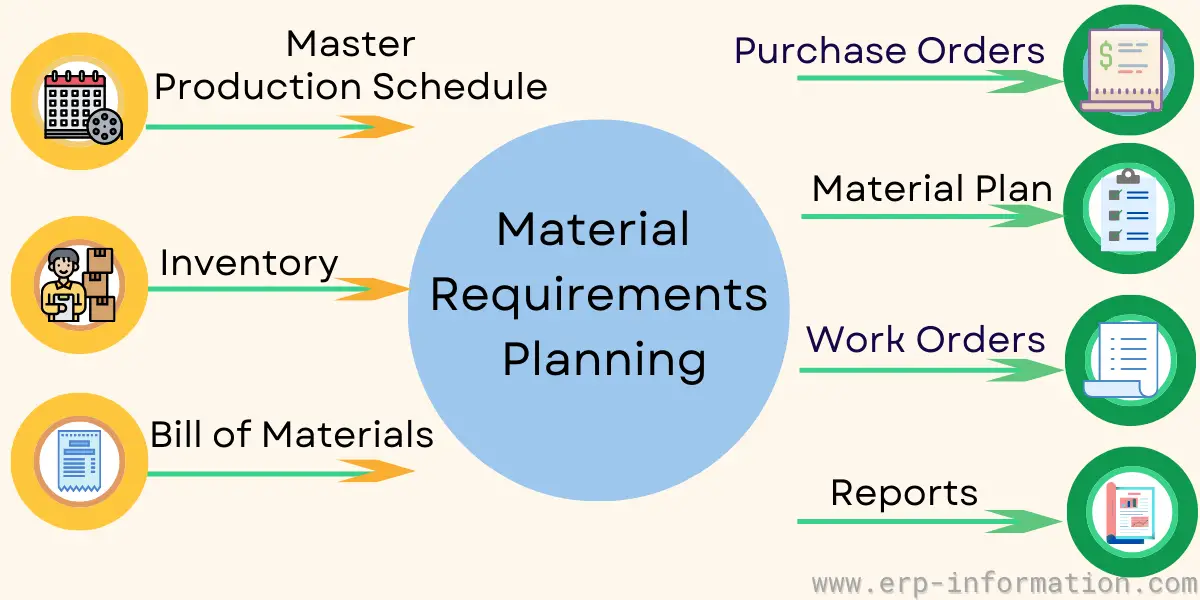

Material Requirements Planning (MRP) A Comprehensive Guide

Material Requirements Planning Sap Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. You can plan material requirements at plant level or for different mrp areas. With mrp at plant level, the system adds together stocks from all. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. The system calculates net requirements for all the requirement quantities that are to be planned. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). Let’s get some deeper insights into the process. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. Are you wondering how material requirements planning works? Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. The system thereby compares available warehouse.

From npp-asia.com

SAP S/4Hana Material Requirements Planning NPP Material Requirements Planning Sap Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). The system thereby compares available warehouse. The system calculates net requirements for all the requirement quantities that are to be planned. With mrp at plant. Material Requirements Planning Sap.

From www.slideshare.net

Sap MRP materials requirements planning Material Requirements Planning Sap The system calculates net requirements for all the requirement quantities that are to be planned. With mrp at plant level, the system adds together stocks from all. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. Mrp is a supply chain planning process used with other planning processes, such as. Material Requirements Planning Sap.

From www.researchgate.net

Procurement Process from Material Requirement Planning (MRP) to Sales Material Requirements Planning Sap The system calculates net requirements for all the requirement quantities that are to be planned. With mrp at plant level, the system adds together stocks from all. Let’s get some deeper insights into the process. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. Mrp is a supply chain. Material Requirements Planning Sap.

From www.erp-information.com

Material Requirements Planning (MRP) A Comprehensive Guide Material Requirements Planning Sap Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. The system calculates net requirements for all the requirement quantities that are to be planned. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. You can plan material requirements. Material Requirements Planning Sap.

From calejoysrosales.blogspot.com

Material Resource Planning CalejoysRosales Material Requirements Planning Sap The system thereby compares available warehouse. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. You can plan material requirements at plant level or for different mrp areas. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). Mrp is a supply chain planning process. Material Requirements Planning Sap.

From fr.slideshare.net

Sap MRP materials requirements planning Material Requirements Planning Sap After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). Let’s get some deeper insights into the. Material Requirements Planning Sap.

From www.youtube.com

Material Requirements Planning in SAP Business One YouTube Material Requirements Planning Sap The system calculates net requirements for all the requirement quantities that are to be planned. With mrp at plant level, the system adds together stocks from all. You can plan material requirements at plant level or for different mrp areas. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in.. Material Requirements Planning Sap.

From www.youtube.com

MRP Process in SAP B1 Material Requirements Planning SAP Business Material Requirements Planning Sap The system calculates net requirements for all the requirement quantities that are to be planned. Are you wondering how material requirements planning works? You can plan material requirements at plant level or for different mrp areas. Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. The sap mrp. Material Requirements Planning Sap.

From www.bol.com

Material Requirements Planning with SAP S/4HANA 9781493218868 Material Requirements Planning Sap Are you wondering how material requirements planning works? The system calculates net requirements for all the requirement quantities that are to be planned. Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. The sap mrp (material requirement planning) is used to procure or produce the required material quantities. Material Requirements Planning Sap.

From www.newsaperp.com

SAP Define an MRP Controller (Material Requirements Planning) Material Requirements Planning Sap Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. The system thereby compares available warehouse. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. Are you wondering how material requirements planning works? You can create purchase requisitions for. Material Requirements Planning Sap.

From bandarq188.com

Material Requirements Planning in SAP Business One [TUTORIAL] (2022) Material Requirements Planning Sap After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. The system calculates net requirements for all the requirement quantities that are to be planned. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). Let’s get some deeper insights into the process. Are you wondering how. Material Requirements Planning Sap.

From www.erp-information.com

Material Requirements Planning (MRP) A Comprehensive Guide Material Requirements Planning Sap You can plan material requirements at plant level or for different mrp areas. With mrp at plant level, the system adds together stocks from all. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations.. Material Requirements Planning Sap.

From www.youtube.com

Material Requirements Planning (MRP) SAP S/4HANA Logistics Training Material Requirements Planning Sap You can create purchase requisitions for stock material automatically using material requirements planning (mrp). With mrp at plant level, the system adds together stocks from all. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. The system thereby compares available warehouse. Are you wondering how material requirements planning works? Let’s. Material Requirements Planning Sap.

From www.guru99.com

SAP MRP (Material Requirement Planning) Material Requirements Planning Sap Let’s get some deeper insights into the process. Are you wondering how material requirements planning works? You can plan material requirements at plant level or for different mrp areas. Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. You can create purchase requisitions for stock material automatically using. Material Requirements Planning Sap.

From www.youtube.com

Material Requirements Planning in SAP Business One [TUTORIAL] YouTube Material Requirements Planning Sap You can plan material requirements at plant level or for different mrp areas. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. Let’s get some deeper insights into the process. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). The system calculates net requirements. Material Requirements Planning Sap.

From www.lonestartech.tw

MRP Material Requirements Planning Material Requirements Planning Sap With mrp at plant level, the system adds together stocks from all. Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. You can plan material requirements at plant level or for different mrp areas. The system thereby compares available warehouse. After a normal mrp run, you check the. Material Requirements Planning Sap.

From www.b1express.com

SAP Business One Material Requirement Planning India B1Express Material Requirements Planning Sap The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. The system thereby compares available warehouse. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). The system calculates net requirements for all the requirement quantities that are to be planned. With mrp at plant level,. Material Requirements Planning Sap.

From www.smartsheet.com

Everything You Need to Know About Material Requirements Planning (MRP Material Requirements Planning Sap You can create purchase requisitions for stock material automatically using material requirements planning (mrp). Let’s get some deeper insights into the process. The system thereby compares available warehouse. You can plan material requirements at plant level or for different mrp areas. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for. Material Requirements Planning Sap.

From www.desertcart.in

Buy Material Requirements Planning with SAP S/4HANA (SAP PRESS) Online Material Requirements Planning Sap The system thereby compares available warehouse. You can plan material requirements at plant level or for different mrp areas. The system calculates net requirements for all the requirement quantities that are to be planned. With mrp at plant level, the system adds together stocks from all. Let’s get some deeper insights into the process. Are you wondering how material requirements. Material Requirements Planning Sap.

From thebrandhopper.com

Marketing Concept Material Requirement Planning The Brand Hopper Material Requirements Planning Sap The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. The system calculates net requirements for all the requirement quantities that are to be planned. Are you wondering how material requirements planning works? With mrp at plant level, the system adds together stocks from all. You can create purchase requisitions. Material Requirements Planning Sap.

From www.wisys.com

How Material Requirements Planning Works With SAP Business One Material Requirements Planning Sap Let’s get some deeper insights into the process. The system thereby compares available warehouse. You can plan material requirements at plant level or for different mrp areas. Are you wondering how material requirements planning works? You can create purchase requisitions for stock material automatically using material requirements planning (mrp). Mrp is a supply chain planning process used with other planning. Material Requirements Planning Sap.

From favpng.com

SAP ERP Material Requirements Planning SAP SE SAP S/4HANA Project, PNG Material Requirements Planning Sap The system calculates net requirements for all the requirement quantities that are to be planned. The system thereby compares available warehouse. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). Are you wondering how material requirements planning works? The sap mrp (material requirement planning) is used to procure or produce the required material quantities on. Material Requirements Planning Sap.

From npp-asia.com

SAP S/4Hana Material Requirements Planning NPP Material Requirements Planning Sap After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. Let’s get some deeper insights into the process. You can plan material requirements at plant level or for different mrp areas. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in.. Material Requirements Planning Sap.

From www.slideshare.net

Sap MRP materials requirements planning Material Requirements Planning Sap The system thereby compares available warehouse. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations.. Material Requirements Planning Sap.

From www.youtube.com

0143 SAP PP Material Requirements Planning MRP Step by Step in Material Requirements Planning Sap Are you wondering how material requirements planning works? Let’s get some deeper insights into the process. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. The system thereby compares available. Material Requirements Planning Sap.

From www.academia.edu

(PDF) Define MRP Controllers in SAP Material Requirement Planning Material Requirements Planning Sap The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. Let’s get some deeper insights into the process. The system thereby compares available warehouse. Are you wondering how material requirements planning works? After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and. Material Requirements Planning Sap.

From studylib.net

Material Requirement Planning Material Requirements Planning Sap You can create purchase requisitions for stock material automatically using material requirements planning (mrp). With mrp at plant level, the system adds together stocks from all. The system thereby compares available warehouse. Let’s get some deeper insights into the process. Are you wondering how material requirements planning works? Mrp is a supply chain planning process used with other planning processes,. Material Requirements Planning Sap.

From www.researchgate.net

Material Requirements Planning System Download Scientific Diagram Material Requirements Planning Sap You can create purchase requisitions for stock material automatically using material requirements planning (mrp). With mrp at plant level, the system adds together stocks from all. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. The system thereby compares available warehouse. The sap mrp (material requirement planning) is used to. Material Requirements Planning Sap.

From www.tutorialspoint.com

SAP PP Material Requirement Planning Material Requirements Planning Sap You can plan material requirements at plant level or for different mrp areas. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. With mrp at plant level, the system adds. Material Requirements Planning Sap.

From www.youtube.com

SAP Business One MRP Material Requirements Planning YouTube Material Requirements Planning Sap With mrp at plant level, the system adds together stocks from all. Are you wondering how material requirements planning works? Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. Let’s get some deeper insights into the process. After a normal mrp run, you check the stock/requirements situation for. Material Requirements Planning Sap.

From paksupplychain.blogspot.com

Material Requirements Planning Process Flow SAP PP Implementation Material Requirements Planning Sap You can plan material requirements at plant level or for different mrp areas. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. Mrp is a supply chain planning process used with other planning processes, such as demand planning, supply planning, sales & operations. You can create purchase requisitions for. Material Requirements Planning Sap.

From www.slideshare.net

Sap MRP materials requirements planning Material Requirements Planning Sap You can create purchase requisitions for stock material automatically using material requirements planning (mrp). With mrp at plant level, the system adds together stocks from all. The system thereby compares available warehouse. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. The system calculates net requirements for all the. Material Requirements Planning Sap.

From www.tutorialspoint.com

SAP PP Material Requirement Planning Material Requirements Planning Sap The system calculates net requirements for all the requirement quantities that are to be planned. After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for in. Are you wondering how material requirements. Material Requirements Planning Sap.

From studylib.net

SAP MRP (Material Requirement Planning) Tutorial MD01, MD02, MD04 Material Requirements Planning Sap Let’s get some deeper insights into the process. You can create purchase requisitions for stock material automatically using material requirements planning (mrp). After a normal mrp run, you check the stock/requirements situation for the planned materials, make necessary changes and save. The sap mrp (material requirement planning) is used to procure or produce the required material quantities on time for. Material Requirements Planning Sap.