Pneumatic Equipment Maintenance . Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Filter your compressed air and track. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Learn 6 steps to better pneumatic tool maintenance and worker safety. Rategy is essential for achieving optimal performance from the equipment. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. Maintenance strategies for pneumatic actuators. Basic pneumatic system maintenance and preventative care can save you costs in the long run. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to.

from gesrepair.com

In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Learn 6 steps to better pneumatic tool maintenance and worker safety. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Filter your compressed air and track. Maintenance strategies for pneumatic actuators. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. Basic pneumatic system maintenance and preventative care can save you costs in the long run. Rategy is essential for achieving optimal performance from the equipment.

What is a Pneumatic System and How Do They Work? GES

Pneumatic Equipment Maintenance Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. Basic pneumatic system maintenance and preventative care can save you costs in the long run. Learn 6 steps to better pneumatic tool maintenance and worker safety. Filter your compressed air and track. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Maintenance strategies for pneumatic actuators. Rategy is essential for achieving optimal performance from the equipment. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to.

From www.engineerlive.com

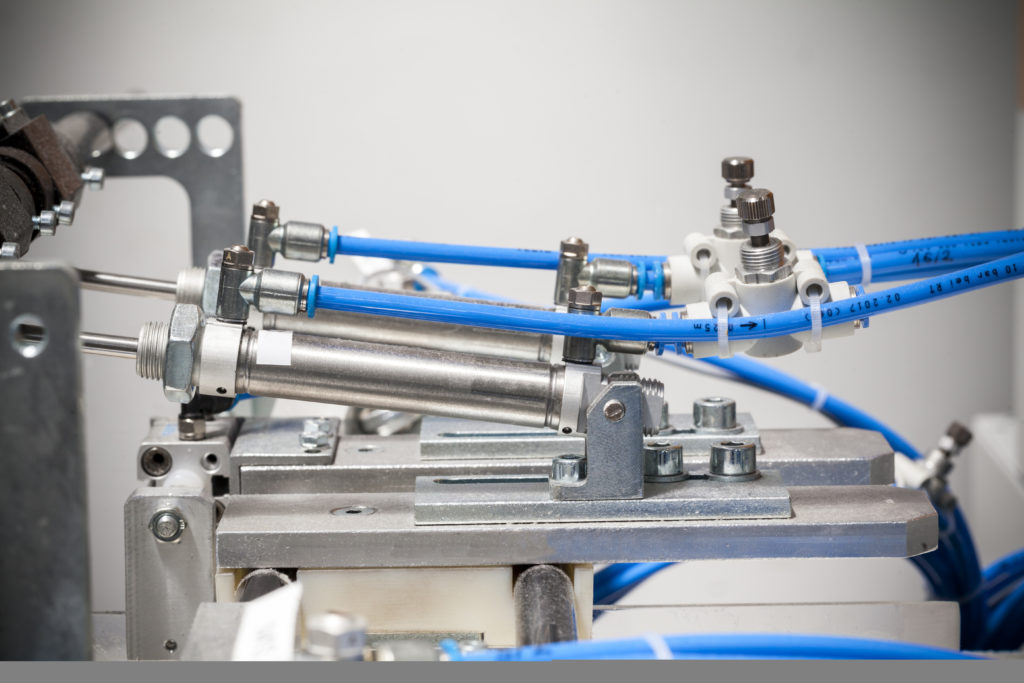

Pneumatic control automation systems, TPM001 Engineer Live Pneumatic Equipment Maintenance Rategy is essential for achieving optimal performance from the equipment. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Learn 6 steps to better pneumatic tool maintenance and worker safety. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Basic pneumatic system maintenance and preventative care can. Pneumatic Equipment Maintenance.

From www.franklyntools.com

Pneumatic Tool Repair Air Tool Repair Florida Pneumatic Tool Services Pneumatic Equipment Maintenance The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Basic pneumatic system maintenance and preventative care can save you costs in the long run. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Rategy is essential for achieving optimal performance from the equipment. Filter your compressed air. Pneumatic Equipment Maintenance.

From www.alamy.com

Roadworks Workman uses a pneumatic drill to dig a hole in the road Pneumatic Equipment Maintenance Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Learn 6 steps to better pneumatic tool maintenance and worker safety. Maintenance strategies for pneumatic actuators. Basic pneumatic. Pneumatic Equipment Maintenance.

From rushhydraulic.ca

Hydraulic Cylinder Repair Rush Hydraulic Pneumatic Pneumatic Equipment Maintenance Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. Rategy is essential for achieving optimal performance from the equipment. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies,. Pneumatic Equipment Maintenance.

From www.hgtv.com

What Are Pneumatic Tools? HGTV Pneumatic Equipment Maintenance Basic pneumatic system maintenance and preventative care can save you costs in the long run. Maintenance strategies for pneumatic actuators. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Rategy is essential for achieving optimal performance from the equipment. Filter your compressed air. Pneumatic Equipment Maintenance.

From www.netech.edu

Pneumatics Industrial Maintenance Northeast Tech Pneumatic Equipment Maintenance Maintenance strategies for pneumatic actuators. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Rategy is essential for achieving optimal performance from the equipment. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment. Pneumatic Equipment Maintenance.

From builderssupplyco.com

Pneumatic Tool Repair to Get You Back to the Job Builders Supply Pneumatic Equipment Maintenance Basic pneumatic system maintenance and preventative care can save you costs in the long run. Learn 6 steps to better pneumatic tool maintenance and worker safety. Filter your compressed air and track. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. In this guide,. Pneumatic Equipment Maintenance.

From tft-pneumatic.com

Maintenance of Pneumatic Impact Wrenches TFT Pneumatic Pneumatic Equipment Maintenance Filter your compressed air and track. Rategy is essential for achieving optimal performance from the equipment. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. Learn 6 steps to better pneumatic tool maintenance and worker safety. The most effective approach to pneumatic maintenance (or. Pneumatic Equipment Maintenance.

From dir.indiamart.com

Pneumatic Tools Repairing Services, Pneumatic Tool Repair & Services in Pneumatic Equipment Maintenance Maintenance strategies for pneumatic actuators. Learn 6 steps to better pneumatic tool maintenance and worker safety. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common. Pneumatic Equipment Maintenance.

From gesrepair.com

What is a Pneumatic System and How Do They Work? GES Pneumatic Equipment Maintenance Learn 6 steps to better pneumatic tool maintenance and worker safety. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. Rategy is essential for achieving optimal performance from the equipment. Filter your compressed air and track. In this guide, we'll journey through the world. Pneumatic Equipment Maintenance.

From ims-s.com

Industrial Pneumatic Tool Repair IMS Memphis (901) 3481155 Pneumatic Equipment Maintenance Maintenance strategies for pneumatic actuators. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Rategy is essential for achieving optimal performance from the equipment. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment. Pneumatic Equipment Maintenance.

From www.atsmro.com

Pneumatic Testing & Repair Services Aircraft Pneumatic Systems Pneumatic Equipment Maintenance Basic pneumatic system maintenance and preventative care can save you costs in the long run. Rategy is essential for achieving optimal performance from the equipment. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. Check out these pneumatic tool safety tips from your favorite. Pneumatic Equipment Maintenance.

From tft-pneumatic.com

How to Know What Pneumatic Tool Repair You Need TFT Pneumatic Pneumatic Equipment Maintenance In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Rategy is essential for achieving optimal performance from the equipment. Filter your compressed air and track. Maintenance strategies for pneumatic. Pneumatic Equipment Maintenance.

From www.rowse.co.uk

11 Steps Troubleshooting Pneumatic Systems Rowse Pneumatic Equipment Maintenance Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. Basic pneumatic system maintenance and preventative care can save you costs in the long run. Filter your compressed air and track. The most effective approach to pneumatic maintenance (or maintenance of any automation system or. Pneumatic Equipment Maintenance.

From www.indiamart.com

Pneumatic Tools Maintenance Work at best price in Pune ID 13005718491 Pneumatic Equipment Maintenance The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Learn 6 steps to better pneumatic tool maintenance and worker safety. Maintenance strategies for pneumatic actuators. Filter your compressed air and track. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Pneumatic systems rely on compressed air and. Pneumatic Equipment Maintenance.

From www.homenish.com

18 Different Types of Pneumatic Tools (Air Tools) Explained Homenish Pneumatic Equipment Maintenance Learn 6 steps to better pneumatic tool maintenance and worker safety. Basic pneumatic system maintenance and preventative care can save you costs in the long run. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Maintenance strategies for pneumatic actuators. In this guide, we'll journey through the world of pneumatic cylinder maintenance,. Pneumatic Equipment Maintenance.

From www.nblida.com

Company News News Pneumatic Equipment Maintenance Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Filter your compressed air and track. Rategy is essential for achieving optimal performance from the equipment. Maintenance strategies for pneumatic actuators. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies,. Pneumatic Equipment Maintenance.

From www.industrialhydraulicsmachines.ca

Stratford Ontario Industrial Hydraulics & Pneumatics Pneumatic Equipment Maintenance Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Basic pneumatic system maintenance and preventative care can save you costs in the long run. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the. Pneumatic Equipment Maintenance.

From www.ifm.com

Pneumatic maintenance unit monitoring ifm Pneumatic Equipment Maintenance Basic pneumatic system maintenance and preventative care can save you costs in the long run. Maintenance strategies for pneumatic actuators. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. In this guide, we'll journey through the world of. Pneumatic Equipment Maintenance.

From instrumentationtools.com

Testing of Pneumatic Systems InstrumentationTools Pneumatic Equipment Maintenance Learn 6 steps to better pneumatic tool maintenance and worker safety. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury. Pneumatic Equipment Maintenance.

From www.doityourself.com

Pneumatic Tool Maintenance Pneumatic Equipment Maintenance The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Filter your compressed air and track. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Rategy is essential for achieving optimal performance from the equipment. Maintenance strategies for pneumatic actuators. Pneumatic systems rely on compressed air and leaks. Pneumatic Equipment Maintenance.

From statesideindustrial.com

THE IMPORTANCE OF PREVENTIVE MAINTENANCE ON A PNEUMATIC SYSTEMS Pneumatic Equipment Maintenance Maintenance strategies for pneumatic actuators. Learn 6 steps to better pneumatic tool maintenance and worker safety. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Filter your compressed air and track. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or. Pneumatic Equipment Maintenance.

From www.atsmro.com

Pneumatic Testing & Repair Services Aircraft Pneumatic Systems Pneumatic Equipment Maintenance Filter your compressed air and track. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Basic pneumatic system maintenance and preventative care can save you costs in the long run. Learn 6 steps to better pneumatic tool maintenance and worker safety. Rategy is essential for achieving optimal performance from the equipment. The most effective approach. Pneumatic Equipment Maintenance.

From www.youtube.com

Pneumatic Equipment Repair Sales & Service YouTube Pneumatic Equipment Maintenance The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Learn 6 steps. Pneumatic Equipment Maintenance.

From blog.slsbearings.com

Pneumatic vs Hydraulic Systems What's the Difference? Pneumatic Equipment Maintenance Filter your compressed air and track. Basic pneumatic system maintenance and preventative care can save you costs in the long run. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Pneumatic systems rely on compressed air and leaks can lead to sudden changes. Pneumatic Equipment Maintenance.

From library.automationdirect.com

The Pneumatic Efficiency Big Picture Library.AutomationDirect Pneumatic Equipment Maintenance Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Rategy is essential for achieving optimal performance from the equipment. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. Basic pneumatic system maintenance and preventative care can save you costs. Pneumatic Equipment Maintenance.

From www.aliexpress.com

SAT1918 Pneumatic 1/2" Wrench Professional Auto Repair Pneumatic Tools Pneumatic Equipment Maintenance Basic pneumatic system maintenance and preventative care can save you costs in the long run. Rategy is essential for achieving optimal performance from the equipment. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Filter your compressed air and track. Learn 6 steps. Pneumatic Equipment Maintenance.

From tft-pneumatic.com

How does a pneumatic drill work? TFT Pneumatic Pneumatic Equipment Maintenance The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the. Pneumatic Equipment Maintenance.

From dir.indiamart.com

Pneumatic Tools Repairing Services in India Pneumatic Equipment Maintenance Maintenance strategies for pneumatic actuators. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Rategy is essential for achieving optimal performance from the equipment. Filter your compressed air and track. Learn 6 steps to better pneumatic tool maintenance. Pneumatic Equipment Maintenance.

From www.diynetwork.com

Pneumatic Tool Maintenance howtos DIY Pneumatic Equipment Maintenance Filter your compressed air and track. Basic pneumatic system maintenance and preventative care can save you costs in the long run. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure,. Pneumatic Equipment Maintenance.

From www.spairusa.com

Pneumatic Tools Air Tools Repair & Parts SP Air USA Inc Pneumatic Equipment Maintenance Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or even injury to workers. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Maintenance strategies for pneumatic actuators. Rategy is essential for achieving optimal performance from the equipment. Learn 6 steps. Pneumatic Equipment Maintenance.

From www.franklyntools.com

Pneumatic Tool Repair Air Tool Repair Florida Pneumatic Tool Services Pneumatic Equipment Maintenance Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Pneumatic systems rely. Pneumatic Equipment Maintenance.

From www.ammarindustrial.com

Types of Pneumatic Tools Ammar Industrial Corporation Pneumatic Equipment Maintenance Filter your compressed air and track. Maintenance strategies for pneumatic actuators. The most effective approach to pneumatic maintenance (or maintenance of any automation system or component) is to. Learn 6 steps to better pneumatic tool maintenance and worker safety. Pneumatic systems rely on compressed air and leaks can lead to sudden changes in pressure that can cause equipment failure or. Pneumatic Equipment Maintenance.

From mydigitalengineer.com

Pneumatic Preventive Maintenance MyDigitalEngineer Pneumatic Equipment Maintenance Rategy is essential for achieving optimal performance from the equipment. Filter your compressed air and track. Basic pneumatic system maintenance and preventative care can save you costs in the long run. Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. Learn 6 steps to better pneumatic tool maintenance and worker safety. The most effective approach. Pneumatic Equipment Maintenance.

From www.diynetwork.com

Pneumatic Tool Maintenance howtos DIY Pneumatic Equipment Maintenance Check out these pneumatic tool safety tips from your favorite fastener supply and pneumatic. In this guide, we'll journey through the world of pneumatic cylinder maintenance, exploring the signs of wear, the common causes of failure, effective repair strategies, and. Rategy is essential for achieving optimal performance from the equipment. Maintenance strategies for pneumatic actuators. The most effective approach to. Pneumatic Equipment Maintenance.