Beer Making Process Mash . Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Mashing grain is what makes beer beer. Mashing is a stage in the brewing process that involves boiling. This guide covers the process of mashing and tips for achieving the perfect brew. Learn how to mash malt and water to create the base of beer. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. The grain will soak for about an hour, and then the liquid will be.

from cartoondealer.com

The grain will soak for about an hour, and then the liquid will be. Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Mashing grain is what makes beer beer. This guide covers the process of mashing and tips for achieving the perfect brew. Mashing is a stage in the brewing process that involves boiling. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Learn how to mash malt and water to create the base of beer. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more.

Beer Brewing Process Alcohol Factory Production Equipment Mashing

Beer Making Process Mash This guide covers the process of mashing and tips for achieving the perfect brew. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Learn how to mash malt and water to create the base of beer. Mashing grain is what makes beer beer. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. The grain will soak for about an hour, and then the liquid will be. This guide covers the process of mashing and tips for achieving the perfect brew. Mashing is a stage in the brewing process that involves boiling. Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more.

From cartoondealer.com

Beer Brewing Process Alcohol Factory Production Equipment Mashing Beer Making Process Mash Mashing grain is what makes beer beer. The grain will soak for about an hour, and then the liquid will be. Mashing is a stage in the brewing process that involves boiling. Learn how to mash malt and water to create the base of beer. Yes, hops, yeast, and water certainly play important roles, but it is only through the. Beer Making Process Mash.

From www.shutterstock.com

Brewery Steps. Beer Brewing Process Elements. Mashing, Lautering Beer Making Process Mash Mashing grain is what makes beer beer. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. The grain will soak for about an hour, and then the liquid will be. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. This guide covers the process of. Beer Making Process Mash.

From www.pinterest.com

Optimizing Your Mash Part 1 Moonshine recipes, Home brewing beer Beer Making Process Mash Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Mashing is a stage in the brewing process that involves boiling. Mashing grain is what makes beer beer. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented.. Beer Making Process Mash.

From www.alamy.com

Beer mash hires stock photography and images Alamy Beer Making Process Mash Mashing grain is what makes beer beer. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing is a stage in the brewing process that involves boiling. Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound. Beer Making Process Mash.

From mavink.com

Beer Making Process Flowchart Beer Making Process Mash This guide covers the process of mashing and tips for achieving the perfect brew. The grain will soak for about an hour, and then the liquid will be. Learn how to mash malt and water to create the base of beer. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Yes, hops, yeast, and water certainly. Beer Making Process Mash.

From circuitdbrousting.z13.web.core.windows.net

Beer Brewing Process Diagram Beer Making Process Mash Mashing grain is what makes beer beer. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Mashing is a stage in the brewing process that involves boiling. Mashing is the process of mixing your. Beer Making Process Mash.

From www.brewinsight.com

Making Beer AllGrain Mashing with "Brew in a Bag" Brew Insight Beer Making Process Mash Mashing grain is what makes beer beer. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Mashing at 148°f (64°c) favors beta amylase, creating a drier. Beer Making Process Mash.

From www.mdpi.com

Beverages Free FullText The Role of Emergent Processing Beer Making Process Mash Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Mashing simply means to combine crushed grain with hot water at a ratio of around. Beer Making Process Mash.

From www.britannica.com

Mashing beverage production Britannica Beer Making Process Mash Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Mashing is a stage in the brewing process that involves boiling. Mashing grain is what makes beer beer. Learn how to mash malt and. Beer Making Process Mash.

From abitabrewery.blogspot.com

The Abita Brewery The Beer Making Process Beer Making Process Mash The grain will soak for about an hour, and then the liquid will be. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. This guide covers the. Beer Making Process Mash.

From www.alamy.com

Beer Mash High Resolution Stock Photography and Images Alamy Beer Making Process Mash Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Learn how to mash. Beer Making Process Mash.

From www.unknownbrewing.com

What is Mashing in Beer Brewing? Beer Making Process Mash Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Learn how to mash malt and water to create the base of beer. Mashing grain is what makes beer beer. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can. Beer Making Process Mash.

From stock.adobe.com

Vector isometric craft beer brewing process. Beer production process Beer Making Process Mash Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Learn how to mash malt and water to create the base of beer. Mashing at. Beer Making Process Mash.

From craftbrewery33.com

Brewing Process Craft Brewery ThirtyThree Beer Making Process Mash Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Learn how to mash malt and water to create the base of beer. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing at 148°f (64°c). Beer Making Process Mash.

From www.downtheroadbrewery.com

beer mashing process articles Degong Beer Brewing Equipment, Brewery Beer Making Process Mash Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. The grain will soak for about an hour, and then the liquid will be. Yes, hops, yeast,. Beer Making Process Mash.

From foodcrumbles.com

The beer brewing process Beer science at home Food Crumbles The Beer Making Process Mash Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. The grain will soak for about an hour, and then the liquid will be. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Mashing grain is. Beer Making Process Mash.

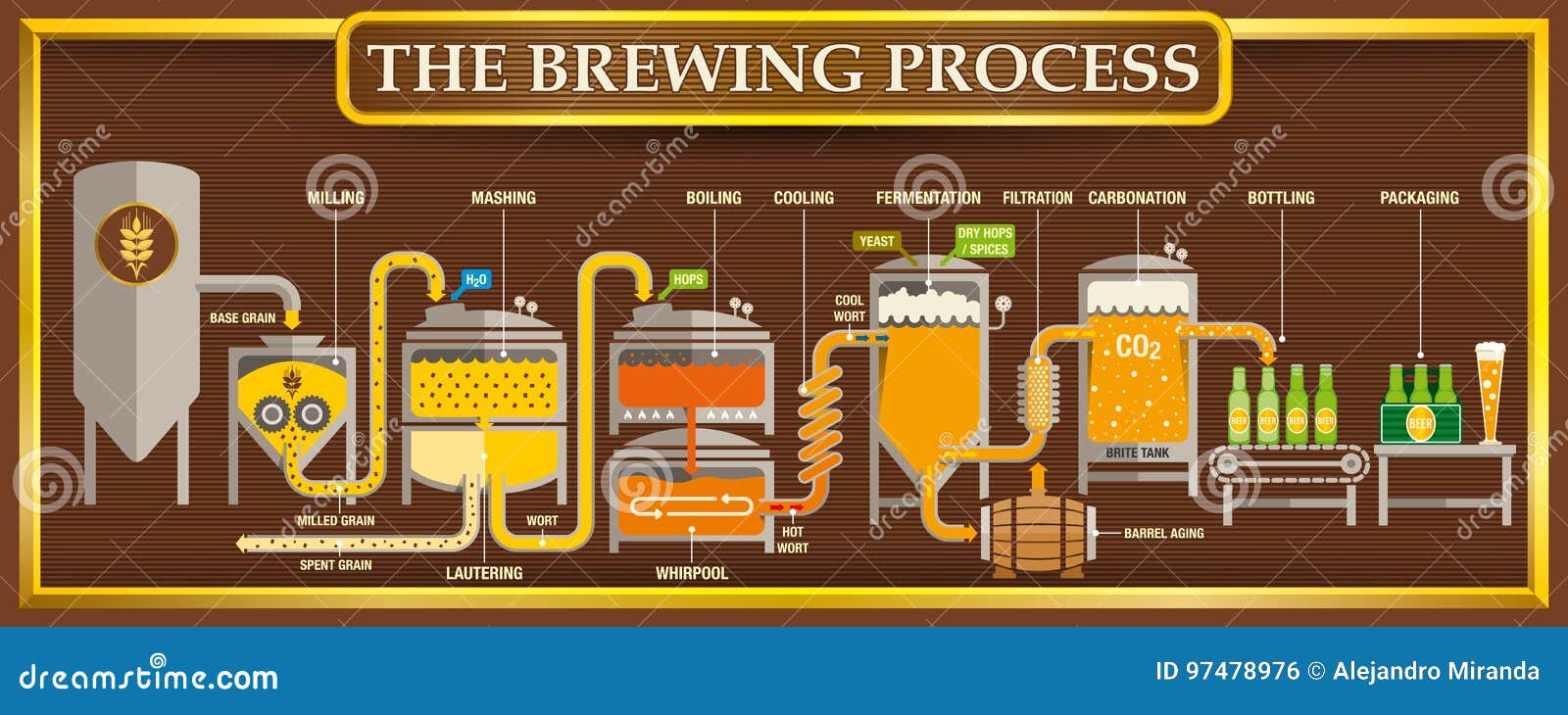

From www.dreamstime.com

Beer Brewing Process Alcohol Factory Production Equipment Mashing Beer Making Process Mash Mashing is a stage in the brewing process that involves boiling. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. This guide covers the process of mashing and tips for achieving the perfect brew. Mashing simply means to combine crushed grain with hot water at a ratio of around. Beer Making Process Mash.

From www.aslanbrewing.com

The Brewing Process — Aslan Brewing Co. Beer Making Process Mash Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. Learn how to mash malt and water to create the base of beer. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Mashing is a stage in the. Beer Making Process Mash.

From grainbrew.com

Method for Improving Mash Efficiency In Beer Brewing / GrainBrew Blog Beer Making Process Mash Mashing grain is what makes beer beer. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Learn how to mash malt and water to create the base. Beer Making Process Mash.

From www.scienceabc.com

How Beer Is Made? Beer Making Process Mash Learn how to mash malt and water to create the base of beer. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. The grain will soak for about an hour, and then the liquid will be. Mashing simply means to combine crushed grain with hot water at a ratio. Beer Making Process Mash.

From www.unknownbrewing.com

What is Mashing in Beer Brewing? Beer Making Process Mash Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Mashing grain is what makes beer beer. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in. Beer Making Process Mash.

From cartoondealer.com

Beer Brewing Process Alcohol Factory Production Equipment Mashing Beer Making Process Mash Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. The grain will soak for. Beer Making Process Mash.

From cancanawards.com

The Mashing Tun and Its Importance in Brewing Beer Beer Making Process Mash Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Mashing is a stage in the brewing process that involves boiling. The grain will soak for about an hour, and then the liquid will be.. Beer Making Process Mash.

From www.dreamstime.com

Process of Mashing of Milled Malt Grains. Stock Image Image of brew Beer Making Process Mash Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. The grain will soak for about an hour, and then the liquid will be. Mashing grain is what makes beer beer. Mashing is the. Beer Making Process Mash.

From brookstonbeerbulletin.com

Patent No. WO2007113292A3 Mashing Process Brookston Beer Bulletin Beer Making Process Mash Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. This guide covers the process of mashing and tips for achieving the perfect brew. Learn how to mash malt and water to create the base of beer. The grain will soak for about an hour, and then the. Beer Making Process Mash.

From www.dreamstime.com

Brewery Process Infographic in Flat Style Stock Vector Illustration Beer Making Process Mash Learn how to mash malt and water to create the base of beer. Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Mashing is a stage in the brewing process that involves boiling. Mashing is,. Beer Making Process Mash.

From www.asianbeernetwork.com

Brewing Process StepByStep With Pictures Asian Beer Network Beer Making Process Mash Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing is the process of mixing your crushed malted grains with water and converting the malted. Beer Making Process Mash.

From www.babezdoor.com

Beer Brewing Process Infographic Flat Style Vector Image The Best Beer Making Process Mash Mashing grain is what makes beer beer. The grain will soak for about an hour, and then the liquid will be. Learn how to mash malt and water to create the base of beer. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing is the. Beer Making Process Mash.

From www.directair.co.uk

Nitrogen in the Beer Brewing Process Direct Air Beer Making Process Mash Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Mashing is. Beer Making Process Mash.

From www.downtheroadbrewery.com

What are the methods of beer mashing Beer Making Process Mash This guide covers the process of mashing and tips for achieving the perfect brew. Learn how to mash malt and water to create the base of beer. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Mashing simply means to combine crushed grain with hot water at. Beer Making Process Mash.

From www.dreamstime.com

Brewery Process Vector Illustration. Labeled Beer Ale Making Process Beer Making Process Mash Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Mashing is a stage. Beer Making Process Mash.

From www.morebeer.com

Mashing 101 For The First Time AllGrain Brewer MoreBeer Beer Making Process Mash Mashing is a stage in the brewing process that involves boiling. Mashing grain is what makes beer beer. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Mashing is the process of mixing your crushed malted grains with water and converting the malted starches into the right.. Beer Making Process Mash.

From www.youtube.com

Homebrew Beer The All Grain Mashing Process Simple Infusion Mash Beer Making Process Mash Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. The grain will soak for about an hour, and then the liquid will be. Learn how to mash malt and water to create the base of beer. This guide covers the process of mashing and tips for. Beer Making Process Mash.

From distilling.com

Mash Chemistry 101 Distiller Magazine Beer Making Process Mash Mashing is a stage in the brewing process that involves boiling. Learn how to mash malt and water to create the base of beer. Yes, hops, yeast, and water certainly play important roles, but it is only through the mash, whether performed in your house or in. This guide covers the process of mashing and tips for achieving the perfect. Beer Making Process Mash.

From www.micetcraft.com

Del grano a la copa Exploring Every Step of the Beer Brewing Process Beer Making Process Mash Mashing grain is what makes beer beer. Learn how to mash malt and water to create the base of beer. Mashing simply means to combine crushed grain with hot water at a ratio of around 1.25 quarts per pound of grain. Mashing at 148°f (64°c) favors beta amylase, creating a drier flavor and more. This guide covers the process of. Beer Making Process Mash.