Tig Welder Weak Arc . Tight arc = less chance that a breeze can sneak in and mess with your gas flow. Lack of penetration in tig welding occurs when the weld does not extend through the full thickness of the materials being joined, leading to a weak joint that is prone to failure. In this section, we will explore the causes of lack of penetration and discuss strategies to ensure your welds are fully penetrated and strong. If i release the torch button it. How do i know if my tig welder is set up correctly? Speaking of which, even the slightest air. Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power supply settings, contamination of the welding environment, and equipment malfunction. The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. If your tig welder isn’t throwing an arc, it could be due to the voltage source. The welder is trying and seems to pulse a weak arc at around 2 per second but it never settles. In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the material you’re welding.

from welderchoice.com

Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power supply settings, contamination of the welding environment, and equipment malfunction. The welder is trying and seems to pulse a weak arc at around 2 per second but it never settles. The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. How do i know if my tig welder is set up correctly? A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the material you’re welding. Speaking of which, even the slightest air. You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. If your tig welder isn’t throwing an arc, it could be due to the voltage source. In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. Lack of penetration in tig welding occurs when the weld does not extend through the full thickness of the materials being joined, leading to a weak joint that is prone to failure.

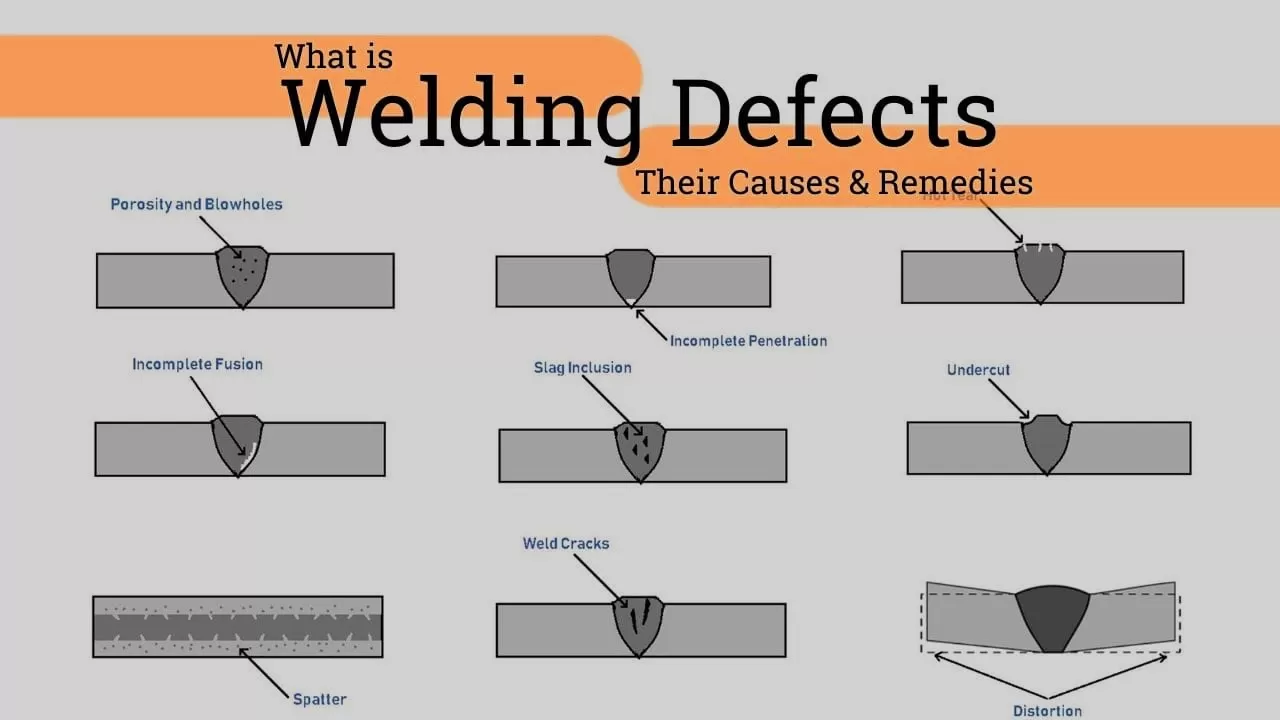

What are Types of Welding Defects? Causes, and Remedies

Tig Welder Weak Arc If i release the torch button it. The welder is trying and seems to pulse a weak arc at around 2 per second but it never settles. Lack of penetration in tig welding occurs when the weld does not extend through the full thickness of the materials being joined, leading to a weak joint that is prone to failure. How do i know if my tig welder is set up correctly? Speaking of which, even the slightest air. If your tig welder isn’t throwing an arc, it could be due to the voltage source. In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the material you’re welding. If i release the torch button it. You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power supply settings, contamination of the welding environment, and equipment malfunction. The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. Tight arc = less chance that a breeze can sneak in and mess with your gas flow. In this section, we will explore the causes of lack of penetration and discuss strategies to ensure your welds are fully penetrated and strong.

From omegastore.co.za

StrikeArc Inverter Welder 120A MIG/TIG/MMA Smart Omega Store Tig Welder Weak Arc The welder is trying and seems to pulse a weak arc at around 2 per second but it never settles. Lack of penetration in tig welding occurs when the weld does not extend through the full thickness of the materials being joined, leading to a weak joint that is prone to failure. Several factors contribute to inconsistent welding arcs, including. Tig Welder Weak Arc.

From www.rapiddirect.com

MIG VS TIG Welding A Guide to Choosing the Right Process RapidDirect Tig Welder Weak Arc The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power supply settings, contamination of the welding environment, and equipment malfunction. In this section, we will explore the causes of lack of penetration and discuss. Tig Welder Weak Arc.

From www.ebay.com

3 in 1 TIG Welder HF TIG ARC Clean Welding Machine 210Amp w/ Pulse Tig Welder Weak Arc The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power. Tig Welder Weak Arc.

From weldguru.com

Arc Welding Explained What Is It & How Does It Work? Weld Guru Tig Welder Weak Arc You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the material you’re. Tig Welder Weak Arc.

From welderchoice.com

What are Types of Welding Defects? Causes, and Remedies Tig Welder Weak Arc Speaking of which, even the slightest air. If i release the torch button it. A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the material you’re welding. The welder is trying and seems to pulse a weak arc at around 2 per second but it never settles. How do i. Tig Welder Weak Arc.

From www.vevor.com

VEVOR TIG Welder 3 in 1, 110V High Frequency TIG/Stick/Clean Welding Tig Welder Weak Arc The welder is trying and seems to pulse a weak arc at around 2 per second but it never settles. The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. Tight arc = less chance that a breeze can sneak in and mess with your gas flow. You’ll need to have. Tig Welder Weak Arc.

From alroys.com

What is TIG welding and how does it work? Alroys Tig Welder Weak Arc If your tig welder isn’t throwing an arc, it could be due to the voltage source. If i release the torch button it. The welder is trying and seems to pulse a weak arc at around 2 per second but it never settles. How do i know if my tig welder is set up correctly? Several factors contribute to inconsistent. Tig Welder Weak Arc.

From omegastore.co.za

StrikeArc Inverter Welder 160A TIG/MMA Omega Store Tig Welder Weak Arc Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power supply settings, contamination of the welding environment, and equipment malfunction. You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. Tight arc = less chance that a breeze can sneak in and mess with. Tig Welder Weak Arc.

From unimig.com.au

MIG vs TIG vs Stick Welding UNIMIG Welding Guides & Tutorials Tig Welder Weak Arc In this section, we will explore the causes of lack of penetration and discuss strategies to ensure your welds are fully penetrated and strong. Lack of penetration in tig welding occurs when the weld does not extend through the full thickness of the materials being joined, leading to a weak joint that is prone to failure. If your tig welder. Tig Welder Weak Arc.

From www.xcelarc.nz

RAZORWELD™ 200 DC TIG Welder XcelArc® Welding Supplies Tig Welder Weak Arc A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the material you’re welding. If your tig welder isn’t throwing an arc, it could be due to the voltage source. Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power supply settings, contamination of. Tig Welder Weak Arc.

From www.vevor.com

VEVOR TIG Welder AC/DC, 3 in 1 TIG/MMA/ARC Welding Machine with 110 Tig Welder Weak Arc How do i know if my tig welder is set up correctly? A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the material you’re welding. In this section, we will explore the causes of lack of penetration and discuss strategies to ensure your welds are fully penetrated and strong. You’ll. Tig Welder Weak Arc.

From www.miganglia.co.uk

TransTig 170 MV MultiVoltage DC TIG ARC Welder Boxed Set MigAnglia Tig Welder Weak Arc How do i know if my tig welder is set up correctly? You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. Tight arc = less chance that a breeze can sneak in and mess with your gas flow. Speaking of which, even the slightest air. In order to create an. Tig Welder Weak Arc.

From www.westweld.com

WS(M)315/400IGBT Pro Inverter Pulse Argon Arc TIG Welding Machine Tig Welder Weak Arc The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. The welder is trying and seems to pulse a weak arc at around 2 per second but. Tig Welder Weak Arc.

From blog.thepipingmart.com

Plasma Arc Welding vs TIG Welding What's the Difference Tig Welder Weak Arc In this section, we will explore the causes of lack of penetration and discuss strategies to ensure your welds are fully penetrated and strong. If i release the torch button it. You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. The minimum voltage that needs to be maintained in the. Tig Welder Weak Arc.

From www.walmart.com

VEVOR 155Amp TIG Welder 110V High Frequency TIG/Stick/Clean 3 in 1 Tig Welder Weak Arc In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power supply settings, contamination of the welding environment, and equipment malfunction. A correctly set up tig welder should have a. Tig Welder Weak Arc.

From www.laserse.com

Welder 250 Amp MIG TIG Arc Welder 3 in 1 Welder Welding Machine 110V Tig Welder Weak Arc The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the material you’re welding. You’ll need to have the proper amount of voltage for your tig welder to work and throw an. Tig Welder Weak Arc.

From tunaak.com

Tungsten Inert Gas Welding (TIG) Tunaak Metals Tig Welder Weak Arc A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the material you’re welding. If i release the torch button it. You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. The minimum voltage that needs to be maintained in the welding. Tig Welder Weak Arc.

From blog.thepipingmart.com

Arc Welding vs TIG Welding What's the Difference Tig Welder Weak Arc If i release the torch button it. You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. In this section, we will explore the causes of lack of penetration and discuss strategies. Tig Welder Weak Arc.

From www.mig-welding.co.uk

Arc (MMA) Welding Flat Joints Tig Welder Weak Arc In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. If i release the torch button it. In this section, we will explore the causes of lack of penetration and discuss strategies to ensure your welds are fully penetrated and strong. The minimum voltage that needs. Tig Welder Weak Arc.

From www.nepal.ubuy.com

Buy hynade Tig Welder TIG215A, HF ARC/TIG/Stick TIG Welders 215 Amp 110 Tig Welder Weak Arc In this section, we will explore the causes of lack of penetration and discuss strategies to ensure your welds are fully penetrated and strong. Speaking of which, even the slightest air. In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. The minimum voltage that needs. Tig Welder Weak Arc.

From www.desertcart.com.au

Buy ARCCAPTAIN TIG Welder AC/DC 200Amp with Pulse, Aluminum TIG Welder Tig Welder Weak Arc If your tig welder isn’t throwing an arc, it could be due to the voltage source. The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. If i release the torch button it. In this section, we will explore the causes of lack of penetration and discuss strategies to ensure your. Tig Welder Weak Arc.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide Tig Welder Weak Arc If your tig welder isn’t throwing an arc, it could be due to the voltage source. In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the. Tig Welder Weak Arc.

From norsemensafety.co.uk

5 Advantages And Disadvantages Of TIG Welding? Welders Choice Tig Welder Weak Arc How do i know if my tig welder is set up correctly? If your tig welder isn’t throwing an arc, it could be due to the voltage source. Tight arc = less chance that a breeze can sneak in and mess with your gas flow. In order to create an arc and transfer the welding current to the base material. Tig Welder Weak Arc.

From www.vevor.com

VEVOR TIG Welder 3 in 1, 110V High Frequency TIG/Stick/Clean Welding Tig Welder Weak Arc The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power supply settings, contamination of the welding environment, and equipment malfunction. Lack of penetration in tig welding occurs when the weld does not extend through. Tig Welder Weak Arc.

From www.chinasuptec.com

Custom TIG WELDER TIG MMA ARC 2 IN 1 WELDING MACHINE 110/220V Tig Welder Weak Arc Speaking of which, even the slightest air. You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. The welder is trying and seems to pulse a weak arc at around 2 per. Tig Welder Weak Arc.

From www.nellisauction.com

VEVOR TIG Welder AC/DC, 3 in 1 TIG/MMA/ARC Welding Machine with 110 Tig Welder Weak Arc Lack of penetration in tig welding occurs when the weld does not extend through the full thickness of the materials being joined, leading to a weak joint that is prone to failure. In this section, we will explore the causes of lack of penetration and discuss strategies to ensure your welds are fully penetrated and strong. The minimum voltage that. Tig Welder Weak Arc.

From www.xcelarc.nz

XCELARC™ TIG200RZ AC/DC TIG WELDER XcelArc® Welding Supplies Tig Welder Weak Arc Speaking of which, even the slightest air. Lack of penetration in tig welding occurs when the weld does not extend through the full thickness of the materials being joined, leading to a weak joint that is prone to failure. You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. A correctly. Tig Welder Weak Arc.

From www.wantitall.co.za

S7 Tig Welder, HF TIG/Stick/Arc TIG Welder,200 Amp 110 & 220V Dual Tig Welder Weak Arc How do i know if my tig welder is set up correctly? Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power supply settings, contamination of the welding environment, and equipment malfunction. The welder is trying and seems to pulse a weak arc at around 2 per second but it never settles. If. Tig Welder Weak Arc.

From www.xcelarc.nz

RAZORWELD™ 200 AC/DC PFC TIG Welder XcelArc® Welding Supplies Tig Welder Weak Arc A correctly set up tig welder should have a stable arc, proper gas flow, and the right amperage for the material you’re welding. If i release the torch button it. The welder is trying and seems to pulse a weak arc at around 2 per second but it never settles. In order to create an arc and transfer the welding. Tig Welder Weak Arc.

From www.desertcart.in

Buy SIMDER TIG Welder 110V 220V 140Amp TIG ARC 2 in 1 Stick Welder IGBT Tig Welder Weak Arc You’ll need to have the proper amount of voltage for your tig welder to work and throw an arc. If i release the torch button it. Tight arc = less chance that a breeze can sneak in and mess with your gas flow. The welder is trying and seems to pulse a weak arc at around 2 per second but. Tig Welder Weak Arc.

From ksupplies.co.uk

PARWELD XTM201DI Mig Tig Arc Multi Process Welder 110/230v Tig Welder Weak Arc If i release the torch button it. Several factors contribute to inconsistent welding arcs, including variations in material thickness, improper welding technique, inadequate power supply settings, contamination of the welding environment, and equipment malfunction. Lack of penetration in tig welding occurs when the weld does not extend through the full thickness of the materials being joined, leading to a weak. Tig Welder Weak Arc.

From www.desertcart.ph

Buy Flameweld MIG ARC TIG 3 In 1 /less MIG Welder Machine, 110/220V Tig Welder Weak Arc Lack of penetration in tig welding occurs when the weld does not extend through the full thickness of the materials being joined, leading to a weak joint that is prone to failure. The minimum voltage that needs to be maintained in the welding circuit to establish an arc is 15.7 volts. If i release the torch button it. Several factors. Tig Welder Weak Arc.

From www.vevor.com

VEVOR TIG Welder 3 in 1, 110V High Frequency TIG/Stick/Clean Welding Tig Welder Weak Arc In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. How do i know if my tig welder is set up correctly? If i release the torch button it. Tight arc = less chance that a breeze can sneak in and mess with your gas flow.. Tig Welder Weak Arc.

From childhealthpolicy.vumc.org

😝 Difference between arc mig and tig welding. The Different Types of Tig Welder Weak Arc Lack of penetration in tig welding occurs when the weld does not extend through the full thickness of the materials being joined, leading to a weak joint that is prone to failure. In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. The minimum voltage that. Tig Welder Weak Arc.

From www.xcelarc.nz

RAZORWELD™ ARC 200 PFC MMA/TIG Welder XcelArc® Welding Supplies Tig Welder Weak Arc Tight arc = less chance that a breeze can sneak in and mess with your gas flow. In order to create an arc and transfer the welding current to the base material being welded, tig welding requires the use of a. Speaking of which, even the slightest air. Lack of penetration in tig welding occurs when the weld does not. Tig Welder Weak Arc.