Application Of Bag Filter . By employing filter bags, can effectively collect and filters the dust present in the process gas. Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. Understanding how a bag filter works can provide insights into its advantages and applications across different industries. Bag filters are used in association with other size separation equipment such as cyclone separator, air separator in order to remove dust or fines. We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses bags made of porous materials, such as woven or felted fabric, to capture and remove particulate matter from industrial process gases. The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. In summary, a bag filter is an important tool used in pharmaceutical production and other filed to ensure air quality and protect from the hazards of dust generated during various processes. One of the most effective and widely used methods for dust collection and air purification is the bag filter system.

from www.hankefilters.com

The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses bags made of porous materials, such as woven or felted fabric, to capture and remove particulate matter from industrial process gases. Understanding how a bag filter works can provide insights into its advantages and applications across different industries. One of the most effective and widely used methods for dust collection and air purification is the bag filter system. By employing filter bags, can effectively collect and filters the dust present in the process gas. We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. Bag filters are used in association with other size separation equipment such as cyclone separator, air separator in order to remove dust or fines. Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. In summary, a bag filter is an important tool used in pharmaceutical production and other filed to ensure air quality and protect from the hazards of dust generated during various processes.

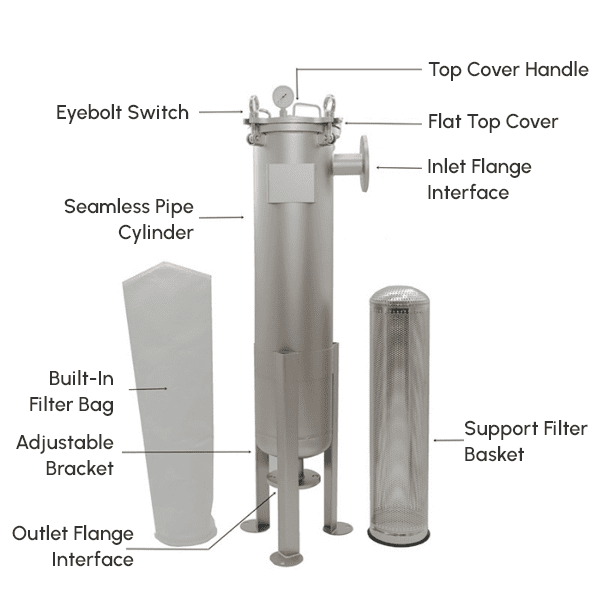

Single Bag Filter for Solid Removal At Low Flow Velocity Range

Application Of Bag Filter In summary, a bag filter is an important tool used in pharmaceutical production and other filed to ensure air quality and protect from the hazards of dust generated during various processes. One of the most effective and widely used methods for dust collection and air purification is the bag filter system. The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. In summary, a bag filter is an important tool used in pharmaceutical production and other filed to ensure air quality and protect from the hazards of dust generated during various processes. Bag filters are used in association with other size separation equipment such as cyclone separator, air separator in order to remove dust or fines. Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses bags made of porous materials, such as woven or felted fabric, to capture and remove particulate matter from industrial process gases. We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. By employing filter bags, can effectively collect and filters the dust present in the process gas. Understanding how a bag filter works can provide insights into its advantages and applications across different industries.

From solutionpharmacy.in

Construction and Working of Bag Filter Solution Parmacy Application Of Bag Filter We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. Understanding how a bag filter works can provide insights into its advantages and applications across different industries. Bag filters are. Application Of Bag Filter.

From www.brotherfiltration.com

Understanding Bag Filter Housing and Its Different Types Brother Application Of Bag Filter Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. One of the most effective and widely used methods for dust collection and air purification is the bag filter system. The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. A bag filter, also. Application Of Bag Filter.

From www.slideserve.com

PPT Bag Filter Selection Introduction PowerPoint Presentation, free Application Of Bag Filter We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. By employing filter bags, can effectively collect and filters the dust present in the process gas. One of the most effective and widely used methods for dust collection and air purification is the bag filter system. Bag filters. Application Of Bag Filter.

From www.tradeindia.com

Multi Bag Filter at 150000.00 INR in Ahmedabad, Gujarat Gopani Application Of Bag Filter Understanding how a bag filter works can provide insights into its advantages and applications across different industries. Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. In summary, a bag filter is an important tool used in pharmaceutical production and other filed to ensure air quality and protect from the hazards. Application Of Bag Filter.

From allindiaevent.com

Bag Filter Housing Exploring Its Types, Components, and Material for Application Of Bag Filter Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. Understanding how a bag filter works can provide insights into its advantages and applications across different industries. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses bags made of porous materials, such. Application Of Bag Filter.

From www.thermodyneboilers.com

Bag Filter in Boilers & Bag filters Working Principle Thermodyne Boilers Application Of Bag Filter The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses bags made of porous materials,. Application Of Bag Filter.

From saveecoenergy.in

Bag Filters SaveEco Energy Application Of Bag Filter Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses. Application Of Bag Filter.

From www.indiamart.com

Despro Tech Activated Carbon Industrial Bag Filters, Automation Grade Application Of Bag Filter Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. One of the most effective and widely used methods for dust collection and air purification is the bag filter. Application Of Bag Filter.

From www.youtube.com

All about Filter Bag Type of filter cloth Application of different Application Of Bag Filter The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. One of the most effective and widely used methods for dust collection and air purification is the bag filter system. By employing filter bags, can effectively collect and filters the dust present in the process gas. Bag filters work by passing the. Application Of Bag Filter.

From electricalworkbook.com

What is Bag Filter? Working Principle, Construction, Diagram Application Of Bag Filter By employing filter bags, can effectively collect and filters the dust present in the process gas. In summary, a bag filter is an important tool used in pharmaceutical production and other filed to ensure air quality and protect from the hazards of dust generated during various processes. Bag filters work by passing the liquid through the filter housing, where the. Application Of Bag Filter.

From www.hirlekarprecision.com

Applications Application Of Bag Filter Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. In summary, a bag filter is an important tool used in pharmaceutical production and other filed to ensure air quality and protect from the hazards of dust generated during various processes. By employing filter bags, can effectively. Application Of Bag Filter.

From www.waterandnature.org

The Working Principle Of Bag Filter IUCN Water Application Of Bag Filter Bag filters are used in association with other size separation equipment such as cyclone separator, air separator in order to remove dust or fines. Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. One of the most effective and widely used methods for dust collection and. Application Of Bag Filter.

From www.youtube.com

Bag Filter Reverse Air Type Bag filter Type of Bag Filter Working Application Of Bag Filter We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. Understanding how a bag filter works can provide insights into its advantages and applications across different industries. The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. Bag filters are. Application Of Bag Filter.

From www.tradeindia.com

Bag Filter System at 100000.00 INR in Pune, Maharashtra Stratgem Application Of Bag Filter Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. By employing filter bags, can effectively collect and filters the dust present in the process gas. Understanding how a bag filter works can provide insights into its advantages and applications across different industries. One of the most effective and widely used methods. Application Of Bag Filter.

From stylex.vn

Discover more than 119 application of bag filter stylex.vn Application Of Bag Filter By employing filter bags, can effectively collect and filters the dust present in the process gas. We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. Bag filters are used in association with other size separation equipment such as cyclone separator, air separator in order to remove dust. Application Of Bag Filter.

From www.filtersciences.com

The Applications of Bag Filter Housings Hydraulic Fracturing Bag Application Of Bag Filter We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses bags made of porous materials, such as woven or felted fabric, to capture and remove particulate matter from industrial. Application Of Bag Filter.

From www.hankefilters.com

Single Bag Filter for Solid Removal At Low Flow Velocity Range Application Of Bag Filter Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. Understanding how a bag filter works can provide insights into its advantages and applications across different industries. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses bags made of porous materials, such. Application Of Bag Filter.

From macigi450.blogspot.com

bag filter construction and working macigi450 Application Of Bag Filter The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses bags. Application Of Bag Filter.

From bagfilter.org

Application of Bag Filter in Pre treatment of Automobile Coating Bag Application Of Bag Filter Understanding how a bag filter works can provide insights into its advantages and applications across different industries. Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. Bag filters are used in association with other size separation equipment such as cyclone separator, air separator in order to. Application Of Bag Filter.

From www.sunsetfiltration.com

Bag Filters Sunset Filtration Products Application Of Bag Filter By employing filter bags, can effectively collect and filters the dust present in the process gas. Understanding how a bag filter works can provide insights into its advantages and applications across different industries. Bag filters are used in association with other size separation equipment such as cyclone separator, air separator in order to remove dust or fines. We will also. Application Of Bag Filter.

From stylex.vn

Discover more than 119 application of bag filter stylex.vn Application Of Bag Filter We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. By employing filter bags, can effectively collect and filters the dust present in the process gas. Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through. Application Of Bag Filter.

From www.tradeindia.com

Stainless Steel Bag Filter Application Industrial at Best Price in Application Of Bag Filter Bag filters are used in association with other size separation equipment such as cyclone separator, air separator in order to remove dust or fines. Understanding how a bag filter works can provide insights into its advantages and applications across different industries. By employing filter bags, can effectively collect and filters the dust present in the process gas. In summary, a. Application Of Bag Filter.

From www.sunsetfiltration.com

Bag Filters Sunset Filtration Products Application Of Bag Filter Understanding how a bag filter works can provide insights into its advantages and applications across different industries. By employing filter bags, can effectively collect and filters the dust present in the process gas. One of the most effective and widely used methods for dust collection and air purification is the bag filter system. Bag filters work by passing the liquid. Application Of Bag Filter.

From www.youtube.com

Working of BagFilter In English Bag filter Animation video How Bag Application Of Bag Filter In summary, a bag filter is an important tool used in pharmaceutical production and other filed to ensure air quality and protect from the hazards of dust generated during various processes. The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. Understanding how a bag filter works can provide insights into its. Application Of Bag Filter.

From acmefluidsystems.wordpress.com

Role of Bag Filters and How Does it Work? ACME Fluid Systems Application Of Bag Filter One of the most effective and widely used methods for dust collection and air purification is the bag filter system. We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags.. Application Of Bag Filter.

From www.pinterest.com

Classification and application of filter bags Filters, Bags Application Of Bag Filter Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. One of the most effective and widely used methods for dust collection and air purification is the bag filter system. The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. In summary, a bag. Application Of Bag Filter.

From www.waterandnature.org

The Working Principle Of Bag Filter IUCN Water Application Of Bag Filter Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. By employing filter bags, can effectively collect and filters the dust present in the process gas. Bag filters work by passing the liquid through the filter housing, where the particles settle in the bags. The process gases. Application Of Bag Filter.

From www.youtube.com

Bag Filter Working Principle Bag Filter Working Animation Bag Application Of Bag Filter Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. In summary, a bag filter is an important tool used in pharmaceutical production and other filed to ensure air quality and protect from the hazards of dust generated during various processes. A bag filter, also known as. Application Of Bag Filter.

From filtrationchina.com

What is Multibag Filter Housing? Filtration Equipment Application Of Bag Filter Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases flow through them. By employing filter bags, can effectively collect and filters the dust present in the process gas. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses bags made. Application Of Bag Filter.

From www.filtersciences.com

What Do Bag Filters Move? Filter Sciences Application Of Bag Filter Understanding how a bag filter works can provide insights into its advantages and applications across different industries. In summary, a bag filter is an important tool used in pharmaceutical production and other filed to ensure air quality and protect from the hazards of dust generated during various processes. Bag filters work by passing the liquid through the filter housing, where. Application Of Bag Filter.

From www.topdistillation.com

How do bag filters work? Application Of Bag Filter By employing filter bags, can effectively collect and filters the dust present in the process gas. Understanding how a bag filter works can provide insights into its advantages and applications across different industries. The process gases pass through the bags, which act as a physical barrier to trap the particulate matter. Bag filters work by passing the liquid through the. Application Of Bag Filter.

From www.eaton.com

CLEARGAF filter bags for food and beverage applications Eaton Application Of Bag Filter Bag filters are used in association with other size separation equipment such as cyclone separator, air separator in order to remove dust or fines. By employing filter bags, can effectively collect and filters the dust present in the process gas. Bag filters operate on the principle of microfiltration, using a series of filter bags to trap particles as flue gases. Application Of Bag Filter.

From todaytime.co

Basic Features of Industrial Bag Filters Today Time Application Of Bag Filter We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. A bag filter, also known as a fabric filter, is a type of air pollution control equipment that uses bags made of porous materials, such as woven or felted fabric, to capture and remove particulate matter from industrial. Application Of Bag Filter.

From pharmasiksha.com

Bag filter working principle construction uses merits and demerits Application Of Bag Filter One of the most effective and widely used methods for dust collection and air purification is the bag filter system. We will also explore the expertise of as engineers in this field, showcasing why they are industry leaders in bag filter technology. The process gases pass through the bags, which act as a physical barrier to trap the particulate matter.. Application Of Bag Filter.