Equipment Utilization Definition . In simple terms, machine utilization is a performance indicator of how well your equipment is working. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Equipment utilization refers to the percentage of time that equipment is actually used compared to the total time it is available. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment.

from www.scribd.com

In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Equipment utilization refers to the percentage of time that equipment is actually used compared to the total time it is available.

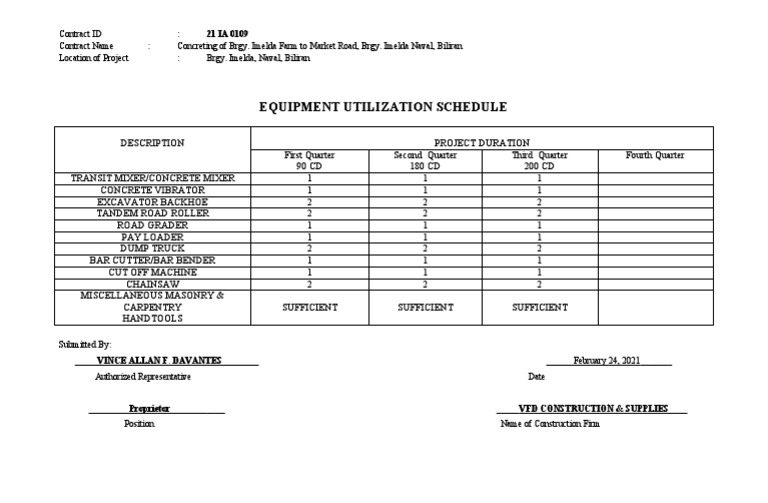

Equipment Utilization Schedule PDF Industrial Equipment Heavy

Equipment Utilization Definition Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Equipment utilization refers to the percentage of time that equipment is actually used compared to the total time it is available.

From www.slidegeeks.com

Assessing Warehouse Equipment Utilization Frequency Pictures PDF Equipment Utilization Definition Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. In simple terms, machine. Equipment Utilization Definition.

From gocodes.com

5 Important Benefits of Tracking Rental Equipment Equipment Utilization Definition Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Overall equipment effectiveness (oee) is a metric used to. Equipment Utilization Definition.

From www.scribd.com

14. Equipment Utilization Schedule Business Equipment Utilization Definition Equipment utilization refers to the percentage of time that equipment is actually used compared to the total time it is available. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Teep (total effective equipment performance) is a performance metric that provides insights as to the true. Equipment Utilization Definition.

From gocodes.com

The Benefits of Using Construction Equipment Tracking Software Equipment Utilization Definition Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Equipment utilization refers to the percentage of time that equipment is actually used compared to the total time it is available. In simple terms,. Equipment Utilization Definition.

From studylib.net

Section 5 Utilization Equipment Equipment Utilization Definition Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Asset utilization measures how intensively an asset (machinery,. Equipment Utilization Definition.

From www.researchgate.net

The equipment utilization chart for the optimized case Download Equipment Utilization Definition Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Asset utilization measures how intensively. Equipment Utilization Definition.

From www.easycheck.io

Understanding Utilization. Knowing what not to order next time EasyCheck Equipment Utilization Definition Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Equipment utilization refers to the percentage of time that equipment is actually used compared to the total time it is available. Overall equipment effectiveness (oee). Equipment Utilization Definition.

From www.canadianmetalworking.com

Entering a New Information Age for Machine Utilization Equipment Utilization Definition Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Teep (total effective. Equipment Utilization Definition.

From marketbusinessnews.com

What is utilization? Definition and example Market Business News Equipment Utilization Definition Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Overall equipment effectiveness[ 1. Equipment Utilization Definition.

From blog.amper.xyz

Everything You Need to Know About Machine Utilization Equipment Utilization Definition Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Equipment. Equipment Utilization Definition.

From gocodes.com

How to Track and Improve Equipment Utilization GoCodes Equipment Utilization Definition Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is. Equipment Utilization Definition.

From gocodes.com

How to Use GoCodes to Track Equipment Utilization Tool Tracking Software Equipment Utilization Definition In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Equipment utilization refers to the percentage of time that. Equipment Utilization Definition.

From gocodes.com

What Is Equipment Utilization Equipment Utilization Definition Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness (oee) is a metric used to measure the. Equipment Utilization Definition.

From gocodes.com

What Is Equipment Utilization Equipment Utilization Definition Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. In simple terms, machine utilization. Equipment Utilization Definition.

From www.assignar.com

Equipment Utilization Assignar Equipment Utilization Definition In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Asset utilization measures how intensively an asset (machinery,. Equipment Utilization Definition.

From dinakarmurthy.com

Utilisation and Overall Equipment Effectiveness Equipment Utilization Definition Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Overall equipment effectiveness[ 1 ] (oee). Equipment Utilization Definition.

From www.slideshare.net

Improving SMT Equipment Utilization Equipment Utilization Definition Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness[ 1 ] (oee) is a. Equipment Utilization Definition.

From gocodes.com

What Is Equipment Utilization Equipment Utilization Definition In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of. Equipment Utilization Definition.

From www.youtube.com

What is Equipment? Definition and Meaning YouTube Equipment Utilization Definition In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Equipment utilization refers to the percentage of time that equipment is actually used compared to the total time it is available. Equipment. Equipment Utilization Definition.

From gocodes.com

7 Key Benefits of Fixed Asset Tracking Equipment Utilization Definition Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Teep (total effective equipment. Equipment Utilization Definition.

From www.slideserve.com

PPT University of Saskatchewan Geological Engineering GEOE 498.3 Equipment Utilization Definition Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Equipment utilization refers to the percentage of time that equipment is actually used compared to the total. Equipment Utilization Definition.

From www.mudamasters.com

Overall Equipment Effectiveness (OEE) MudaMasters Equipment Utilization Definition Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment.. Equipment Utilization Definition.

From www.slideshare.net

Capacity utilization Calculation Methods...!!!! Equipment Utilization Definition Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any. Equipment Utilization Definition.

From www.thestreet.com

What Are Industrial Production and Capacity Utilization? Definition Equipment Utilization Definition Equipment utilization refers to the percentage of time that equipment is actually used compared to the total time it is available. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Teep. Equipment Utilization Definition.

From gocodes.com

What Is Equipment Utilization Equipment Utilization Definition Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness[ 1 ] (oee) is a measure of. Equipment Utilization Definition.

From gocodes.com

How to Track and Improve Equipment Utilization GoCodes Equipment Utilization Definition Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. In simple terms, machine utilization. Equipment Utilization Definition.

From www.tenna.com

Equipment Utilization Equipment Utilization Tracking Tenna Equipment Utilization Definition Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment.. Equipment Utilization Definition.

From www.automationworld.com

How to Calculate Overall Equipment Effectiveness A Practical Guide Equipment Utilization Definition In simple terms, machine utilization is a performance indicator of how well your equipment is working. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Equipment utilization refers to the percentage of time that equipment is actually used compared to the total time it is available. Overall equipment. Equipment Utilization Definition.

From www.scribd.com

Equipment Utilization Schedule PDF Industrial Equipment Heavy Equipment Utilization Definition Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness[. Equipment Utilization Definition.

From technology.gov.capital

Equipment utilization analysis Technology.Gov.Capital Equipment Utilization Definition Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. In simple terms, machine utilization is a performance indicator of how well your equipment is working. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment.. Equipment Utilization Definition.

From www.researchgate.net

Utilization rate/UC of equipment Download Table Equipment Utilization Definition Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Teep (total effective equipment performance) is a performance metric that provides insights as to the true. Equipment Utilization Definition.

From www.scribd.com

Equipment Utilization Schedule PDF Equipment Utilization Definition In simple terms, machine utilization is a performance indicator of how well your equipment is working. Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Overall equipment effectiveness. Equipment Utilization Definition.

From www.infsoft.com

infsoft Use Case Utilization Analysis of Work Devices Equipment Utilization Definition Overall equipment effectiveness[ 1 ] (oee) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared. Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Equipment utilization refers to. Equipment Utilization Definition.

From www.researchgate.net

Conceptual framework for medical equipment utilization in public Equipment Utilization Definition Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Overall equipment effectiveness (oee) is a metric used to measure the effectiveness and performance of manufacturing processes or any individual piece of equipment. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. Overall equipment effectiveness[ 1. Equipment Utilization Definition.

From www.samsara.com

How to Measure and Improve Equipment Utilization Equipment Utilization Definition Asset utilization measures how intensively an asset (machinery, equipment, system, process, etc.) is utilized compared to what it theoretically could do. Teep (total effective equipment performance) is a performance metric that provides insights as to the true capacity of your manufacturing. Equipment utilization data measures how efficiently businesses use machinery, vehicles, heavy equipment and. In simple terms, machine utilization is. Equipment Utilization Definition.