Vacuum Forming Diagram . View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Preheated sheet prior to forming b: Discover the art of vacuum forming plastic in this comprehensive guide! Vacuum forming is a type of thermoforming used to shape plastic materials. See the process stages, materials, applications, advantages, challenges, and resources for further learning. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Sheet prestretched with air pressure c: Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied.

from electricalworkbook.com

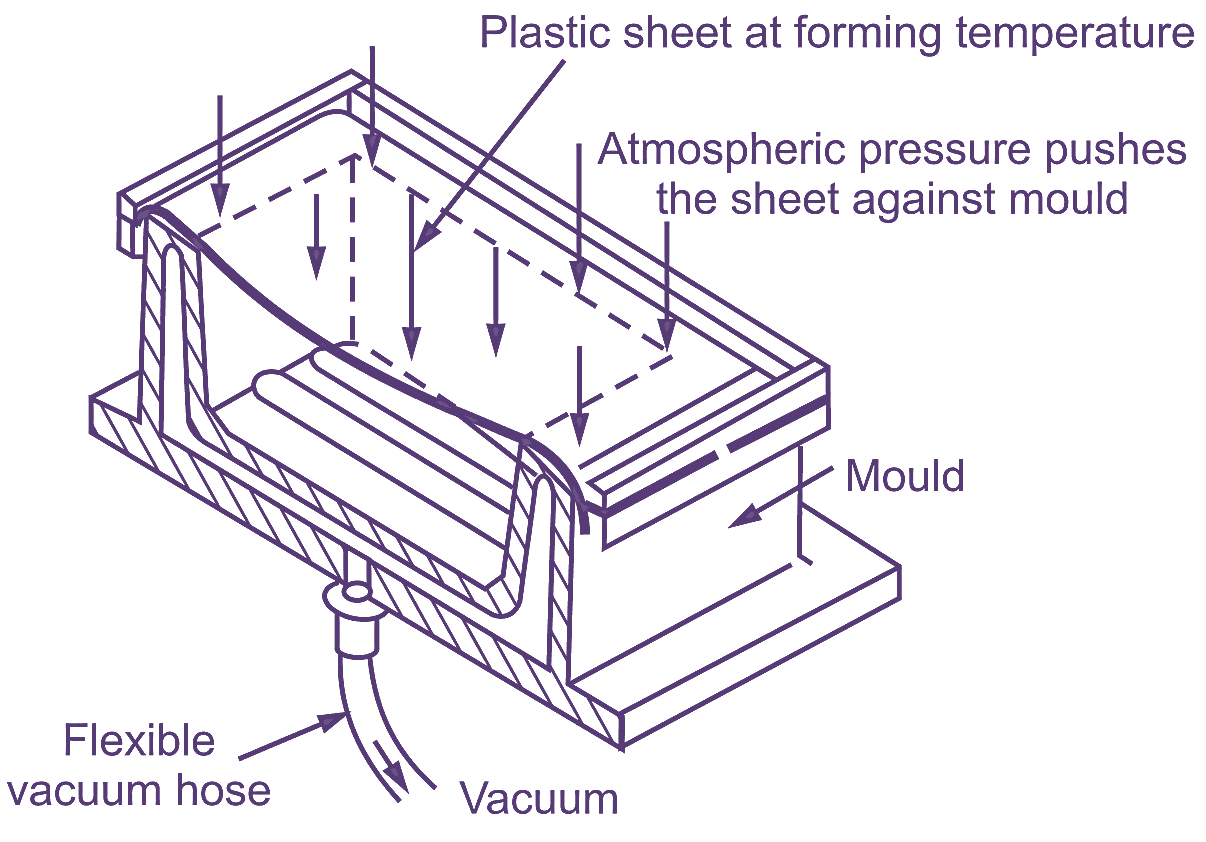

Vacuum forming is a type of thermoforming used to shape plastic materials. In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Preheated sheet prior to forming b: Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Sheet prestretched with air pressure c: Discover the art of vacuum forming plastic in this comprehensive guide! See the process stages, materials, applications, advantages, challenges, and resources for further learning. View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets.

What is Vacuum Forming? Process, Applications, Products & Advantages

Vacuum Forming Diagram View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Vacuum forming is a type of thermoforming used to shape plastic materials. Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. Sheet prestretched with air pressure c: See the process stages, materials, applications, advantages, challenges, and resources for further learning. View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Discover the art of vacuum forming plastic in this comprehensive guide! In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Preheated sheet prior to forming b:

From sulplast.com.br

Vacuum Forming Termoplástico Sulplast Fibra de vidro e Termoplástico Vacuum Forming Diagram Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Preheated sheet prior to forming b: Vacuum forming is a type of thermoforming used to shape plastic materials. Discover the art of vacuum. Vacuum Forming Diagram.

From onlinelibrary.wiley.com

Effects of thermoforming operation and tooling on the thermoformability Vacuum Forming Diagram Discover the art of vacuum forming plastic in this comprehensive guide! Sheet prestretched with air pressure c: Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Vacuum forming is a process that. Vacuum Forming Diagram.

From www.pinterest.se

vacuum forming GCSE_Graphics_Packaging Exam revision, Vacuum Vacuum Forming Diagram Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. See the process stages, materials, applications, advantages, challenges, and resources for further learning. View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Vacuum forming is a type of thermoforming used to shape plastic materials. In. Vacuum Forming Diagram.

From www.manufacturingguide.com

Vacuum forming Find suppliers, processes & material Vacuum Forming Diagram Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. Vacuum forming is a type of thermoforming used to shape plastic materials. In its simplest form thermoforming is the heating of a plastic sheet which. Vacuum Forming Diagram.

From www.la-plastic.com

What Causes bing in Vacuum Forming? Vacuum Forming Diagram Sheet prestretched with air pressure c: Discover the art of vacuum forming plastic in this comprehensive guide! View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. In its simplest form thermoforming is the heating of. Vacuum Forming Diagram.

From www.build-stuff.com

Publishing DIY Build Your Own Vacuum Forming Machine Vacuum Forming Diagram Discover the art of vacuum forming plastic in this comprehensive guide! Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. In its simplest form thermoforming is the heating of a plastic sheet which is. Vacuum Forming Diagram.

From www.nameplates.co.uk

Vacuum Formed & Printed Components Nameplates.co.uk Vacuum Forming Diagram See the process stages, materials, applications, advantages, challenges, and resources for further learning. In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Preheated sheet prior to forming b: Vacuum forming is a type of thermoforming used to shape plastic materials. Learn the basics of vacuum. Vacuum Forming Diagram.

From www.rutlandplastics.co.uk

Plastics Moulding Methods Vac Rutland Plastics Vacuum Forming Diagram Vacuum forming is a type of thermoforming used to shape plastic materials. View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. In its simplest form thermoforming is the heating of a plastic. Vacuum Forming Diagram.

From birdsaustra.blogspot.com

Vacuum Forming Facts Vacuum Forming 1/4" ABS plastic Deep Draw Vacuum Forming Diagram Preheated sheet prior to forming b: Sheet prestretched with air pressure c: In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Discover the art of vacuum forming plastic in. Vacuum Forming Diagram.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Vacuum Forming Diagram In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. See the process stages, materials, applications, advantages, challenges, and resources for further learning. Sheet prestretched with air pressure c: Vacuum. Vacuum Forming Diagram.

From www.petervaldivia.com

Fabrication of Plastics. Tecnología ESO en Ingles Vacuum Forming Diagram Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Sheet prestretched with air pressure c: Vacuum forming is a type of thermoforming used to shape plastic materials. See the process stages, materials, applications, advantages, challenges, and resources for further learning. In its simplest form thermoforming is the heating of a plastic sheet which. Vacuum Forming Diagram.

From spottingit.com

The advantages of vacuum forming Spotting IT Vacuum Forming Diagram Sheet prestretched with air pressure c: Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. Preheated sheet prior to forming b: In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Vacuum forming is a type. Vacuum Forming Diagram.

From www.google.com

Patent EP2206595A1 Vacuum forming machine and method of making vacuum Vacuum Forming Diagram Sheet prestretched with air pressure c: Vacuum forming is a type of thermoforming used to shape plastic materials. Preheated sheet prior to forming b: Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. See the process stages, materials, applications, advantages, challenges, and resources for further learning. View our vacuum forming design guide for. Vacuum Forming Diagram.

From www.researchgate.net

5 Vacuum forming with the female mould (a) and male moulds (b Vacuum Forming Diagram In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Vacuum forming is a type of thermoforming used to shape plastic materials. Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. Discover the art of vacuum. Vacuum Forming Diagram.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Vacuum Forming Diagram Preheated sheet prior to forming b: Vacuum forming is a type of thermoforming used to shape plastic materials. See the process stages, materials, applications, advantages, challenges, and resources for further learning. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Learn the basics of vacuum forming, a plastic molding technique that uses heat. Vacuum Forming Diagram.

From www.youtube.com

Formech explores how vacuum forming is innovating design at Pratt Vacuum Forming Diagram In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Sheet prestretched with air pressure c: View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. See the process stages, materials, applications, advantages, challenges, and resources for further. Vacuum Forming Diagram.

From www.krk.co.jp

真空成形 | 技術情報 | キョーラク株式会社 Vacuum Forming Diagram Vacuum forming is a type of thermoforming used to shape plastic materials. See the process stages, materials, applications, advantages, challenges, and resources for further learning. Sheet prestretched with air pressure c: View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Preheated sheet prior to forming b: Learn the basics of vacuum. Vacuum Forming Diagram.

From 3dprintscape.com

Is Vacuum Forming Cheaper than Injection Molding? Vacuum Forming Diagram See the process stages, materials, applications, advantages, challenges, and resources for further learning. Vacuum forming is a type of thermoforming used to shape plastic materials. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Sheet prestretched with air pressure c: Preheated sheet prior to forming b: Learn the basics of vacuum forming, a. Vacuum Forming Diagram.

From www.productiveplastics.com

Plastic Thermoforming, Pressure Forming, Vacuum Forming What's the Vacuum Forming Diagram View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Discover the art of vacuum forming plastic in this comprehensive guide! Vacuum forming is a type of thermoforming used to shape plastic materials. In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould. Vacuum Forming Diagram.

From plasticmouldingsnorthern.co.uk

How To Vacuum Form Plastic Mouldings Northern Vacuum Forming Diagram Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Preheated sheet prior to forming b: Vacuum forming is a type of thermoforming used to shape plastic. Vacuum Forming Diagram.

From www.slideshare.net

Vacuum forming Vacuum Forming Diagram Sheet prestretched with air pressure c: Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Discover the art of vacuum forming plastic in this comprehensive guide! In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Vacuum forming is. Vacuum Forming Diagram.

From www.rocheindustry.com

Handbook The Ultimate Guide To Vacuum Forming 2024 Updated Vacuum Forming Diagram Discover the art of vacuum forming plastic in this comprehensive guide! Preheated sheet prior to forming b: View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. See. Vacuum Forming Diagram.

From www.goconqr.com

VACUUM FORMING Mind Map Vacuum Forming Diagram View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Sheet prestretched with air pressure c: Preheated sheet prior to forming b: See the process stages, materials, applications, advantages, challenges, and resources for further learning. Vacuum. Vacuum Forming Diagram.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research Vacuum Forming Diagram View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Preheated sheet prior to forming b: Vacuum forming is a type of thermoforming used to shape plastic materials. See the process stages, materials, applications, advantages, challenges, and resources for further learning. Discover the art of vacuum forming plastic in this comprehensive guide!. Vacuum Forming Diagram.

From www.weetect.com

Plastic Fabrication The Complete Guide In 2018 Wee Tect Vacuum Forming Diagram Sheet prestretched with air pressure c: Preheated sheet prior to forming b: See the process stages, materials, applications, advantages, challenges, and resources for further learning. Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. In its simplest form thermoforming is the heating of a plastic sheet which is then draped. Vacuum Forming Diagram.

From saopaulovidracaria.com.br

Per National flag Out of date vacuum forming diagram lecture Asser Peruse Vacuum Forming Diagram In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Vacuum forming. Vacuum Forming Diagram.

From www.techsoft.co.uk

Vacuum Forming TechSoft Vacuum Forming Diagram Discover the art of vacuum forming plastic in this comprehensive guide! See the process stages, materials, applications, advantages, challenges, and resources for further learning. View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Preheated sheet prior to forming b: Vacuum forming is a process that uses heat and vacuum pressure to. Vacuum Forming Diagram.

From www.ditaiplastic.com

Vacuum Forming Process DitaiPlastic Vacuum Forming Diagram Sheet prestretched with air pressure c: In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. See the process stages, materials, applications, advantages, challenges, and resources for further learning. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Learn. Vacuum Forming Diagram.

From www.plas-tech.co.uk

Vac Forming The Advantages of Vacuum Forming Vacuum Forming Diagram View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Discover the art of vacuum forming plastic in this comprehensive guide! Vacuum forming is a type of thermoforming used to shape plastic materials. Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets.. Vacuum Forming Diagram.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Vacuum Forming Diagram View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Preheated sheet prior to forming b: In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Learn the basics of vacuum forming, a plastic molding technique that uses. Vacuum Forming Diagram.

From www.scandivac.com

Scandivac Thermoforming Vacuum Forming Diagram Discover the art of vacuum forming plastic in this comprehensive guide! Sheet prestretched with air pressure c: Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Preheated sheet prior to forming b: In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a. Vacuum Forming Diagram.

From www.youtube.com

Vacuum forming 01 main process YouTube Vacuum Forming Diagram Sheet prestretched with air pressure c: Learn the basics of vacuum forming, a plastic molding technique that uses heat and vacuum to shape plastic sheets. In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Vacuum forming is a process that uses heat and vacuum pressure. Vacuum Forming Diagram.

From www.pinterest.com

Vacuum forming process Vacuum forming, Vacuum Vacuum Forming Diagram Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. Discover the art of vacuum forming plastic in this comprehensive guide! See the process stages, materials, applications, advantages, challenges, and resources for further learning. In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst. Vacuum Forming Diagram.

From mavink.com

Vacuum Forming Process Diagram Vacuum Forming Diagram In its simplest form thermoforming is the heating of a plastic sheet which is then draped over a mould whilst a vacuum is applied. Discover the art of vacuum forming plastic in this comprehensive guide! Preheated sheet prior to forming b: Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. See the process. Vacuum Forming Diagram.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited Vacuum Forming Diagram Vacuum forming is a type of thermoforming used to shape plastic materials. See the process stages, materials, applications, advantages, challenges, and resources for further learning. Vacuum forming is a process that uses heat and vacuum pressure to mold plastic sheets into. View our vacuum forming design guide for more detailed advice on draft angles, pocket depths, undercuts & more. Sheet. Vacuum Forming Diagram.