Define Sleeve Joint With Suitable Sketch . The first one is the socket and spigot cotter joint. A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. Types of cotter joints following are the three commonly used cotter joints to connect two rods by a cotter: In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. Socket and spigot cotter joint, 2. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. 1 and the other end of the other rod (say b) is inserted. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. What is a sleeve and cotter joint? The other two are the sleeve and cotter joint, and gib and cotter joint.

from www.scielo.br

Socket and spigot cotter joint, 2. The first one is the socket and spigot cotter joint. 1 and the other end of the other rod (say b) is inserted. In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. What is a sleeve and cotter joint? In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. The other two are the sleeve and cotter joint, and gib and cotter joint. Types of cotter joints following are the three commonly used cotter joints to connect two rods by a cotter: The sleeve and cotter joint is used to connect two coaxial cylindrical rods.

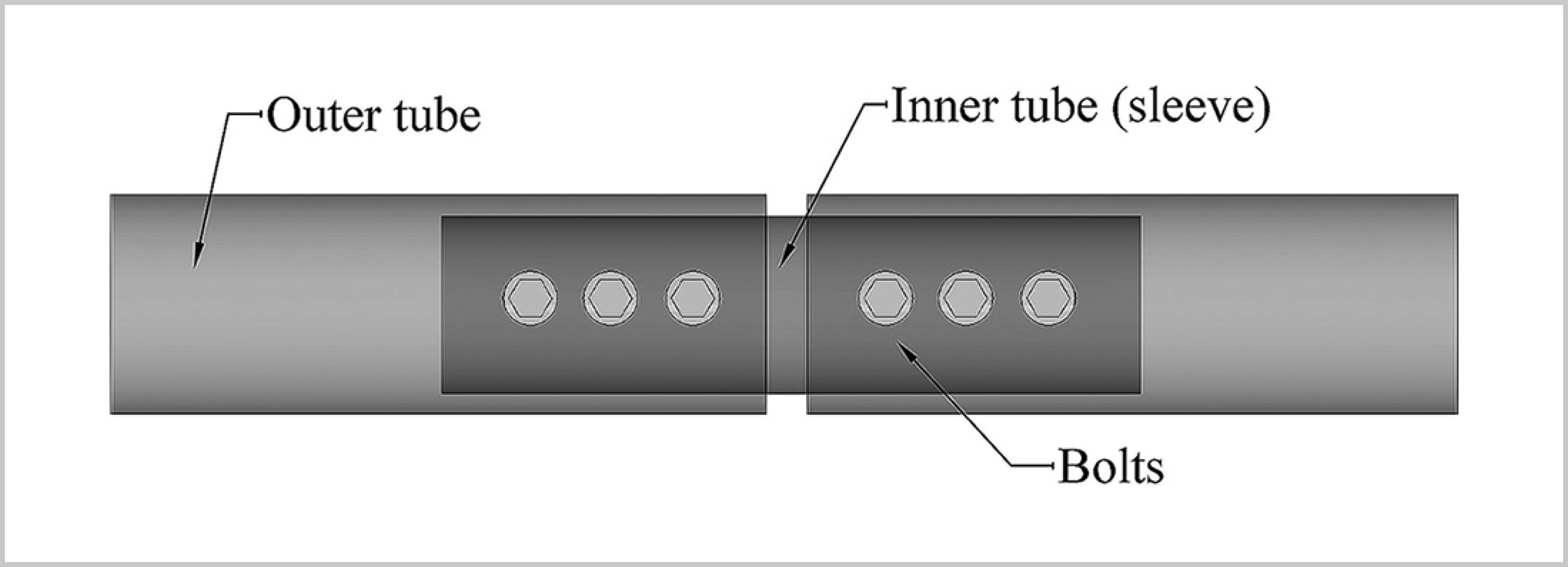

SciELO Brasil Bearing failure in bolted sleeve connections with

Define Sleeve Joint With Suitable Sketch The first one is the socket and spigot cotter joint. Types of cotter joints following are the three commonly used cotter joints to connect two rods by a cotter: The other two are the sleeve and cotter joint, and gib and cotter joint. 1 and the other end of the other rod (say b) is inserted. What is a sleeve and cotter joint? Socket and spigot cotter joint, 2. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. The first one is the socket and spigot cotter joint. In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is.

From machine-drawing.blogspot.com

Machine Drawing SLEEVE AND COTTER JOINT REVISITED Define Sleeve Joint With Suitable Sketch A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint. Define Sleeve Joint With Suitable Sketch.

From www.youtube.com

Sleev Joint (स्लीव जोड़) YouTube Define Sleeve Joint With Suitable Sketch The sleeve and cotter joint is used to connect two coaxial cylindrical rods. A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint. Define Sleeve Joint With Suitable Sketch.

From www.pinterest.co.uk

Pinterest Define Sleeve Joint With Suitable Sketch A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. The first. Define Sleeve Joint With Suitable Sketch.

From www.scielo.br

SciELO Brasil Bearing failure in bolted sleeve connections with Define Sleeve Joint With Suitable Sketch A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. Socket and. Define Sleeve Joint With Suitable Sketch.

From www.modumic.com

5 Types of Welding Joints Explained Fractory manbetx2.0.ios Define Sleeve Joint With Suitable Sketch A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. The other two are the sleeve and cotter joint, and gib and cotter joint. The first one is the socket and spigot cotter joint. Types of cotter joints following are the three commonly used. Define Sleeve Joint With Suitable Sketch.

From machine-drawing.blogspot.com

Machine Drawing Sleeve and cotter joint , Socket and spigot joint and Define Sleeve Joint With Suitable Sketch The other two are the sleeve and cotter joint, and gib and cotter joint. In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. A knuckle joint is used to connect. Define Sleeve Joint With Suitable Sketch.

From www.abaconproducts.com.au

External Sleeve Joiner for 42mm or 48mm Galvanised Pipe. By Interclamp Define Sleeve Joint With Suitable Sketch In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. What is a sleeve and cotter joint? The first one is the socket and spigot cotter joint. The other two are the sleeve and cotter joint, and gib. Define Sleeve Joint With Suitable Sketch.

From blog.thepipingmart.com

What is Sleeve Coupling? Define Sleeve Joint With Suitable Sketch In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. The other two are the sleeve and cotter joint, and gib and cotter joint. Types. Define Sleeve Joint With Suitable Sketch.

From www.researchgate.net

1 Schematic of a bolted joint d Download Scientific Diagram Define Sleeve Joint With Suitable Sketch Socket and spigot cotter joint, 2. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. What is a sleeve and cotter joint? The sleeve and cotter joint is used to connect two coaxial cylindrical rods. Types of. Define Sleeve Joint With Suitable Sketch.

From www.pinterest.com

Pin on CAD Define Sleeve Joint With Suitable Sketch The other two are the sleeve and cotter joint, and gib and cotter joint. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. 1 and the other end of the other rod (say b) is inserted. What. Define Sleeve Joint With Suitable Sketch.

From selectfit.co.nz

Sleeve Joint C00 FastClamp Steel Pipe Fittings Define Sleeve Joint With Suitable Sketch What is a sleeve and cotter joint? In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. The other two are the sleeve and cotter joint, and gib and cotter joint. A knuckle joint is used to connect. Define Sleeve Joint With Suitable Sketch.

From machine-drawing.blogspot.com

Machine Drawing Sleeve and cotter joint , Socket and spigot joint and Define Sleeve Joint With Suitable Sketch The first one is the socket and spigot cotter joint. What is a sleeve and cotter joint? The other two are the sleeve and cotter joint, and gib and cotter joint. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. In this article, we are going to discuss this sleeve and cotter joint construction and how. Define Sleeve Joint With Suitable Sketch.

From machine-drawing.blogspot.com

Machine Drawing Sleeve and cotter joint & Socket and spigot joint Define Sleeve Joint With Suitable Sketch The sleeve and cotter joint is used to connect two coaxial cylindrical rods. What is a sleeve and cotter joint? Types of cotter joints following are the three commonly used cotter joints to connect two rods by a cotter: In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of. Define Sleeve Joint With Suitable Sketch.

From www.physicsforums.com

Bolted Sleeve Connections with Hollow Sections Define Sleeve Joint With Suitable Sketch In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. Socket and spigot cotter joint, 2. What is a sleeve and cotter joint? Types of cotter joints following are the three commonly used cotter joints to connect two rods by a cotter: The sleeve. Define Sleeve Joint With Suitable Sketch.

From seven.edu.vn

Update more than 53 sleeve joint sketch best seven.edu.vn Define Sleeve Joint With Suitable Sketch Socket and spigot cotter joint, 2. What is a sleeve and cotter joint? Types of cotter joints following are the three commonly used cotter joints to connect two rods by a cotter: In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. A knuckle. Define Sleeve Joint With Suitable Sketch.

From www.pinterest.es

Machine Drawing Sleeve and cotter joint , Socket and spigot joint and Define Sleeve Joint With Suitable Sketch What is a sleeve and cotter joint? 1 and the other end of the other rod (say b) is inserted. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. Socket and spigot cotter joint, 2. A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of. Define Sleeve Joint With Suitable Sketch.

From www.sunnysteel.com

Ceramic Lined Sleeve Type Expansion Joints, Ceramic Lined Expansion Define Sleeve Joint With Suitable Sketch 1 and the other end of the other rod (say b) is inserted. Socket and spigot cotter joint, 2. What is a sleeve and cotter joint? The sleeve and cotter joint is used to connect two coaxial cylindrical rods. The first one is the socket and spigot cotter joint. In a socket and spigot cotter joint, one end of the. Define Sleeve Joint With Suitable Sketch.

From www.iqsdirectory.com

Expansion Joints Types, Characteristics, Uses & Benefits Define Sleeve Joint With Suitable Sketch The other two are the sleeve and cotter joint, and gib and cotter joint. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. In a socket and spigot cotter joint, one end of the rods (say a). Define Sleeve Joint With Suitable Sketch.

From engineersblog.net

What is Sleeve Splice Joint? Explain in details step by step procedure Define Sleeve Joint With Suitable Sketch A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. 1 and the other end of the other rod (say b) is inserted. Types of cotter joints following are the three commonly used cotter joints to connect two rods by a cotter: The other. Define Sleeve Joint With Suitable Sketch.

From extrudesign.com

How to Design a Sleeve and Cotter Joint? ExtruDesign Define Sleeve Joint With Suitable Sketch The other two are the sleeve and cotter joint, and gib and cotter joint. A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. Types of cotter joints following are the three commonly used cotter joints to connect two rods by a cotter: In. Define Sleeve Joint With Suitable Sketch.

From www.mdpi.com

Buildings Free FullText Seismic Performance of a Novel Precast Define Sleeve Joint With Suitable Sketch The other two are the sleeve and cotter joint, and gib and cotter joint. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. A knuckle joint is used to connect. Define Sleeve Joint With Suitable Sketch.

From www.researchgate.net

Schematic diagram and images for brazed joints 1 and 1′parent Define Sleeve Joint With Suitable Sketch Socket and spigot cotter joint, 2. What is a sleeve and cotter joint? The sleeve and cotter joint is used to connect two coaxial cylindrical rods. The first one is the socket and spigot cotter joint. In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown. Define Sleeve Joint With Suitable Sketch.

From www.youtube.com

HOW TO DRAW 2D KNUCKLE JOINT IN SOLID EDGE YouTube Define Sleeve Joint With Suitable Sketch The sleeve and cotter joint is used to connect two coaxial cylindrical rods. The other two are the sleeve and cotter joint, and gib and cotter joint. In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. Types of cotter joints following are the. Define Sleeve Joint With Suitable Sketch.

From www.youtube.com

Assembly of sleeve and cotter joint Engineering drawing Engineering Define Sleeve Joint With Suitable Sketch In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. Socket and spigot cotter joint, 2. The other two are the sleeve and cotter joint, and gib and cotter joint. 1 and the other end of the other rod (say b) is inserted. Types. Define Sleeve Joint With Suitable Sketch.

From www.youtube.com

Types of failures in bolted Connections Block shear failure Prying Define Sleeve Joint With Suitable Sketch In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. The sleeve. Define Sleeve Joint With Suitable Sketch.

From www.researchgate.net

Geometric dimension of platetosleeve welded joints. Download Define Sleeve Joint With Suitable Sketch The first one is the socket and spigot cotter joint. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. In this article, we are going to discuss this sleeve and. Define Sleeve Joint With Suitable Sketch.

From cruisemaster.com.au

The Importance of Bolted Joints & How They Work Cruisemaster Define Sleeve Joint With Suitable Sketch The first one is the socket and spigot cotter joint. 1 and the other end of the other rod (say b) is inserted. Types of cotter joints following are the three commonly used cotter joints to connect two rods by a cotter: The sleeve and cotter joint is used to connect two coaxial cylindrical rods. What is a sleeve and. Define Sleeve Joint With Suitable Sketch.

From www.bellowshellas.com

Sleeve Type Expansion Joints Bellows Hellas Define Sleeve Joint With Suitable Sketch The other two are the sleeve and cotter joint, and gib and cotter joint. In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount. Define Sleeve Joint With Suitable Sketch.

From www.haigewei.com

sleeve joint HGW Define Sleeve Joint With Suitable Sketch What is a sleeve and cotter joint? Socket and spigot cotter joint, 2. In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. The other two are the sleeve and cotter joint, and gib and cotter joint. The first one is the socket and. Define Sleeve Joint With Suitable Sketch.

From www.pinterest.com

Pinterest Define Sleeve Joint With Suitable Sketch Socket and spigot cotter joint, 2. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. 1 and the other end of the other rod. Define Sleeve Joint With Suitable Sketch.

From www.mdpi.com

Applied Sciences Free FullText Properties of Sleeve Joints Made Define Sleeve Joint With Suitable Sketch The first one is the socket and spigot cotter joint. A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. The other two are the sleeve and cotter joint, and gib and cotter joint. Socket and spigot cotter joint, 2. What is a sleeve. Define Sleeve Joint With Suitable Sketch.

From www.youtube.com

COTTER JOINT WITH SLEEVE ASSEMBLY DRAWING LEARN AND DRAW YouTube Define Sleeve Joint With Suitable Sketch The first one is the socket and spigot cotter joint. 1 and the other end of the other rod (say b) is inserted. Socket and spigot cotter joint, 2. In a socket and spigot cotter joint, one end of the rods (say a) is provided with a socket type of end as shown in fig. A knuckle joint is used. Define Sleeve Joint With Suitable Sketch.

From dailycivil.com

Types Of Pipe Joints Used In Plumbing System Plumbing Joints Define Sleeve Joint With Suitable Sketch The first one is the socket and spigot cotter joint. In this article, we are going to discuss this sleeve and cotter joint construction and how to design this cotter joint to avoid possible failures in different parts of this cotter joint. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. In a socket and spigot. Define Sleeve Joint With Suitable Sketch.

From in.eteachers.edu.vn

Top more than 103 sleeve joint sketch in.eteachers Define Sleeve Joint With Suitable Sketch 1 and the other end of the other rod (say b) is inserted. A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. What is a sleeve and cotter joint? Types of cotter joints following are the three commonly used cotter joints to connect. Define Sleeve Joint With Suitable Sketch.

From blog.thepipingmart.com

12 Types of Pipe Joints and Their Uses Define Sleeve Joint With Suitable Sketch Types of cotter joints following are the three commonly used cotter joints to connect two rods by a cotter: A knuckle joint is used to connect two rods which are under the action of tensile load, when small amount of flexibility or angular moment is. The sleeve and cotter joint is used to connect two coaxial cylindrical rods. In a. Define Sleeve Joint With Suitable Sketch.