Slip Casting Viscosity . The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. Schematic showing the steps used in slip casting. First the slip is prepared by. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. The slip casting process is illustrated below in figure 1. My mold leaks when i pour slip into it. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Here are a few of the major slip casting problems and suggestions for correcting them: Your mold parts don't match up correctly.

from www.slideserve.com

Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Schematic showing the steps used in slip casting. The slip casting process is illustrated below in figure 1. My mold leaks when i pour slip into it. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. First the slip is prepared by. Here are a few of the major slip casting problems and suggestions for correcting them: Your mold parts don't match up correctly. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol.

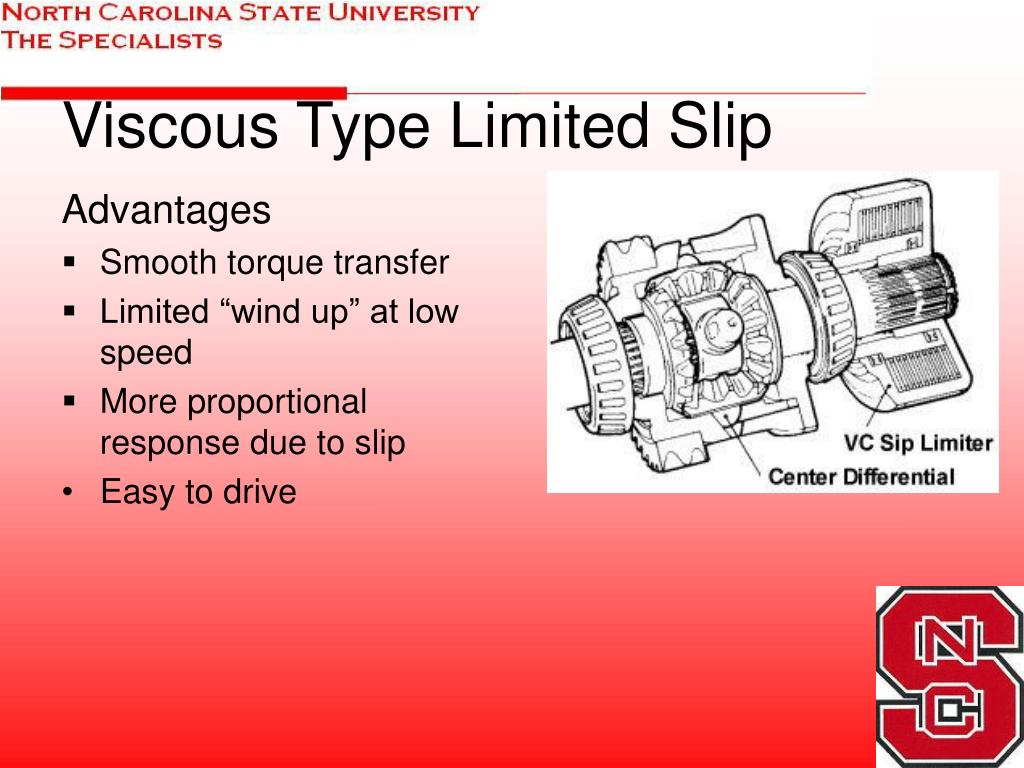

PPT Limited Slip Differential PowerPoint Presentation ID689657

Slip Casting Viscosity Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. First the slip is prepared by. My mold leaks when i pour slip into it. The slip casting process is illustrated below in figure 1. The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Here are a few of the major slip casting problems and suggestions for correcting them: Your mold parts don't match up correctly. Schematic showing the steps used in slip casting.

From www.slideserve.com

PPT Casting Techniques PowerPoint Presentation, free download ID Slip Casting Viscosity Schematic showing the steps used in slip casting. First the slip is prepared by. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. The slip casting process is illustrated below in figure 1. Distinct viscosity trends were observed during. Slip Casting Viscosity.

From www.best-synthetic-oil.com.au

Amsoil Australia Blog Understanding Oil Viscosity Slip Casting Viscosity Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Here are a few of the major slip casting problems and suggestions for correcting them: First the slip is prepared by. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a. Slip Casting Viscosity.

From ebooks.com.vn

Effect of viscosity on slip boundary conditions in rarefied gas flows Slip Casting Viscosity Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Schematic showing the steps used in slip casting. My mold leaks when i pour slip into it. Understanding the magic of deflocculation and how to measure specific gravity and viscosity,. Slip Casting Viscosity.

From www.slideserve.com

PPT Casting Techniques PowerPoint Presentation, free download ID Slip Casting Viscosity Schematic showing the steps used in slip casting. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. The casting slip is a suspension of fine particles (<5 µm) in. Slip Casting Viscosity.

From digitalfire.com

Understanding the Deflocculation Process in Slip Casting Slip Casting Viscosity Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. Your mold parts don't match up correctly. Understanding the magic of deflocculation. Slip Casting Viscosity.

From studygefahrenb4.z21.web.core.windows.net

Viscosity Grade Comparison Chart Slip Casting Viscosity Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Schematic showing the steps used in slip casting. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control.. Slip Casting Viscosity.

From www.slideserve.com

PPT Casting Techniques PowerPoint Presentation, free download ID Slip Casting Viscosity First the slip is prepared by. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. Distinct viscosity trends were observed during slip casting, characterized by an initial. Slip Casting Viscosity.

From www.slideserve.com

PPT Viscosity of Biological Fluids PowerPoint Presentation, free Slip Casting Viscosity Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. First the slip is prepared by. The casting slip is a suspension of fine particles (<5 µm) in a liquid. Slip Casting Viscosity.

From pubs.acs.org

Surface Tension and Viscosity Dependence of Slip Length over Slip Casting Viscosity First the slip is prepared by. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. My mold leaks when i pour slip into it. The slip casting process is illustrated below in figure 1. Schematic showing the steps used in slip casting. Your mold parts don't match up correctly. The casting. Slip Casting Viscosity.

From www.researchgate.net

Apparent viscosity ( η ) versus deflocculant concentration ( c d ) for Slip Casting Viscosity Your mold parts don't match up correctly. The slip casting process is illustrated below in figure 1. The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. Slip casting is experiencing a. Slip Casting Viscosity.

From www.mdpi.com

Colloids and Interfaces Free FullText Principles of Dispersing Slip Casting Viscosity Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. Here are a few of the major slip casting problems and suggestions for correcting them: The slip casting process is illustrated below in figure 1. First the slip is prepared by. Understanding the magic of deflocculation and how to measure specific gravity. Slip Casting Viscosity.

From www.researchgate.net

scosity curves of casting slips. Download Scientific Diagram Slip Casting Viscosity Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. First the slip is prepared by. Here are a few of the. Slip Casting Viscosity.

From www.open.edu

Slipcasting OpenLearn Open University Slip Casting Viscosity Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests.. Slip Casting Viscosity.

From slidetodoc.com

Shaping Overview of shaping technologies method product geometry Slip Casting Viscosity Your mold parts don't match up correctly. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. Distinct viscosity trends were observed during slip casting, characterized by an. Slip Casting Viscosity.

From www.scielo.br

SciELO Brasil Humic Acid as Dispersant of an Alumina Suspension and Slip Casting Viscosity The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. Here are a few of the major slip casting problems and suggestions for correcting them: Schematic showing the steps used in slip casting. My mold leaks when i pour slip into it. First the slip is prepared by. Slip casting. Slip Casting Viscosity.

From sciencenotes.org

Viscosity Definition and Examples Slip Casting Viscosity Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Here are a few of the major slip casting problems and suggestions for correcting them: My mold leaks when i pour slip into it. The slip casting process is illustrated. Slip Casting Viscosity.

From klostrategic.weebly.com

Oil and gas viscosity test klostrategic Slip Casting Viscosity My mold leaks when i pour slip into it. The slip casting process is illustrated below in figure 1. Your mold parts don't match up correctly. Schematic showing the steps used in slip casting. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. First the slip is. Slip Casting Viscosity.

From www.youtube.com

Engine Oil Viscosity Explained How Heat changes Multi grade oil to Slip Casting Viscosity Your mold parts don't match up correctly. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Understanding the magic of deflocculation. Slip Casting Viscosity.

From nathenwociul.blogspot.com

Mu Vs Nu Viscosity Cgs System Of Units For Viscosity The Centipoise Slip Casting Viscosity Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. The slip casting process is illustrated below in figure 1. Your mold parts don't match up correctly. The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. Slip casting is experiencing a. Slip Casting Viscosity.

From www.mdpi.com

Polymers Free FullText Wall SlipFree Viscosity Determination of Slip Casting Viscosity The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. Your mold parts don't match up correctly. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Schematic showing the. Slip Casting Viscosity.

From www.researchgate.net

Relationship between slipcorrected viscosity and shear rate Download Slip Casting Viscosity The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. The slip casting process is illustrated below in figure 1. Schematic showing the steps used in slip casting. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests.. Slip Casting Viscosity.

From www.researchgate.net

Viscosity of a series of casting solutions with (a) different PAR Slip Casting Viscosity Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Distinct viscosity trends were observed during slip casting,. Slip Casting Viscosity.

From www.pinterest.com

Understanding the Deflocculation Process in Slip Casting It cast Slip Casting Viscosity The slip casting process is illustrated below in figure 1. Your mold parts don't match up correctly. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Here are a few of the major slip casting problems and suggestions for correcting them: The casting slip is a suspension. Slip Casting Viscosity.

From www.researchgate.net

(PDF) Examining the Quality of Local Omani Clays for Ceramic Slip Slip Casting Viscosity Your mold parts don't match up correctly. First the slip is prepared by. The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. My mold leaks when i pour slip into it. Here are a few of the major slip casting problems and suggestions for correcting them: Distinct viscosity trends. Slip Casting Viscosity.

From digitalfire.com

Confirming slip viscosity using a paintmeasuring device Slip Casting Viscosity Here are a few of the major slip casting problems and suggestions for correcting them: The slip casting process is illustrated below in figure 1. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and. Slip Casting Viscosity.

From www.slideserve.com

PPT Casting Techniques PowerPoint Presentation ID5564594 Slip Casting Viscosity Here are a few of the major slip casting problems and suggestions for correcting them: Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. My mold leaks when i pour slip into it. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the. Slip Casting Viscosity.

From www.researchgate.net

(PDF) Optimization of the Rheological Properties of Alumina Slurries Slip Casting Viscosity Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. My mold leaks when i pour slip into it. First the slip. Slip Casting Viscosity.

From www.researchgate.net

(PDF) The Effects of Density and Viscosity in Slip Casting Slip Casting Viscosity Here are a few of the major slip casting problems and suggestions for correcting them: My mold leaks when i pour slip into it. Your mold parts don't match up correctly. The slip casting process is illustrated below in figure 1. First the slip is prepared by. Schematic showing the steps used in slip casting. The casting slip is a. Slip Casting Viscosity.

From www.researchgate.net

Effect of various concentrations of CMCc and CMCp on viscosity of slips Slip Casting Viscosity The slip casting process is illustrated below in figure 1. First the slip is prepared by. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a. Slip Casting Viscosity.

From www.researchgate.net

Apparent viscosity of 35 vol slips at a shear rate (γ) of 542 s1 as a Slip Casting Viscosity The casting slip is a suspension of fine particles (<5 µm) in a liquid medium such as water or alcohol. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Schematic showing the steps used in slip casting. Distinct viscosity. Slip Casting Viscosity.

From www.slideserve.com

PPT Limited Slip Differential PowerPoint Presentation ID689657 Slip Casting Viscosity Here are a few of the major slip casting problems and suggestions for correcting them: Your mold parts don't match up correctly. Schematic showing the steps used in slip casting. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. My mold leaks when i pour slip into. Slip Casting Viscosity.

From vikingpump.com

Viscosity Through Thick and Thin Viking Pump Slip Casting Viscosity Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. Here are a few of the major slip casting problems and suggestions for correcting them: The slip casting process is illustrated below in figure 1. My mold leaks when i pour slip into it. Your mold parts don't match up correctly. Slip. Slip Casting Viscosity.

From www.researchgate.net

Viscosity ratios and slip length variations with the surface charge Slip Casting Viscosity Here are a few of the major slip casting problems and suggestions for correcting them: Your mold parts don't match up correctly. Schematic showing the steps used in slip casting. The slip casting process is illustrated below in figure 1. Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision. Slip Casting Viscosity.

From www.researchgate.net

Effects of the nanofluid volume fraction, viscosity, suction, slips and Slip Casting Viscosity Slip casting is experiencing a renewed exuberance with a new generation of makers learning to build and mold their vision into a unique business to manufacture with quality and control. Understanding the magic of deflocculation and how to measure specific gravity and viscosity, and how to interpret the results of these tests. Here are a few of the major slip. Slip Casting Viscosity.

From www.mdpi.com

Materials Free FullText Manufacturing of Large Size and Highly Slip Casting Viscosity Your mold parts don't match up correctly. Distinct viscosity trends were observed during slip casting, characterized by an initial slow increase followed by a rapid. Here are a few of the major slip casting problems and suggestions for correcting them: First the slip is prepared by. Slip casting is experiencing a renewed exuberance with a new generation of makers learning. Slip Casting Viscosity.