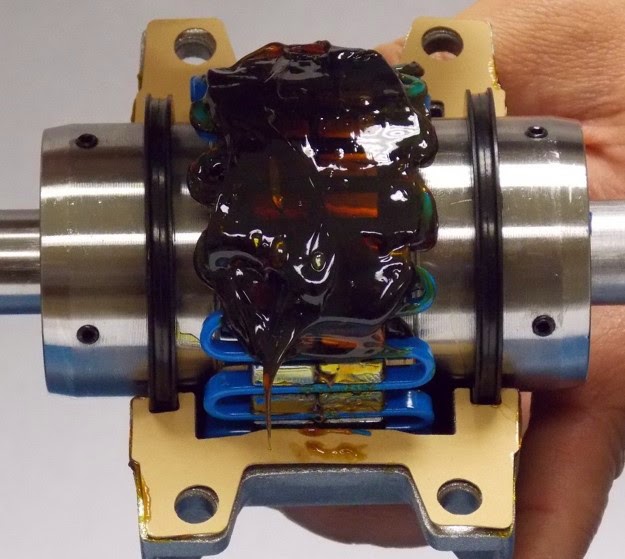

Gear Coupling Failure . Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum. Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. The gear coupling eventually wears without a spectacular failure.

from www.couplinganswers.com

Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. The gear coupling eventually wears without a spectacular failure. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque.

How should you pack the grease in a Grid Coupling? Coupling Answers

Gear Coupling Failure The gear coupling eventually wears without a spectacular failure. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. The gear coupling eventually wears without a spectacular failure. Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum.

From www.couplinganswers.com

Coupling Answers Where the World Turns for Coupling Knowledge Gear Coupling Failure Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque.. Gear Coupling Failure.

From www.couplinganswers.com

Coupling Answers Where the World Turns for Coupling Knowledge Gear Coupling Failure The gear coupling eventually wears without a spectacular failure. Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. When the gear coupling type is not chosen with the necessary dampening levels in mind,. Gear Coupling Failure.

From www.couplinganswers.com

Gear Coupling Tutorial Part V Failure Analysis (with photos Gear Coupling Failure The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. Evaluating gear tooth wear and being. Gear Coupling Failure.

From www.ipesearch.co.uk

IPE Curvedtooth Nylon sleeve gear couplings Gear Coupling Failure Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure.. Gear Coupling Failure.

From www.slideserve.com

PPT A Brief Guide on Gear Coupling! PowerPoint Presentation, free Gear Coupling Failure However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. Gear couplings offer several advantages over other. Gear Coupling Failure.

From www.powertransmissionworld.com

Fretting wear damage in crowned splined couplings Power Transmission Gear Coupling Failure Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. Gear coupling hub. Gear Coupling Failure.

From www.researchgate.net

(PDF) Design and Simulation of the Controlled Failure of CustomBuilt Gear Coupling Failure Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. When the gear coupling type. Gear Coupling Failure.

From www.sintechpumps.com

Causes for Pump Coupling Failures & How to Avoid Them Sintech Pumps Gear Coupling Failure When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum.. Gear Coupling Failure.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Gear Coupling Failure When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. The gear coupling eventually wears without a spectacular failure. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. As might be expected, approximately 75% of gear and chain coupling failures are. Gear Coupling Failure.

From openbookalliance.org

Troubleshooting measures for gear pump failure Leader Industrial Gear Coupling Failure As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. When the gear. Gear Coupling Failure.

From fractory.com

Types of Couplings Fractory Gear Coupling Failure Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. The gear coupling eventually wears without a spectacular failure. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. Evaluating gear tooth wear and being able to root cause. Gear Coupling Failure.

From blog.emersonbearing.com

Common Causes of Bearing Failure and How to Avoid Them Gear Coupling Failure When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring. Gear Coupling Failure.

From www.machinerylubrication.com

How to Achieve Gear Coupling Reliability Gear Coupling Failure Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring. Gear Coupling Failure.

From heidyfersli.blogspot.com

Explain Different Types of Coupling With Suitable Example Gear Coupling Failure Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum. The. Gear Coupling Failure.

From tms.in.th

Coupling คืออะไร? (11 ประเภทของคัปปลิ้ง) TMS Gear Coupling Failure Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. The gear coupling eventually wears without a spectacular failure. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum. When the gear coupling type is not chosen with the necessary. Gear Coupling Failure.

From www.couplinganswers.com

How should you pack the grease in a Grid Coupling? Coupling Answers Gear Coupling Failure When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's. Gear Coupling Failure.

From nexxis.com

6 Common Mistakes In Assembly & Maintenance Of Flexible Couplings Nexxis Gear Coupling Failure Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. The gear coupling eventually wears without a spectacular failure. The typical failure mode of gear couplings is that the teeth. Gear Coupling Failure.

From binsfeld.com

A Beginner's Guide to Torsional Vibration Analysis & Testing Gear Coupling Failure Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum. The gear coupling eventually wears without a spectacular failure. When the gear coupling type is not chosen with the necessary. Gear Coupling Failure.

From www.couplingtips.com

Reaction forces from couplings How to prevent or mitigate? Gear Coupling Failure Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. The gear coupling eventually wears without a spectacular failure. When the gear coupling type is not chosen with the necessary dampening. Gear Coupling Failure.

From limblecmms.com

An Introduction To Equipment Failure Patterns Gear Coupling Failure As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density.. Gear Coupling Failure.

From www.researchgate.net

Typical gear failures on analyzed gearboxes Download Scientific Diagram Gear Coupling Failure However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. Evaluating gear tooth wear and being able. Gear Coupling Failure.

From www.rollingmachinery.net

Blog Things To Consider For The Longer Life Span Of Gear Coupling Gear Coupling Failure Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient.. Gear Coupling Failure.

From fractory.com

Types of Couplings Fractory Gear Coupling Failure Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. When the gear coupling type. Gear Coupling Failure.

From technorm.ca

Fatigue Failure of a Drive Shaft Technorm Gear Coupling Failure The gear coupling eventually wears without a spectacular failure. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. Gear coupling hub failures can occur from a combination of loads produced by the. Gear Coupling Failure.

From www.scribd.com

Coupling Failure Analysis Jaw Couplings (Includes Hub & Spider Photos Gear Coupling Failure The gear coupling eventually wears without a spectacular failure. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum. Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness. Gear Coupling Failure.

From mpta.org

Bulletins Mechanical Power Transmission Association Gear Coupling Failure When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. Gear couplings. Gear Coupling Failure.

From dokumen.tips

(PDF) Causes of Coupling Failures DOKUMEN.TIPS Gear Coupling Failure When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. The gear coupling eventually wears without a spectacular failure. Gear couplings offer several advantages over other couplings, including moderate. Gear Coupling Failure.

From www.couplinganswers.com

Maintenance Procedures for Couplings Coupling Answers Where the Gear Coupling Failure The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. The gear coupling eventually wears without a spectacular failure. Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. As might be expected, approximately 75% of gear and chain coupling failures are caused by. Gear Coupling Failure.

From www.drsmiles.in

Analysis on Gear Coupling Failures Dr. Smiles Gear Coupling Failure Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. Evaluating gear tooth. Gear Coupling Failure.

From www.meoexamz.co.in

Mechanical Flexing Couplings Gear Coupling Failure Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. The gear coupling eventually wears without a spectacular failure. Gear coupling hub failures can occur from a combination of. Gear Coupling Failure.

From mechstuff.com

gear coupling MechStuff Gear Coupling Failure Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum. Gear coupling hub. Gear Coupling Failure.

From www.meoexamz.co.in

Mechanical Flexing Couplings Gear Coupling Failure Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. Gear couplings can be sized to make sure that wear life is consistent with the rest of the machine's design. Gear couplings offer several advantages over other couplings, including moderate misalignment capacity, exceptional torsional stiffness and very high torque density. However,. Gear Coupling Failure.

From www.researchgate.net

(PDF) FAILURE ANALYSIS AND COMPARISON OF FLANGE COUPLINGS USED IN INDUSTRY Gear Coupling Failure When the gear coupling type is not chosen with the necessary dampening levels in mind, the risk of early coupling failure. The gear coupling eventually wears without a spectacular failure. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment or improper or insufficient. However, when it comes to gear coupling reliability, there are. Gear Coupling Failure.

From www.pumpsandcouplings.com

Common failure of pump and motor Pumps & Couplings Gear Coupling Failure Gear coupling hub failures can occur from a combination of loads produced by the interference fit and transmitted torque. The gear coupling eventually wears without a spectacular failure. The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. As might be expected, approximately 75% of gear and chain coupling failures are caused by misalignment. Gear Coupling Failure.

From www.passagemaker.com

Troubleshooter Preventing Shaft Failure PassageMaker Gear Coupling Failure The typical failure mode of gear couplings is that the teeth wear away from improper lubrication. However, when it comes to gear coupling reliability, there are many areas where failures may be initiated. Evaluating gear tooth wear and being able to root cause and address coupling failure are both critical to ensuring maximum. Gear couplings can be sized to make. Gear Coupling Failure.