Metric Drill Speed Chart Stainless Steel . Suitable for deep drilling and operations where low power consumption is. For specific information on carbide drill feeds and speeds. By understanding these critical factors, you can enhance precision and productivity in your machining processes. Click on cell b12, and use the drop down to select the material you want to calculate a drilling speed to suit. Suitable for severe cutting conditions. Always use the correct drill size when drilling the hole before you ream it. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a drilling speed to suit. Centre punch the drilling position, and begin drilling. First choice for stainless steel. Go to the front tab, “surface cutting speeds”. Scroll to the black table in rows 11 to 12. This will also help reduce burring. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. This article explores the essential drilling speed charts and formulas for carbon and stainless steel.

from tubingchina.com

Always use the correct drill size when drilling the hole before you ream it. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. The hole saw arbour will be fitted with its own pilot drill. This will also help reduce burring. Go to the front tab, “surface cutting speeds”. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. Scroll to the black table in rows 11 to 12. Centre punch the drilling position, and begin drilling. For specific information on carbide drill feeds and speeds. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a drilling speed to suit.

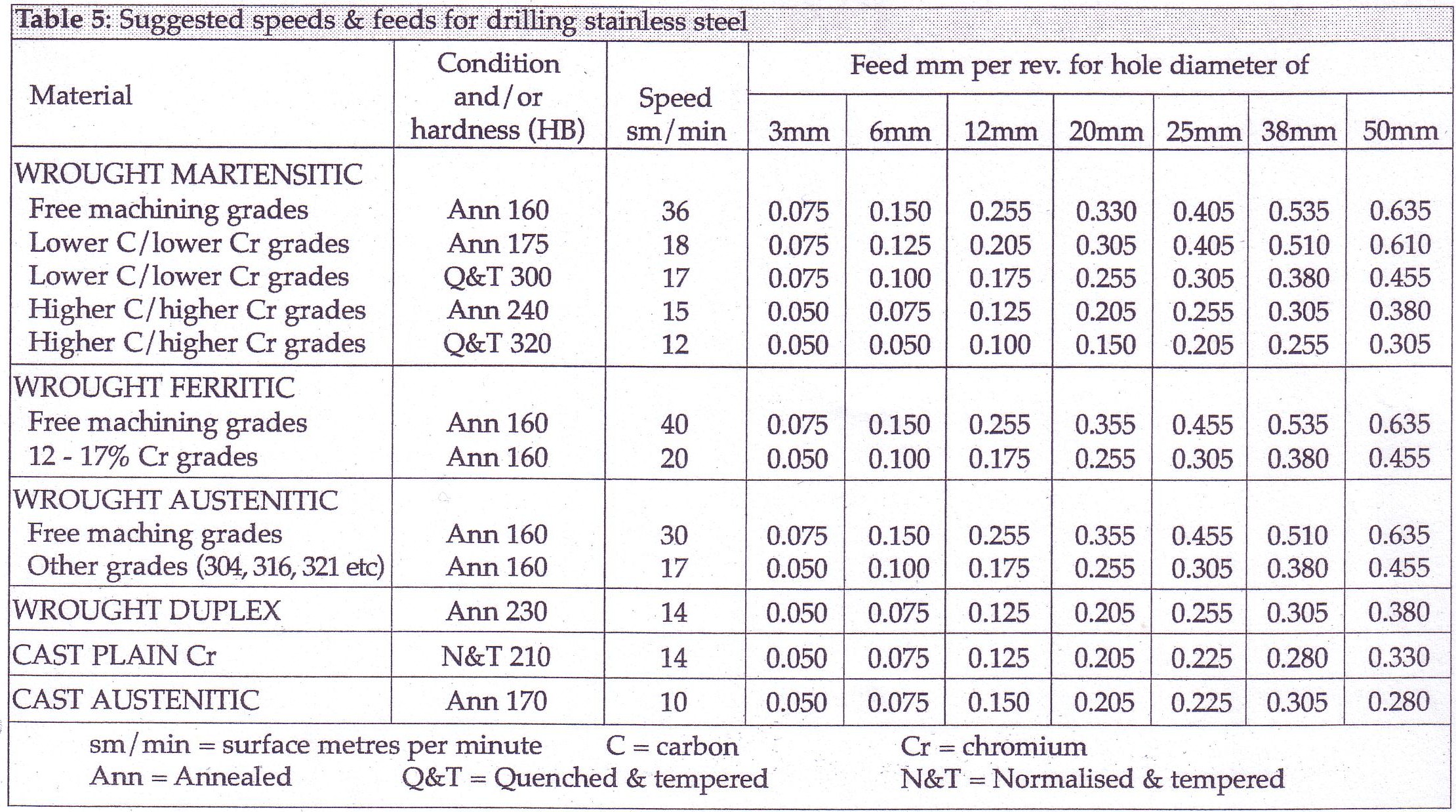

Speeds and Feeds for Drilling and Reaming Stainless Steel

Metric Drill Speed Chart Stainless Steel Go to the front tab, “surface cutting speeds”. By understanding these critical factors, you can enhance precision and productivity in your machining processes. Click on cell b12, and use the drop down to select the material you want to calculate a drilling speed to suit. For specific information on carbide drill feeds and speeds. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. Suitable for deep drilling and operations where low power consumption is. First choice for stainless steel. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. Go to the front tab, “surface cutting speeds”. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a drilling speed to suit. This will also help reduce burring. Suitable for severe cutting conditions. The hole saw arbour will be fitted with its own pilot drill. Always use the correct drill size when drilling the hole before you ream it. This article explores the essential drilling speed charts and formulas for carbon and stainless steel. Scroll to the black table in rows 11 to 12.

From www.chegg.com

Problem 1.30 ptsA company manufactures parts using Metric Drill Speed Chart Stainless Steel This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. Suitable for deep drilling and operations where low power consumption is. By understanding these critical factors, you can enhance precision and productivity in your machining processes. Go to the front tab, “surface cutting speeds”. The hole saw arbour will be. Metric Drill Speed Chart Stainless Steel.

From www.walmart.com

340W Mini Table Electric Drill Press, DNYSYSJ 3Speed Bench Drill Press Metric Drill Speed Chart Stainless Steel First choice for stainless steel. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. This will also help reduce burring. For specific information on carbide drill feeds and speeds. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a. Metric Drill Speed Chart Stainless Steel.

From www.hillindustrialtools.com

Carbide Reamers Speeds and Feeds Hill Industrial Tools Metric Drill Speed Chart Stainless Steel Centre punch the drilling position, and begin drilling. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. Always use the correct drill size when drilling the hole before you ream it. Suitable for deep drilling and operations where low power consumption is. Click on cell b12, and use the. Metric Drill Speed Chart Stainless Steel.

From www.templateroller.com

Pillar Drill Speed Chart Download Printable PDF Templateroller Metric Drill Speed Chart Stainless Steel The hole saw arbour will be fitted with its own pilot drill. For specific information on carbide drill feeds and speeds. Scroll to the black table in rows 11 to 12. This article explores the essential drilling speed charts and formulas for carbon and stainless steel. Always use the correct drill size when drilling the hole before you ream it.. Metric Drill Speed Chart Stainless Steel.

From www.amazon.com

TTP HARD drills Bit 10mm 1 X Metric Drill Bit Cobalt for Drilling Metric Drill Speed Chart Stainless Steel Always use the correct drill size when drilling the hole before you ream it. The hole saw arbour will be fitted with its own pilot drill. For specific information on carbide drill feeds and speeds. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. Click on cell d12, and. Metric Drill Speed Chart Stainless Steel.

From www.dibbos.com

Chicago Pneumatic CP860 Review dibbos Metric Drill Speed Chart Stainless Steel First choice for stainless steel. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. For specific information on carbide drill feeds and speeds. Click on cell d12, and use the drop down to select the drill bit size. Metric Drill Speed Chart Stainless Steel.

From exooeycjx.blob.core.windows.net

Speeds And Feeds For Spot Drills at Elliott Carlson blog Metric Drill Speed Chart Stainless Steel Go to the front tab, “surface cutting speeds”. By understanding these critical factors, you can enhance precision and productivity in your machining processes. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. Click on cell d12, and use the drop down to select the drill bit size you want. Metric Drill Speed Chart Stainless Steel.

From shopee.ph

SKEACE Carbon Fiber 144BCD 1/8*49T*165mm Track Fixie Single Speed Metric Drill Speed Chart Stainless Steel This article explores the essential drilling speed charts and formulas for carbon and stainless steel. Centre punch the drilling position, and begin drilling. First choice for stainless steel. The hole saw arbour will be fitted with its own pilot drill. This will also help reduce burring. Suitable for deep drilling and operations where low power consumption is. Always use the. Metric Drill Speed Chart Stainless Steel.

From www.scribd.com

Drill Speed Chart Drill Metalworking Metric Drill Speed Chart Stainless Steel The hole saw arbour will be fitted with its own pilot drill. This will also help reduce burring. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a drilling speed to suit. Always use the correct drill size when drilling the hole before you ream it. Click on cell b12,. Metric Drill Speed Chart Stainless Steel.

From tubingchina.com

Speeds and Feeds for Drilling and Reaming Stainless Steel Metric Drill Speed Chart Stainless Steel 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. Scroll to the black table in rows 11 to 12. This will also help reduce burring. Go to the front tab, “surface cutting speeds”. Always use the correct drill size when drilling the hole before you ream it. This article explores the essential drilling speed charts and formulas for. Metric Drill Speed Chart Stainless Steel.

From www.dibbos.com

Chicago Pneumatic CP7500D Review dibbos Metric Drill Speed Chart Stainless Steel The hole saw arbour will be fitted with its own pilot drill. First choice for stainless steel. Suitable for severe cutting conditions. Scroll to the black table in rows 11 to 12. Go to the front tab, “surface cutting speeds”. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills.. Metric Drill Speed Chart Stainless Steel.

From www.scribd.com

HSS Twist Drill Speeds and Point Angles Motor Oil Metric Drill Speed Chart Stainless Steel By understanding these critical factors, you can enhance precision and productivity in your machining processes. This will also help reduce burring. The hole saw arbour will be fitted with its own pilot drill. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable. Metric Drill Speed Chart Stainless Steel.

From www.etsy.com

Drill Press Speed Chart 5 Drill Types Vector Files for CNC Dxf. Svg. Ai Metric Drill Speed Chart Stainless Steel Centre punch the drilling position, and begin drilling. The hole saw arbour will be fitted with its own pilot drill. Suitable for deep drilling and operations where low power consumption is. Click on cell b12, and use the drop down to select the material you want to calculate a drilling speed to suit. Always use the correct drill size when. Metric Drill Speed Chart Stainless Steel.

From dat.perueduca.edu.pe

Hss Drill Speeds And Feeds Chart Pdf Printable Templates Free Metric Drill Speed Chart Stainless Steel The hole saw arbour will be fitted with its own pilot drill. For specific information on carbide drill feeds and speeds. Go to the front tab, “surface cutting speeds”. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a drilling speed to suit. Centre punch the drilling position, and begin. Metric Drill Speed Chart Stainless Steel.

From shopee.ph

SKEACE Carbon Fiber 144BCD 1/8*49T*165mm Track Fixie Single Speed Metric Drill Speed Chart Stainless Steel Click on cell b12, and use the drop down to select the material you want to calculate a drilling speed to suit. Always use the correct drill size when drilling the hole before you ream it. First choice for stainless steel. Click on cell d12, and use the drop down to select the drill bit size you want to calculate. Metric Drill Speed Chart Stainless Steel.

From www.hillindustrialtools.com

HSS Reamer Speeds Feeds Hill Industrial Tools Metric Drill Speed Chart Stainless Steel Go to the front tab, “surface cutting speeds”. This article explores the essential drilling speed charts and formulas for carbon and stainless steel. Centre punch the drilling position, and begin drilling. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. Suitable for severe cutting conditions. By understanding these critical. Metric Drill Speed Chart Stainless Steel.

From www.pinterest.com

Speeds and feeds for drills Machine tools, Metal lathe tools, Tool Metric Drill Speed Chart Stainless Steel The hole saw arbour will be fitted with its own pilot drill. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. First choice for stainless steel. Scroll to the black table in rows 11 to 12. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a drilling speed. Metric Drill Speed Chart Stainless Steel.

From woodworking.stackexchange.com

drilling When should I use high speed and when lower speed with a Metric Drill Speed Chart Stainless Steel Scroll to the black table in rows 11 to 12. Centre punch the drilling position, and begin drilling. This article explores the essential drilling speed charts and formulas for carbon and stainless steel. Click on cell b12, and use the drop down to select the material you want to calculate a drilling speed to suit. Click on cell d12, and. Metric Drill Speed Chart Stainless Steel.

From arturowbryant.github.io

Drill Bit Speed Chart Metric Drill Speed Chart Stainless Steel 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. Always use the correct drill size when drilling the hole before you ream it. Suitable for severe cutting conditions. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a drilling speed to suit. Go to the front tab, “surface. Metric Drill Speed Chart Stainless Steel.

From exomlutrb.blob.core.windows.net

Morse Carbide Drill Speeds And Feeds at Jose Fierro blog Metric Drill Speed Chart Stainless Steel First choice for stainless steel. Go to the front tab, “surface cutting speeds”. Centre punch the drilling position, and begin drilling. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. Suitable for severe cutting conditions. Scroll to the black table in rows 11 to 12. For specific information on. Metric Drill Speed Chart Stainless Steel.

From shopee.ph

SKEACE Carbon Fiber 144BCD 1/8*49T*165mm Track Fixie Single Speed Metric Drill Speed Chart Stainless Steel This will also help reduce burring. Suitable for deep drilling and operations where low power consumption is. Go to the front tab, “surface cutting speeds”. Scroll to the black table in rows 11 to 12. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. Click on cell b12, and use the drop down to select the material you. Metric Drill Speed Chart Stainless Steel.

From www.pinterest.com

Dynabrade Drill Speed Chart Drill bit sizes, Wood Metric Drill Speed Chart Stainless Steel This will also help reduce burring. By understanding these critical factors, you can enhance precision and productivity in your machining processes. Centre punch the drilling position, and begin drilling. Suitable for severe cutting conditions. This article explores the essential drilling speed charts and formulas for carbon and stainless steel. Always use the correct drill size when drilling the hole before. Metric Drill Speed Chart Stainless Steel.

From ddsgsgsds.blogspot.com

eeeeeeeeeee Get 38 Printable Drill Press Speed Chart Metal Metric Drill Speed Chart Stainless Steel This will also help reduce burring. For specific information on carbide drill feeds and speeds. The hole saw arbour will be fitted with its own pilot drill. Suitable for severe cutting conditions. Suitable for deep drilling and operations where low power consumption is. Scroll to the black table in rows 11 to 12. Click on cell d12, and use the. Metric Drill Speed Chart Stainless Steel.

From mungfali.com

Drill Speed Chart For Steel Metric Drill Speed Chart Stainless Steel Suitable for severe cutting conditions. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. This will also help reduce burring. This article explores the essential drilling speed charts and formulas for carbon and stainless steel. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all twist drills. For specific information. Metric Drill Speed Chart Stainless Steel.

From bssa.org.uk

Speeds and feeds for turning stainless steels British Stainless Steel Metric Drill Speed Chart Stainless Steel Click on cell b12, and use the drop down to select the material you want to calculate a drilling speed to suit. Centre punch the drilling position, and begin drilling. By understanding these critical factors, you can enhance precision and productivity in your machining processes. Suitable for severe cutting conditions. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711. Metric Drill Speed Chart Stainless Steel.

From www.pinterest.com

SFM Chart Surface, It cast, Speed Metric Drill Speed Chart Stainless Steel For specific information on carbide drill feeds and speeds. Go to the front tab, “surface cutting speeds”. Suitable for deep drilling and operations where low power consumption is. Click on cell b12, and use the drop down to select the material you want to calculate a drilling speed to suit. Always use the correct drill size when drilling the hole. Metric Drill Speed Chart Stainless Steel.

From www.sexiezpix.com

Kennametal Speeds And Feeds Chart A Visual Reference Of Charts Chart Metric Drill Speed Chart Stainless Steel Always use the correct drill size when drilling the hole before you ream it. The hole saw arbour will be fitted with its own pilot drill. Centre punch the drilling position, and begin drilling. Suitable for deep drilling and operations where low power consumption is. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. Click on cell d12,. Metric Drill Speed Chart Stainless Steel.

From www.alibaba.com

CNC Horizontal Machining Center BT40 machining spindle Metal HMC 5 Axis Metric Drill Speed Chart Stainless Steel Scroll to the black table in rows 11 to 12. For specific information on carbide drill feeds and speeds. Suitable for deep drilling and operations where low power consumption is. Always use the correct drill size when drilling the hole before you ream it. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. Click on cell b12, and. Metric Drill Speed Chart Stainless Steel.

From tubingchina.com

Speeds and Feeds for Drilling and Reaming Stainless Steel Metric Drill Speed Chart Stainless Steel Suitable for severe cutting conditions. Go to the front tab, “surface cutting speeds”. First choice for stainless steel. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a drilling speed to suit. This article is lesson 9 from our free feeds and speeds master class.it contains information applicable to all. Metric Drill Speed Chart Stainless Steel.

From www.chegg.com

Calculate the rmin required to drill a 516in. hole Metric Drill Speed Chart Stainless Steel Suitable for deep drilling and operations where low power consumption is. Go to the front tab, “surface cutting speeds”. For specific information on carbide drill feeds and speeds. Centre punch the drilling position, and begin drilling. This will also help reduce burring. 1.0 970 3878 9695 14542 1.5 647 2589 6474 9711 2.0. Scroll to the black table in rows. Metric Drill Speed Chart Stainless Steel.

From openoregon.pressbooks.pub

Unit 5 Tapping Manufacturing Processes 45 Metric Drill Speed Chart Stainless Steel First choice for stainless steel. Suitable for deep drilling and operations where low power consumption is. Suitable for severe cutting conditions. Centre punch the drilling position, and begin drilling. This article explores the essential drilling speed charts and formulas for carbon and stainless steel. Always use the correct drill size when drilling the hole before you ream it. This article. Metric Drill Speed Chart Stainless Steel.

From shopee.ph

SKEACE Carbon Fiber 144BCD 1/8*49T*165mm Track Fixie Single Speed Metric Drill Speed Chart Stainless Steel This will also help reduce burring. Centre punch the drilling position, and begin drilling. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a drilling speed to suit. Click on cell b12, and use the drop down to select the material you want to calculate a drilling speed to suit.. Metric Drill Speed Chart Stainless Steel.

From www.scribd.com

HSS Drill Speeds and Feeds Cast Iron Steel Metric Drill Speed Chart Stainless Steel Click on cell b12, and use the drop down to select the material you want to calculate a drilling speed to suit. Click on cell d12, and use the drop down to select the drill bit size you want to calculate a drilling speed to suit. This will also help reduce burring. This article is lesson 9 from our free. Metric Drill Speed Chart Stainless Steel.

From woodworkadvice.com

Drill Press Speed Chart Your 2021 Guide Woodwork Advice Metric Drill Speed Chart Stainless Steel Always use the correct drill size when drilling the hole before you ream it. Suitable for deep drilling and operations where low power consumption is. Suitable for severe cutting conditions. Click on cell b12, and use the drop down to select the material you want to calculate a drilling speed to suit. Go to the front tab, “surface cutting speeds”.. Metric Drill Speed Chart Stainless Steel.