Bearing Shaft Surface Finish . one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. For roughness value less than 25μm, the equilateral triangular symbol is used. it is suggested to indicate the surface roughness on drawing by symbols. The bis recommended symbols for indicating the surface finish are shown in table a. The roughness of a shaft plays an important part in the life of your application, especially when paired. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. when it comes to deciding which shaft/pin solution is best for your application there are a lot of factors to consider; Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. surface roughness of shafting. For the roughness values greater than 25μm, the symbol is used.

from www.slideserve.com

The bis recommended symbols for indicating the surface finish are shown in table a. surface roughness of shafting. the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. The roughness of a shaft plays an important part in the life of your application, especially when paired. Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. For the roughness values greater than 25μm, the symbol is used. when it comes to deciding which shaft/pin solution is best for your application there are a lot of factors to consider; it is suggested to indicate the surface roughness on drawing by symbols. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and.

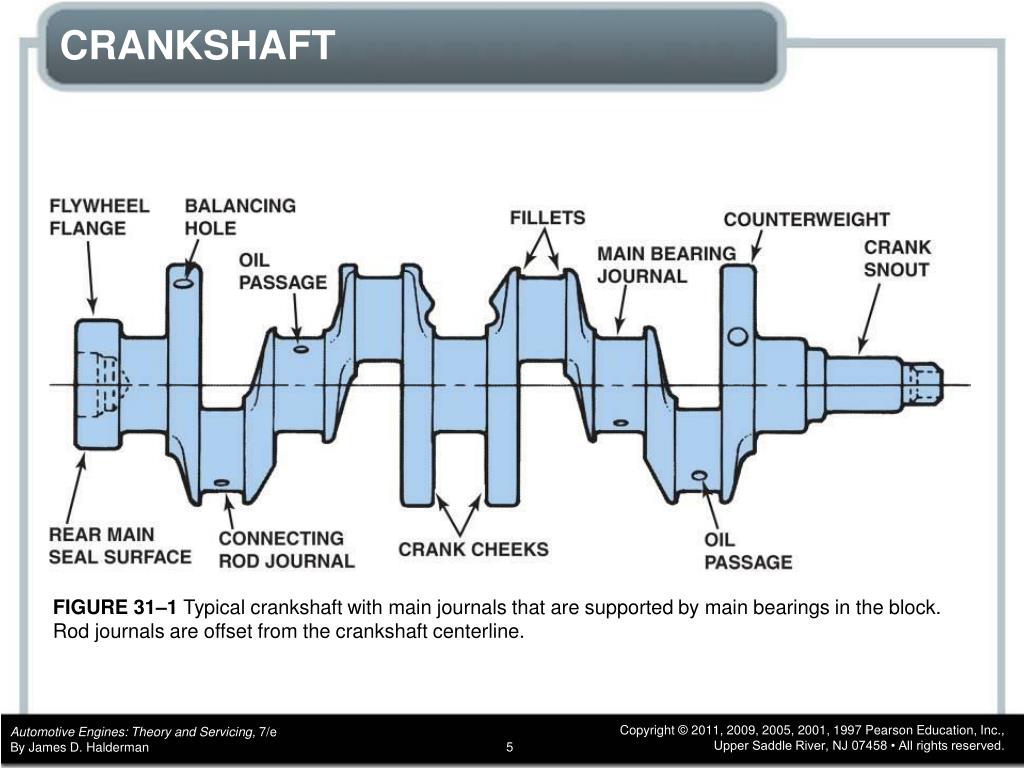

PPT CHAPTER 31 CRANKSHAFTS, BALANCE SHAFTS, AND BEARINGS PowerPoint

Bearing Shaft Surface Finish the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. The roughness of a shaft plays an important part in the life of your application, especially when paired. For roughness value less than 25μm, the equilateral triangular symbol is used. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. surface roughness of shafting. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. it is suggested to indicate the surface roughness on drawing by symbols. Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. when it comes to deciding which shaft/pin solution is best for your application there are a lot of factors to consider; For the roughness values greater than 25μm, the symbol is used. The bis recommended symbols for indicating the surface finish are shown in table a.

From fr.slideserve.com

PPT MECHANICAL DRAWING Chapter 9 SURFACE FINISH PowerPoint Bearing Shaft Surface Finish The bis recommended symbols for indicating the surface finish are shown in table a. For roughness value less than 25μm, the equilateral triangular symbol is used. surface roughness of shafting. The roughness of a shaft plays an important part in the life of your application, especially when paired. For the roughness values greater than 25μm, the symbol is used.. Bearing Shaft Surface Finish.

From www.gmnbt.com

Understanding Bearing Loads GMN Bearing USA Bearing Shaft Surface Finish surface roughness of shafting. the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. For roughness value less than 25μm, the equilateral triangular symbol is used. For the roughness. Bearing Shaft Surface Finish.

From www.bearingtips.com

Plain bearings (sleeve bearings) and the shafts they ride Bearing Tips Bearing Shaft Surface Finish when it comes to deciding which shaft/pin solution is best for your application there are a lot of factors to consider; one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. the most effective way to fix the mating surfaces between a bearing and. Bearing Shaft Surface Finish.

From www.aliexpress.com

Dia 10mm L235mm 3pcs/lot linear bearings shaft HRC57 sus400 stainless Bearing Shaft Surface Finish it is suggested to indicate the surface roughness on drawing by symbols. The bis recommended symbols for indicating the surface finish are shown in table a. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. The roughness of a shaft plays an important part in the life. Bearing Shaft Surface Finish.

From lectures-nd-notes.blogspot.com

Lecture Notes July 2014 Bearing Shaft Surface Finish The bis recommended symbols for indicating the surface finish are shown in table a. it is suggested to indicate the surface roughness on drawing by symbols. surface roughness of shafting. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. For roughness value less than 25μm, the. Bearing Shaft Surface Finish.

From metallicbonds.com

Bearing Shaft Repair Service Metallic Bonds, Ltd. Bearing Shaft Surface Finish Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. it is suggested to indicate the surface roughness on drawing by symbols. the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. The bis recommended symbols for indicating the. Bearing Shaft Surface Finish.

From isaactalbot.z21.web.core.windows.net

Ra Surface Finish Chart Bearing Shaft Surface Finish surface roughness of shafting. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. the most effective way to fix the mating surfaces. Bearing Shaft Surface Finish.

From www.bearingtips.com

igus plain bearings Bearing Shaft Surface Finish the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. For roughness value less than 25μm, the equilateral triangular symbol is used. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. The. Bearing Shaft Surface Finish.

From www.slideserve.com

PPT CHAPTER 31 CRANKSHAFTS, BALANCE SHAFTS, AND BEARINGS PowerPoint Bearing Shaft Surface Finish For roughness value less than 25μm, the equilateral triangular symbol is used. The bis recommended symbols for indicating the surface finish are shown in table a. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. it is suggested to indicate the surface roughness on. Bearing Shaft Surface Finish.

From blog.igus.ca

Shaft considerations for bearing applications part 2 roughness igus Bearing Shaft Surface Finish the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. it is suggested to indicate the surface roughness on drawing by symbols. The roughness of a shaft plays an important part in the life of your application, especially when paired. the surface texture of a. Bearing Shaft Surface Finish.

From www.remchem.com

Improved Metal Surface Finish for Bearings with REM Surface Engineering Bearing Shaft Surface Finish Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. The bis recommended symbols for indicating the surface finish are shown in table a. the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. when it comes to deciding. Bearing Shaft Surface Finish.

From mavink.com

Machining Surface Finish Symbols Chart Bearing Shaft Surface Finish one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. the most effective way to fix the mating surfaces between a bearing and shaft. Bearing Shaft Surface Finish.

From hallite.com

Surface Roughness & Finish for Bearings and Seals Hallite Bearing Shaft Surface Finish one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. it is suggested to indicate the surface roughness on drawing by symbols. surface. Bearing Shaft Surface Finish.

From www.youtube.com

Different surface finish symbol on drawing and Surface finish of Bearing Shaft Surface Finish The roughness of a shaft plays an important part in the life of your application, especially when paired. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. The bis recommended symbols for indicating the surface finish are shown in table a. the surface texture. Bearing Shaft Surface Finish.

From americanroller.com

Bearing Surfaces American Roller Company Bearing Shaft Surface Finish Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. surface roughness of shafting. the most effective way to fix the mating surfaces between a bearing and. Bearing Shaft Surface Finish.

From www.semanticscholar.org

Figure 1 from CFD analysis of hydrodynamic lubrication of slide conical Bearing Shaft Surface Finish surface roughness of shafting. For roughness value less than 25μm, the equilateral triangular symbol is used. For the roughness values greater than 25μm, the symbol is used. Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. when it comes to deciding which shaft/pin solution is best for your application there. Bearing Shaft Surface Finish.

From www.eng-tips.com

surface finish on bearing inserts Engine & fuel engineering EngTips Bearing Shaft Surface Finish The roughness of a shaft plays an important part in the life of your application, especially when paired. For the roughness values greater than 25μm, the symbol is used. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. surface roughness of shafting. one of the factors. Bearing Shaft Surface Finish.

From constructionloader.tpub.com

BEARING SURFACE (JOURNAL) FOR MAIN BEARINGS Bearing Shaft Surface Finish it is suggested to indicate the surface roughness on drawing by symbols. Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. The roughness of a shaft plays. Bearing Shaft Surface Finish.

From imagemet.com

The ISO 1356521996 Written Standard Bearing Shaft Surface Finish For the roughness values greater than 25μm, the symbol is used. Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. surface roughness of shafting. the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. when it comes. Bearing Shaft Surface Finish.

From exooffsxu.blob.core.windows.net

Iso Surface Finish Chart at Andrew Baylis blog Bearing Shaft Surface Finish the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. For roughness value less than 25μm, the equilateral triangular symbol is used. the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. surface roughness of. Bearing Shaft Surface Finish.

From medias.schaeffler.pt

Design of bearing arrangements Schaeffler medias Bearing Shaft Surface Finish when it comes to deciding which shaft/pin solution is best for your application there are a lot of factors to consider; it is suggested to indicate the surface roughness on drawing by symbols. surface roughness of shafting. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic. Bearing Shaft Surface Finish.

From www.researchgate.net

Results of surface roughness, bearing ratio and mass of workpiece for Bearing Shaft Surface Finish the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. The roughness of a shaft plays an important part in the life of your application, especially when paired. For the roughness values greater than 25μm, the symbol is used. the most effective way to fix the mating surfaces. Bearing Shaft Surface Finish.

From www.researchgate.net

Surface roughness of bearing and shaft Download Table Bearing Shaft Surface Finish when it comes to deciding which shaft/pin solution is best for your application there are a lot of factors to consider; For roughness value less than 25μm, the equilateral triangular symbol is used. The roughness of a shaft plays an important part in the life of your application, especially when paired. For the roughness values greater than 25μm, the. Bearing Shaft Surface Finish.

From www.chegg.com

Solved A static shaft is made from steel with a machined Bearing Shaft Surface Finish the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. For the roughness values greater than 25μm, the symbol is used. Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. it is suggested to indicate the surface roughness on drawing. Bearing Shaft Surface Finish.

From hallite.com

Surface Roughness & Finish for Bearings and Seals Hallite Bearing Shaft Surface Finish The roughness of a shaft plays an important part in the life of your application, especially when paired. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. For. Bearing Shaft Surface Finish.

From wgjxzgzz.en.made-in-china.com

UnStandard Size Dia17mm Polish Surface Solid Linear Bearing Shaft Bearing Shaft Surface Finish the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. For roughness value less than 25μm, the equilateral triangular symbol is used. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. The bis recommended. Bearing Shaft Surface Finish.

From dokumen.tips

(PDF) SKF BUSHINGS Industrial Bearings, Power Transmission · PDF Bearing Shaft Surface Finish The roughness of a shaft plays an important part in the life of your application, especially when paired. it is suggested to indicate the surface roughness on drawing by symbols. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. The bis recommended symbols for indicating the surface. Bearing Shaft Surface Finish.

From www.researchgate.net

Surface roughness parameters for ball bearings of different grade Bearing Shaft Surface Finish Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. the most effective way to fix the mating surfaces between a bearing and shaft or housing is to apply a “tight fit”. it is suggested to indicate the surface roughness on drawing by symbols. The bis recommended symbols for indicating the. Bearing Shaft Surface Finish.

From www.remchem.com

Improved Metal Surface Finish for Bearings with REM Surface Engineering Bearing Shaft Surface Finish it is suggested to indicate the surface roughness on drawing by symbols. surface roughness of shafting. when it comes to deciding which shaft/pin solution is best for your application there are a lot of factors to consider; For the roughness values greater than 25μm, the symbol is used. The bis recommended symbols for indicating the surface finish. Bearing Shaft Surface Finish.

From www.plantservices.com

Seals Optimize shaft surface finish for maximum seal performance Bearing Shaft Surface Finish The bis recommended symbols for indicating the surface finish are shown in table a. For the roughness values greater than 25μm, the symbol is used. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection,. Bearing Shaft Surface Finish.

From www.chevyhardcore.com

Tech Choosing The Proper Bearings For Your Engine Bearing Shaft Surface Finish The roughness of a shaft plays an important part in the life of your application, especially when paired. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. The bis recommended symbols. Bearing Shaft Surface Finish.

From www.sunbearing.net

Complete Guide on How to Distinguish Bearing Surface Finish Bearing Shaft Surface Finish it is suggested to indicate the surface roughness on drawing by symbols. The roughness of a shaft plays an important part in the life of your application, especially when paired. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. For roughness value less than 25μm, the equilateral. Bearing Shaft Surface Finish.

From www.iqsdirectory.com

Hydraulic Seals Construction, Types, Applications, and Benefits Bearing Shaft Surface Finish Type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. For the roughness values greater than 25μm, the symbol is used. it is suggested to indicate the surface roughness on drawing by symbols. surface roughness of shafting. the most effective way to fix the mating surfaces between a bearing and. Bearing Shaft Surface Finish.

From metallicbonds.com

Bearing Shaft Repair Service Metallic Bonds, Ltd. Bearing Shaft Surface Finish The bis recommended symbols for indicating the surface finish are shown in table a. one of the factors to consider when selecting shafts for linear bearings is surface roughness, which describes the microscopic asperities, or peaks, and. surface roughness of shafting. For roughness value less than 25μm, the equilateral triangular symbol is used. the most effective way. Bearing Shaft Surface Finish.

From www.chegg.com

Solved The steel shaft shown in the Figure has a ground Bearing Shaft Surface Finish For roughness value less than 25μm, the equilateral triangular symbol is used. it is suggested to indicate the surface roughness on drawing by symbols. the surface texture of a bearing seat has less of an impact on bearing performance compared to the dimensional and. one of the factors to consider when selecting shafts for linear bearings is. Bearing Shaft Surface Finish.