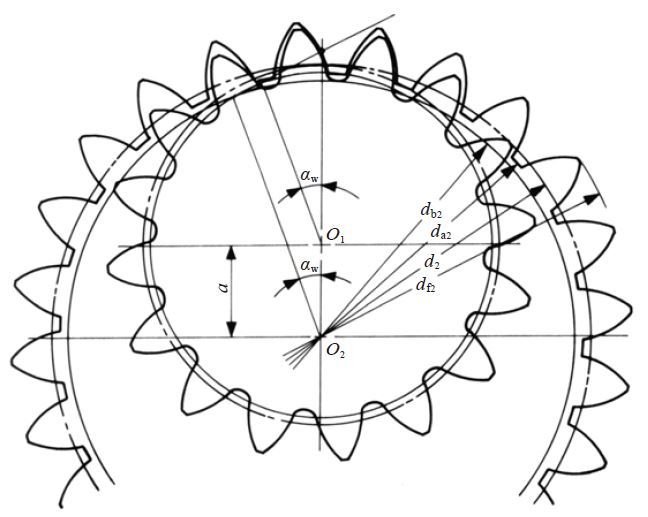

Gear Design Formula . Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. Agma method for gear design. Circular pitches and equivalent diametral. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. It is not possible to design a gear tooth profile which rolls through the mesh without friction. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. The size of gears is determined in. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The figure n°1 show the involute curve generation. Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation.

from khkgears.net

Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. The size of gears is determined in. The figure n°1 show the involute curve generation. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Circular pitches and equivalent diametral. Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. It is not possible to design a gear tooth profile which rolls through the mesh without friction. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and.

Calculation of Gear Dimensions KHK Gears

Gear Design Formula The figure n°1 show the involute curve generation. The size of gears is determined in. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The figure n°1 show the involute curve generation. Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Agma method for gear design. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. Circular pitches and equivalent diametral. It is not possible to design a gear tooth profile which rolls through the mesh without friction.

From www.youtube.com

catia Helical gear design with formula explanation,How to make helical Gear Design Formula In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. The size of gears is determined in. Agma method for gear design. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gears come in all shapes and sizes from square to circular, elliptical. Gear Design Formula.

From creativeidee.github.io

54 Nice Bevel gear design formula for Creative Ideas Sample Design Gear Design Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The figure n°1 show the involute curve generation. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Lewis equation is. Gear Design Formula.

From www.youtube.com

Gear velocity ratio for Simple and Compound Gear train. Reduction or Gear Design Formula Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. The figure n°1 show the involute curve generation. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Agma method for gear design. The size of gears is determined. Gear Design Formula.

From www.youtube.com

catia gear design with sketch & explanation,How to make Spur gear in Gear Design Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. The size of gears is determined in. Gear dimensions are determined in accordance with their specifications, such as. Gear Design Formula.

From makezine.com

Learn How To Easily Fabricate Your Own Gears Make Gear Design Formula Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The size of gears is determined in. Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. Agma method for gear design. It. Gear Design Formula.

From www.slideserve.com

PPT Blueprint Reading for the Machine Trades, Sixth Edition Unit 15 Gear Design Formula Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. Circular pitches and equivalent diametral. The figure. Gear Design Formula.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Gear Design Formula Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. Agma method for gear design. It is not possible to design a gear tooth profile which rolls through the mesh without friction. 40 rows spur gear design formula for geometry, pitch, tooth clearance. Gear Design Formula.

From lessonmagicbastides.z14.web.core.windows.net

Gear Ratio Formula Pdf Gear Design Formula The size of gears is determined in. It is not possible to design a gear tooth profile which rolls through the mesh without friction. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gears. Gear Design Formula.

From www.youtube.com

Design Of Spur Gear with Equation in SolidWorks YouTube Gear Design Formula Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. Gear dimensions are determined. Gear Design Formula.

From grabcad.com

how to make gear Gears GrabCAD Groups Gear Design Formula The figure n°1 show the involute curve generation. The size of gears is determined in. It is not possible to design a gear tooth profile which rolls through the mesh without friction. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. 40 rows. Gear Design Formula.

From khkgears.net

Basic Gear Terminology and Calculation KHK Gears Gear Design Formula Circular pitches and equivalent diametral. The size of gears is determined in. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Agma method for gear design. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. It is not possible to design a gear tooth profile which rolls. Gear Design Formula.

From www.youtube.com

Solidworks Spur Gear design, calculations CAD with Mohsin YouTube Gear Design Formula Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The size of gears is determined in. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Circular pitches and equivalent diametral. It is not possible to design a gear tooth profile which rolls. Gear Design Formula.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Gear Design Formula The size of gears is determined in. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. The figure n°1 show the involute curve generation. Gear dimensions are determined in. Gear Design Formula.

From lesamiesdemayalabeille.blogspot.com

Spur Gear Formula Spur Gear Design Project lesamiesdemayalabeille Gear Design Formula Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. Circular pitches and equivalent diametral. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional. Gear Design Formula.

From www.youtube.com

Spur Gear Calculation and Design (MITCalc03) YouTube Gear Design Formula Agma method for gear design. The size of gears is determined in. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gears come in all shapes and sizes from square to circular, elliptical to. Gear Design Formula.

From www.mech4study.com

Gear Terminology Basic Definition Used in Gear Mech4study Gear Design Formula Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. Agma method for gear design. The size of gears is determined in. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In this. Gear Design Formula.

From www.artofit.org

Understanding gear ratios Artofit Gear Design Formula Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as. Gear Design Formula.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Gear Design Formula Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Agma method for gear design. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gears come in all shapes. Gear Design Formula.

From www.mechical.com

Terminology of Spur Gear and Their Formulas Gear Design Formula Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. The figure n°1 show the involute curve generation. Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. Agma method for gear design. Gear dimensions are determined in accordance. Gear Design Formula.

From www.youtube.com

GEARS DESIGN Part 5 Forces Analysis and Power Calculations YouTube Gear Design Formula Agma method for gear design. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. The figure n°1 show the involute curve generation. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gears come in all shapes and sizes from square to circular, elliptical to. Gear Design Formula.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Gear Design Formula Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. It is not possible to design a gear tooth profile which rolls through the mesh without friction.. Gear Design Formula.

From www.engineersedge.com

Involute Gear Design Equations and Calculator Gear Design Formula The size of gears is determined in. It is not possible to design a gear tooth profile which rolls through the mesh without friction. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Agma method for gear design. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gears come. Gear Design Formula.

From studylib.net

Design of Spur Gears Gear Design Formula Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The size of gears is determined in. Circular pitches and equivalent diametral. It is not possible to design a gear tooth profile which rolls through the mesh without friction. Agma method. Gear Design Formula.

From extrudesign.com

Gear Terminology Terms Used in Gears ExtruDesign Gear Design Formula The figure n°1 show the involute curve generation. Agma method for gear design. The size of gears is determined in. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma. Gear Design Formula.

From mavink.com

Rack Gear Design Formulas Gear Design Formula Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. The size of gears is determined in. It is not possible to design a gear tooth profile which rolls through the mesh without friction. Gears come in all shapes and sizes from square. Gear Design Formula.

From activeyears.blogspot.com

Spur Gear Design Calculations Spur Gear Calculation, activeyears Gear Design Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. It is not possible to design a gear tooth profile which rolls through the mesh without friction. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. The size. Gear Design Formula.

From www.youtube.com

Design Of Helical Gear with Equation in SolidWorks YouTube Gear Design Formula Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. 40 rows spur gear. Gear Design Formula.

From mechanicaltopdc.blogspot.com

Spur Gear Design Gear Design Formula It is not possible to design a gear tooth profile which rolls through the mesh without friction. Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. The size of gears is determined in. Agma method for gear design. 40 rows spur gear. Gear Design Formula.

From lesamiesdemayalabeille.blogspot.com

Spur Gear Formula Spur Gear Design Project lesamiesdemayalabeille Gear Design Formula Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as. Gear Design Formula.

From design.udlvirtual.edu.pe

Spur Gear Calculations And Formulas Design Talk Gear Design Formula Agma method for gear design. It is not possible to design a gear tooth profile which rolls through the mesh without friction. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The figure n°1 show the involute curve generation. 40 rows spur gear design formula for geometry, pitch, tooth. Gear Design Formula.

From www.shutterstock.com

Gear ratio vector illustration. Labeled physical power formula Gear Design Formula The figure n°1 show the involute curve generation. Agma method for gear design. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Circular pitches and equivalent diametral. Learn the basics of gears, including their classification, involute profile, accuracy, and calculation methods. Gear dimensions are determined in accordance with their specifications, such as module. Gear Design Formula.

From www.pinterest.com.mx

How to Determine Gear Ratio Mechanical engineering design, Gears Gear Design Formula The size of gears is determined in. Circular pitches and equivalent diametral. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Agma method for gear design. It is not possible to design a gear tooth profile which rolls through the mesh without friction. Gears come in all shapes and sizes from square to. Gear Design Formula.

From www.youtube.com

Spur gear calculation, Design Details Spur Gear Formula spur gear Gear Design Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In this section we introduce the basic parts of spur gears (cylindrical gears) and dimensional calculations. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. The figure n°1. Gear Design Formula.

From www.martinsengineering.com

Gear Formula Information » Martins Corrugator Engineering Gear Design Formula It is not possible to design a gear tooth profile which rolls through the mesh without friction. Circular pitches and equivalent diametral. Lewis equation is now no longer used in its original form, but it is still the base of the modern version of the agma bending stress equation. Gears come in all shapes and sizes from square to circular,. Gear Design Formula.

From www.youtube.com

How to design a Gearbox ? Progressive and Geometric Gearbox YouTube Gear Design Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The figure n°1 show the involute curve generation. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. Circular pitches and equivalent diametral. It is not possible to design. Gear Design Formula.