Abrasive Flow Machining Literature Review . Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form.

from www.semanticscholar.org

Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form.

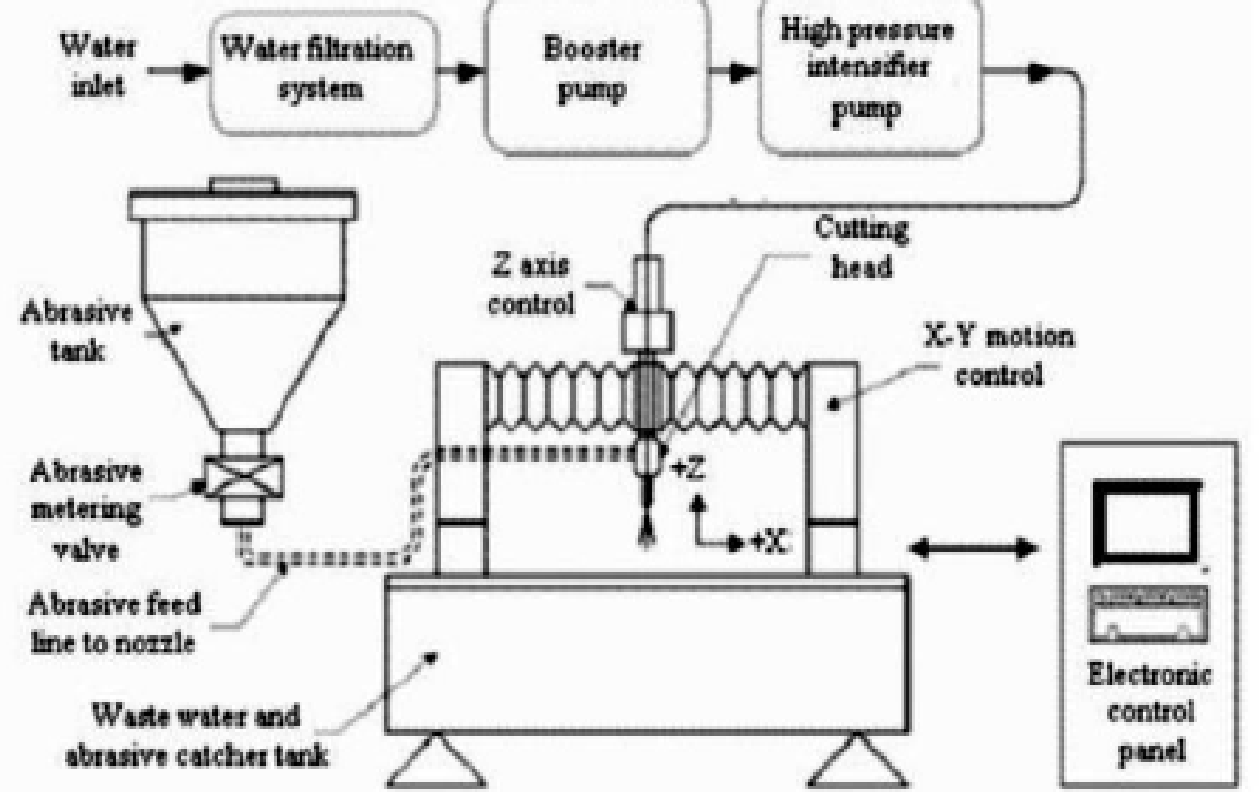

Figure 1 from A LITERATURE REVIEW ON THE ABRASIVE WATER JET MACHINING

Abrasive Flow Machining Literature Review Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have.

From dokumen.tips

(PDF) A neural network process model for abrasive flow machining Abrasive Flow Machining Literature Review This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. This paper presents the past research on different developments in hybrid. Abrasive Flow Machining Literature Review.

From www.scribd.com

Abrasive Flow Machining PDF Machining Diesel Engine Abrasive Flow Machining Literature Review Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with. Abrasive Flow Machining Literature Review.

From www.scribd.com

Abrasive Flow Machining PDF Machining Abrasive Abrasive Flow Machining Literature Review Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents a review on advances and trends in contemporary abrasive machining related to. Abrasive Flow Machining Literature Review.

From www.researchgate.net

(PDF) A critical study and review on abrasive flow micro machining Abrasive Flow Machining Literature Review This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. In this paper, various innovations done in the field of abrasive flow machining have. Abrasive Flow Machining Literature Review.

From www.waterjet-cutting.com

Abrasive Flow Machining Companies Services Abrasive Flow Machining Literature Review This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. This paper presents the past research on different developments in hybrid. Abrasive Flow Machining Literature Review.

From www.researchgate.net

(PDF) Recent Developments in Abrasive Flow Machining Abrasive Flow Machining Literature Review A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. This paper presents the. Abrasive Flow Machining Literature Review.

From www.academia.edu

(PDF) Abrasive flow machining A review on new developed hybrid AFM Abrasive Flow Machining Literature Review This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. This paper presents the past research. Abrasive Flow Machining Literature Review.

From www.scribd.com

Abrasive Flow Machining PDF Abrasive Machining Abrasive Flow Machining Literature Review In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. A novel process named magnetically assisted abrasive flow. Abrasive Flow Machining Literature Review.

From www.academia.edu

(PDF) Literature Review on Abrasive Jet Machining KK SHARMA Abrasive Flow Machining Literature Review Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish. Abrasive Flow Machining Literature Review.

From www.scribd.com

Abrasive Flow Machining PDF Machining Abrasive Abrasive Flow Machining Literature Review A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. Magnetic flux density (mfd),. Abrasive Flow Machining Literature Review.

From www.researchgate.net

(PDF) Pressure Variation in Abrasive Flow Machining Modelling and Abrasive Flow Machining Literature Review Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of. Abrasive Flow Machining Literature Review.

From www.researchgate.net

(PDF) Various developments in Abrasive Flow Machining Process A Review Abrasive Flow Machining Literature Review This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. Magnetically assisted abrasive finishing (maaf) processes. Abrasive Flow Machining Literature Review.

From www.researchgate.net

(PDF) Influence of Machining Conditions on Friction in Abrasive Flow Abrasive Flow Machining Literature Review Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. In this paper, various innovations done in the field of abrasive flow machining have been. Abrasive Flow Machining Literature Review.

From www.scribd.com

Abrasive Flow Machining1 PDF Shear Stress Machining Abrasive Flow Machining Literature Review In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. A novel process named magnetically assisted. Abrasive Flow Machining Literature Review.

From www.scientific.net

Study on Abrasive Flow Machining Pipe Inner Surface Abrasive Flow Machining Literature Review This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. In this paper, various innovations done in the field of abrasive flow machining have. Abrasive Flow Machining Literature Review.

From www.scribd.com

Abrasive Flow Machining Process Principle, Parameters and Capabilities Abrasive Flow Machining Literature Review This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. Magnetically assisted abrasive finishing. Abrasive Flow Machining Literature Review.

From www.academia.edu

(PDF) Literature Review on Abrasive Jet Machining IJRAME Journal Abrasive Flow Machining Literature Review A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents the past research on different. Abrasive Flow Machining Literature Review.

From www.semanticscholar.org

Figure 1 from A Review on Abrasive Flow Machining (AFM) Semantic Scholar Abrasive Flow Machining Literature Review This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. In this paper, various innovations done in the field of. Abrasive Flow Machining Literature Review.

From www.researchgate.net

27 Schematic illustration of one abrasive flow machining setup. The Abrasive Flow Machining Literature Review In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. Magnetic flux density (mfd), extrusion pressure, flow volume,. Abrasive Flow Machining Literature Review.

From www.scribd.com

Abrasive Flow Machining PDF Abrasive Metalworking Abrasive Flow Machining Literature Review Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish. Abrasive Flow Machining Literature Review.

From www.academia.edu

(PDF) IJERTInvestigations into Optimization of Abrasive Flow Machining Abrasive Flow Machining Literature Review In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. Magnetic flux density (mfd), extrusion pressure, flow volume,. Abrasive Flow Machining Literature Review.

From www.researchgate.net

(PDF) Towards simulations of abrasive flow machining Abrasive Flow Machining Literature Review Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal. Abrasive Flow Machining Literature Review.

From mungfali.com

Machining Process Flow Chart Abrasive Flow Machining Literature Review In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. This paper presents the past research on different. Abrasive Flow Machining Literature Review.

From www.researchgate.net

(PDF) A Literature Review on Parameters Influencing Abrasive Jet Abrasive Flow Machining Literature Review This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that. Abrasive Flow Machining Literature Review.

From www.youtube.com

Working principle of Abrasive Flow Machining (AFM) YouTube Abrasive Flow Machining Literature Review A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. This paper presents the past research on different developments in hybrid abrasive flow. Abrasive Flow Machining Literature Review.

From www.researchgate.net

(PDF) Investigation of Abrasive Flow Finishing While Machining Abrasive Flow Machining Literature Review This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents the past research. Abrasive Flow Machining Literature Review.

From www.scribd.com

Abrasive Flow Machining Process Principle, Parameters and Capabilities Abrasive Flow Machining Literature Review This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. This paper presents a review on advances and trends in contemporary abrasive machining. Abrasive Flow Machining Literature Review.

From www.scribd.com

Simulation of Surface Generated in Abrasive Flow Machining Process Abrasive Flow Machining Literature Review This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. In this paper, various innovations done in the field of abrasive flow machining. Abrasive Flow Machining Literature Review.

From issuu.com

Abrasive Flow Machining using Abrasive Paste with Oiticica Oil by Abrasive Flow Machining Literature Review A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size,. Abrasive Flow Machining Literature Review.

From www.semanticscholar.org

Figure 1 from A LITERATURE REVIEW ON THE ABRASIVE WATER JET MACHINING Abrasive Flow Machining Literature Review Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. Magnetic flux density (mfd), extrusion pressure,. Abrasive Flow Machining Literature Review.

From www.researchgate.net

Schematic diagram of abrasive flow machining Download Scientific Diagram Abrasive Flow Machining Literature Review This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the. Abrasive Flow Machining Literature Review.

From www.academia.edu

(PDF) Hybrid Abrasive Flow Machining for Nano Finishing A Review Abrasive Flow Machining Literature Review This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the principal machining parameters that control the surface finish characteristics. In this paper, various innovations done in the field of abrasive flow machining. Abrasive Flow Machining Literature Review.

From www.mdpi.com

Processes Free FullText Study of the Polishing Characteristics by Abrasive Flow Machining Literature Review This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetically assisted abrasive finishing (maaf) processes are the precision material removal processes that have. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. In this paper, various innovations done in the field of abrasive flow. Abrasive Flow Machining Literature Review.

From www.researchgate.net

(PDF) Review Paper on Abrasive Machining Process Abrasive Flow Machining Literature Review In this paper, various innovations done in the field of abrasive flow machining have been studied in detail in a tabulated form. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. Magnetic flux density (mfd), extrusion pressure, flow volume, abrasive type, grit size, number of process cycles, medium, and workpiece configuration are the. Abrasive Flow Machining Literature Review.

From journals.sagepub.com

A review on assisted abrasive flow machining and abrasive Abrasive Flow Machining Literature Review A novel process named magnetically assisted abrasive flow finishing (maafm) was introduced with the integration of. This paper presents a review on advances and trends in contemporary abrasive machining related to the application of. This paper presents the past research on different developments in hybrid abrasive flow machining processes, different. In this paper, various innovations done in the field of. Abrasive Flow Machining Literature Review.