Abrasive Wear For Gears . Abrasive machining is one of the key technologies in gear manufacturing. It occurs when hard particles make their way between the gears and slide or roll. Abrasive wear is the removal of material due to the presence of hard particles e.g. Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. This article discusses the abrasive wear. Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. Abrasive wear is sometimes called cutting wear. These specific wear patterns often result in tooth surface. The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. Amongst abrasive finishing processes of hardened gears,. Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial joints by abrasion and producing large. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. There are two types of abrasive wear:

from global-pam.com

This article discusses the abrasive wear. There are two types of abrasive wear: These specific wear patterns often result in tooth surface. The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. Amongst abrasive finishing processes of hardened gears,. Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. Abrasive wear is the removal of material due to the presence of hard particles e.g. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. It occurs when hard particles make their way between the gears and slide or roll. Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial joints by abrasion and producing large.

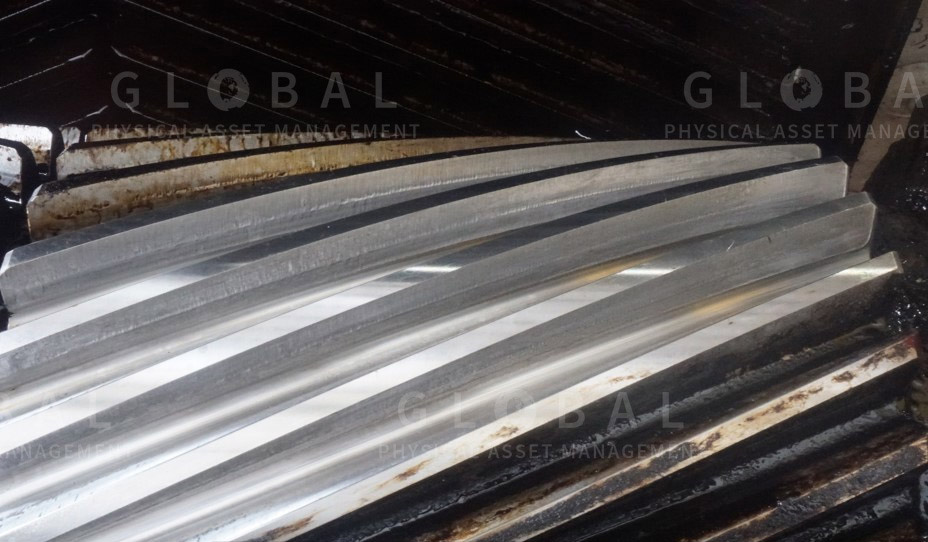

5 Common Classes of Girth Gear Potential Failure Modes Global Physical Asset Management, Inc.

Abrasive Wear For Gears Abrasive wear is sometimes called cutting wear. It occurs when hard particles make their way between the gears and slide or roll. There are two types of abrasive wear: This article discusses the abrasive wear. Abrasive wear is the removal of material due to the presence of hard particles e.g. Abrasive machining is one of the key technologies in gear manufacturing. The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. Abrasive wear is sometimes called cutting wear. These specific wear patterns often result in tooth surface. Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial joints by abrasion and producing large. Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. Amongst abrasive finishing processes of hardened gears,. Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion.

From www.slideserve.com

PPT CONCRETE INDUSTRY AND ABRASIVE WEAR PowerPoint Presentation, free download ID3218030 Abrasive Wear For Gears These specific wear patterns often result in tooth surface. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. It occurs when hard particles make their way between the gears and slide or roll. The hard particles will. Abrasive Wear For Gears.

From global-pam.com

5 Common Classes of Girth Gear Potential Failure Modes Global Physical Asset Management, Inc. Abrasive Wear For Gears Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. Abrasive wear is sometimes called cutting wear. There are two types of abrasive wear: This article discusses the abrasive wear. These specific wear patterns often result in tooth surface.. Abrasive Wear For Gears.

From www.youtube.com

M7033T WEAR 1 Part3 Abrasive wear YouTube Abrasive Wear For Gears This article discusses the abrasive wear. Abrasive machining is one of the key technologies in gear manufacturing. Amongst abrasive finishing processes of hardened gears,. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. These specific wear patterns often result in tooth surface. Abrasive wear is the removal of material due to the presence of. Abrasive Wear For Gears.

From www.researchgate.net

Schematic illustration of the abrasive sliding wear test and the... Download Scientific Diagram Abrasive Wear For Gears It occurs when hard particles make their way between the gears and slide or roll. Abrasive machining is one of the key technologies in gear manufacturing. This article discusses the abrasive wear. The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. Particle contamination or a lack of lubrication. Abrasive Wear For Gears.

From www.semanticscholar.org

Figure 3 from STUDY AND CHARACTERISTIC OF ABRASIVE WEAR MECHANISMS Semantic Scholar Abrasive Wear For Gears Abrasive wear is sometimes called cutting wear. Abrasive machining is one of the key technologies in gear manufacturing. The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. Surface wear in gear teeth. Abrasive Wear For Gears.

From www.researchgate.net

Schematic wear modes a adhesive wear by adhesive shear and transfer; b... Download Scientific Abrasive Wear For Gears Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial joints by abrasion and producing large. Abrasive wear is the removal of material due to the presence of hard particles e.g. Amongst abrasive finishing processes of hardened gears,. It. Abrasive Wear For Gears.

From www.youtube.com

Abrasive Wear(Two Body And Three Body) YouTube Abrasive Wear For Gears Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. It occurs when hard particles make their way between the gears and slide or roll. These specific wear patterns often result in tooth surface. Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. Abrasive wear is. Abrasive Wear For Gears.

From www.researchgate.net

Figure E.4 Three body abrasive wear observed at the top of an inner... Download Scientific Abrasive Wear For Gears Abrasive wear is sometimes called cutting wear. Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial joints by abrasion and producing large. The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. These specific wear patterns often result in tooth surface. There are. Abrasive Wear For Gears.

From www.slideserve.com

PPT Material Wear PowerPoint Presentation ID2353939 Abrasive Wear For Gears These specific wear patterns often result in tooth surface. There are two types of abrasive wear: Abrasive wear is the removal of material due to the presence of hard particles e.g. Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. Abrasive machining is one of the key technologies in gear manufacturing. Particle. Abrasive Wear For Gears.

From www.researchgate.net

Mechanisms of wear in general adhesive wear; abrasive wear; fatigue... Download Scientific Abrasive Wear For Gears Abrasive machining is one of the key technologies in gear manufacturing. Abrasive wear is sometimes called cutting wear. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. There are two types of abrasive wear: Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. The hard particles. Abrasive Wear For Gears.

From www.researchgate.net

Various kinds of gear teeth wear [72] (a) moderate wear, (b)... Download Scientific Diagram Abrasive Wear For Gears Abrasive wear is sometimes called cutting wear. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. It occurs when hard particles make their way between the gears and slide or roll. Abrasive wear is the removal of material due to the presence of hard particles e.g. Particle contamination or a lack of lubrication could. Abrasive Wear For Gears.

From www.researchgate.net

Schematic diagram of impactabrasive wear test Download Scientific Diagram Abrasive Wear For Gears There are two types of abrasive wear: This article discusses the abrasive wear. The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. These specific wear patterns often result in tooth surface. It occurs when hard particles make their way between the gears and slide or roll. Amongst abrasive. Abrasive Wear For Gears.

From slideplayer.com

Part III Design of Power Transmission Systems ppt download Abrasive Wear For Gears Amongst abrasive finishing processes of hardened gears,. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. Abrasive wear is the removal of material due to the presence of hard particles e.g. Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. This article discusses the abrasive wear. Abrasive. Abrasive Wear For Gears.

From www.researchgate.net

(PDF) Abrasive Wear Resistance of Ultrafine Ausferritic Ductile Iron Intended for the Abrasive Wear For Gears Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. Abrasive wear is the removal of material due to the presence of hard particles e.g. There are two types of abrasive wear: Amongst abrasive finishing processes of hardened gears,. This article discusses the abrasive wear. Abrasive wear is sometimes called cutting wear. Surface wear in. Abrasive Wear For Gears.

From heliosgearproducts.com

Abrasive Tools Helios Gear Products Abrasive Wear For Gears Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial joints by abrasion and producing large. Abrasive wear is sometimes called cutting wear. There are two types of abrasive wear: Visually, this wear mechanism is represented by radial scratches. Abrasive Wear For Gears.

From www.researchgate.net

Schematic diagram of the mechanism of the improved wear performance... Download Scientific Diagram Abrasive Wear For Gears Abrasive wear is the removal of material due to the presence of hard particles e.g. It occurs when hard particles make their way between the gears and slide or roll. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial. Abrasive Wear For Gears.

From www.researchgate.net

Main wear mechanisms (a) Adhesive wear, (b) Twobody abrasive wear,... Download Scientific Abrasive Wear For Gears It occurs when hard particles make their way between the gears and slide or roll. Abrasive wear is the removal of material due to the presence of hard particles e.g. These specific wear patterns often result in tooth surface. Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. The hard particles will. Abrasive Wear For Gears.

From www.mdpi.com

JMMP Free FullText ThreeBody Abrasive WearResistance Characteristics of a 27CrBased 3V Abrasive Wear For Gears Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial joints by abrasion and producing large. This article discusses the abrasive wear. Amongst abrasive finishing processes of hardened gears,. Abrasive wear is the removal of material due to the presence of hard particles e.g. Surface wear in gear teeth is often the result of mechanical. Abrasive Wear For Gears.

From www.researchgate.net

Five Processes of Abrasive Wear [7] Download Scientific Diagram Abrasive Wear For Gears This article discusses the abrasive wear. It occurs when hard particles make their way between the gears and slide or roll. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. These specific wear. Abrasive Wear For Gears.

From www.researchgate.net

(a) Adhesive wear, 53,58 (b) abrasive wear, 54,59,60 (c) fatigue wear,... Download Scientific Abrasive Wear For Gears Abrasive wear is the removal of material due to the presence of hard particles e.g. Abrasive wear is sometimes called cutting wear. There are two types of abrasive wear: It occurs when hard particles make their way between the gears and slide or roll. Amongst abrasive finishing processes of hardened gears,. This article discusses the abrasive wear. These specific wear. Abrasive Wear For Gears.

From www.researchgate.net

Examples of abrasive wear Download Scientific Diagram Abrasive Wear For Gears Abrasive machining is one of the key technologies in gear manufacturing. This article discusses the abrasive wear. Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. There are two types of abrasive wear: Amongst abrasive finishing processes of hardened gears,. It occurs when hard particles make their way between the gears and. Abrasive Wear For Gears.

From www.researchgate.net

(PDF) Fundamental aspects of abrasive wear Abrasive Wear For Gears These specific wear patterns often result in tooth surface. Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. This article discusses the abrasive wear. Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. Abrasive wear is sometimes called cutting wear. Abrasive wear is a classic. Abrasive Wear For Gears.

From www.engineerdo.com

Abrasive Wear » Engineerdo Abrasive Wear For Gears Abrasive machining is one of the key technologies in gear manufacturing. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. Abrasive wear is the removal of material due to the presence of hard particles e.g. It occurs when hard particles make their way between the gears and slide or roll. These specific wear patterns. Abrasive Wear For Gears.

From www.researchgate.net

Wear growth on gear teeth. Download Scientific Diagram Abrasive Wear For Gears Abrasive machining is one of the key technologies in gear manufacturing. Abrasive wear is the removal of material due to the presence of hard particles e.g. Abrasive wear is sometimes called cutting wear. The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. Amongst abrasive finishing processes of hardened. Abrasive Wear For Gears.

From www.machinerylubrication.com

The Pros and Cons of Polishing Wear Abrasive Wear For Gears The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. Abrasive wear is the removal of material due to the presence of hard particles e.g. Abrasive wear is sometimes called cutting wear. Amongst abrasive finishing processes of hardened gears,. Surface wear in gear teeth is often the result of. Abrasive Wear For Gears.

From www.youtube.com

Abrasive wear YouTube Abrasive Wear For Gears The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. This article discusses the abrasive wear. These specific wear patterns often result in tooth surface. Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial joints by abrasion and producing large. Visually, this wear. Abrasive Wear For Gears.

From www.nuclear-power.com

Abrasive Wear Mechanisms and Characteristics Abrasive Wear For Gears This article discusses the abrasive wear. Amongst abrasive finishing processes of hardened gears,. Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. Abrasive wear is sometimes called cutting wear. The hard particles will be suspended in the lubricant and picked up by the gear tooth when travelling through the lubricant. Surface wear in. Abrasive Wear For Gears.

From www.researchgate.net

Schematic illustration of threebody abrasive wear a MLD10) and impact... Download Scientific Abrasive Wear For Gears These specific wear patterns often result in tooth surface. Abrasive machining is one of the key technologies in gear manufacturing. Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. Particle contamination or a lack of lubrication could lead to sliding contact, resulting in abrasive wear. It occurs when hard particles make their. Abrasive Wear For Gears.

From www.dreamstime.com

Abrasive Wear of Roller Bearing Stock Image Image of vehicle, lighting 223365843 Abrasive Wear For Gears Abrasive wear is the removal of material due to the presence of hard particles e.g. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. Abrasive machining is one of the key technologies in gear manufacturing. It occurs when hard particles make their way between the gears and slide or roll. This article discusses the. Abrasive Wear For Gears.

From abrasivewearsolutions.com

Home Abrasive Wear Solutions Abrasive Wear For Gears Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. Abrasive machining is one of the key technologies in gear manufacturing. There are two types of abrasive wear: Amongst abrasive finishing processes of hardened gears,. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. The hard particles. Abrasive Wear For Gears.

From www.bearingtips.com

What do your bearings say about the condition of your equipment? Bearing Tips Abrasive Wear For Gears Abrasive machining is one of the key technologies in gear manufacturing. It occurs when hard particles make their way between the gears and slide or roll. Abrasive wear is the removal of material due to the presence of hard particles e.g. Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. The hard. Abrasive Wear For Gears.

From heliosgearproducts.com

Abrasive Tools Helios Gear Products Abrasive Wear For Gears Surface wear in gear teeth is often the result of mechanical processes like abrasion, adhesion and corrosion. Abrasive wear is sometimes called cutting wear. Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial joints by abrasion and producing large. The hard particles will be suspended in the lubricant and picked up by the gear. Abrasive Wear For Gears.

From www.nuclear-power.com

Adhesive Wear vs Abrasion Wear Mechanisms and Characteristics Abrasive Wear For Gears Abrasive machining is one of the key technologies in gear manufacturing. These specific wear patterns often result in tooth surface. Abrasive wear is the removal of material due to the presence of hard particles e.g. Amongst abrasive finishing processes of hardened gears,. It occurs when hard particles make their way between the gears and slide or roll. This article discusses. Abrasive Wear For Gears.

From www.slideserve.com

PPT Theory of cutting Tool wear PowerPoint Presentation, free download ID4808700 Abrasive Wear For Gears Abrasive wear is the removal of material due to the presence of hard particles e.g. These specific wear patterns often result in tooth surface. Visually, this wear mechanism is represented by radial scratches which appear on the mating gear. This article discusses the abrasive wear. Amongst abrasive finishing processes of hardened gears,. It occurs when hard particles make their way. Abrasive Wear For Gears.

From www.researchgate.net

Excessive abrasion type wear. Download Scientific Diagram Abrasive Wear For Gears There are two types of abrasive wear: Abrasive machining is one of the key technologies in gear manufacturing. Amongst abrasive finishing processes of hardened gears,. Abrasive wear is a classic wear mechanism, causing damage to the bearing surfaces of artificial joints by abrasion and producing large. These specific wear patterns often result in tooth surface. It occurs when hard particles. Abrasive Wear For Gears.