Lubrication Of Tools . Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. The 2 most common lubricants. There are 4 types of lubricants: Ever wondered how proper lubrication can make or break industrial equipment? Ever wondered how proper lubrication can make or break industrial equipment? Following recommended lubrication techniques and frequencies is important for maintaining. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. Oil, grease, penetrating lubricants, and dry lubricants. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… This article delves into the critical role of mechanical equipment lubrication, detailing its. Choosing the right lubricant for specific power tools is crucial.

from nutechcompany.net

Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… There are 4 types of lubricants: Ever wondered how proper lubrication can make or break industrial equipment? Oil, grease, penetrating lubricants, and dry lubricants. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. Choosing the right lubricant for specific power tools is crucial. Ever wondered how proper lubrication can make or break industrial equipment? Following recommended lubrication techniques and frequencies is important for maintaining. This article delves into the critical role of mechanical equipment lubrication, detailing its.

» Metal Working Lubricants

Lubrication Of Tools This article delves into the critical role of mechanical equipment lubrication, detailing its. The 2 most common lubricants. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… Oil, grease, penetrating lubricants, and dry lubricants. Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Ever wondered how proper lubrication can make or break industrial equipment? There are 4 types of lubricants: Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. This article delves into the critical role of mechanical equipment lubrication, detailing its. Following recommended lubrication techniques and frequencies is important for maintaining. Ever wondered how proper lubrication can make or break industrial equipment? Choosing the right lubricant for specific power tools is crucial.

From www.calameo.com

Calaméo Klüber Special knowledge for the lubrication of cutting Lubrication Of Tools Choosing the right lubricant for specific power tools is crucial. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… This article delves into the critical role of mechanical equipment lubrication, detailing its. There are 4 types of lubricants: The 2 most common lubricants. Proper lubrication facilitates uninterrupted machine operation and. Lubrication Of Tools.

From www.hydroservice.it

Central lubrication unit for hydrostatic machine tool guides Projects Lubrication Of Tools This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. Choosing the right lubricant for specific power tools is crucial. Ever wondered how proper lubrication can make or break industrial equipment? Ever wondered. Lubrication Of Tools.

From tikweld.com

Importance of Lubricants for Machine Maintenance Tikweld products and Lubrication Of Tools Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. The 2 most common lubricants. Ever wondered how proper lubrication can make or break industrial equipment? Apart from cutting fluids, hydraulic oils are volumetrically the most significant group. Lubrication Of Tools.

From www.aviationpros.com

Lubrication Tool Kit From G&W Lube Tools Inc. Aviation Pros Lubrication Of Tools Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. Choosing the right lubricant for specific power tools is crucial. Following recommended lubrication techniques and frequencies is important for maintaining. There are 4 types of lubricants: Ever wondered how proper lubrication can make or break industrial equipment? The 2 most common lubricants.. Lubrication Of Tools.

From chestertonlubricants.chesterton.com

Industrial Lubrication Chesterton Toolbox Essentials Lubrication Of Tools Following recommended lubrication techniques and frequencies is important for maintaining. There are 4 types of lubricants: Choosing the right lubricant for specific power tools is crucial. Oil, grease, penetrating lubricants, and dry lubricants. Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. This section covers lubricating oils, hydraulic fluids, spindle oils,. Lubrication Of Tools.

From couplers.com.au

Lubrication & Greasing Couplers Malaga, WA Lubrication Of Tools Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Ever wondered how proper lubrication can make or break industrial equipment? Following recommended lubrication techniques and frequencies is important for maintaining. The 2 most common lubricants. This article delves. Lubrication Of Tools.

From nutechcompany.net

» Metal Working Lubricants Lubrication Of Tools Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… This article delves into the critical role of mechanical equipment lubrication, detailing its. Ever wondered how proper lubrication can make or break industrial. Lubrication Of Tools.

From www.afi.com.sa

AFI Group Lubrication Of Tools Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. Ever wondered how proper lubrication can make or break industrial equipment? This article delves into the critical role of mechanical equipment lubrication, detailing its. Following recommended lubrication techniques and frequencies is important for maintaining. Oil, grease, penetrating lubricants, and dry lubricants. This. Lubrication Of Tools.

From www.iqsdirectory.com

Industrial Lubricants Types, Uses, Features and Benefits Lubrication Of Tools Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. Following recommended lubrication techniques and frequencies is important for maintaining. Oil, grease, penetrating lubricants, and dry lubricants. This article delves into the critical role of mechanical equipment lubrication,. Lubrication Of Tools.

From www.lubricatingsystems.com

Lubrication Equipment Manufacturers Lubrication Equipment Lubrication Of Tools Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. Oil, grease, penetrating lubricants, and dry lubricants. Choosing the right lubricant for specific power tools is crucial. Ever wondered how proper lubrication can make or break industrial equipment? This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools.. Lubrication Of Tools.

From www.familyhandyman.com

8 Tool Maintenance Tips You Need to Follow Family Handyman Lubrication Of Tools There are 4 types of lubricants: Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. Ever wondered how proper lubrication can make or break industrial equipment? The 2 most common lubricants. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… Oil,. Lubrication Of Tools.

From www.uslube.com

The Cost of Deferring Lubricant Maintenance Lubrication Of Tools Ever wondered how proper lubrication can make or break industrial equipment? The 2 most common lubricants. Choosing the right lubricant for specific power tools is crucial. This article delves into the critical role of mechanical equipment lubrication, detailing its. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. Proper lubrication facilitates uninterrupted machine operation and. Lubrication Of Tools.

From thetradersindia.com

Dass Lubrication Equipment Lubrication Of Tools Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Oil, grease, penetrating lubricants, and dry lubricants. This article delves into the critical role of mechanical equipment lubrication, detailing its. Choosing the right lubricant for specific power tools is crucial. There are 4 types of lubricants: Proper lubrication facilitates uninterrupted machine operation and is one of the. Lubrication Of Tools.

From www.parktool.com

The Park Tool Guide to Bicycle Lubricants and Compounds Park Tool Lubrication Of Tools Ever wondered how proper lubrication can make or break industrial equipment? This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… The 2 most common lubricants. Oil, grease, penetrating lubricants, and dry lubricants. This article delves into the critical role of mechanical equipment lubrication, detailing its. Proper lubrication facilitates uninterrupted machine. Lubrication Of Tools.

From atlaslab.in

Lube Oil Analysis, Machinery Lubrication Service, Lubricating Oil and Lubrication Of Tools Ever wondered how proper lubrication can make or break industrial equipment? Following recommended lubrication techniques and frequencies is important for maintaining. This article delves into the critical role of mechanical equipment lubrication, detailing its. There are 4 types of lubricants: This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… Apart. Lubrication Of Tools.

From www.advancedtech.com

Manufacturing Equipment Lubrication Fact vs. Fiction Lubrication Of Tools Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Ever wondered how proper lubrication can make or break industrial equipment? Oil, grease, penetrating lubricants, and dry lubricants. There are 4 types of lubricants: Ever wondered how proper lubrication can make or break industrial equipment? Proper lubrication facilitates uninterrupted machine operation and is one of the most. Lubrication Of Tools.

From wd40.com.au

The Importance of Tool & Equipment Lubrication WD40 Australia Lubrication Of Tools Oil, grease, penetrating lubricants, and dry lubricants. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. This article delves into the critical role of mechanical equipment lubrication, detailing its. Ever wondered how proper lubrication can make or break industrial equipment? Following recommended lubrication techniques and frequencies is important for maintaining. Ever wondered how proper lubrication. Lubrication Of Tools.

From www.machinerylubrication.com

Lubrication Basics Lubrication Of Tools The 2 most common lubricants. There are 4 types of lubricants: Ever wondered how proper lubrication can make or break industrial equipment? Choosing the right lubricant for specific power tools is crucial. Oil, grease, penetrating lubricants, and dry lubricants. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… Following recommended. Lubrication Of Tools.

From iselinc.com

Explore The Many Benefits Of Lubrication Isel Lubrication Of Tools This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Oil, grease, penetrating lubricants, and dry lubricants. Choosing the right lubricant for specific power tools is crucial. Ever wondered how proper lubrication can make or break industrial equipment?. Lubrication Of Tools.

From shieldoils.com

Lubrication and Greasing Greases Shield Lubricants Lubrication Of Tools Following recommended lubrication techniques and frequencies is important for maintaining. Ever wondered how proper lubrication can make or break industrial equipment? This article delves into the critical role of mechanical equipment lubrication, detailing its. Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. Ever wondered how proper lubrication can make or. Lubrication Of Tools.

From www.dreamstime.com

Metalworking Gearwheel Machining with Oil Lubrication Stock Photo Lubrication Of Tools There are 4 types of lubricants: This article delves into the critical role of mechanical equipment lubrication, detailing its. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… Ever wondered how proper lubrication can make or. Lubrication Of Tools.

From www.jetlube.com

Machinery Lubrication 10 Lubrication Best Practices for Improved… Lubrication Of Tools Choosing the right lubricant for specific power tools is crucial. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… Oil, grease, penetrating lubricants, and dry lubricants. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. This article delves into the critical role of mechanical equipment. Lubrication Of Tools.

From virtuousind.com

Lubrication equipment Virtuous Industries LLP Lubrication Of Tools Following recommended lubrication techniques and frequencies is important for maintaining. The 2 most common lubricants. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… Ever wondered how proper lubrication can make or break industrial equipment? This article delves into the critical role of mechanical equipment lubrication, detailing its. Proper lubrication. Lubrication Of Tools.

From www.dreamstime.com

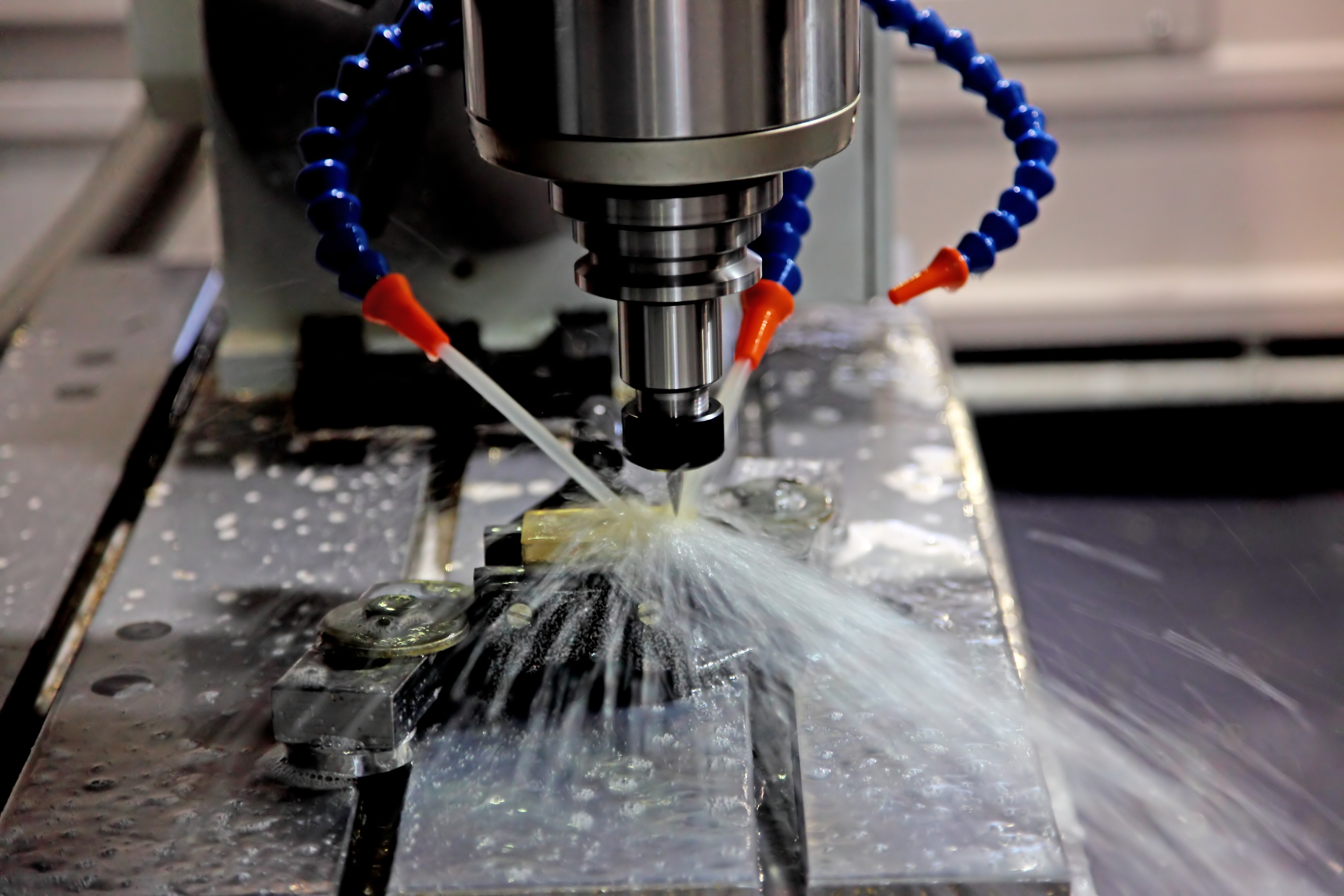

CNC Milling Machine Work. Coolant and Lubrication in Gear Metalwork Lubrication Of Tools This article delves into the critical role of mechanical equipment lubrication, detailing its. Oil, grease, penetrating lubricants, and dry lubricants. Ever wondered how proper lubrication can make or break industrial equipment? Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. There are 4 types of lubricants: Choosing the right lubricant for. Lubrication Of Tools.

From www.jcgibbons.com

Milling metalworking process. Industrial CNC metal machining by Lubrication Of Tools Following recommended lubrication techniques and frequencies is important for maintaining. Proper lubrication facilitates uninterrupted machine operation and is one of the most important aspects of machine health and. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… The 2 most common lubricants. Choosing the right lubricant for specific power tools. Lubrication Of Tools.

From www.dropsa.com

OIL and AIROIL Lubrication system for machine tools Dropsa Lubrication Of Tools There are 4 types of lubricants: This article delves into the critical role of mechanical equipment lubrication, detailing its. Ever wondered how proper lubrication can make or break industrial equipment? Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Oil, grease, penetrating lubricants, and dry lubricants. Ever wondered how proper lubrication can make or break industrial. Lubrication Of Tools.

From www.exportersindia.com

lubrication tools at Best Price in Gurugram Groz Engineering Tools Pv Ltd Lubrication Of Tools Following recommended lubrication techniques and frequencies is important for maintaining. Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Choosing the right lubricant for specific power tools is crucial. Ever wondered how proper lubrication can make or break industrial equipment? This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. There are. Lubrication Of Tools.

From www.holmatro.com

Rescue Tool Maintenance Lubrication Of Tools Ever wondered how proper lubrication can make or break industrial equipment? This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. Choosing the right lubricant for specific power tools is crucial. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… Following recommended lubrication techniques and frequencies. Lubrication Of Tools.

From www.indiamart.com

Lubricant Tools at best price in Alwar by Shreemanglam Powertech Lubrication Of Tools There are 4 types of lubricants: Following recommended lubrication techniques and frequencies is important for maintaining. The 2 most common lubricants. This article delves into the critical role of mechanical equipment lubrication, detailing its. Ever wondered how proper lubrication can make or break industrial equipment? Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Ever wondered. Lubrication Of Tools.

From aircrafttoolhire.com

Lubrication Tool Set Trailing Edge F8016713 Aircraft Tool Hire Ltd Lubrication Of Tools Choosing the right lubricant for specific power tools is crucial. Oil, grease, penetrating lubricants, and dry lubricants. Following recommended lubrication techniques and frequencies is important for maintaining. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. Ever wondered how proper lubrication can make or break industrial equipment? This article delves into the critical role of. Lubrication Of Tools.

From www.jetlube.com

Best Practices for Oil Lubricating Your Industrial Equipment Lubrication Of Tools Choosing the right lubricant for specific power tools is crucial. Ever wondered how proper lubrication can make or break industrial equipment? This article delves into the critical role of mechanical equipment lubrication, detailing its. Oil, grease, penetrating lubricants, and dry lubricants. Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. This article delves into the critical. Lubrication Of Tools.

From www.lubeaboom.com

Proper Lubrication for Industrial Crane and Heavy Equipment Maintenance Lubrication Of Tools There are 4 types of lubricants: Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Choosing the right lubricant for specific power tools is crucial. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear,. Lubrication Of Tools.

From www.machinerylubrication.com

A Guide to Oil Sampling Hardware Machinery Lubrication Lubrication Of Tools Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. Following recommended lubrication techniques and frequencies is important for maintaining. The 2 most common lubricants. Ever wondered how proper lubrication can make or break industrial equipment? Choosing the right lubricant for specific power tools is crucial. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases. Lubrication Of Tools.

From www.abmtools.com

Lubrication Equipment's ABM Tools Lubrication Of Tools Oil, grease, penetrating lubricants, and dry lubricants. This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. The 2 most common lubricants. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… There are 4 types of lubricants: Proper lubrication facilitates uninterrupted machine operation and is one. Lubrication Of Tools.

From makezine.com

4 Types of Lubricants and How to Use Them Make Lubrication Of Tools Apart from cutting fluids, hydraulic oils are volumetrically the most significant group of. This article delves into the critical role of mechanical equipment lubrication, detailing its significance in preventing wear, reducing maintenance… This section covers lubricating oils, hydraulic fluids, spindle oils, and greases for machine tools. The 2 most common lubricants. Following recommended lubrication techniques and frequencies is important for. Lubrication Of Tools.