Lube Oil Header Pressure . Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure and utilizes a standard pressure reducing regulator. Starting the standby pump is necessary when lube oil (header) pressure falls. The separate lube oil scheme provides the. After completing this module you will be able to: A fast response time is essential, and although there are other solutions and configurations. It consists of a primary and an auxiliary pump which drive lubricating oil throughout the system. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is.

from www.marineinsight.com

The separate lube oil scheme provides the. 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. After completing this module you will be able to: Starting the standby pump is necessary when lube oil (header) pressure falls. To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. A fast response time is essential, and although there are other solutions and configurations. Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure and utilizes a standard pressure reducing regulator. On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is.

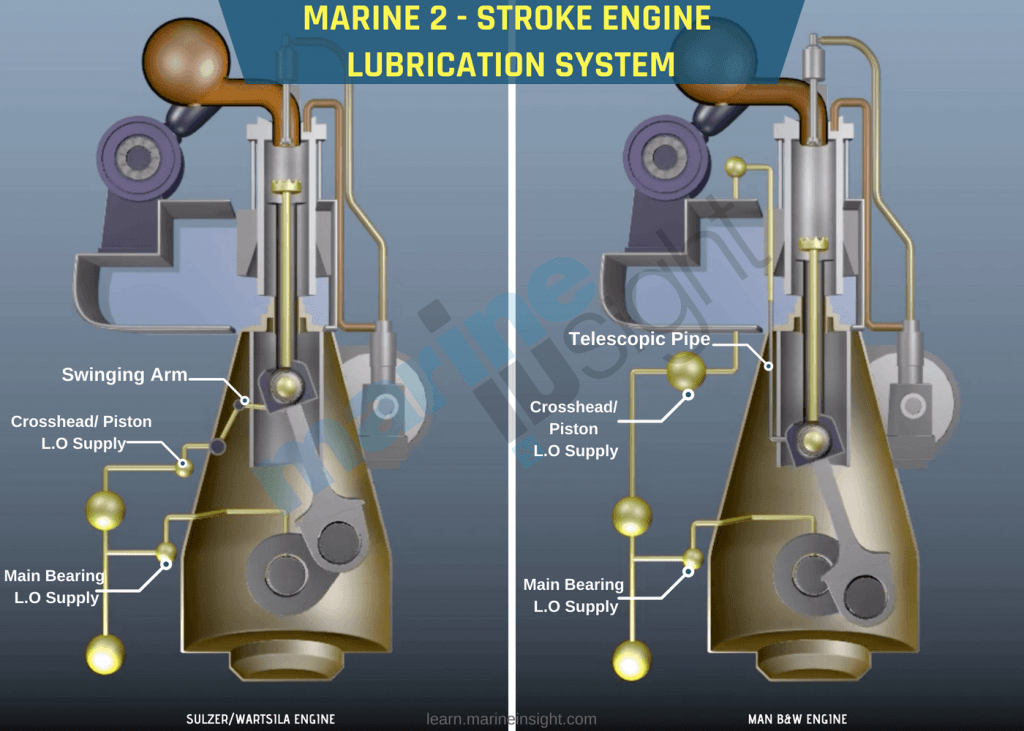

Ship's Main Engine Lubrication System Explained

Lube Oil Header Pressure The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. Starting the standby pump is necessary when lube oil (header) pressure falls. Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure and utilizes a standard pressure reducing regulator. A fast response time is essential, and although there are other solutions and configurations. After completing this module you will be able to: The separate lube oil scheme provides the. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. It consists of a primary and an auxiliary pump which drive lubricating oil throughout the system.

From www.linsdevasconcellos.org.br

Lubricants To Reduce Friction Lube Oil Header Pressure 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. Starting the standby pump is necessary when lube oil (header) pressure falls. Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure and utilizes a standard pressure reducing regulator. On our ge ms5001. Lube Oil Header Pressure.

From www.bruker.com

Lubricants Bruker Lube Oil Header Pressure Starting the standby pump is necessary when lube oil (header) pressure falls. The separate lube oil scheme provides the. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by. Lube Oil Header Pressure.

From www.youtube.com

Mechanism of Lubrication ll Extreme Pressure Lubrication ll Lubricants Lube Oil Header Pressure A fast response time is essential, and although there are other solutions and configurations. Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure and utilizes a standard pressure reducing regulator. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump.. Lube Oil Header Pressure.

From www.marineengineersknowledge.com

STERN TUBE LUBRICATION SYSTEM Marine engineers knowledge Lube Oil Header Pressure The separate lube oil scheme provides the. 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure and utilizes a standard pressure reducing regulator. Starting the standby pump is necessary when lube oil. Lube Oil Header Pressure.

From blog.softinway.com

[en]Gas Turbine Lubrication Systems[] Turbomachinery blog Lube Oil Header Pressure A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. It consists of a primary and an auxiliary pump which drive lubricating oil throughout. Lube Oil Header Pressure.

From www.nepalisupplier.com

Lube Oil Pressure Sensor Lube Oil Header Pressure To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. It consists of a primary and an auxiliary pump which drive lubricating oil throughout the system. The separate lube oil scheme provides the. Starting the standby pump is necessary when lube oil (header) pressure falls. The lube oil system duty is. Lube Oil Header Pressure.

From www.hcbrands.com

Lube Oil Pressure 1360 PSI Lube Oil Header Pressure A fast response time is essential, and although there are other solutions and configurations. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure and utilizes a standard pressure reducing regulator.. Lube Oil Header Pressure.

From www.youtube.com

SHIP'S MAIN ENGINE LUBE OIL SYSTEM YouTube Lube Oil Header Pressure 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. It consists of a primary and an auxiliary pump which drive lubricating oil throughout the system. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil. Lube Oil Header Pressure.

From www.pinterest.com

Lube Oil Lubricants, Oils, Lube Lube Oil Header Pressure To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. Starting the standby pump is necessary when lube oil (header) pressure falls. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. On our ge ms5001 gas. Lube Oil Header Pressure.

From fixenginethanatism123.z21.web.core.windows.net

Engine Oil And Lubricants Lube Oil Header Pressure It consists of a primary and an auxiliary pump which drive lubricating oil throughout the system. A fast response time is essential, and although there are other solutions and configurations. The separate lube oil scheme provides the. On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. After. Lube Oil Header Pressure.

From www.researchgate.net

Sensors in the lube oil circuit. Download Scientific Diagram Lube Oil Header Pressure 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. Bearing oil or lubricating oil, is commonly driven through the bearings at a stable. Lube Oil Header Pressure.

From www.semanticscholar.org

Figure 1.3 from Turbine Lube Oil System Monitoring and Control using Lube Oil Header Pressure On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. Starting the standby pump is necessary when lube oil (header) pressure falls. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. Bearing oil. Lube Oil Header Pressure.

From www.youtube.com

How is an Aircraft Engine Lubricated? Engine Oil System in 3 minutes Lube Oil Header Pressure Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure and utilizes a standard pressure reducing regulator. On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. After completing this module you will be able to: The lube oil system duty is to. Lube Oil Header Pressure.

From www.airbestpractices.com

Lubricants for Centrifugal Air Compressors Compressed Air Best Practices Lube Oil Header Pressure The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. After completing this module you will be able to: It consists of a primary and an auxiliary pump which drive lubricating oil throughout the system. To allow the oil film to be formed, the lube oil. Lube Oil Header Pressure.

From instrumentationbasic.com

Lube oil system in turbine Instrumentation basics Lube Oil Header Pressure To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. A fast response time is essential, and although there are other solutions and configurations. On our ge ms5001 gas. Lube Oil Header Pressure.

From www.bptparts.com

R35286 Way Lube Oil Pressure Switch BptParts Lube Oil Header Pressure To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. A fast response time is essential, and although there are other solutions and configurations. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. After completing this. Lube Oil Header Pressure.

From www.grainger.com

9 psi, 120 sec Delay, Mechanical Lube Oil Pressure Control 20RF58 Lube Oil Header Pressure On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. It consists of a primary and an auxiliary pump which drive lubricating oil throughout. Lube Oil Header Pressure.

From www.marineinsight.com

Ship's Main Engine Lubrication System Explained Lube Oil Header Pressure On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. Bearing oil or lubricating oil, is commonly driven through the bearings at a stable. Lube Oil Header Pressure.

From www.shell.ca

Shell Engine Oils & Lubricants Shell Canada Lube Oil Header Pressure It consists of a primary and an auxiliary pump which drive lubricating oil throughout the system. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. Starting the standby pump is necessary when lube oil (header) pressure falls. The separate lube oil scheme provides the. To. Lube Oil Header Pressure.

From www.bookpika.com

Low Lube Air Oil Pressure Switch as Compared to Haas® PN 931311 / 93 Lube Oil Header Pressure 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. A fast response time is essential, and although there are other solutions and configurations.. Lube Oil Header Pressure.

From garage.grumpysperformance.com

basic info on your v8 lube system Grumpys Performance Garage Lube Oil Header Pressure The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. 10.1 a) explain how the bearing inlet oil pressure is controlled when. Lube Oil Header Pressure.

From shinlube.en.made-in-china.com

Lube Original PB35 209136 3.5MPa Pressure gauge for Oil lubrication Lube Oil Header Pressure To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. The separate lube oil scheme provides the. After completing this module you will be able to: It. Lube Oil Header Pressure.

From www.tuv-nord.com

Lube Oil / Lubricating Oil Analysis Blog TUV India Lube Oil Header Pressure To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure and utilizes a standard pressure reducing regulator. 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of. Lube Oil Header Pressure.

From thepipingtalk.com

Back pressure valve on Lube Oil System The piping talk Lube Oil Header Pressure To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. After completing this module you will be able to: On our ge ms5001 gas turbine, we've observed. Lube Oil Header Pressure.

From diagramwallsmatsuyama.z14.web.core.windows.net

Engine Oil Flow Diagram Lube Oil Header Pressure To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of. Lube Oil Header Pressure.

From www.ccj-online.com

Turbine Tip 13 How to test your emergency lubeoil pumps Combined Lube Oil Header Pressure After completing this module you will be able to: The separate lube oil scheme provides the. It consists of a primary and an auxiliary pump which drive lubricating oil throughout the system. To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. The lube oil system duty is to provide oil. Lube Oil Header Pressure.

From www.pinterest.com

Lubricants, Oil pan, Car mechanic Lube Oil Header Pressure A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. The separate lube oil scheme provides the. It consists of a primary and an. Lube Oil Header Pressure.

From www.coalhandlingplants.com

Steam Turbine Lube Oil System in Thermal Power Plant Lube Oil Header Pressure The separate lube oil scheme provides the. 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. It consists of a primary and an auxiliary pump which drive lubricating oil throughout the system. Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure. Lube Oil Header Pressure.

From www.slideserve.com

PPT Lube Oil System Flushing PowerPoint Presentation, free download Lube Oil Header Pressure On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. The lube oil system duty is to provide oil with the designed pressure, temperature,. Lube Oil Header Pressure.

From instrumentationtools.com

Lubrication Control System Turbo Alternator Lube Oil Header Pressure On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. After completing this module you will be able to: Starting the standby pump is necessary when lube oil (header) pressure falls. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for. Lube Oil Header Pressure.

From peacecommission.kdsg.gov.ng

Lube Oil Pressure Sensor Lube Oil Header Pressure On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. After completing this module you will be able to: Starting the standby pump is necessary when lube oil (header) pressure falls. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for. Lube Oil Header Pressure.

From mungfali.com

Lube Oil System Diagram Lube Oil Header Pressure Bearing oil or lubricating oil, is commonly driven through the bearings at a stable pressure and utilizes a standard pressure reducing regulator. The lube oil system duty is to provide oil with the designed pressure, temperature, and quality for the bearings, gears, jack oil pumps, etc. A fast response time is essential, and although there are other solutions and configurations.. Lube Oil Header Pressure.

From www.castrol.com

Types, Uses, Benefits, and Uses of Industrial Lubricants CASTROL INDIA Lube Oil Header Pressure A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. To allow the oil film to be formed, the lube oil header pressure should be maintained at 2.8 ksc. Starting the standby pump is necessary when lube oil (header) pressure falls. Bearing oil or lubricating oil,. Lube Oil Header Pressure.

From repairenginegullied99.z13.web.core.windows.net

Engine Oil System Diagram Model A Ford Lube Oil Header Pressure Starting the standby pump is necessary when lube oil (header) pressure falls. It consists of a primary and an auxiliary pump which drive lubricating oil throughout the system. A pressure regulating valve on the main lube oil header maintains proper oil pressure by dumping excess oil back to the lube oil sump. The separate lube oil scheme provides the. A. Lube Oil Header Pressure.

From mappingmemories.ca

Contribuir Hacer De alguna manera steam turbine lubrication system Lube Oil Header Pressure Starting the standby pump is necessary when lube oil (header) pressure falls. 10.1 a) explain how the bearing inlet oil pressure is controlled when the oil is supplied by each of the following pumps:. On our ge ms5001 gas turbine, we've observed that the lube oil bearing header pressure is 2.1bar when auxiliary pump (qa) is. A pressure regulating valve. Lube Oil Header Pressure.