Press Brake Die Size . Unless you’re calculating the exact values for the die opening, you should. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. Note that this is the entire die body width, not. — the narrow punch. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate terminology to describe them. It is much narrower along its entire length. Select the right die opening. — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. — rule no. The press brake die, typically found on the lower side, is where the sheet metal gets pressed into, forming.

from www.youtube.com

This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. Unless you’re calculating the exact values for the die opening, you should. It is much narrower along its entire length. Note that this is the entire die body width, not. — rule no. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate terminology to describe them. Select the right die opening. — the narrow punch. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools.

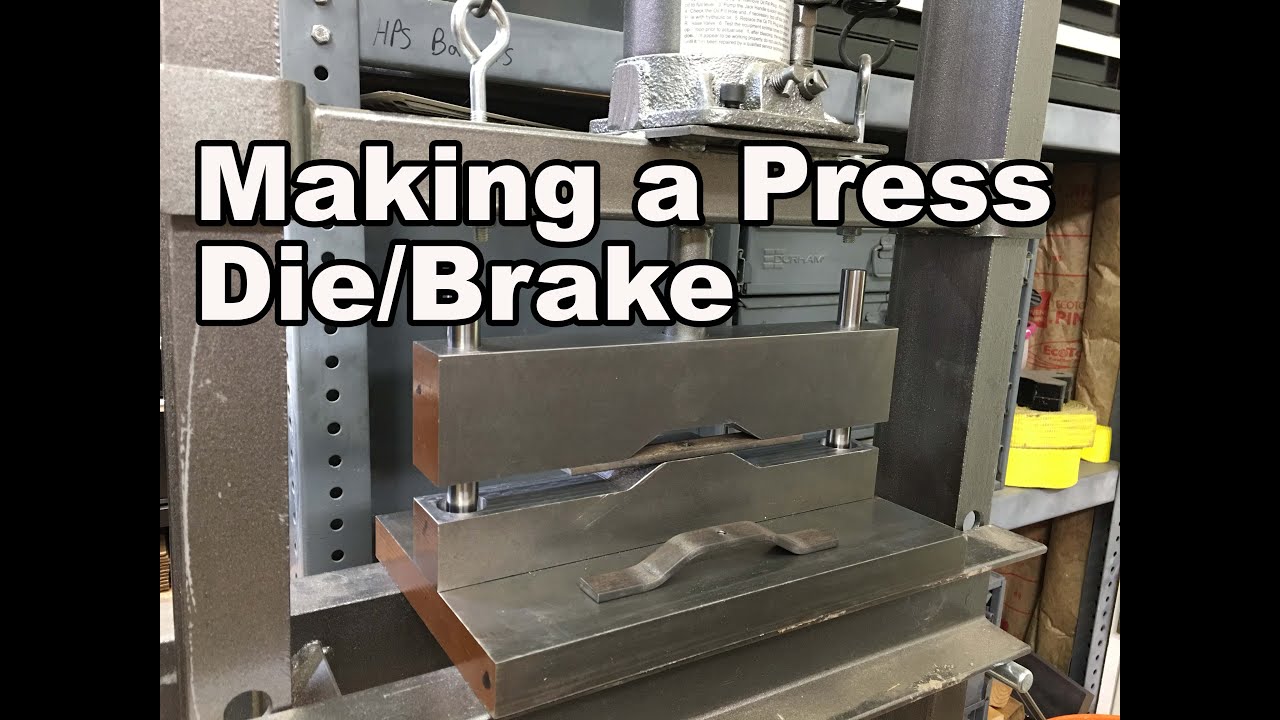

Making a Press Die/Press Brake YouTube

Press Brake Die Size This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. Select the right die opening. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate terminology to describe them. Note that this is the entire die body width, not. The press brake die, typically found on the lower side, is where the sheet metal gets pressed into, forming. Unless you’re calculating the exact values for the die opening, you should. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; — the narrow punch. It is much narrower along its entire length. — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. — rule no. This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape.

From g2000inc.com

12′ 4 Way Press Brake Die G2000 Inc. Press Brake Die Size in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate terminology to describe them. Unless you’re calculating the exact values for the die opening, you should. The narrow punch is the master of tight spaces, in essence it fulfils much the same role. Press Brake Die Size.

From www.adhmt.com

Press Brake Die Material A Comprehensive Guide ADH Machine Tool Press Brake Die Size This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; — rule no. — selecting the. Press Brake Die Size.

From dxoozeyqs.blob.core.windows.net

Die And Punch For Press Brake at Roberta Glass blog Press Brake Die Size Select the right die opening. — rule no. The press brake die, typically found on the lower side, is where the sheet metal gets pressed into, forming. Unless you’re calculating the exact values for the die opening, you should. — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity. Press Brake Die Size.

From www.rongwinmachinery.com

Buy CNC Press Brakes,Press Brake Tooling,Press Brake Dies prises Press Brake Die Size — the narrow punch. Select the right die opening. Unless you’re calculating the exact values for the die opening, you should. It is much narrower along its entire length. — rule no. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one. Press Brake Die Size.

From www.youtube.com

How to Change Out 4 Way V Die on Press Brake Press Brake Tutorial Press Brake Die Size — the narrow punch. — rule no. Unless you’re calculating the exact values for the die opening, you should. — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. Note that this is the entire die body width, not. The narrow punch is the master. Press Brake Die Size.

From extremehardfacing.com

Large Assortment of Press Brake Dies Extreme Hardfacing & Welding LLC Press Brake Die Size The press brake die, typically found on the lower side, is where the sheet metal gets pressed into, forming. Select the right die opening. — rule no. This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. Note that this is the entire die body. Press Brake Die Size.

From midwestpressbrake.com

Gooseneck Midwest Press Brake Dies Inc. Press Brake Die Size Note that this is the entire die body width, not. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; It is much narrower along its entire length. This guide covers the essential criteria for choosing top punches and lower dies based. Press Brake Die Size.

From jstmt.com

Press Brake Punch And Die Press Brake Die Size in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate terminology to describe them. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; Unless. Press Brake Die Size.

From hogimachine.com

press brake die press brake tool punch die mold manufacturer Press Brake Die Size — the narrow punch. It is much narrower along its entire length. Unless you’re calculating the exact values for the die opening, you should. This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. Select the right die opening. The narrow punch is the master. Press Brake Die Size.

From www.scpressbrake.com

What is Brake Press Dies Minimum Bending Size? Metalforming Press Brake Die Size Note that this is the entire die body width, not. Select the right die opening. This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. Unless you’re calculating the exact values for the die opening, you should. The press brake die, typically found on the lower. Press Brake Die Size.

From inchbyinch.de

INCH Technical English press brake Press Brake Die Size Note that this is the entire die body width, not. Unless you’re calculating the exact values for the die opening, you should. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate terminology to describe them. — selecting the right press brake. Press Brake Die Size.

From www.adhmt.com

Select Toolings for Press Brake 5 Key Points You Must Know ADH Press Brake Die Size — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. — the narrow punch. It is much narrower along its entire length. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies. Press Brake Die Size.

From selmach.com

Press Brake Toolings, A Guide to Punches and Dies Selmach™ Press Brake Die Size Unless you’re calculating the exact values for the die opening, you should. Note that this is the entire die body width, not. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate terminology to describe them. Select the right die opening. —. Press Brake Die Size.

From dxokccjob.blob.core.windows.net

Neoprene Press Brake Dies at Norman Claxton blog Press Brake Die Size — rule no. Unless you’re calculating the exact values for the die opening, you should. Note that this is the entire die body width, not. — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. It is much narrower along its entire length. — the. Press Brake Die Size.

From yafei-machinery.en.made-in-china.com

Multi V Press Brake Dies China Press Brake Tooling and Press Brake Die Press Brake Die Size — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. The narrow punch is the master of tight spaces, in essence it fulfils. Press Brake Die Size.

From www.pressbrakebuyersguide.com

Press Brake Buyer's Guide Cincinnati Inc. Press Brakes Press Brake Die Size Unless you’re calculating the exact values for the die opening, you should. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; It is much narrower along its entire length. — selecting the right press brake punch and die is crucial. Press Brake Die Size.

From www.machinesused.com

Machines Used Press Brake Dies Assorted Press Brake Die Size Unless you’re calculating the exact values for the die opening, you should. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; — rule no. — the narrow punch. in this article, we will introduce the press brake dies. Press Brake Die Size.

From www.thefabricator.com

The (really) basic basics of press brake tooling Press Brake Die Size Note that this is the entire die body width, not. — the narrow punch. Unless you’re calculating the exact values for the die opening, you should. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; This guide covers the essential. Press Brake Die Size.

From www.youtube.com

Making a Press Die/Press Brake YouTube Press Brake Die Size Unless you’re calculating the exact values for the die opening, you should. It is much narrower along its entire length. — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. Select the right die opening. in this article, we will introduce the press brake dies used. Press Brake Die Size.

From alukemt.en.made-in-china.com

Press Brake Die with Adjustable Function China Press Brake Die and Press Brake Die Size This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. — the narrow punch. Note that this is the entire die body width, not. It is much narrower along its entire length. — selecting the right press brake punch and die is crucial for. Press Brake Die Size.

From www.mullinmachinery.com

Press Brake Dies Large Capacity Mullin Machinery Press Brake Die Size Select the right die opening. — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate terminology to describe them. It. Press Brake Die Size.

From www.primalasercut.com

Wila Press Brake Die wila type press brake tooling press brake bending Press Brake Die Size This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. Select the right die opening. — rule no. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important. Press Brake Die Size.

From www.china-prima.com

bending machine Multi V Blocks Hydraulic Press Brake Dies Tooling for Press Brake Die Size — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate terminology to describe them. Note that this is the entire. Press Brake Die Size.

From mfmachinery.com

Press brake punch and die selection_Maanshan MF Heavy Machinery Co.,Ltd. Press Brake Die Size — rule no. Unless you’re calculating the exact values for the die opening, you should. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; in this article, we will introduce the press brake dies used in press brake machines,. Press Brake Die Size.

From www.machinesused.com

Machines Used Large Assortment of Press Brake Dies with Rack Press Brake Die Size Note that this is the entire die body width, not. It is much narrower along its entire length. Unless you’re calculating the exact values for the die opening, you should. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate terminology to describe. Press Brake Die Size.

From www.youtube.com

3D Printed **Press Brake Dies* *That Really Work** YouTube Press Brake Die Size Select the right die opening. Note that this is the entire die body width, not. — the narrow punch. Unless you’re calculating the exact values for the die opening, you should. It is much narrower along its entire length. — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity. Press Brake Die Size.

From www.canadianmetalworking.com

Press Brake Tooling Designed in LVD Style Press Brake Die Size — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. Unless you’re calculating the exact values for the die opening, you should. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and. Press Brake Die Size.

From www.powerbrakedies.com

FAQ — Power Brake Dies Press Brake Die Size Unless you’re calculating the exact values for the die opening, you should. — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. The press brake die, typically found on the lower side, is where the sheet metal gets pressed into, forming. Note that this is the entire. Press Brake Die Size.

From selmach.com

Press Brake Toolings, A Guide to Punches and Dies Selmach™ Press Brake Die Size This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. Note that this is the entire die body width, not. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one. Press Brake Die Size.

From www.cnstamp.net

30 Degree Press brake DieCnstamp Press Brake Die Size Unless you’re calculating the exact values for the die opening, you should. The narrow punch is the master of tight spaces, in essence it fulfils much the same role as its standard and acute companions, but with one important difference; This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material. Press Brake Die Size.

From www.prima-press.com

bending machine Multi V Blocks Hydraulic Press Brake Dies Tooling for Press Brake Die Size Unless you’re calculating the exact values for the die opening, you should. Select the right die opening. The press brake die, typically found on the lower side, is where the sheet metal gets pressed into, forming. Note that this is the entire die body width, not. — selecting the right press brake punch and die is crucial for achieving. Press Brake Die Size.

From www.machinemfg.com

Press Brake Dies (Toolings) The Ultimate Guide MachineMfg Press Brake Die Size — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. Select the right die opening. — the narrow punch. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate. Press Brake Die Size.

From www.budsmt.com

Press Brake Die Press Brake Die Size This guide covers the essential criteria for choosing top punches and lower dies based on factors like bending force, material thickness, and punch shape. — rule no. Select the right die opening. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the appropriate. Press Brake Die Size.

From www.machines4u.com.au

New cmt MULTI VEE PRESS BRAKE BOTTOM DIES 100 120 150MM SQ 3 4M LENGTHS Press Brake Die Size Note that this is the entire die body width, not. — the narrow punch. The press brake die, typically found on the lower side, is where the sheet metal gets pressed into, forming. in this article, we will introduce the press brake dies used in press brake machines, discussing the different types of press brake dies and the. Press Brake Die Size.

From www.machinemfg.com

The Ultimate Press Brake Dies Guide for Precision Bending MachineMFG Press Brake Die Size — selecting the right press brake punch and die is crucial for achieving precise bends and ensuring the longevity of your tools. The press brake die, typically found on the lower side, is where the sheet metal gets pressed into, forming. Unless you’re calculating the exact values for the die opening, you should. It is much narrower along its. Press Brake Die Size.