Vsm Example Manufacturing . In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. Originating from the principles of lean. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the.

from www.cnccookbook.com

Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Originating from the principles of lean. Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history

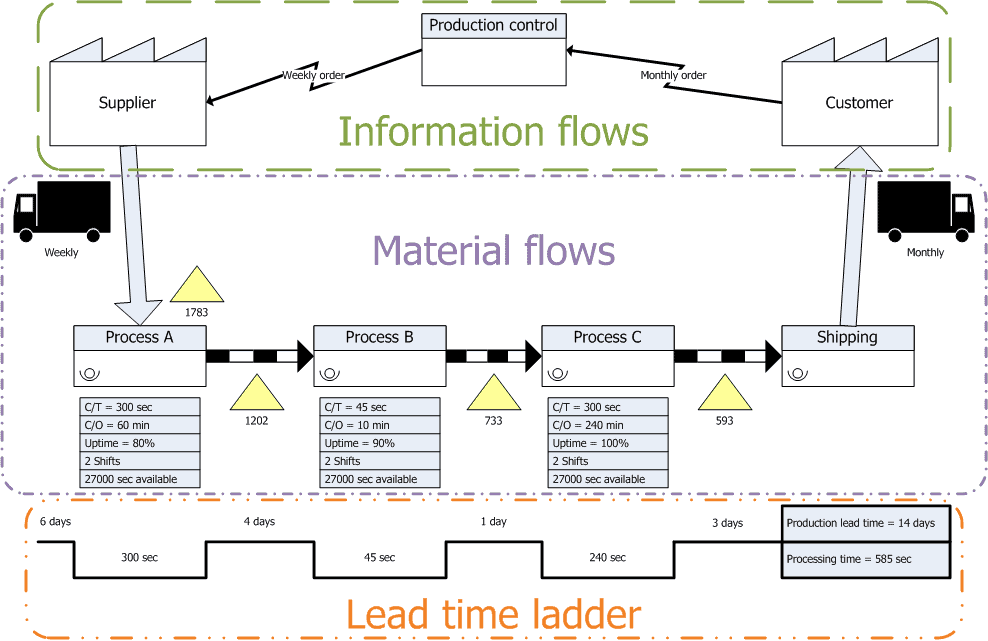

Value Stream Mapping Lean Manufacturing Principles Part 4

Vsm Example Manufacturing Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Originating from the principles of lean. Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the.

From dl-uk.apowersoft.com

Value Stream Mapping Template Excel Free Vsm Example Manufacturing Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Originating from the principles of lean. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Creating an ideal state vsm value stream mapping (vsm) is a lean. Vsm Example Manufacturing.

From slidemodel.com

Value Stream Mapping Tool Template SlideModel Vsm Example Manufacturing Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process. Vsm Example Manufacturing.

From alexsibaja.blogspot.com

Lean Manufacturing & Six Sigma junio 2014 Vsm Example Manufacturing Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement. Vsm Example Manufacturing.

From www.conceptdraw.com

Value stream map example Value stream mapping diagram Value Stream Vsm Example Manufacturing Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Originating from the principles of lean. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Helping us recognize how value flows and think of ways to improve. Vsm Example Manufacturing.

From www.conceptdraw.com

The Value Stream Mapping Process Value Stream Mapping Software Vsm Example Manufacturing In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of. Vsm Example Manufacturing.

From www.congress-intercultural.eu

Vsm Templates Editable Online Or Download For Free Creately, 47 OFF Vsm Example Manufacturing Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Creating an ideal state. Vsm Example Manufacturing.

From mosimtec.com

Value Stream Mapping Examples for Different Industries MOSIMTEC Vsm Example Manufacturing Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Value stream mapping (vsm) is a powerful tool that is used to. Vsm Example Manufacturing.

From www.conceptdraw.com

Value Stream Mapping How to Create a VSM Diagram Using Solutions Vsm Example Manufacturing Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. In this comprehensive guide, we’ll dive into the ins and outs of. Vsm Example Manufacturing.

From blog.hubspot.com

Value Stream Mapping (VSM) 6 Steps to Improve Sales & Operations Vsm Example Manufacturing Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Originating from the principles of lean. In this comprehensive guide, we’ll dive into the. Vsm Example Manufacturing.

From monroe.com.au

What Is A Value Stream Map Amp Why Is One Important I Nexus Riset Vsm Example Manufacturing In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Originating from the principles of lean. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing. Vsm Example Manufacturing.

From www.smartdraw.com

Value Stream Mapping Software VSM Tools, Online App and Download Vsm Example Manufacturing Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. Originating from the principles of lean. Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Value stream mapping (vsm). Vsm Example Manufacturing.

From www.micoope.com.gt

Value Stream Mapping (VSM) Guide For Manufacturing Leaders, 51 OFF Vsm Example Manufacturing Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Helping us recognize how value flows and think of ways to improve. Vsm Example Manufacturing.

From cd.foundation

From Harness ValueStream Mapping (VSM) Your Software Delivery CD Vsm Example Manufacturing In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer,. Vsm Example Manufacturing.

From alexsibaja.blogspot.mx

Lean Manufacturing & Six Sigma Material and Information Flow Mapping Vsm Example Manufacturing Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. In this comprehensive guide, we’ll dive into the ins and outs of. Vsm Example Manufacturing.

From www.bank2home.com

Lean Manufacturing Value Stream Mapping Vsm Example Manufacturing Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Originating from the principles of lean. Helping us recognize how value flows. Vsm Example Manufacturing.

From www.conceptdraw.com

Lean Manufacturing Diagrams Value Stream Mapping Software Vsm Example Manufacturing Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Creating an ideal state vsm value stream mapping (vsm) is a lean. Vsm Example Manufacturing.

From www.cnccookbook.com

Value Stream Mapping Lean Manufacturing Principles Part 4 Vsm Example Manufacturing Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Helping us recognize how value flows and think of ways to improve it as. Vsm Example Manufacturing.

From creately.com

Value Stream Mapping Templates to Quickly Analyze Your Workflows Vsm Example Manufacturing Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Helping us recognize how value flows and think of ways to improve it as well as spot the. Vsm Example Manufacturing.

From www.reliableplant.com

Value Stream Mapping Details and Examples Reliable Plant Vsm Example Manufacturing Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. Originating from the principles of lean. In this comprehensive guide,. Vsm Example Manufacturing.

From rowher.saisonsdumonde.fr

Manufacturing Value Stream Map Vsm Example Manufacturing Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map. Vsm Example Manufacturing.

From leanmanufacturingupdate.com

Value Stream Mapping Information Flow Vsm Example Manufacturing Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including. Vsm Example Manufacturing.

From blog.imec.org

A Practical Guide to Value Stream Mapping Part 1 of 5 Vsm Example Manufacturing Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. In this comprehensive guide, we’ll dive into the ins and outs of. Vsm Example Manufacturing.

From mungfali.com

Value Stream Mapping Logo Vsm Example Manufacturing In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of. Vsm Example Manufacturing.

From mungfali.com

Ejemplos De VSM Vsm Example Manufacturing In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Originating from the principles of lean. Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Value stream mapping (vsm) is a transformative lean management tool that serves. Vsm Example Manufacturing.

From www.pinterest.com.mx

Value Stream Map Examples for review and comparison After 4 posts about Vsm Example Manufacturing In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Originating from the principles of lean. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Helping us recognize how value flows and think of ways to improve it as well as spot the. Vsm Example Manufacturing.

From medium.com

The Ultimate Guide to Value Stream Mapping Thousand Words by Creately Vsm Example Manufacturing Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of. Vsm Example Manufacturing.

From sixsigmadsi.com

Lean Six Sigma Value Stream Map Online Training Vsm Example Manufacturing Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Originating from the principles of lean. Value stream mapping (vsm) is a transformative lean management tool that serves. Vsm Example Manufacturing.

From alexsibaja.blogspot.com

Lean Manufacturing & Six Sigma Quick guidelines to Identify Typical Vsm Example Manufacturing Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. In this comprehensive guide, we’ll dive into the ins and outs of. Vsm Example Manufacturing.

From sixsigmadsi.blogspot.com

Blog Six Sigma Development Solutions, Inc. Value Stream Map in 10 Vsm Example Manufacturing Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process. Vsm Example Manufacturing.

From kyloot.com

Value Stream Mapping (VSM) Tutorial with Examples & Tips (2022) Vsm Example Manufacturing Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times,. Vsm Example Manufacturing.

From blog.hubspot.com

Value Stream Mapping (VSM) 6 Steps to Improve Sales & Operations Vsm Example Manufacturing Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Originating from the principles of lean. Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. Value stream mapping (vsm) is a. Vsm Example Manufacturing.

From www.semanticscholar.org

Figure 1 from VALUE STREAM MAPPING ( VSM ) IN CONSTRUCTION INDUSTRY Vsm Example Manufacturing In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. Originating from the principles of lean. Helping us recognize how value flows and think of ways to improve it as well as spot the. Vsm Example Manufacturing.

From www.mbizm.com

Lean Six Sigma Tools Streamline, Improve and Optimize Vsm Example Manufacturing In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Helping us recognize how value flows and think of ways to improve it as well as spot the sources of waste and think of ways to eliminate it. Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process. Vsm Example Manufacturing.

From sixsigmadsi.com

10 Easy Steps to Complete a Value Stream Map (VSM) Vsm Example Manufacturing Many lean practitioners use value stream mapping as a fundamental tool to identify waste, cut process cycle times, and implement process improvement. In this comprehensive guide, we’ll dive into the ins and outs of vsm, including its history Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Helping us. Vsm Example Manufacturing.

From leanmanufacturingtools.org

VSM Value Stream Mapping Vsm Example Manufacturing Creating an ideal state vsm value stream mapping (vsm) is a lean manufacturing tool that seeks to map your process from supplier to customer, highlighting the. Value stream mapping (vsm) is a transformative lean management tool that serves as a critical component in enhancing operational efficiency. Originating from the principles of lean. Helping us recognize how value flows and think. Vsm Example Manufacturing.