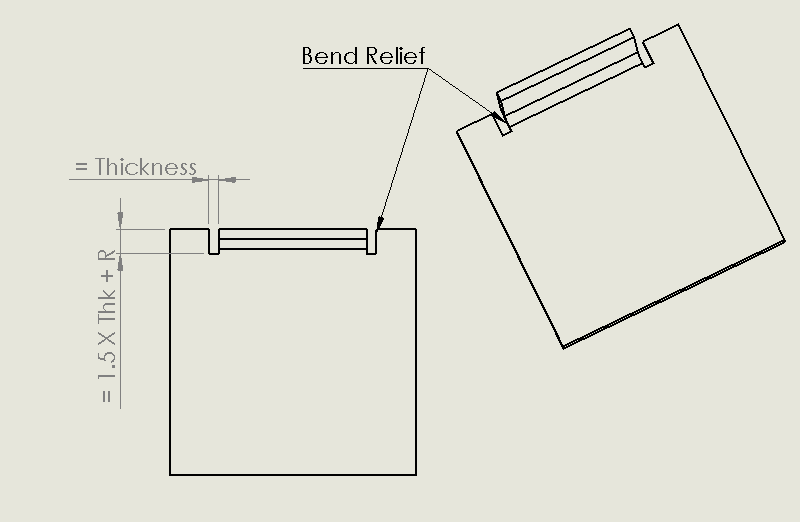

Sheet Metal Bend To Hole Distance . to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. Recommended inside bend radius for sheet metal parts. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. Minimum inside bend radius for sheet metal parts. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending.

from smlease.com

Minimum inside bend radius for sheet metal parts. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Recommended inside bend radius for sheet metal parts. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers.

Sheetmetal Design Guidelines SMLease Design SMLease Design

Sheet Metal Bend To Hole Distance to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. Recommended inside bend radius for sheet metal parts. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Minimum inside bend radius for sheet metal parts. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers.

From www.vowin.cn

A Designer’s Guide For Ensuring The Manufacturability Of Sheet Metal Sheet Metal Bend To Hole Distance bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Minimum inside bend radius for sheet metal parts. in most. Sheet Metal Bend To Hole Distance.

From www.youtube.com

Exploring Sheet Metal Bending YouTube Sheet Metal Bend To Hole Distance Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Recommended inside bend radius for sheet metal parts. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. Sheet metal bending should be as close to perpendicular as possible to. Sheet Metal Bend To Hole Distance.

From xometry.eu

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe Sheet Metal Bend To Hole Distance Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into. Sheet Metal Bend To Hole Distance.

From forum.onshape.com

Hole through sheet metal bend. — Onshape Sheet Metal Bend To Hole Distance Recommended inside bend radius for sheet metal parts. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from. Sheet Metal Bend To Hole Distance.

From robu.in

Sheet Metal Design Basics in 2021 Complete List of Things Sheet Metal Bend To Hole Distance bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. Recommended inside bend radius for sheet. Sheet Metal Bend To Hole Distance.

From www.mech4study.com

Different Sheet Metal Bending Process Mech4study Sheet Metal Bend To Hole Distance Recommended inside bend radius for sheet metal parts. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1). Sheet Metal Bend To Hole Distance.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bend To Hole Distance bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Recommended inside bend radius for sheet metal parts. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. Sheet metal fabrication is. Sheet Metal Bend To Hole Distance.

From ar.inspiredpencil.com

Sheet Metal Bending Techniques Sheet Metal Bend To Hole Distance bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Minimum inside bend radius for sheet metal parts. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Sheet metal bending. Sheet Metal Bend To Hole Distance.

From www.vowin.cn

A Designer’s Guide For Ensuring The Manufacturability Of Sheet Metal Sheet Metal Bend To Hole Distance Recommended inside bend radius for sheet metal parts. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. bending is a fundamental process in sheet metal working that involves deforming a metal. Sheet Metal Bend To Hole Distance.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bend To Hole Distance to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. Sheet metal fabrication is the process of forming parts from a metal sheet by punching,. Sheet Metal Bend To Hole Distance.

From dfmpro.geometricglobal.com

DFMPro provides Sheet Metal Design Guidelines Sheet Metal Bend To Hole Distance Minimum inside bend radius for sheet metal parts. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Recommended inside bend radius for sheet metal parts. Sheet metal bending should. Sheet Metal Bend To Hole Distance.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend To Hole Distance Recommended inside bend radius for sheet metal parts. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: to avoid workpiece. Sheet Metal Bend To Hole Distance.

From in.pinterest.com

Engineering First Principles (engineering_first_principles) en Sheet Metal Bend To Hole Distance Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Recommended inside bend radius for sheet metal parts. Sheet metal fabrication is. Sheet Metal Bend To Hole Distance.

From dfmpro.com

Sheet Metal Design Guidelines DFMPro Sheet Metal Bend To Hole Distance Minimum inside bend radius for sheet metal parts. Recommended inside bend radius for sheet metal parts. Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. in most cases, minimum hole bend. Sheet Metal Bend To Hole Distance.

From exoiwwdme.blob.core.windows.net

How To Bend Aluminum Sheet at Jan McElhaney blog Sheet Metal Bend To Hole Distance to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. Sheet metal bending should be as close to perpendicular as possible to the direction of. Sheet Metal Bend To Hole Distance.

From localrevive.com

Sheet Metal Fabrication 101 A Basic Knowledge Guide RapidDirect Blog Sheet Metal Bend To Hole Distance Recommended inside bend radius for sheet metal parts. Minimum inside bend radius for sheet metal parts. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the. Sheet Metal Bend To Hole Distance.

From unitymanufacture.com

How To Bend A Radius In Sheet Metal? Unity Manufacture Sheet Metal Bend To Hole Distance Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1). Sheet Metal Bend To Hole Distance.

From grabcad.com

sheet metal bend relief kerf for holes Sheet Metal Design GrabCAD Sheet Metal Bend To Hole Distance Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into. Sheet Metal Bend To Hole Distance.

From sendcutsend.com

Step By Step Guide To Sheet Metal Bending SendCutSend Sheet Metal Bend To Hole Distance Recommended inside bend radius for sheet metal parts. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Minimum inside bend radius for sheet metal parts. Sheet metal fabrication is the process of forming parts from a metal sheet by. Sheet Metal Bend To Hole Distance.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend To Hole Distance Recommended inside bend radius for sheet metal parts. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. Minimum inside bend radius for sheet metal parts. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. to avoid workpiece failure,. Sheet Metal Bend To Hole Distance.

From exozzueaq.blob.core.windows.net

Sheet Metal Bend Radius Calculator at Horace Winfield blog Sheet Metal Bend To Hole Distance Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. Recommended inside bend radius for sheet metal parts. bending is a fundamental process in sheet metal working. Sheet Metal Bend To Hole Distance.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend To Hole Distance Recommended inside bend radius for sheet metal parts. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a. Sheet Metal Bend To Hole Distance.

From www.smlease.com

Sheet Metal Design Guidelines How to Design Good Sheet Metal Parts Sheet Metal Bend To Hole Distance Minimum inside bend radius for sheet metal parts. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. bending is a fundamental process in. Sheet Metal Bend To Hole Distance.

From exozzueaq.blob.core.windows.net

Sheet Metal Bend Radius Calculator at Horace Winfield blog Sheet Metal Bend To Hole Distance Minimum inside bend radius for sheet metal parts. Recommended inside bend radius for sheet metal parts. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools. Sheet Metal Bend To Hole Distance.

From metalscut4u.com

How To Bend Sheet Metal The Ultimate Guide Sheet Metal Bend To Hole Distance bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. in most cases, minimum hole bend distance equals 1.5 times. Sheet Metal Bend To Hole Distance.

From exoiwczss.blob.core.windows.net

Sheet Metal Bending K Factor Calculator at Jack Gautier blog Sheet Metal Bend To Hole Distance bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Recommended inside bend radius for sheet metal parts. to avoid. Sheet Metal Bend To Hole Distance.

From smlease.com

Sheetmetal Design Guidelines SMLease Design SMLease Design Sheet Metal Bend To Hole Distance to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. Minimum inside bend radius for sheet metal parts. Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. bending is a fundamental process in sheet metal working. Sheet Metal Bend To Hole Distance.

From exofbscwe.blob.core.windows.net

Sheet Metal Bend Height at Brandy Richards blog Sheet Metal Bend To Hole Distance Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Recommended inside bend radius for sheet metal parts. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1). Sheet Metal Bend To Hole Distance.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bend To Hole Distance bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. in most cases, minimum hole. Sheet Metal Bend To Hole Distance.

From artizono.com

Guide To Calculating Unfolded Dimensions For Sheet Metal Bending Artizono Sheet Metal Bend To Hole Distance Recommended inside bend radius for sheet metal parts. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. in most. Sheet Metal Bend To Hole Distance.

From www.javelin-tech.com

Learn Sheet Metal Design Terminology including Bend Deduction Sheet Metal Bend To Hole Distance to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Sheet metal fabrication is the process. Sheet Metal Bend To Hole Distance.

From www.thefabricator.com

What to know about sheet metal bend radius and minimum flange Sheet Metal Bend To Hole Distance Minimum inside bend radius for sheet metal parts. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. to avoid workpiece failure, dfm guidelines recommend a minimum distance (d1) from hole to the sheet edge equal to at least the plate. Recommended inside bend radius for sheet metal. Sheet Metal Bend To Hole Distance.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bend To Hole Distance Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. Recommended inside bend radius for sheet metal parts. in most cases, minimum hole bend distance equals 1.5 times sheet thickness plus bend radius, though the multiplying factor may. bending is a fundamental process in sheet metal working that involves deforming. Sheet Metal Bend To Hole Distance.

From exoxvrmdk.blob.core.windows.net

Sheet Metal Cut Length Calculator at Carolyn Lewis blog Sheet Metal Bend To Hole Distance Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: Sheet metal fabrication is the process of forming parts from a metal. Sheet Metal Bend To Hole Distance.

From www.thelibraryofmanufacturing.com

Sheet Metal Bending Sheet Metal Bend To Hole Distance Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. Minimum inside bend radius for sheet metal parts. bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: in most. Sheet Metal Bend To Hole Distance.