Water Chiller Components . In this system, water is circulated through the condenser to remove heat from the refrigerant A) compressor, b) condenser, c). In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. The water chiller system diagram illustrates the various components that make up a typical water chiller system. Centralized equipment uses more efficient, larger motors. A chiller is made up of the 4 major components required for the refrigeration process which are: These components work together to cool and circulate water to. As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process:

from schematiclibruttish101.z21.web.core.windows.net

Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: The water chiller system diagram illustrates the various components that make up a typical water chiller system. A chiller is made up of the 4 major components required for the refrigeration process which are: These components work together to cool and circulate water to. In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. In this system, water is circulated through the condenser to remove heat from the refrigerant A) compressor, b) condenser, c). Centralized equipment uses more efficient, larger motors.

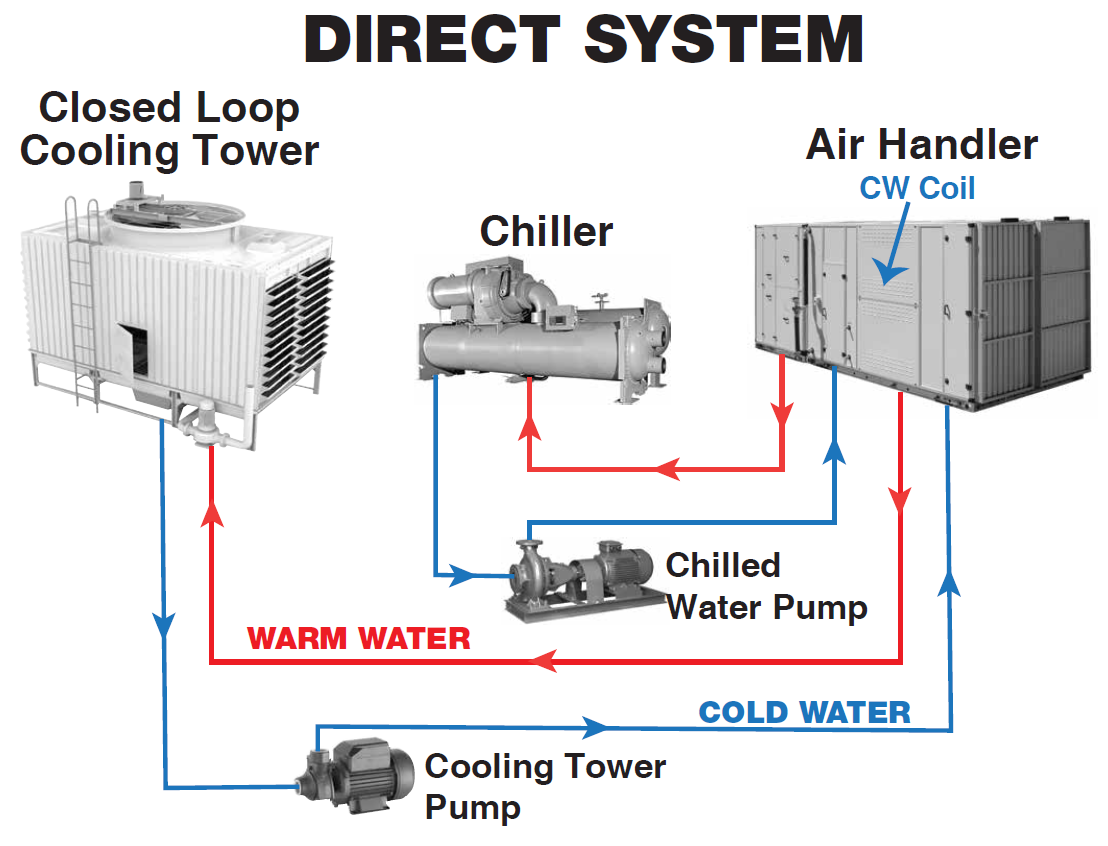

Closed Loop Cooling Tower Piping Schematic

Water Chiller Components Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. Centralized equipment uses more efficient, larger motors. Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. A) compressor, b) condenser, c). The water chiller system diagram illustrates the various components that make up a typical water chiller system. As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: In this system, water is circulated through the condenser to remove heat from the refrigerant These components work together to cool and circulate water to. A chiller is made up of the 4 major components required for the refrigeration process which are:

From jmxiecheng.en.made-in-china.com

Water Chiller Components/Standing Chiller with Chiller Temperature Water Chiller Components The water chiller system diagram illustrates the various components that make up a typical water chiller system. A chiller is made up of the 4 major components required for the refrigeration process which are: In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. These components work together to. Water Chiller Components.

From ar.inspiredpencil.com

Water Cooled Chiller Working Principle Water Chiller Components In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. A chiller is made up of the 4 major components required for the refrigeration process which are: A) compressor, b) condenser, c). As we covered in our previous blog article, the following are the main components of process chillers. Water Chiller Components.

From www.carrier.com

AquaEdge® 19XR HighEfficiency SemiHermetic Centrifugal Chiller Water Chiller Components Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. A chiller is made up of the 4 major components required for the refrigeration process which are: These components work together to cool and circulate water to. In this system, water is circulated through the condenser to remove heat. Water Chiller Components.

From hvactrainingshop.com

How a Chilled Water System Works HVAC Training Shop Water Chiller Components As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: Centralized equipment uses more efficient, larger motors. In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. A) compressor, b) condenser, c). The water. Water Chiller Components.

From www.skillcatapp.com

Aircooled Chiller & Watercooled Chiller Startup Procedures Water Chiller Components A) compressor, b) condenser, c). A chiller is made up of the 4 major components required for the refrigeration process which are: The water chiller system diagram illustrates the various components that make up a typical water chiller system. Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air.. Water Chiller Components.

From www.carrier.com

AquaSnap® 30MP Indoor WaterCooled/Condenserless Liquid Chiller Water Chiller Components A) compressor, b) condenser, c). In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. A chiller is made up of the 4 major components required for the refrigeration process which are: Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including. Water Chiller Components.

From industrial.ph

Water Chiller Philippines Industrial PH Water Chiller Components Centralized equipment uses more efficient, larger motors. A chiller is made up of the 4 major components required for the refrigeration process which are: Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. As we covered in our previous blog article, the following are the main components of. Water Chiller Components.

From www.carrier.com

AquaEdge® 19DV WaterCooled Centrifugal Chiller Carrier Commercial Water Chiller Components The water chiller system diagram illustrates the various components that make up a typical water chiller system. Centralized equipment uses more efficient, larger motors. In this system, water is circulated through the condenser to remove heat from the refrigerant A chiller is made up of the 4 major components required for the refrigeration process which are: Key system components include. Water Chiller Components.

From www.researchgate.net

Watercooled chiller diagram and the measurement points. Download Water Chiller Components Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. In this system, water is circulated through the condenser to remove heat from the refrigerant A) compressor, b) condenser, c). As we covered in our previous blog article, the following are the main components of process chillers and how. Water Chiller Components.

From www.carrier.com

AquaEdge® 19DV WaterCooled Centrifugal Chiller Carrier Commercial Water Chiller Components These components work together to cool and circulate water to. Centralized equipment uses more efficient, larger motors. A) compressor, b) condenser, c). In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. As we covered in our previous blog article, the following are the main components of process chillers. Water Chiller Components.

From www.electrical-knowhow.com

Electrical Wiring Diagrams for Air Conditioning Systems Part Three Water Chiller Components Centralized equipment uses more efficient, larger motors. The water chiller system diagram illustrates the various components that make up a typical water chiller system. As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: A) compressor, b) condenser, c). A chiller is made up of. Water Chiller Components.

From hvactechguide.com

Chiller components & their working HVAC & Engineering Water Chiller Components Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. In this system, water is circulated through the condenser to remove heat from the refrigerant The water chiller system diagram illustrates the various components that make up a typical water chiller system. These components work together to cool and. Water Chiller Components.

From www.youtube.com

Components of Chiller & Chilled water System YouTube Water Chiller Components The water chiller system diagram illustrates the various components that make up a typical water chiller system. These components work together to cool and circulate water to. In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. In this system, water is circulated through the condenser to remove heat. Water Chiller Components.

From instrumentationtools.com

HVAC Water Chillers Principle Inst Tools Water Chiller Components These components work together to cool and circulate water to. Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. A) compressor, b) condenser, c). Centralized equipment uses. Water Chiller Components.

From hvactechguide.com

Chiller components & their working HVAC & Engineering Water Chiller Components As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: The water chiller system diagram illustrates the various components that make up a typical water chiller system. These components work together to cool and circulate water to. Key system components include chilled and condenser water. Water Chiller Components.

From www.pinnaxis.com

Chiller Components Their Working HVAC Engineering, 48 OFF Water Chiller Components In this system, water is circulated through the condenser to remove heat from the refrigerant A) compressor, b) condenser, c). The water chiller system diagram illustrates the various components that make up a typical water chiller system. A chiller is made up of the 4 major components required for the refrigeration process which are: These components work together to cool. Water Chiller Components.

From www.senho-chiller.com

Air Cooled Water Chillers, Air Cooled Type Chillers丨Senho Chiller Water Chiller Components Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. Centralized equipment uses more efficient, larger motors. A) compressor, b) condenser, c). As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: The water. Water Chiller Components.

From ar.inspiredpencil.com

Water Cooled Chiller Working Principle Water Chiller Components A) compressor, b) condenser, c). In this system, water is circulated through the condenser to remove heat from the refrigerant As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: In summary, a chiller consists of several key components, including the compressor, condenser, chilled water. Water Chiller Components.

From www.carrier.com

AquaEdge® 23XRV HighEfficiency VariableSpeed Screw Chiller Water Chiller Components These components work together to cool and circulate water to. Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. In this system, water is circulated through the condenser to remove heat from the refrigerant The water chiller system diagram illustrates the various components that make up a typical. Water Chiller Components.

From www.researchgate.net

Schematic diagram of chiller components and refrigerant flow paths Water Chiller Components As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: These components work together to cool and circulate water to. The water chiller system diagram illustrates the various components that make up a typical water chiller system. Centralized equipment uses more efficient, larger motors. Key. Water Chiller Components.

From theengineeringmindset.com

How Air Cooled Chillers Work The Engineering Mindset Water Chiller Components A chiller is made up of the 4 major components required for the refrigeration process which are: Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. In this system, water is circulated through the condenser to remove heat from the refrigerant A) compressor, b) condenser, c). The water. Water Chiller Components.

From www.scribd.com

Water Chiller Components Water Chiller Components A chiller is made up of the 4 major components required for the refrigeration process which are: These components work together to cool and circulate water to. As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: In summary, a chiller consists of several key. Water Chiller Components.

From www.electrician-1.com

on video Air cooled chiller parts name and workwhat components use in Water Chiller Components Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. A) compressor, b) condenser, c). As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: A chiller is made up of the 4 major. Water Chiller Components.

From www.youtube.com

Air Cooled & Water Cooled Chiller's and Major Components HVAC SYSTEM Water Chiller Components A) compressor, b) condenser, c). In this system, water is circulated through the condenser to remove heat from the refrigerant As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: A chiller is made up of the 4 major components required for the refrigeration process. Water Chiller Components.

From www.carrier.com

AquaEdge® 19XR HighEfficiency SemiHermetic Centrifugal Chiller Water Chiller Components Centralized equipment uses more efficient, larger motors. Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. These components work together to cool and circulate water to. In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. A. Water Chiller Components.

From reg.expobde.com

Water Chiller Components/Standing Chiller with Chiller Temperature Water Chiller Components A chiller is made up of the 4 major components required for the refrigeration process which are: As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: Centralized equipment uses more efficient, larger motors. In this system, water is circulated through the condenser to remove. Water Chiller Components.

From mavink.com

Air Cooled Chiller Components Water Chiller Components As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: A) compressor, b) condenser, c). The water chiller system diagram illustrates the various components that make up a typical water chiller system. Key system components include chilled and condenser water pumps, cooling towers, heat exchangers,. Water Chiller Components.

From wensui1990.en.made-in-china.com

2024 Hot Selling Water Components/Standing Chiller with Chiller Water Chiller Components These components work together to cool and circulate water to. Centralized equipment uses more efficient, larger motors. A chiller is made up of the 4 major components required for the refrigeration process which are: A) compressor, b) condenser, c). In this system, water is circulated through the condenser to remove heat from the refrigerant In summary, a chiller consists of. Water Chiller Components.

From schematiclibruttish101.z21.web.core.windows.net

Closed Loop Cooling Tower Piping Schematic Water Chiller Components These components work together to cool and circulate water to. Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. In this system, water is circulated through the condenser to remove heat from the refrigerant Centralized equipment uses more efficient, larger motors. A) compressor, b) condenser, c). In summary,. Water Chiller Components.

From www.hvacinvestigators.com

WaterCooled Chiller Diagram HVAC Investigators Water Chiller Components In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. As we covered in our previous blog article, the following are the main components of process chillers and how they contribute to the cooling process: In this system, water is circulated through the condenser to remove heat from the. Water Chiller Components.

From www.carrier.com

AquaEdge® 19DV WaterCooled Centrifugal Chiller Carrier Commercial Water Chiller Components The water chiller system diagram illustrates the various components that make up a typical water chiller system. Centralized equipment uses more efficient, larger motors. In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. A) compressor, b) condenser, c). As we covered in our previous blog article, the following. Water Chiller Components.

From www.senho-chiller.com

Industrial Water Chiller Manufacturers Industrial Water Chiller SENHO Water Chiller Components Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. These components work together to cool and circulate water to. In this system, water is circulated through the. Water Chiller Components.

From hvac-system-basics.blogspot.com

HVAC System , HVAC Water Chillers,Valves and Pumps Water Chiller Components These components work together to cool and circulate water to. A) compressor, b) condenser, c). Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. The water chiller system diagram illustrates the various components that make up a typical water chiller system. A chiller is made up of the. Water Chiller Components.

From www.carrier.com

AquaSnap® 30RB AirCooled Liquid Chiller with Greenspeed® Intelligence Water Chiller Components In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. The water chiller system diagram illustrates the various components that make up a typical water chiller system. Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. These. Water Chiller Components.

From www.carrier.com

AquaForce® 30XA AirCooled Screw Chiller Water Chiller Components In summary, a chiller consists of several key components, including the compressor, condenser, chilled water pump, evaporator, expansion valve, and control. Key system components include chilled and condenser water pumps, cooling towers, heat exchangers, and hydronic specialties including water pressure regulators, air. In this system, water is circulated through the condenser to remove heat from the refrigerant Centralized equipment uses. Water Chiller Components.