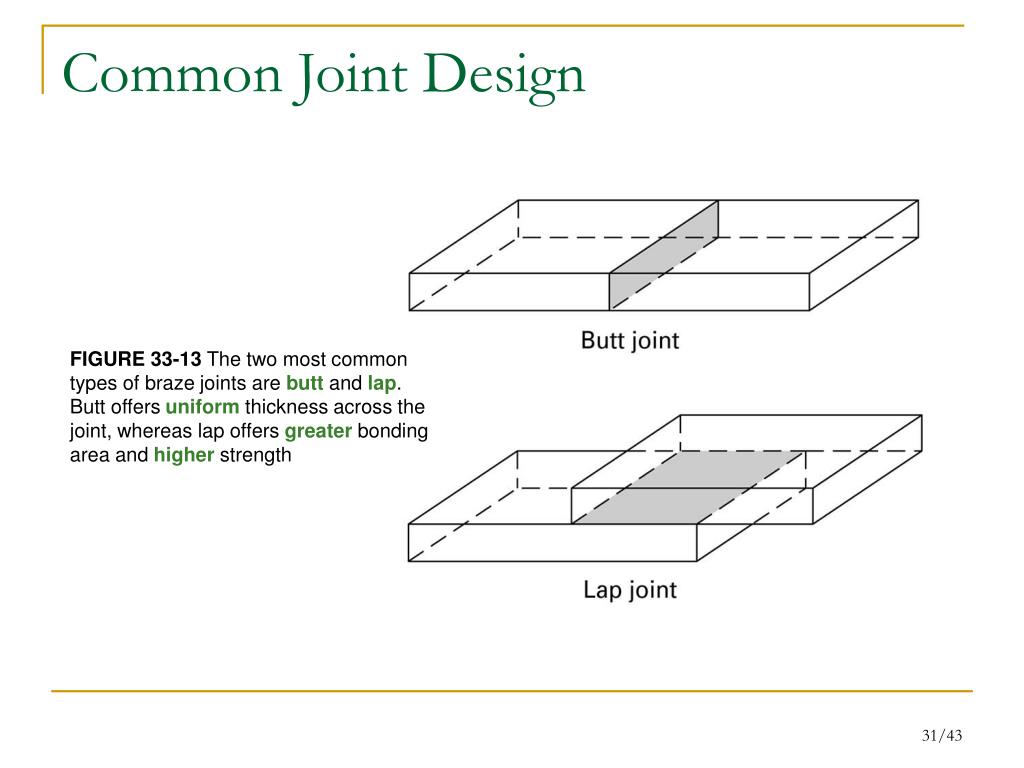

Brazed Joint Design . For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. What type of brazed joint should you design? Brazing depends on what is happening inside the joint, not on the outside. Make component pieces of the assembly self locating, so the. Brazing experts at lucas milhaupt offer these tips for improving your joint design: To design a braze joint and calculate the. Ten tips for designing braze joints. The two most common joints are the butt and the lap. The real skill lies in the design and. To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint.

from www.slideserve.com

For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. To design a braze joint and calculate the. What type of brazed joint should you design? To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. Brazing experts at lucas milhaupt offer these tips for improving your joint design: The real skill lies in the design and. Brazing depends on what is happening inside the joint, not on the outside. The two most common joints are the butt and the lap. Make component pieces of the assembly self locating, so the. Ten tips for designing braze joints.

PPT Chapter 33 Other Welding Processes, Brazing and Soldering

Brazed Joint Design For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. The two most common joints are the butt and the lap. What type of brazed joint should you design? To design a braze joint and calculate the. To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. The real skill lies in the design and. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. Ten tips for designing braze joints. Make component pieces of the assembly self locating, so the. A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. Brazing depends on what is happening inside the joint, not on the outside. Brazing experts at lucas milhaupt offer these tips for improving your joint design:

From www.littlepeng.com

Welded and Brazed Joints Brazed Joint Design A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. Make component pieces of the assembly self locating, so the. The two most common joints are the butt and the lap. Brazing depends on what is happening inside the joint, not on the outside. The real skill lies in the design. Brazed Joint Design.

From kaybrazing.com

Braze Joint Design Considerations Part 2 Kay & Associates Brazing Brazed Joint Design For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. Brazing experts at lucas milhaupt offer these tips for improving your joint design: Ten tips for designing braze joints. To design a braze joint and calculate the. The real skill lies in the. Brazed Joint Design.

From www.slideserve.com

PPT Chapter 33 Other Welding Processes, Brazing and Soldering Brazed Joint Design Brazing depends on what is happening inside the joint, not on the outside. Make component pieces of the assembly self locating, so the. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. What type of brazed joint should you design? A brazed. Brazed Joint Design.

From dokumen.tips

(PDF) Design of Brazed Joints brazetec.de DOKUMEN.TIPS Brazed Joint Design Make component pieces of the assembly self locating, so the. The real skill lies in the design and. The two most common joints are the butt and the lap. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. What type of brazed. Brazed Joint Design.

From www.littlepeng.com

Welded and Brazed Joints Brazed Joint Design The real skill lies in the design and. Brazing experts at lucas milhaupt offer these tips for improving your joint design: Make component pieces of the assembly self locating, so the. To design a braze joint and calculate the. Brazing depends on what is happening inside the joint, not on the outside. To properly design a braze joint, we recommend. Brazed Joint Design.

From www.youtube.com

Manufacturing Process Tutorial Brazed Joints YouTube Brazed Joint Design Brazing depends on what is happening inside the joint, not on the outside. To design a braze joint and calculate the. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. What type of brazed joint should you design? The two most common. Brazed Joint Design.

From kaybrazing.com

Essential Criteria for Brazing Item 1 Proper Design for Brazing Brazed Joint Design A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. The two most common joints are the butt and the lap. What type of brazed joint should you design? Ten tips for designing braze joints. To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than. Brazed Joint Design.

From www.saldobrase.com

Aluminium brazing how to braze or solder an aluminiumtoaluminium Brazed Joint Design A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. To design a braze joint and calculate the. Brazing depends on what is happening inside the joint, not on the outside. Ten tips for designing braze joints. The two most common joints are the butt and the lap. What type of. Brazed Joint Design.

From dzcqksbqeco.blob.core.windows.net

Aluminum Brazed Joints at Jimmy Creech blog Brazed Joint Design Make component pieces of the assembly self locating, so the. A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. Brazing experts at lucas milhaupt offer these tips for improving your joint design: What type of brazed joint should you design? The real skill lies in the design and. Brazing depends. Brazed Joint Design.

From kaybrazing.com

Braze Joint Design "Percentage of Voids in a Joint can Increase with Brazed Joint Design The real skill lies in the design and. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. What type of brazed joint should you. Brazed Joint Design.

From slidetodoc.com

Chapter 32 Brazing Soldering AdhesiveBonding and MechanicalFastening Brazed Joint Design To design a braze joint and calculate the. Brazing depends on what is happening inside the joint, not on the outside. The real skill lies in the design and. Ten tips for designing braze joints. The two most common joints are the butt and the lap. Make component pieces of the assembly self locating, so the. A brazed joint basically. Brazed Joint Design.

From www.littlepeng.com

Welded and Brazed Joints Brazed Joint Design Make component pieces of the assembly self locating, so the. Ten tips for designing braze joints. What type of brazed joint should you design? The two most common joints are the butt and the lap. To design a braze joint and calculate the. Brazing depends on what is happening inside the joint, not on the outside. To properly design a. Brazed Joint Design.

From www.pinterest.com

My first brazed joint 1... Brazing, Bike craft, Bike frame Brazed Joint Design Brazing experts at lucas milhaupt offer these tips for improving your joint design: A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. Ten tips for designing braze joints. For successful brazing to. Brazed Joint Design.

From engineeringlearn.com

8 Types of Pipe Joints and Their Uses in Plumbing Guide Brazed Joint Design To design a braze joint and calculate the. Brazing depends on what is happening inside the joint, not on the outside. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. The two most common joints are the butt and the lap. Make. Brazed Joint Design.

From www.youtube.com

ChannelFlux Brazing Alloy Braze Aluminum to Aluminum or Copper YouTube Brazed Joint Design Ten tips for designing braze joints. Make component pieces of the assembly self locating, so the. Brazing experts at lucas milhaupt offer these tips for improving your joint design: Brazing depends on what is happening inside the joint, not on the outside. To design a braze joint and calculate the. What type of brazed joint should you design? The real. Brazed Joint Design.

From www.youtube.com

Brazing 04 Brazing Step 1 Joint Design YouTube Brazed Joint Design Make component pieces of the assembly self locating, so the. To design a braze joint and calculate the. Brazing depends on what is happening inside the joint, not on the outside. Brazing experts at lucas milhaupt offer these tips for improving your joint design: The real skill lies in the design and. For successful brazing to occur, the joints to. Brazed Joint Design.

From vacaero.com

Braze Joint Design How Much Overlap is Enough? Brazed Joint Design Make component pieces of the assembly self locating, so the. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. Ten tips for designing. Brazed Joint Design.

From www.jiayuanfitting.com

Types of brazed tube Fitting joints Knowledge Yuyao Jiayuan Brazed Joint Design The two most common joints are the butt and the lap. To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. Brazing depends on what is happening inside the joint, not on the outside. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly. Brazed Joint Design.

From vacaero.com

Braze Joint Design Considerations Brazed Joint Design The real skill lies in the design and. Make component pieces of the assembly self locating, so the. To design a braze joint and calculate the. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. Brazing experts at lucas milhaupt offer these. Brazed Joint Design.

From navyaviation.tpub.com

Silverbrazed joints. Brazed Joint Design A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. The real skill lies in the design and. Brazing experts at lucas milhaupt offer these tips for improving your joint design: Ten tips for designing braze joints. To design a braze joint and calculate the. Brazing depends on what is happening. Brazed Joint Design.

From shahab-co.com

What is Induction brazing Brazing uses heat and a filler metal (alloy Brazed Joint Design To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. Brazing experts at lucas milhaupt offer these tips for improving your joint design: Brazing depends on what is happening inside the joint, not. Brazed Joint Design.

From www.diydoctor.org.uk

Brazing a Joint Using a Blow Torch and How to use a Brazing Rod DIY Brazed Joint Design To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. The two most common joints are the butt and the lap. The real skill lies in the design and. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain. Brazed Joint Design.

From technologystudent.com

Creating a Brazed Joint Brazed Joint Design A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. The two most common joints are the butt and the lap. Make component pieces of the assembly self locating, so the. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to. Brazed Joint Design.

From www.pinterest.com

Fillet brazed joints super heated brass melted into tubes, and carried Brazed Joint Design The real skill lies in the design and. The two most common joints are the butt and the lap. Brazing depends on what is happening inside the joint, not on the outside. To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. Make component pieces of the assembly self locating, so the.. Brazed Joint Design.

From www.slideshare.net

Brazing Brazed Joint Design To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. Ten tips for designing braze joints. What type of brazed joint should you design? For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. A. Brazed Joint Design.

From www.weldingtipsandtricks.com

TIg Brazing vs Tig Welding Brazed Joint Design The two most common joints are the butt and the lap. A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. Brazing experts at lucas milhaupt offer these tips for improving your joint design: To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room. Brazed Joint Design.

From www.pipsisland.com

10 Simple Steps to Braze Copper Pipe (Extended Tips) Brazed Joint Design To design a braze joint and calculate the. Brazing experts at lucas milhaupt offer these tips for improving your joint design: The two most common joints are the butt and the lap. For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. To. Brazed Joint Design.

From www.slideserve.com

PPT Chapter 33 Other Welding Processes, Brazing and Soldering Brazed Joint Design Ten tips for designing braze joints. The two most common joints are the butt and the lap. A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. To design a braze joint and. Brazed Joint Design.

From www.researchgate.net

Schematic diagram and images for brazed joints 1 and 1′parent Brazed Joint Design To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. To design a braze joint and calculate the. Ten tips for designing braze joints. Brazing depends on what is happening inside the joint, not on the outside. The real skill lies in the design and. For successful brazing to occur, the joints. Brazed Joint Design.

From vacaero.com

Essential Criteria for Brazing Item 1 Proper Design for Brazing Brazed Joint Design For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. To properly design a braze joint, we recommend calculating joint clearance at brazing temperature. Brazed Joint Design.

From www.youtube.com

How to braze copper coppercopper joint YouTube Brazed Joint Design For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly manufactured to attain and maintain those shapes and dimensions. Make component pieces of the assembly self locating, so the. A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. To design a braze. Brazed Joint Design.

From www.slideserve.com

PPT Chapter 33 Other Welding Processes, Brazing and Soldering Brazed Joint Design Ten tips for designing braze joints. The two most common joints are the butt and the lap. What type of brazed joint should you design? To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. Brazing depends on what is happening inside the joint, not on the outside. For successful brazing to. Brazed Joint Design.

From www.youtube.com

Symbols Used for WELDING, BRAZING & SOLDERING JOINTS in Engineering Brazed Joint Design Ten tips for designing braze joints. The two most common joints are the butt and the lap. To design a braze joint and calculate the. Make component pieces of the assembly self locating, so the. Brazing experts at lucas milhaupt offer these tips for improving your joint design: What type of brazed joint should you design? Brazing depends on what. Brazed Joint Design.

From blog.thepipingmart.com

12 Types of Pipe Joints and Their Uses Brazed Joint Design To design a braze joint and calculate the. Brazing depends on what is happening inside the joint, not on the outside. To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. A brazed joint basically can make itself—capillary action, more than operator skill, ensures filler metal distribution into the joint. The two. Brazed Joint Design.

From www.slideserve.com

PPT Chapter 33 Other Welding Processes, Brazing and Soldering Brazed Joint Design To properly design a braze joint, we recommend calculating joint clearance at brazing temperature rather than room temperature. The real skill lies in the design and. To design a braze joint and calculate the. What type of brazed joint should you design? For successful brazing to occur, the joints to be brazed have to be designed properly, and then properly. Brazed Joint Design.