Bevel Gear Diameter . If the text pertains to one or more, but not. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of formulae. Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. Hypoid gears with optimal offsets are superior to spiral bevel. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. Iso 23509:2016 specifies the geometry of bevel gears.

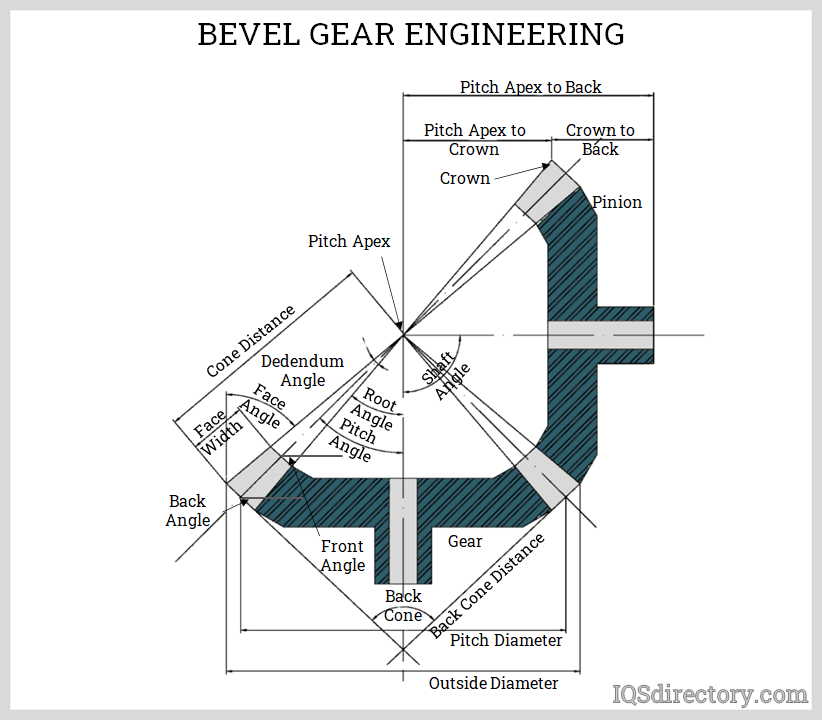

from www.iqsdirectory.com

Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. Iso 23509:2016 specifies the geometry of bevel gears. Hypoid gears with optimal offsets are superior to spiral bevel. If the text pertains to one or more, but not. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of formulae. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs.

Bevel Gear What Is It? How Does It Work? Types, Uses

Bevel Gear Diameter For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of formulae. Iso 23509:2016 specifies the geometry of bevel gears. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. Hypoid gears with optimal offsets are superior to spiral bevel. If the text pertains to one or more, but not. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Bevel Gear Diameter If the text pertains to one or more, but not. Hypoid gears with optimal offsets are superior to spiral bevel. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. Iso 23509:2016 specifies the geometry of bevel gears. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in. Bevel Gear Diameter.

From dxoiccsdl.blob.core.windows.net

Bevel Gear Specification at Michael Goins blog Bevel Gear Diameter Hypoid gears with optimal offsets are superior to spiral bevel. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. Iso 23509:2016 specifies the geometry of bevel gears. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete. Bevel Gear Diameter.

From www.geartechnology.com

A Practical Approach for Modeling a Bevel Gear Gear Technology Magazine Bevel Gear Diameter Hypoid gears with optimal offsets are superior to spiral bevel. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. The set of the geometrical dimensions recommended for bevel. Bevel Gear Diameter.

From www.youtube.com

How to accurately design a Bevel Gear ;베벨기어 정확히 모델링하기 YouTube Bevel Gear Diameter 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of formulae. Iso 23509:2016 specifies the geometry of bevel gears. If the text pertains to one or more, but not. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular),. Bevel Gear Diameter.

From selmec.org.uk

The Theory of Meccano Gears Part 3 — Bevel Gears — South East London Bevel Gear Diameter Iso 23509:2016 specifies the geometry of bevel gears. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. Hypoid gears with optimal offsets are superior to spiral bevel. If the text pertains to one or more, but not. For bevel gearing, when the number of teeth in the pinion is. Bevel Gear Diameter.

From dxoiccsdl.blob.core.windows.net

Bevel Gear Specification at Michael Goins blog Bevel Gear Diameter For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. If the text pertains to one or more, but not. Iso 23509:2016 specifies the geometry of bevel gears. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. The. Bevel Gear Diameter.

From www.semanticscholar.org

[PDF] Design and Analysis of a Spiral Bevel Gear Semantic Scholar Bevel Gear Diameter The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth. Bevel Gear Diameter.

From www.iqsdirectory.com

Bevel Gear What Are They? How Do They Work? Types and Uses Bevel Gear Diameter Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. Hypoid gears with optimal offsets are superior to spiral bevel. The term bevel. Bevel Gear Diameter.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Diameter For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. Iso 23509:2016 specifies the geometry of bevel gears. Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. Hypoid gears with optimal offsets. Bevel Gear Diameter.

From chinawuxing.en.made-in-china.com

Bevel Gear Spur Gear Gear Shaft Diameter 389mm Module11 Teeth 35 Bevel Gear Diameter 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of formulae. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. The term bevel gears is used to mean straight, spiral,. Bevel Gear Diameter.

From www.tbksoft.com

TBK Spiral bevel gears Bevel Gear Diameter For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. If the text pertains to one or more, but not. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. The term bevel gears is. Bevel Gear Diameter.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Diameter Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. The term bevel gears is used to mean straight, spiral, zerol bevel and. Bevel Gear Diameter.

From www.precisionwormgear.com

Industrial Steel Straight Bevel And Mitre Gears 16T M2.0 96mm Pitch Bevel Gear Diameter 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of formulae. If the text pertains to one or more, but not. Iso 23509:2016 specifies the geometry of bevel gears. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. The. Bevel Gear Diameter.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Bevel Gear Diameter For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. Hypoid gears with optimal offsets are superior to spiral bevel. If the text pertains to one or more, but not. Diameter of gears (size) the size of gears is determined in accordance with the reference. Bevel Gear Diameter.

From gear.com.my

Bevel Gear Malaysia, Bevel Gear Supplier Malaysia Bevel Gear Diameter Iso 23509:2016 specifies the geometry of bevel gears. Hypoid gears with optimal offsets are superior to spiral bevel. Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into. Bevel Gear Diameter.

From present5.com

BEVEL GEARSBEVEL GEARSGEOMETRY OF BEVEL GEARSGEOMETRY OF BEVEL Bevel Gear Diameter The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed. Bevel Gear Diameter.

From www.tbksoft.com

TBK Straight and helical bevel gears Bevel Gear Diameter Hypoid gears with optimal offsets are superior to spiral bevel. If the text pertains to one or more, but not. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. Bevel Gear Diameter.

From present5.com

BEVEL GEARSBEVEL GEARSGEOMETRY OF BEVEL GEARSGEOMETRY OF BEVEL Bevel Gear Diameter 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of formulae. Iso 23509:2016 specifies the geometry of bevel gears. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. Diameter of gears (size) the size of. Bevel Gear Diameter.

From link.springer.com

Fundamentals of Bevel Gears SpringerLink Bevel Gear Diameter If the text pertains to one or more, but not. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. Iso 23509:2016 specifies the geometry of bevel gears. Hypoid gears with optimal offsets are superior to spiral bevel. 96 rows this document integrates straight bevel gears and the three major design generation methods for. Bevel Gear Diameter.

From www.gearsandsprockets.co.uk

Metric Plastic Bevel Gears Bevel Gear Diameter For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined. Bevel Gear Diameter.

From www.efunda.com

Gears Nomenclature Bevel Gear Diameter 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of formulae. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. Iso 23509:2016 specifies the geometry of bevel gears. The term bevel gears is used to. Bevel Gear Diameter.

From dxoiccsdl.blob.core.windows.net

Bevel Gear Specification at Michael Goins blog Bevel Gear Diameter Hypoid gears with optimal offsets are superior to spiral bevel. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. 96 rows this document integrates straight bevel gears and the three major. Bevel Gear Diameter.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Diameter Iso 23509:2016 specifies the geometry of bevel gears. If the text pertains to one or more, but not. Hypoid gears with optimal offsets are superior to spiral bevel. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. Diameter of gears (size) the size of gears is determined in accordance with the reference diameter. Bevel Gear Diameter.

From www.hexagon.de

ZAR6 Bevel Gear Calculation Bevel Gear Diameter The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. Hypoid gears with optimal offsets are superior to spiral bevel. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. If the text pertains to. Bevel Gear Diameter.

From camnetics.com

Bevel Gears Bevel Gear Diameter Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. Hypoid gears with optimal offsets are superior to spiral bevel. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso. Bevel Gear Diameter.

From www.pinterest.com

Bevel Gears Linn Gear Manufactures Bevel gear, Bevel, Gears Bevel Gear Diameter For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. If the text pertains to one or more, but not. Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. 96 rows this. Bevel Gear Diameter.

From khkgears.net

Calculation of Gear Dimensions KHK Gears Bevel Gear Diameter The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear. Bevel Gear Diameter.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Diameter Iso 23509:2016 specifies the geometry of bevel gears. For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. Hypoid gears with optimal offsets are superior to spiral bevel. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral. Bevel Gear Diameter.

From exohauxqb.blob.core.windows.net

What Is The Use Of The Bevel Gear at Rosemary Howard blog Bevel Gear Diameter Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. Iso 23509:2016 specifies the geometry of bevel gears. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. For bevel gearing, when the number of teeth in the pinion is equal to. Bevel Gear Diameter.

From khkgears.net

Pitch Circle Diameter GearWords KHK Gears Bevel Gear Diameter For bevel gearing, when the number of teeth in the pinion is equal to the number of teeth in the bevel gear, the speed ratio. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of formulae. The term bevel gears is used to mean straight, spiral,. Bevel Gear Diameter.

From khkgears.net

Bending Strength of Bevel Gears KHK Gears Bevel Gear Diameter Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by these other. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. Hypoid gears with optimal offsets are superior to spiral bevel. For bevel gearing, when the number of teeth in the pinion is. Bevel Gear Diameter.

From www.linngear.com

Bevel Gears Linn Gear Manufactures Bevel Gear Diameter The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. Hypoid gears with optimal offsets are superior to spiral bevel. If the text pertains to one or more, but not. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. Diameter of gears (size). Bevel Gear Diameter.

From indianpremiumgears.com

Straight Bevel Gears Indian Premium Gears Bevel Gear Diameter Hypoid gears with optimal offsets are superior to spiral bevel. If the text pertains to one or more, but not. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. Diameter of gears (size) the size of gears is determined in accordance with the reference diameter (d) and determined by. Bevel Gear Diameter.

From www.researchgate.net

Straight bevel gear parameters Download Scientific Diagram Bevel Gear Diameter If the text pertains to one or more, but not. Hypoid gears with optimal offsets are superior to spiral bevel. The term bevel gears is used to mean straight, spiral, zerol bevel and hypoid gear designs. The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. 96 rows this document. Bevel Gear Diameter.

From www.researchgate.net

Graphical development of the pitch circle diameters of helical bevel Bevel Gear Diameter The set of the geometrical dimensions recommended for bevel gearing by ansi/agma/iso standards ( [1] in particular), is shown in. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of formulae. Diameter of gears (size) the size of gears is determined in accordance with the reference. Bevel Gear Diameter.