Compressor Lubrication Systems . The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. This system works by circulating oil through the. An oil pump driven by the compressor lubricates the bearings and gears on each end. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. In a gas compressor, there are two states of lubrication: Hydrodynamic lubrication is when the two. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently.

from www.marineinsight.com

An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. This system works by circulating oil through the. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. Hydrodynamic lubrication is when the two. In a gas compressor, there are two states of lubrication: Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. An oil pump driven by the compressor lubricates the bearings and gears on each end.

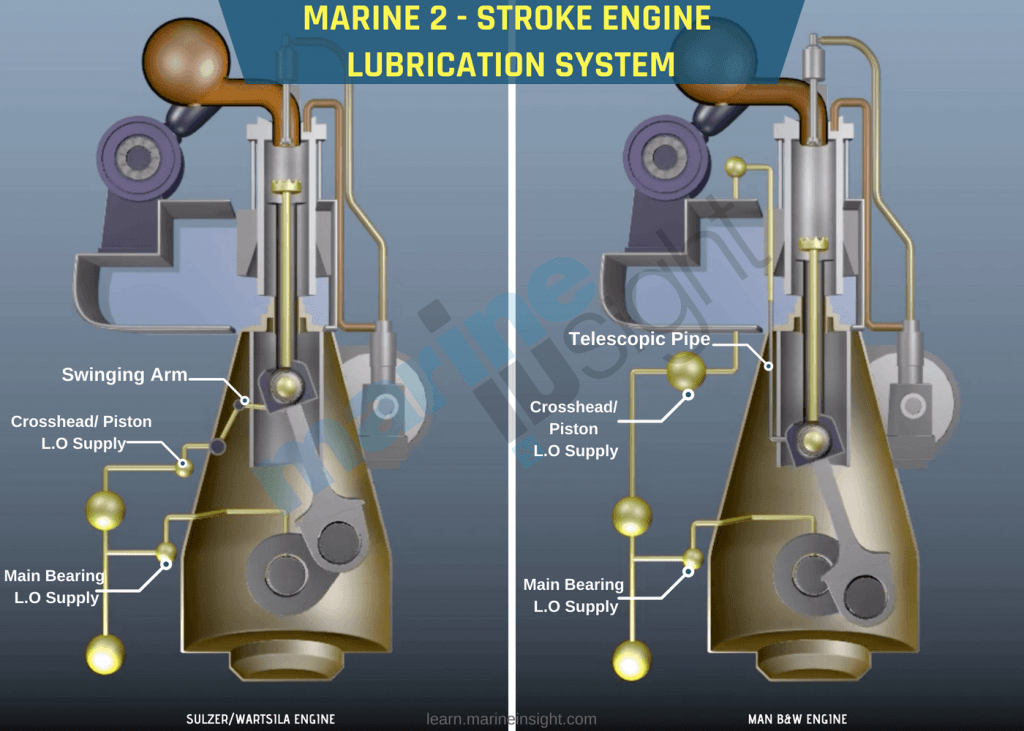

Ship's Main Engine Lubrication System Explained

Compressor Lubrication Systems Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. This system works by circulating oil through the. Hydrodynamic lubrication is when the two. An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. An oil pump driven by the compressor lubricates the bearings and gears on each end. In a gas compressor, there are two states of lubrication: Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler.

From allube.co.uk

SKF licoln dual line lubrication system Allube Compressor Lubrication Systems This system works by circulating oil through the. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. In a gas compressor, there are two states of lubrication: An oil pump driven by the compressor lubricates the bearings and gears on each end.. Compressor Lubrication Systems.

From www.alibaba.com

Steam Turbine Gas Turbine Ammonia Compressor Lube Oil Station Compressor Lubrication Systems The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. In. Compressor Lubrication Systems.

From gascompressorhodakan.blogspot.com

Gas Compressor Gas Compressor Lubrication System Compressor Lubrication Systems The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. Hydrodynamic lubrication is when the two. Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. An oil pump driven by the compressor lubricates the bearings and gears. Compressor Lubrication Systems.

From www.researchgate.net

Compressor Package Lubrication Oil System MATLAB/Simulink Compressor Lubrication Systems An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. The lubrication system on reciprocating compressors plays a crucial role in. Compressor Lubrication Systems.

From www.billspitzerassoc.com

BSA Compressor Cylinder & Packing Lube Systems — Bill Spitzer & Associates Compressor Lubrication Systems In a gas compressor, there are two states of lubrication: This system works by circulating oil through the. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. Hydrodynamic lubrication is when the two. An oil pump driven by the compressor lubricates the. Compressor Lubrication Systems.

From allube.co.uk

SKF lincoln progressive lubrication system Allube Compressor Lubrication Systems The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. An oil pump driven by the compressor lubricates the bearings and gears on each end. In a gas compressor, there are two states of lubrication: A compressor lubrication system is an important component. Compressor Lubrication Systems.

From www.hi-techcompressor.com

Lube Systems HiTech Compressor & Pump Products, Inc. Compressor Lubrication Systems An oil pump driven by the compressor lubricates the bearings and gears on each end. Hydrodynamic lubrication is when the two. An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving. Compressor Lubrication Systems.

From www.marineengineersknowledge.com

Lubrication system for air compressor Marine engineers knowledge Compressor Lubrication Systems A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. An oil pump driven by the compressor lubricates the bearings and gears on each end. Hydrodynamic lubrication is when the two. The lubrication system on reciprocating compressors plays a crucial. Compressor Lubrication Systems.

From www.powershow.com

PPT Compressor Lubrication System All You Need to Know PowerPoint Compressor Lubrication Systems An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. In a gas compressor, there are two states of lubrication: This system works by circulating oil through the. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear,. Compressor Lubrication Systems.

From www.terrauniversal.com

Compressors Compressor Lubrication Systems Hydrodynamic lubrication is when the two. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. This system works by circulating oil through the. Figure 2. Compressor Lubrication Systems.

From samcoenterprises.com

Reciprocating Compressor Lubrication System Best Practices Samco Compressor Lubrication Systems A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. Figure 2 shows a typical rotary screw compressor lubrication circulation system. Compressor Lubrication Systems.

From sloanlubrication.com

Ariel Sloan Lubrication Systems Compressor Lubrication Systems The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. Hydrodynamic lubrication is when the two. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. This system works by circulating oil through the. An oil. Compressor Lubrication Systems.

From tpub.com

Lubrication Systems Compressor Lubrication Systems An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. Hydrodynamic lubrication is when the two. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. An oil pump driven by the compressor lubricates. Compressor Lubrication Systems.

From www.alibaba.com

Steam Turbine Gas Turbine Ammonia Compressor Lube Oil Station Compressor Lubrication Systems Hydrodynamic lubrication is when the two. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. An oil pump driven by the compressor lubricates the bearings and gears on each end. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent. Compressor Lubrication Systems.

From evolution.skf.com

Pure refrigerant lubrication technology in oilfree centrifugal Compressor Lubrication Systems Hydrodynamic lubrication is when the two. An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. An oil pump driven by the compressor lubricates the bearings and gears on each end. This system works by circulating. Compressor Lubrication Systems.

From noria.mx

Compressor Lubrication Best Practices Noria Latín América Compressor Lubrication Systems The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. In a gas compressor, there are two states of lubrication: Hydrodynamic lubrication is when the two. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity.. Compressor Lubrication Systems.

From www.youtube.com

Reciprocating Compressor Lubrication System YouTube Compressor Lubrication Systems This system works by circulating oil through the. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. Figure 2 shows a typical. Compressor Lubrication Systems.

From en.ppt-online.org

Air Compressor Lubrication online presentation Compressor Lubrication Systems This system works by circulating oil through the. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. An oil pump driven by the compressor lubricates. Compressor Lubrication Systems.

From aheinfo.com

Industrial Lubrication Systems Automatic Lubrication System Compressor Lubrication Systems A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. The better you and your team understand a compressor’s function, the effects of. Compressor Lubrication Systems.

From gascompressorhodakan.blogspot.com

Gas Compressor Gas Compressor Lubrication System Compressor Lubrication Systems An oil pump driven by the compressor lubricates the bearings and gears on each end. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. This system works by circulating oil through the. The better you and your team understand. Compressor Lubrication Systems.

From www.marineinsight.com

Ship's Main Engine Lubrication System Explained Compressor Lubrication Systems The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. An oil pump driven by the compressor lubricates the bearings and gears on each end. This system works by circulating oil through the. An air compressor lubrication system is an essential component that. Compressor Lubrication Systems.

From www.marineengineersknowledge.com

Lubrication system for air compressor Marine engineers knowledge Compressor Lubrication Systems In a gas compressor, there are two states of lubrication: An oil pump driven by the compressor lubricates the bearings and gears on each end. This system works by circulating oil through the. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat. Compressor Lubrication Systems.

From www.arielcorp.com

Enhanced Lubrication Compressor Lubrication Systems An oil pump driven by the compressor lubricates the bearings and gears on each end. Hydrodynamic lubrication is when the two. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. Figure 2 shows a typical rotary screw compressor lubrication circulation system with. Compressor Lubrication Systems.

From baycompservices.com

Lubrication System Install Bay Compressor Services Compressor Lubrication Systems The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. In a gas compressor, there are two states of lubrication: Hydrodynamic lubrication is when the two. An air compressor lubrication system is an essential component that helps to. Compressor Lubrication Systems.

From www.arielcorp.com

KBE Compressor Lubrication Systems Hydrodynamic lubrication is when the two. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. The better you and your team understand a compressor’s. Compressor Lubrication Systems.

From www.stle.org

Lubrication Fundamentals Compressor Lubrication Systems Hydrodynamic lubrication is when the two. A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. In a gas compressor, there. Compressor Lubrication Systems.

From www.machinerylubrication.com

What You Need to Know About Compressor Lubrication Compressor Lubrication Systems A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. Hydrodynamic lubrication is when the two. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and. Compressor Lubrication Systems.

From www.machinerylubrication.com

Compressor Lubrication Best Practices Compressor Lubrication Systems The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. Hydrodynamic. Compressor Lubrication Systems.

From www.compair.com

All About Oil lubricated Air Compressor Technology CompAir Compressor Lubrication Systems The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity. This system works by circulating oil through the. An oil pump driven by the compressor lubricates the bearings and gears on each end. Hydrodynamic lubrication is when the two. In a gas compressor, there are two states of lubrication: A compressor lubrication system. Compressor Lubrication Systems.

From www.machinerylubrication.com

Compressor Lubrication Best Practices Compressor Lubrication Systems In a gas compressor, there are two states of lubrication: A compressor lubrication system is an important component of many types of compressors, designed to reduce the friction between moving parts, prevent wear, and help in heat dissipation, hence increasing. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant. Compressor Lubrication Systems.

From www.alamy.com

Reciprocating Reciprocating Compressor Lubrication system Stock Vector Compressor Lubrication Systems This system works by circulating oil through the. An oil pump driven by the compressor lubricates the bearings and gears on each end. An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. Hydrodynamic lubrication is when the two. Figure 2 shows a typical rotary screw compressor lubrication circulation system with. Compressor Lubrication Systems.

From www.zenithhydromatic.com

Compressor Lubrication System All You Need to Know Compressor Lubrication Systems The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant should be selected and what oil analysis. An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and. Compressor Lubrication Systems.

From www.slideserve.com

PPT Compressor Lubrication System All You Need to Know PowerPoint Compressor Lubrication Systems Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. Hydrodynamic lubrication is when the two. The better you and your team understand a compressor’s function, the effects of the system on the lubricant, which lubricant. Compressor Lubrication Systems.

From www.airbestpractices.com

Lubricants for Centrifugal Air Compressors Compressed Air Best Practices Compressor Lubrication Systems In a gas compressor, there are two states of lubrication: An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. Hydrodynamic lubrication is when the two. This system works by circulating oil through the. The lubrication system on reciprocating compressors plays a crucial role in ensuring their optimal performance and longevity.. Compressor Lubrication Systems.

From www.oilngasprocess.com

Reciprocating Compressors Frame Lubrication System Oil & Gas Compressor Lubrication Systems Figure 2 shows a typical rotary screw compressor lubrication circulation system with separator and cooler. Hydrodynamic lubrication is when the two. An air compressor lubrication system is an essential component that helps to keep your compressor running smoothly and efficiently. In a gas compressor, there are two states of lubrication: The lubrication system on reciprocating compressors plays a crucial role. Compressor Lubrication Systems.