Gun Drill Bit Geometry . The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. Nose geometries are one of the most important characteristics of successful hole making. Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to drill deep holes into metal. Learn when to use gundrilling, how it works, and benefits for manufacturers. There are numerous nose grinds that have been established by end users to critique applications. Depending on the type of hole to be created, a. The purpose of this document is to highlight main differences of point geometry. Gundrill tools use internal coolant, and external chip evacuation to reach tolerance requirements with ease. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used.

from www.atlanticfasteners.com

The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. The purpose of this document is to highlight main differences of point geometry. Nose geometries are one of the most important characteristics of successful hole making. Learn when to use gundrilling, how it works, and benefits for manufacturers. Depending on the type of hole to be created, a. Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. There are numerous nose grinds that have been established by end users to critique applications. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to drill deep holes into metal.

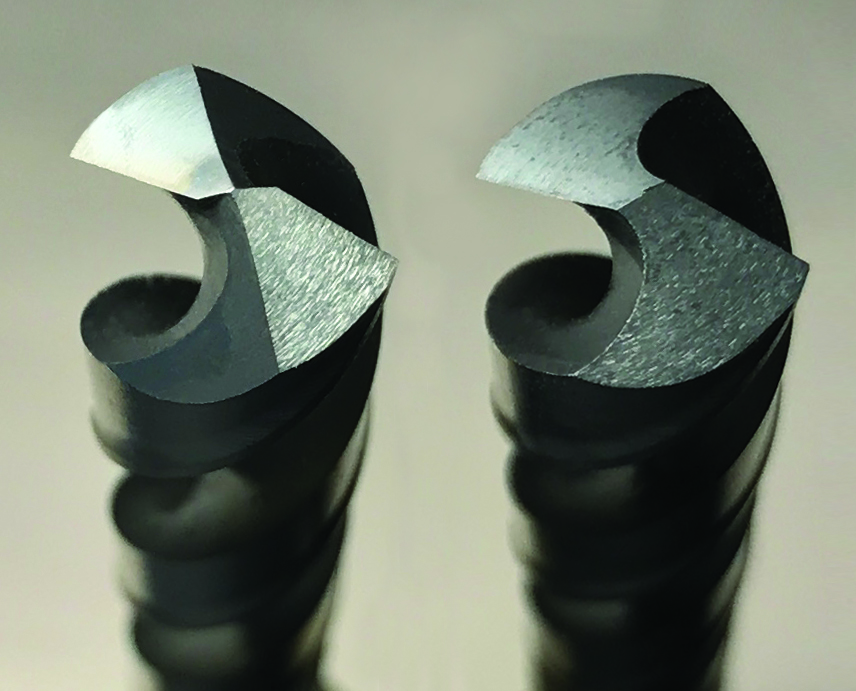

Drill Point Styles Comparison

Gun Drill Bit Geometry Gundrill tools use internal coolant, and external chip evacuation to reach tolerance requirements with ease. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. Learn when to use gundrilling, how it works, and benefits for manufacturers. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. Depending on the type of hole to be created, a. Nose geometries are one of the most important characteristics of successful hole making. The purpose of this document is to highlight main differences of point geometry. There are numerous nose grinds that have been established by end users to critique applications. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to drill deep holes into metal. Gundrill tools use internal coolant, and external chip evacuation to reach tolerance requirements with ease.

From www.mdpi.com

Metals Free FullText A Review of Surgical Bone Drilling and Drill Gun Drill Bit Geometry The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. Gundrilling is a deep hole drilling operation that. Gun Drill Bit Geometry.

From www.bidspotter.com

Gun Drill Bits Gun Drill Bit Geometry The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. There are numerous nose grinds that have been established by end users to critique applications. Learn when to use gundrilling, how it works, and benefits for manufacturers. The purpose of. Gun Drill Bit Geometry.

From www.unisig.com

What is Gun Drilling? Gundrill Process and Specifications UNISIG Gun Drill Bit Geometry The purpose of this document is to highlight main differences of point geometry. Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. Gundrill tools use internal coolant, and external chip evacuation to reach tolerance requirements with ease. Gundrilling is a deep hole drilling operation that uses specialty. Gun Drill Bit Geometry.

From benchmarkinstitute.org

gun drill bits Gun Drill Bit Geometry The purpose of this document is to highlight main differences of point geometry. Nose geometries are one of the most important characteristics of successful hole making. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. Depending on the type. Gun Drill Bit Geometry.

From topcordlesstools.com

What is a Split Point Drill Bit? TC Tools Gun Drill Bit Geometry Gundrill tools use internal coolant, and external chip evacuation to reach tolerance requirements with ease. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to drill deep holes into metal. Nose geometries are one of the most important. Gun Drill Bit Geometry.

From www.alibaba.com

Deep Hole Drills Gun Barrel Drill Bit Set Buy Drill Bit Set,Deep Hole Gun Drill Bit Geometry There are numerous nose grinds that have been established by end users to critique applications. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. Nose geometries are one of the most important characteristics of successful hole making. Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to. Gun Drill Bit Geometry.

From unitacinc.com

News UNITAC Deep Hole Drilling Tools Gun Drill Bit Geometry Nose geometries are one of the most important characteristics of successful hole making. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex. Gun Drill Bit Geometry.

From www.aliexpress.com

DrillBits112mmTwistBitTungstenGunDrillBitsForCNCLathe Gun Drill Bit Geometry The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. Depending on the type of hole to be created, a. Nose geometries are one of the most important characteristics of successful hole making. Gundrilling is a deep hole drilling operation. Gun Drill Bit Geometry.

From www.youtube.com

Twist Drill Tool Nomenclature for Drilling (Parts And Important Angles Gun Drill Bit Geometry Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to drill deep holes into metal. Learn when to use gundrilling, how it works, and benefits for manufacturers. Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. Nose geometries are one of the most. Gun Drill Bit Geometry.

From www.taiwantrade.com

Gun drill ( deep hole drill) / Gun drill bit / Single Flute Gun drill Gun Drill Bit Geometry This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. There are numerous nose grinds that have been established by end users to critique applications. Nose geometries are one of the most important characteristics of successful hole making. The developed and validated 3d fe model can be used for optimizing the cutting. Gun Drill Bit Geometry.

From www.youtube.com

Best Angle Sharpen Twist Drill Bit 135° vs 118° YouTube Gun Drill Bit Geometry There are numerous nose grinds that have been established by end users to critique applications. Gundrill tools use internal coolant, and external chip evacuation to reach tolerance requirements with ease. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. Gundrilling is a deep hole drilling operation that uses specialty tools and. Gun Drill Bit Geometry.

From www.unisig.com

Gunning for Better Results UNISIG Deep Hole Drilling Machines Gun Drill Bit Geometry Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to drill deep holes into metal. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. Nose geometries are one of the most important characteristics of successful hole making. Depending on the type of hole to be created,. Gun Drill Bit Geometry.

From www.researchgate.net

Drill geometry (Lindberg, 1990) Download Scientific Diagram Gun Drill Bit Geometry Nose geometries are one of the most important characteristics of successful hole making. There are numerous nose grinds that have been established by end users to critique applications. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. Depending on the type of hole to be created, a. Gundrilling is a deep. Gun Drill Bit Geometry.

From www.atlanticfasteners.com

Drill Point Styles Comparison Gun Drill Bit Geometry The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. Learn when to use gundrilling, how it works, and benefits for manufacturers. Nose geometries are one of the most important characteristics of successful hole making. The purpose of this document. Gun Drill Bit Geometry.

From www.researchgate.net

Specifications and geometry of a twist drill (Astakhov, 2010 Gun Drill Bit Geometry The purpose of this document is to highlight main differences of point geometry. There are numerous nose grinds that have been established by end users to critique applications. Learn when to use gundrilling, how it works, and benefits for manufacturers. Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to drill deep holes into metal. This. Gun Drill Bit Geometry.

From www.lazada.com.ph

POWERHOUSE Masonry SDS Rotary Hammer Chipping Gun Drill Drill Bit SOLD Gun Drill Bit Geometry There are numerous nose grinds that have been established by end users to critique applications. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to drill deep holes into metal. Single flute gundrills consist of a carbide. Gun Drill Bit Geometry.

From guehring.com

Gun Drills for every task a suitable gun drill Gühring Gun Drill Bit Geometry Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. Depending on the type of hole to be. Gun Drill Bit Geometry.

From dmetool.com

Nose Geometries & Chip Breakers Drill Masters Eldorado Tool Gun Drill Bit Geometry Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to drill deep holes into metal. Nose geometries are one of the most important characteristics of successful hole making. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. There are numerous nose grinds that have been established. Gun Drill Bit Geometry.

From www.youtube.com

Gun Drill Blanks YouTube Gun Drill Bit Geometry The purpose of this document is to highlight main differences of point geometry. There are numerous nose grinds that have been established by end users to critique applications. Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. The drill geometry is the number and position of the. Gun Drill Bit Geometry.

From www.deepholemachines.com

Gundrills Gundrill Tooling Deep hole drills, single lip deep hole Gun Drill Bit Geometry Gundrill tools use internal coolant, and external chip evacuation to reach tolerance requirements with ease. The purpose of this document is to highlight main differences of point geometry. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. There are. Gun Drill Bit Geometry.

From guehring.com

Gun Drills for every task a suitable gun drill Gühring Gun Drill Bit Geometry Learn when to use gundrilling, how it works, and benefits for manufacturers. There are numerous nose grinds that have been established by end users to critique applications. Depending on the type of hole to be created, a. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. The developed and validated 3d. Gun Drill Bit Geometry.

From www.slideserve.com

PPT HW for Chapter 22 PowerPoint Presentation, free download ID6660470 Gun Drill Bit Geometry Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. Gundrill tools use internal coolant, and external chip evacuation to reach tolerance requirements with ease. Gundrilling is a deep hole. Gun Drill Bit Geometry.

From www.carousell.ph

SDS Hex Chisel Drill Bits for Demolition Hammer Chipping Gun Drill Gun Drill Bit Geometry The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. Nose geometries are one of the most important characteristics of successful hole making. Depending on the type of hole to be created, a. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life.. Gun Drill Bit Geometry.

From www.ebay.com

Starcut 14.2x430mm OAL 2 Flute Carbide Tipped Coolant Fed Gun Drill Bit Gun Drill Bit Geometry The purpose of this document is to highlight main differences of point geometry. Nose geometries are one of the most important characteristics of successful hole making. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. Gundrill tools use internal coolant, and external chip evacuation to reach tolerance requirements with ease.. Gun Drill Bit Geometry.

From www.researchgate.net

Twist drill geometry. 16 Download Scientific Diagram Gun Drill Bit Geometry Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. There are numerous nose grinds that have been. Gun Drill Bit Geometry.

From www.researchgate.net

Detailed geometry of the twist drill [108] Download Scientific Diagram Gun Drill Bit Geometry Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. The purpose of this document is to highlight main differences of point geometry. Learn when to use gundrilling, how it works, and benefits for manufacturers. The drill geometry is the number and position of the drill cutting edges,. Gun Drill Bit Geometry.

From www.alibaba.com

Solid Carbide Gun Drill Bits Singlefluted With 2 Coolant Holes Deep Gun Drill Bit Geometry Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. There are numerous nose grinds that have been established by end users to critique applications. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness). Gun Drill Bit Geometry.

From www.animalia-life.club

Drill Bit Geometry Pdf Gun Drill Bit Geometry This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. Gundrilling is a deep hole drilling operation that uses specialty tools and equipment to drill deep holes into metal. The. Gun Drill Bit Geometry.

From www.pinterest.com.mx

Drill Sharpening Ullrich Fasteners Catalogue Woodworking tools Gun Drill Bit Geometry There are numerous nose grinds that have been established by end users to critique applications. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. Learn when to use gundrilling, how it works, and benefits for manufacturers. The purpose of this document is to highlight main differences of point geometry. Gundrill tools. Gun Drill Bit Geometry.

From www.indiamart.com

Carbon Steel Gun Drill Bit at Rs 12000/piece in Hyderabad ID 22766497512 Gun Drill Bit Geometry Single flute gundrills consist of a carbide tip, a heat treated alloy shank, and a steel driver, typically silver brazed together into. This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. Nose. Gun Drill Bit Geometry.

From www.researchgate.net

Design and geometry parameters of a gundrill Download Scientific Diagram Gun Drill Bit Geometry There are numerous nose grinds that have been established by end users to critique applications. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. Learn when to use gundrilling, how it works, and benefits for manufacturers. Single flute gundrills. Gun Drill Bit Geometry.

From www.intechopen.com

Drilling of Bone Practicality, Limitations and Complications Gun Drill Bit Geometry This paper examines experimentally the combined influence of various design and regime parameters in gundrilling on tool life. The purpose of this document is to highlight main differences of point geometry. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. Gundrill tools use internal coolant, and external chip evacuation to. Gun Drill Bit Geometry.

From exobsegqz.blob.core.windows.net

Drill Bit Cutter Hs Code at Madeline Timmerman blog Gun Drill Bit Geometry Depending on the type of hole to be created, a. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. Gundrilling. Gun Drill Bit Geometry.

From www.researchgate.net

Design and configuration of the gun drill with N8 nosegrind and 'form Gun Drill Bit Geometry Learn when to use gundrilling, how it works, and benefits for manufacturers. Depending on the type of hole to be created, a. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. Nose geometries are one of the most important. Gun Drill Bit Geometry.

From www.pinterest.co.kr

An idea for drill sharpening jig in 2023 Drill, Drill bits, Lathe tools Gun Drill Bit Geometry Nose geometries are one of the most important characteristics of successful hole making. The purpose of this document is to highlight main differences of point geometry. The developed and validated 3d fe model can be used for optimizing the cutting process in gun drilling (good surface finish and straightness) taking into account the complex gun drill. Single flute gundrills consist. Gun Drill Bit Geometry.