Spot Welding Electrode Shape . the paper presents a study on the effect of electrode surface geometry on welding quality, using four different types of. It really depends on your application. The electrodes used in spot welding are used to transfer pressure and current to the workpiece. Your next step can be simple… or hard. Various electrode shapes are made for all different sorts of unusual applications. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. Weld time is indicated in cycles of 60 cycle. common electrode materials and structures used in spot welding. radius face electrodes may be used: spot welding is generally divided into two categories: Tensile shear strength values are based on.

from www.english.e-smk.co.jp

The electrodes used in spot welding are used to transfer pressure and current to the workpiece. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Various electrode shapes are made for all different sorts of unusual applications. Tensile shear strength values are based on. Weld time is indicated in cycles of 60 cycle. common electrode materials and structures used in spot welding. With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. It really depends on your application. Your next step can be simple… or hard. radius face electrodes may be used:

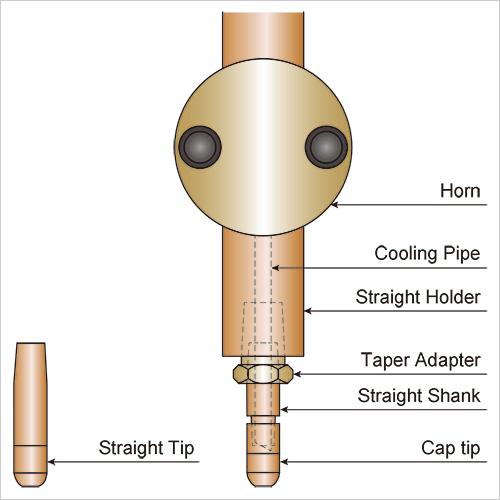

Examples of combination of ElectrodesThe welding electrode is SMK

Spot Welding Electrode Shape Your next step can be simple… or hard. the paper presents a study on the effect of electrode surface geometry on welding quality, using four different types of. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Weld time is indicated in cycles of 60 cycle. radius face electrodes may be used: With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. common electrode materials and structures used in spot welding. It really depends on your application. Tensile shear strength values are based on. Your next step can be simple… or hard. Various electrode shapes are made for all different sorts of unusual applications. spot welding is generally divided into two categories: The electrodes used in spot welding are used to transfer pressure and current to the workpiece.

From www.indiamart.com

Copper Spot Welding Electrodes, Rs 250 /unit Nashik Autoweld Systems Spot Welding Electrode Shape Your next step can be simple… or hard. Tensile shear strength values are based on. The electrodes used in spot welding are used to transfer pressure and current to the workpiece. With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. Weld time is indicated in cycles of. Spot Welding Electrode Shape.

From www.indiamart.com

Wadson Cucrzr Spot Welding Electrodes, Rs 168 /piece Wadson Metals Pvt Spot Welding Electrode Shape The electrodes used in spot welding are used to transfer pressure and current to the workpiece. Your next step can be simple… or hard. radius face electrodes may be used: the paper presents a study on the effect of electrode surface geometry on welding quality, using four different types of. welding parameters are applicable when using electrode. Spot Welding Electrode Shape.

From www.leisto.com

Spot Welding Electrode's Tip, Spot Welding Tip, Micro Welding Tip Spot Welding Electrode Shape Various electrode shapes are made for all different sorts of unusual applications. Weld time is indicated in cycles of 60 cycle. With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. common electrode materials and structures used in spot welding. Tensile shear strength values are based on.. Spot Welding Electrode Shape.

From www.dahching.com

What is Spot Welding Machine and how does it work? Daching Electric Spot Welding Electrode Shape The electrodes used in spot welding are used to transfer pressure and current to the workpiece. Various electrode shapes are made for all different sorts of unusual applications. common electrode materials and structures used in spot welding. radius face electrodes may be used: Weld time is indicated in cycles of 60 cycle. Your next step can be simple…. Spot Welding Electrode Shape.

From www.indiamart.com

Spot Welding Electrode at Rs 150/piece Spot Welding rod in Chennai Spot Welding Electrode Shape Tensile shear strength values are based on. It really depends on your application. The electrodes used in spot welding are used to transfer pressure and current to the workpiece. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Weld time is indicated in cycles of 60 cycle. With the current spot welding. Spot Welding Electrode Shape.

From rosenweld.com

Spot Welding Electrodes Material Rosen Welding Spot Welding Electrode Shape the paper presents a study on the effect of electrode surface geometry on welding quality, using four different types of. radius face electrodes may be used: It really depends on your application. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Weld time is indicated in cycles of 60 cycle.. Spot Welding Electrode Shape.

From medium.com

Spot Welding Electrodes Tips PARENTNashik Medium Spot Welding Electrode Shape The electrodes used in spot welding are used to transfer pressure and current to the workpiece. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. It really depends on your application. the paper presents a study on the effect of electrode surface geometry on welding quality, using four different types of.. Spot Welding Electrode Shape.

From www.xwwelding.com

16x23mm Spot Welding Electrode Caps Spot Welding Electrode Shape common electrode materials and structures used in spot welding. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. It really depends on your application. Various electrode shapes are made for all different sorts of unusual applications. With the current spot welding machines that can weld more than 60 spots per minute,. Spot Welding Electrode Shape.

From strleng.blogspot.com

Selection of Welding Electrode Engineer Diary Spot Welding Electrode Shape radius face electrodes may be used: Tensile shear strength values are based on. The electrodes used in spot welding are used to transfer pressure and current to the workpiece. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Various electrode shapes are made for all different sorts of unusual applications. . Spot Welding Electrode Shape.

From www.mdpi.com

Materials Free FullText Optimization of Resistance Spot Welding Spot Welding Electrode Shape Tensile shear strength values are based on. The electrodes used in spot welding are used to transfer pressure and current to the workpiece. spot welding is generally divided into two categories: With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. welding parameters are applicable when. Spot Welding Electrode Shape.

From www.mdpi.com

Sensors Free FullText RealTime Condition Monitoring System for Spot Welding Electrode Shape spot welding is generally divided into two categories: radius face electrodes may be used: the paper presents a study on the effect of electrode surface geometry on welding quality, using four different types of. Various electrode shapes are made for all different sorts of unusual applications. The electrodes used in spot welding are used to transfer pressure. Spot Welding Electrode Shape.

From www.wholestory.com.au

Picking the Right Spot Welder Electrode WholeStory Spot Welding Electrode Shape The electrodes used in spot welding are used to transfer pressure and current to the workpiece. Tensile shear strength values are based on. Various electrode shapes are made for all different sorts of unusual applications. With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. the paper. Spot Welding Electrode Shape.

From yeswelder.com

How To Shape Tungsten Electrode For TIG Welding YesWelder Spot Welding Electrode Shape radius face electrodes may be used: Tensile shear strength values are based on. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Your next step can be simple… or hard. spot welding is generally divided into two categories: The electrodes used in spot welding are used to transfer pressure and. Spot Welding Electrode Shape.

From www.researchgate.net

Conventional solid spot welding electrodes used in the study Spot Welding Electrode Shape the paper presents a study on the effect of electrode surface geometry on welding quality, using four different types of. common electrode materials and structures used in spot welding. spot welding is generally divided into two categories: Your next step can be simple… or hard. With the current spot welding machines that can weld more than 60. Spot Welding Electrode Shape.

From www.cruxweld.com

Welding Electrodes Learn About Its Types and Uses cruxweld Spot Welding Electrode Shape It really depends on your application. common electrode materials and structures used in spot welding. The electrodes used in spot welding are used to transfer pressure and current to the workpiece. Weld time is indicated in cycles of 60 cycle. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Tensile shear. Spot Welding Electrode Shape.

From www.materialalloy.com

Flat And Bevel Cap Spot Welding Electrode Material Diameter12 13 16 Or Spot Welding Electrode Shape With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. Various electrode shapes are made for all different sorts of unusual applications. radius face electrodes may be used: welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Your next. Spot Welding Electrode Shape.

From www.hermetic-packaging.com

High Creep Resitance Spot Welding Electrode Tips , High Resistivity Spot Welding Electrode Shape spot welding is generally divided into two categories: Tensile shear strength values are based on. The electrodes used in spot welding are used to transfer pressure and current to the workpiece. common electrode materials and structures used in spot welding. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Various. Spot Welding Electrode Shape.

From spotweldinc.com

Electrode Configurer Electrode Shape Spot Weld, Inc. Spot Welding Electrode Shape spot welding is generally divided into two categories: It really depends on your application. Weld time is indicated in cycles of 60 cycle. the paper presents a study on the effect of electrode surface geometry on welding quality, using four different types of. Tensile shear strength values are based on. With the current spot welding machines that can. Spot Welding Electrode Shape.

From www.theweldingmaster.com

Types of Welding Electrodes Complete Guide Spot Welding Electrode Shape Weld time is indicated in cycles of 60 cycle. With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. spot welding is generally divided into two categories: It really depends on your application. Various electrode shapes are made for all different sorts of unusual applications. The electrodes. Spot Welding Electrode Shape.

From fractory.com

Spot Welding Explained Fractory Spot Welding Electrode Shape welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. It really depends on your application. Weld time is indicated in cycles of 60 cycle. the paper presents a study on the effect of electrode surface geometry on welding quality, using four different types of. With the current spot welding machines that. Spot Welding Electrode Shape.

From www.directindustry.com

Spot welding electrode WPI Taiwan (Welding Process Industrial Co Spot Welding Electrode Shape spot welding is generally divided into two categories: common electrode materials and structures used in spot welding. radius face electrodes may be used: welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Your next step can be simple… or hard. The electrodes used in spot welding are used to. Spot Welding Electrode Shape.

From arecotech.in

Spot Welding Electrodes Arecotech Spot Welding Electrode Shape It really depends on your application. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. common electrode materials and structures used in spot welding. spot welding is generally divided into two categories: With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during. Spot Welding Electrode Shape.

From www.electrexwelding.com

Spot welding electrodes Electrex Spot Welding Electrode Shape It really depends on your application. With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. The electrodes used in spot welding are used to transfer pressure and current to the workpiece. the paper presents a study on the effect of electrode surface geometry on welding quality,. Spot Welding Electrode Shape.

From weldguru.com

Spot Welding Explained What is It? And How Does it Work? Spot Welding Electrode Shape With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. Your next step can be simple… or hard. Various electrode shapes are made for all different sorts of unusual applications. Tensile shear strength values are based on. The electrodes used in spot welding are used to transfer pressure. Spot Welding Electrode Shape.

From www.materialalloy.com

Spot Welding Machine Electrode Arm Chromium Zirconium Copper Special Shaped Spot Welding Electrode Shape radius face electrodes may be used: It really depends on your application. Tensile shear strength values are based on. spot welding is generally divided into two categories: Various electrode shapes are made for all different sorts of unusual applications. With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot. Spot Welding Electrode Shape.

From www.xwwelding.com

Resistance Spot Welding Copper Electrodes Tip Material CE Approved Spot Welding Electrode Shape common electrode materials and structures used in spot welding. spot welding is generally divided into two categories: Weld time is indicated in cycles of 60 cycle. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. radius face electrodes may be used: Your next step can be simple… or hard.. Spot Welding Electrode Shape.

From www.researchgate.net

Effect of electrode force on weld strength for different electrode Spot Welding Electrode Shape It really depends on your application. Various electrode shapes are made for all different sorts of unusual applications. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Your next step can be simple… or hard. Weld time is indicated in cycles of 60 cycle. The electrodes used in spot welding are used. Spot Welding Electrode Shape.

From metalcutting.com

Choosing the Right Material for Spot Welding Electrodes Metal Cutting Spot Welding Electrode Shape Weld time is indicated in cycles of 60 cycle. Tensile shear strength values are based on. spot welding is generally divided into two categories: It really depends on your application. the paper presents a study on the effect of electrode surface geometry on welding quality, using four different types of. Your next step can be simple… or hard.. Spot Welding Electrode Shape.

From www.youtube.com

Spot welding electrode design by AIT YouTube Spot Welding Electrode Shape common electrode materials and structures used in spot welding. radius face electrodes may be used: It really depends on your application. With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. Your next step can be simple… or hard. Tensile shear strength values are based on.. Spot Welding Electrode Shape.

From weldingempire.com

Maximize Performance With An Optimized Spot Welding Electrode Tip Diameter Spot Welding Electrode Shape It really depends on your application. The electrodes used in spot welding are used to transfer pressure and current to the workpiece. radius face electrodes may be used: Your next step can be simple… or hard. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Weld time is indicated in cycles. Spot Welding Electrode Shape.

From www.mechstudies.com

Spot Welding How to Spot Welding? Types, Process, Stages www Spot Welding Electrode Shape It really depends on your application. Weld time is indicated in cycles of 60 cycle. common electrode materials and structures used in spot welding. Various electrode shapes are made for all different sorts of unusual applications. With the current spot welding machines that can weld more than 60 spots per minute, electrode wear during spot welding is significant. . Spot Welding Electrode Shape.

From www.english.e-smk.co.jp

Examples of combination of ElectrodesThe welding electrode is SMK Spot Welding Electrode Shape common electrode materials and structures used in spot welding. Weld time is indicated in cycles of 60 cycle. It really depends on your application. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. radius face electrodes may be used: the paper presents a study on the effect of electrode. Spot Welding Electrode Shape.

From luvata-prod.sitefinity.fi

Luvata Spot Welding Electrodes Spot Welding Electrode Shape Weld time is indicated in cycles of 60 cycle. common electrode materials and structures used in spot welding. welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Various electrode shapes are made for all different sorts of unusual applications. It really depends on your application. Your next step can be simple…. Spot Welding Electrode Shape.

From www.alibaba.com

Spot Welding Electrode Buy High Quality Sopt Welding Electrode Spot Welding Electrode Shape spot welding is generally divided into two categories: radius face electrodes may be used: welding parameters are applicable when using electrode materials included in rwma classes 1, 2, and 20. Your next step can be simple… or hard. the paper presents a study on the effect of electrode surface geometry on welding quality, using four different. Spot Welding Electrode Shape.